Multi-component water-based primer coating composition and coating method

A water-based primer, multi-component technology, used in primers, polyurea/polyurethane coatings, coatings, etc., can solve the problems of insufficient adhesion, water resistance, adhesion and finishing, and achieve good finishing and water resistance. Excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

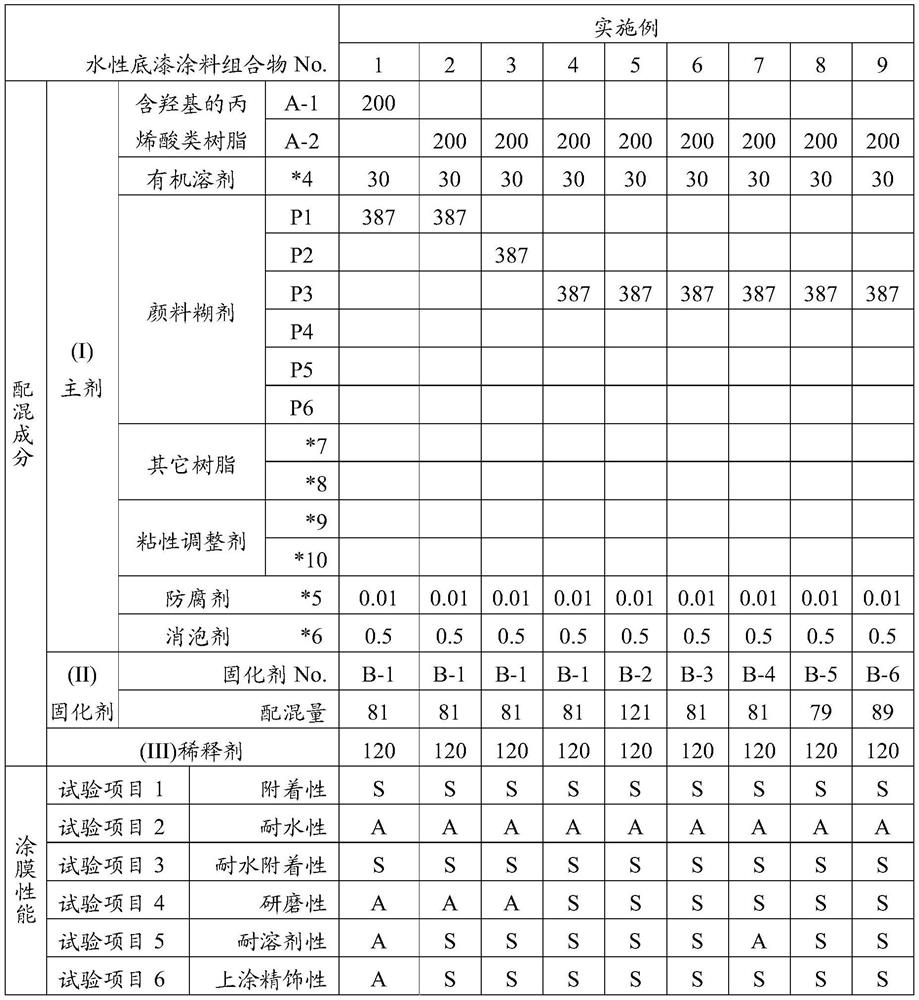

Examples

manufacture example 1

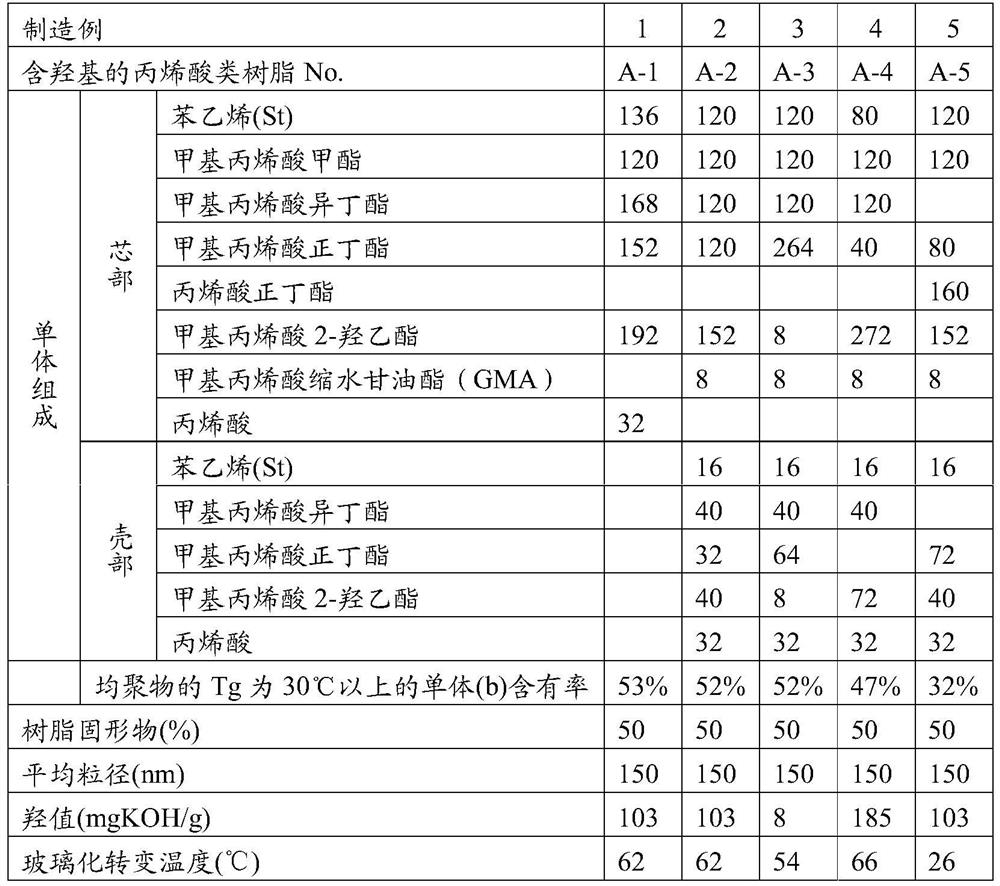

[0159] (Production Example 1) Production of a hydroxyl-containing acrylic resin

[0160] Equipped with a stirrer, a thermometer, a 2-liter glass reactor vessel condenser, were added 300 parts of deionized water, 1 part of sodium dodecylbenzenesulfonate, the air inside was replaced with nitrogen, and then stirring improved to an internal temperature of 82 deg.] C and melted. To another vessel, was added 320 parts of deionized water, 40 parts of sodium dodecylbenzenesulfonate, 2 parts of ammonium persulfate, stirring sufficiently, thereto was added 136 parts of styrene containing, 120 parts of methyl methacrylate , 168 parts of isobutyl methacrylate, 152 parts of n-butyl methacrylate, methacrylic acid, 192 parts of 2-hydroxyethyl methacrylate and 32 parts of acrylic monomer mixture, stirring to prepare an emulsion, the spending 4 hours emulsion was continuously added dropwise to the prior reaction vessel.

[0161] After the addition, further stirring at 82 ℃ 2 hours, cooled to 40 ℃,...

manufacture example 2

[0162] (Production Example 2) Production of hydroxyl group-containing acrylic resin

[0163]Equipped with a stirrer, a thermometer, a 2-liter glass reactor vessel condenser, were added 300 parts of deionized water, 1 part of sodium dodecylbenzenesulfonate, the air inside was replaced with nitrogen, and then stirring improved to an internal temperature of 82 deg.] C and melted. To the other vessel, 320 parts of deionized water, 20 parts of sodium dodecylbenzenesulfonate, 1 part of ammonium persulfate, stirring sufficiently, thereto was added 120 parts of styrene containing, 120 parts of methyl methacrylate, 120 parts of isobutyl methacrylate, 120 parts of n-butyl methacrylate, methacrylic acid, 152 parts of 2-hydroxyethyl methacrylate, glycidyl methacrylate, 8 parts of a monomer mixture, stirring to prepare an emulsion, spending the two hours before the emulsion was continuously added dropwise to the reaction vessel.

[0164] After the completion of dropwise addition, aging at the ...

manufacture example 6

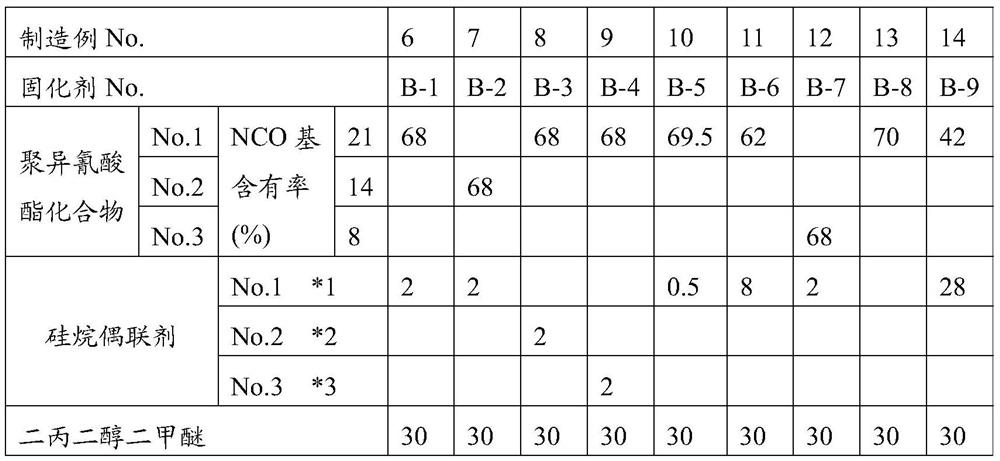

[0170] (Production Example 6) Production of curing agent component

[0171] Adding the isocyanate group content of 21% commercially available polyisocyanate compound No.1 (100% solids) 68 parts of 3-glycidoxypropyl trimethoxy silane coupling agent of silane No.1 2 and parts of dipropylene glycol dimethyl ether (water-soluble solvent having no hydroxyl group) 30 parts, stirred for 30 minutes to produce a 70% solids of the curing agent (B-1).

[0172] (Production Examples 7 to 14) for producing a curing agent component

[0173] In Production Example 6, as shown in Table 2 is set as a polyisocyanate compound, the kind and amount of the silane coupling agent, except the same manner as in Production Example 6, to obtain a curing agent (B-2) ~ (B- 9). The formulated Examples 6 to 14 shown in Table 2.

[0174] 【Table 2】

[0175]

[0176] Table polyisocyanate compound Nos. 1 to 3, and * refers to a 1 to 3.

[0177] Polyisocyanate compound No.1: (hexamethylene diisocyanate-based compound...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com