Cationic electrodeposition coating composition

A cationic electrodeposition and composition technology, used in electrophoretic coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc. Processability and other issues, to achieve the effect of improving the applicability of electrodeposition coating, good thermal fluidity, and excellent finishing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] Compound (1) can be prepared by adding an alkylene oxide represented by the following general formula (3) to bisphenol A to obtain a hydroxyl-terminated polyether compound, and then reacting the polyether compound with epihalohydrin to carry out bicyclic Oxidation to prepare.

[0060]

[0061] In general formula (3), R 3 represents a hydrogen atom or an alkyl group having 1 to 6 carbon atoms.

[0062] Among them, examples of the alkylene oxide represented by the general formula (3) include alkylene oxides having 2 to 8 carbon atoms, such as ethylene oxide, propylene oxide, and butylene oxide.

[0063] Wherein, preferred oxirane (R in general formula (3) 3 is the compound of hydrogen atom), propylene oxide (R in the general formula (3) 3 for methyl compounds).

[0064] Compound (2):

[0065] Moreover, the compound (2) represented by General formula (2) can be used as a diepoxide compound (a11).

[0066]

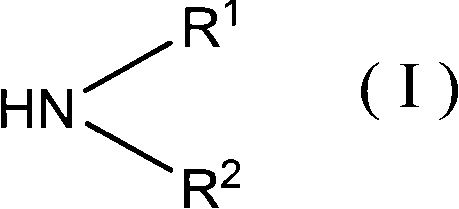

[0067] In general formula (2), R 2 The same or diff...

Embodiment

[0130] Hereinafter, the present invention will be described in more detail by way of preparation examples, examples and comparative examples, but the present invention is not limited thereto. "Part" in each example shows a mass part, and "%" shows a mass %.

[0131] Preparation of Amino-Containing Modified Epoxy Resin (A)

preparation example 1

[0132] Preparation Example 1 Preparation Example of Base Resin No.1

[0133] Add 162 parts of Glyci-ale PP-300P (Note 1), 1000 parts of jER828EL (Note 3), 440 parts of bisphenol A and 1.6 parts of Tetrabutyl to a 2-liter flask with a thermometer, a reflux condenser and a stirrer. Ammonium bromide was reacted at a temperature of 160° C. until the epoxy equivalent became 800.

[0134] Next, add 430 parts of methyl isobutyl ketone, and then add 130 parts of 2-methylamino-1-ethanol, and make it react for 4 hours at a temperature of 100° C. to obtain a solution of base resin No.1, This base resin No. 1 is an amino group-containing modified epoxy resin with a resin solid content of 80%.

[0135] The ratio of the diepoxy compound (a11) to the constituents of the epoxy resin (A1) is 10% by mass, and the equivalent ratio ([amino group in the amine compound (A2)] / [epoxy group in the epoxy resin (A1) ])=0.9, the amine value of the obtained base resin No.1 was 58 mg KOH / g, and the numbe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com