Putty composition and repair coating method using same

A composition and putty technology, applied in the direction of filling slurry, etc., can solve the problems of reducing physical properties such as curability, surface dryness, water resistance and adhesion, and achieve the effect of excellent water resistance and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

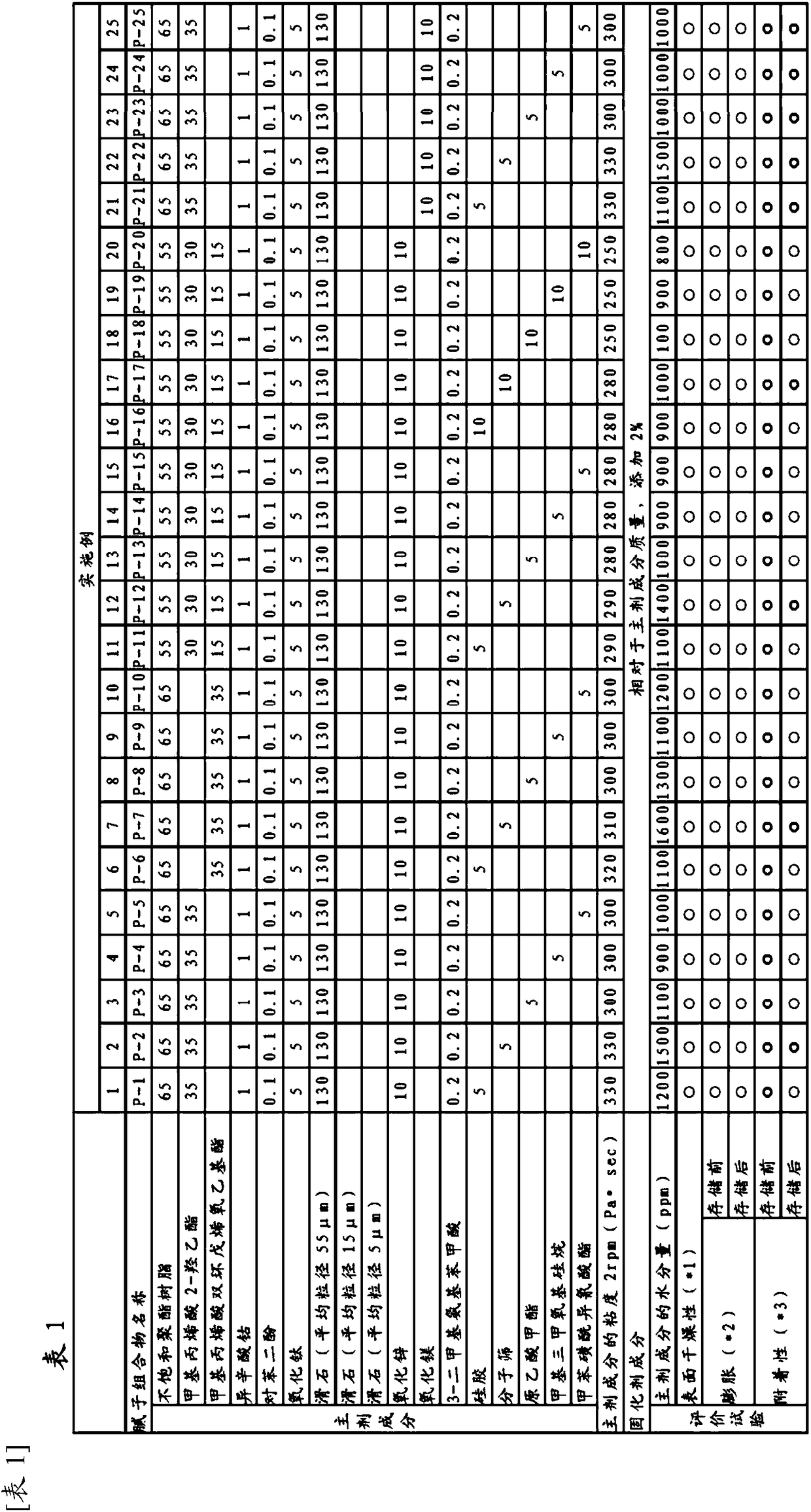

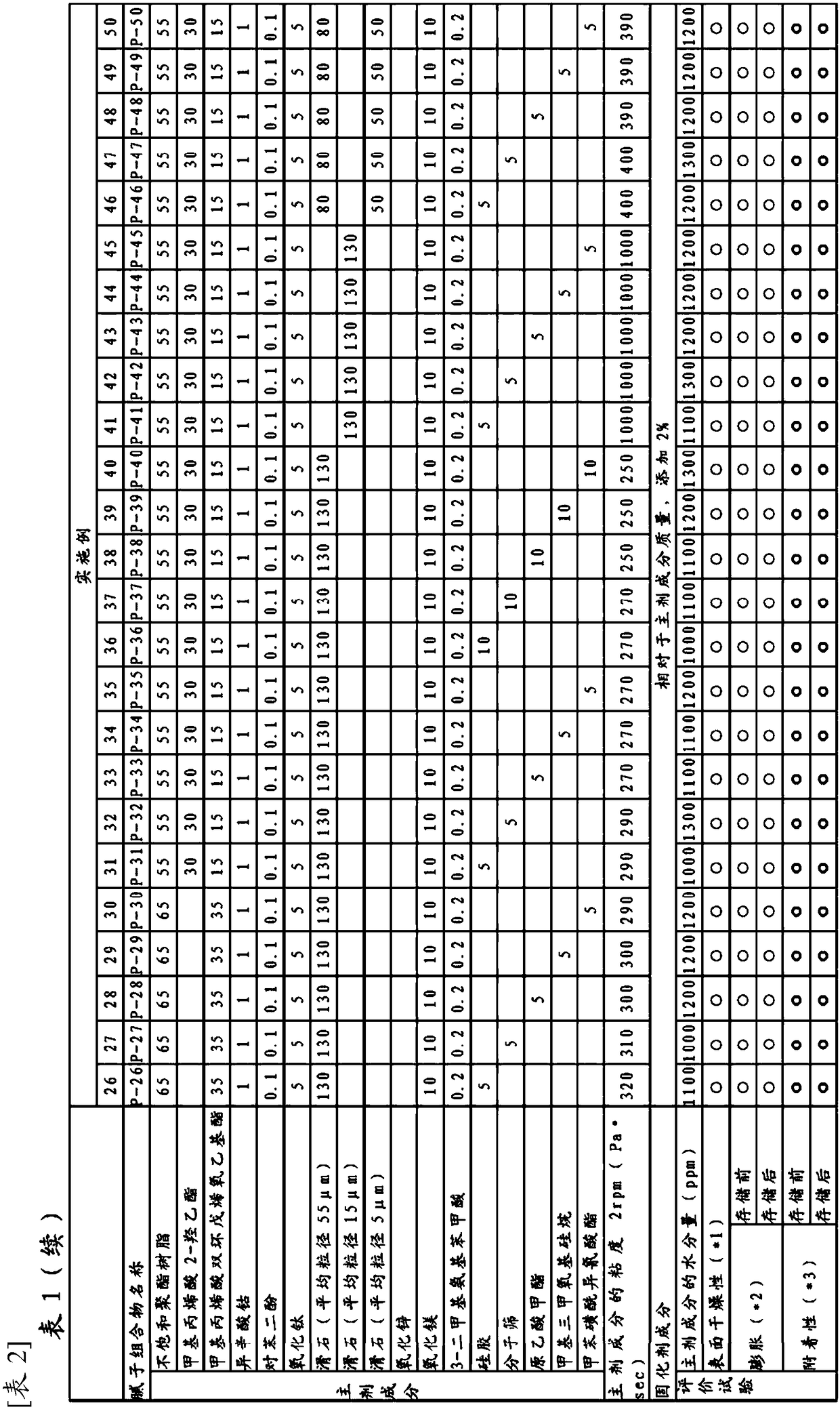

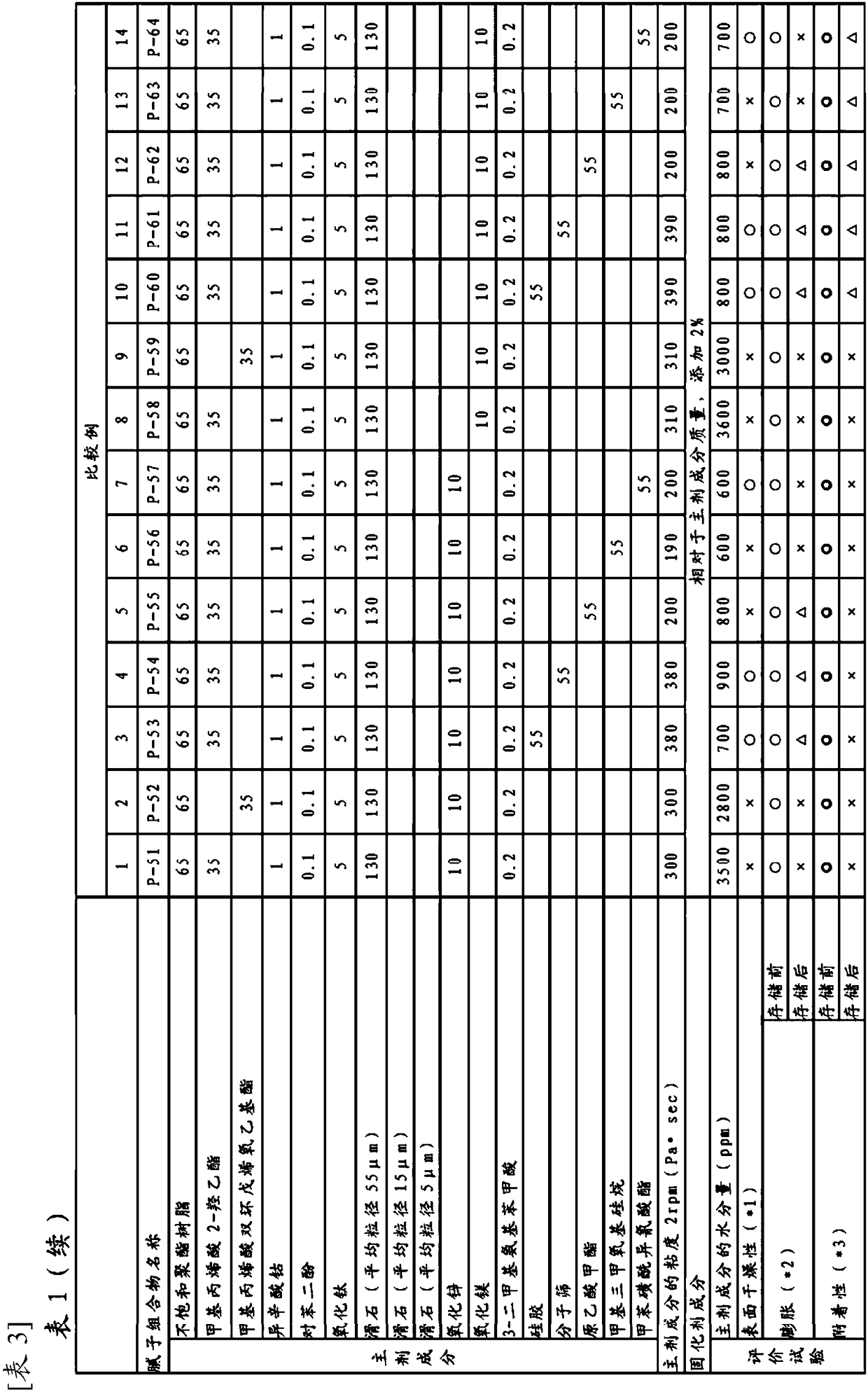

[0116] Hereinafter, the present invention will be further explained by giving examples. Here, "parts" and "%" refer to "parts by mass" and "% by mass", respectively.

[0117]

manufacture example 1

[0119] Add 397.5 parts of diethylene glycol, 134 parts of dipropylene glycol, 580 parts of fumaric acid, and 256 parts of pentaerythritol to a 2-liter four-necked flask with a stirrer, gas tube, rectification column, thermometer, pressure reducing device and reflux cooler. Triallyl ether and 0.5 part of hydroquinone were heated to 150°C while blowing in nitrogen, and then the temperature was raised to 180°C. Next, the rectifying column was replaced with a water separator at the same temperature, the toluene was refluxed and the condensation reaction was carried out. At the end of the reaction, the toluene was removed under reduced pressure to obtain an acid value of 35 mgKOH / g and a weight average molecular weight of 3000 Unsaturated polyester resin (A-1). This resin (A-1) was dissolved in 2-hydroxyethyl methacrylate and adjusted so that the solid content concentration might reach 65%, to obtain an unsaturated polyester resin composition.

manufacture example 2

[0121] In Production Example 1, an equivalent amount of dicyclopentenoxy ethyl methacrylate was used instead of 2-hydroxyethyl methacrylate, and the rest was the same as in Production Example 1 to obtain an unsaturated polyester resin composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com