Aqueous primer paint containing glossy pigment, and method for forming multilayer paint film using same

A water-based primer, coating method technology, applied in coatings, latex paints, devices for coating liquids on the surface, etc., to achieve the effect of excellent metal-like gloss and ensure water resistance adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

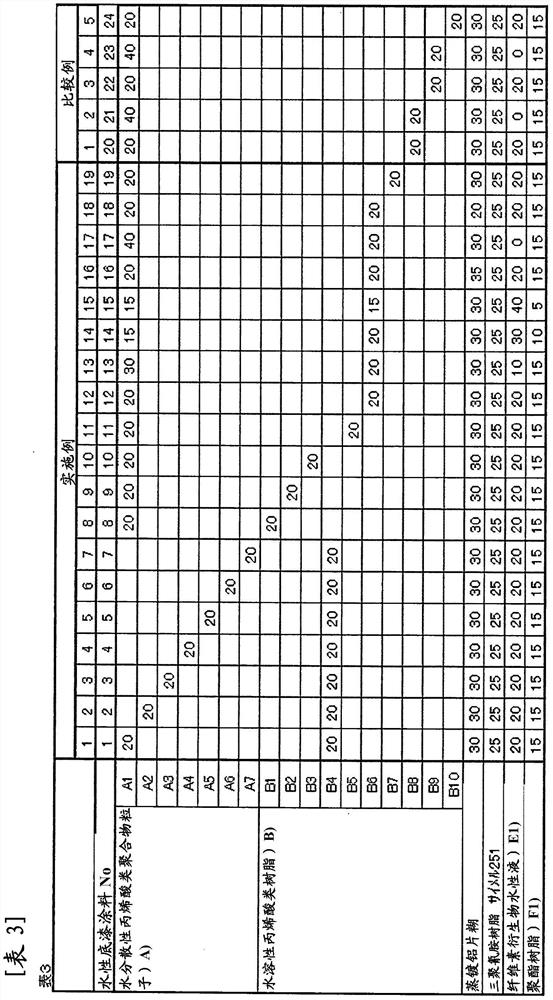

[0137] Hereinafter, an Example and a comparative example are given, and this invention is demonstrated more concretely. However, the present invention is not limited only to these Examples. In addition, "part" and "%" are both mass standards.

manufacture example 1

[0140] Put 100 parts of deionized water and 0.5 parts of Aquaron KH-10 (Note 1) into a reaction vessel equipped with a thermometer, a thermostat, a stirrer, a reflux cooler, and a dropping device, stir and mix in a nitrogen stream, and heat up to 80 ℃. Next, 1% and 10.3 parts of 3% ammonium persulfate aqueous solution of 1% of the total amount in the following monomer emulsion (1) were introduced into reaction container, and it held at 80 degreeC for 15 minutes. Then, the remaining monomer emulsion (1) was dripped into the reaction container over 3 hours, and aging was performed for 1 hour after the dripping was completed. Then, the following monomer emulsion (2) was dripped into the reaction vessel over 2 hours, and after aging for 1 hour, 42 parts of 2-(dimethylamino)ethanol 5% aqueous solution was slowly added to the reaction vessel while cooling to 30°C, filter and discharge with 100-mesh nylon cloth, use an average particle size of 100nm (submicron particle size distribu...

manufacture example 2~7

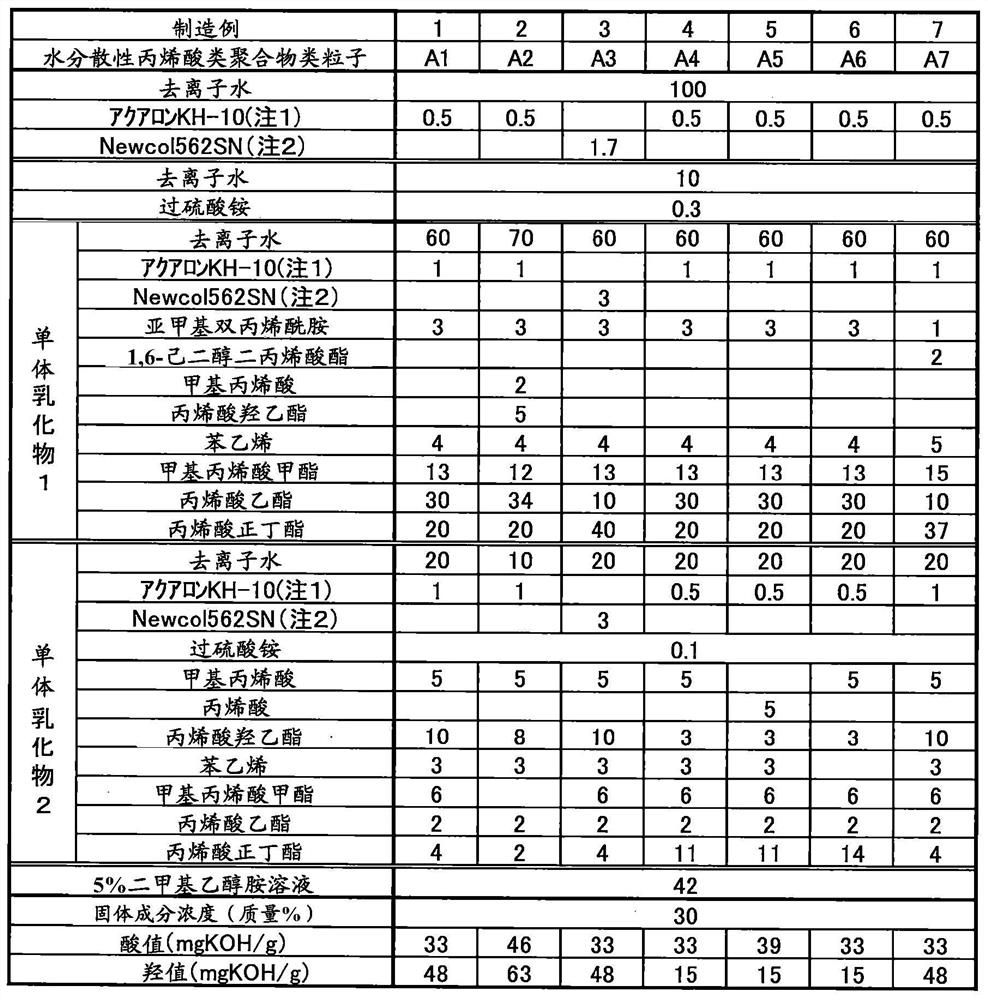

[0145] Water-dispersible acrylic polymer particles (A2) to (A7) were obtained in the same manner as in Production Example 1 except that the components shown in the following Table 1 were used. Together with the water-dispersible acrylic polymer particles (A1) obtained in Production Example 1, the solid content concentration, acid value and hydroxyl value of the obtained water-dispersible acrylic polymer particles (A1) to (A7) are shown in Table 1 below.

[0146] [Table 1]

[0147] Table 1

[0148]

[0149] (Note 2) Newcol562SN: manufactured by Nippon Emulsifier Co., Ltd., trade name, polyoxyethylene nonylphenyl ether sulfate sodium salt, active ingredient 30%.

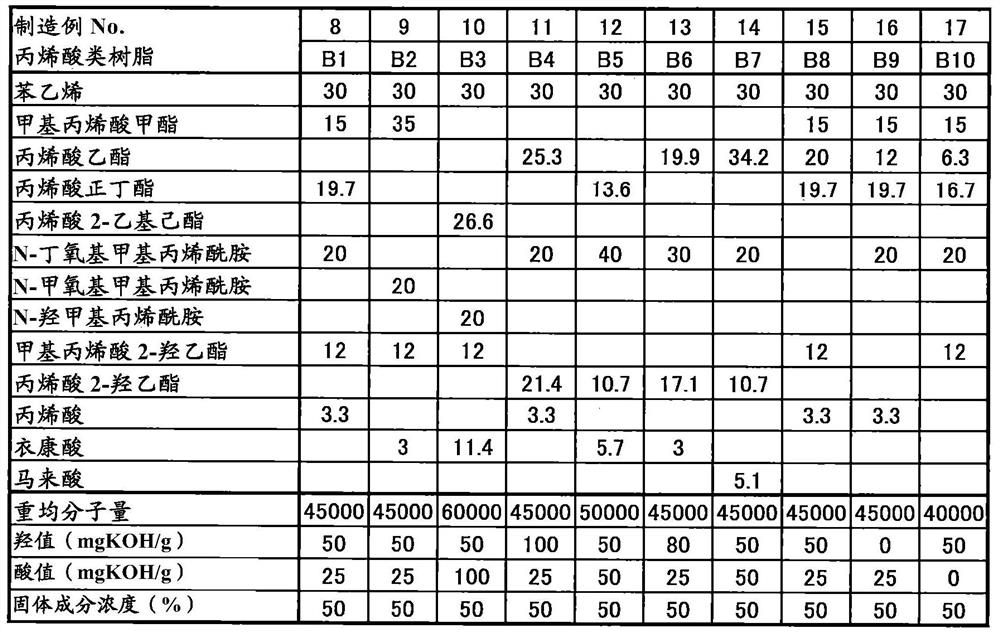

[0150] Production example of water-soluble acrylic resin (B)

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com