Antirust agent composition and antirust method using the same

A composition and technology of rust inhibitor, applied in the field of rust inhibitor composition, can solve the problems of corrosion, low rust inhibitor, low toxicity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

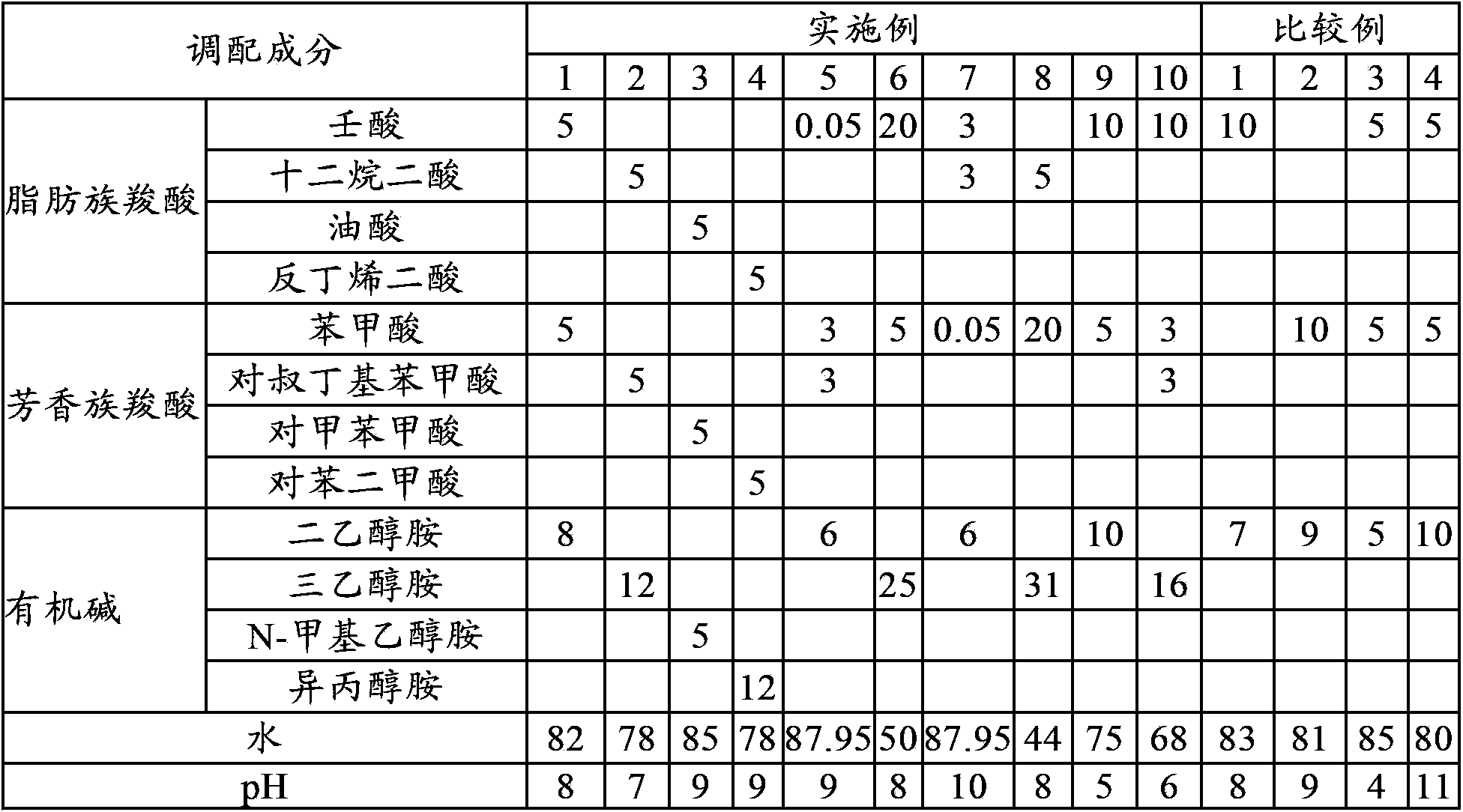

[0034] Next, the present invention will be described based on examples and comparative examples, but the present invention is not limited to these examples. In addition, unless otherwise stated, the compounding ratio etc. are based on mass (mass part, mass %).

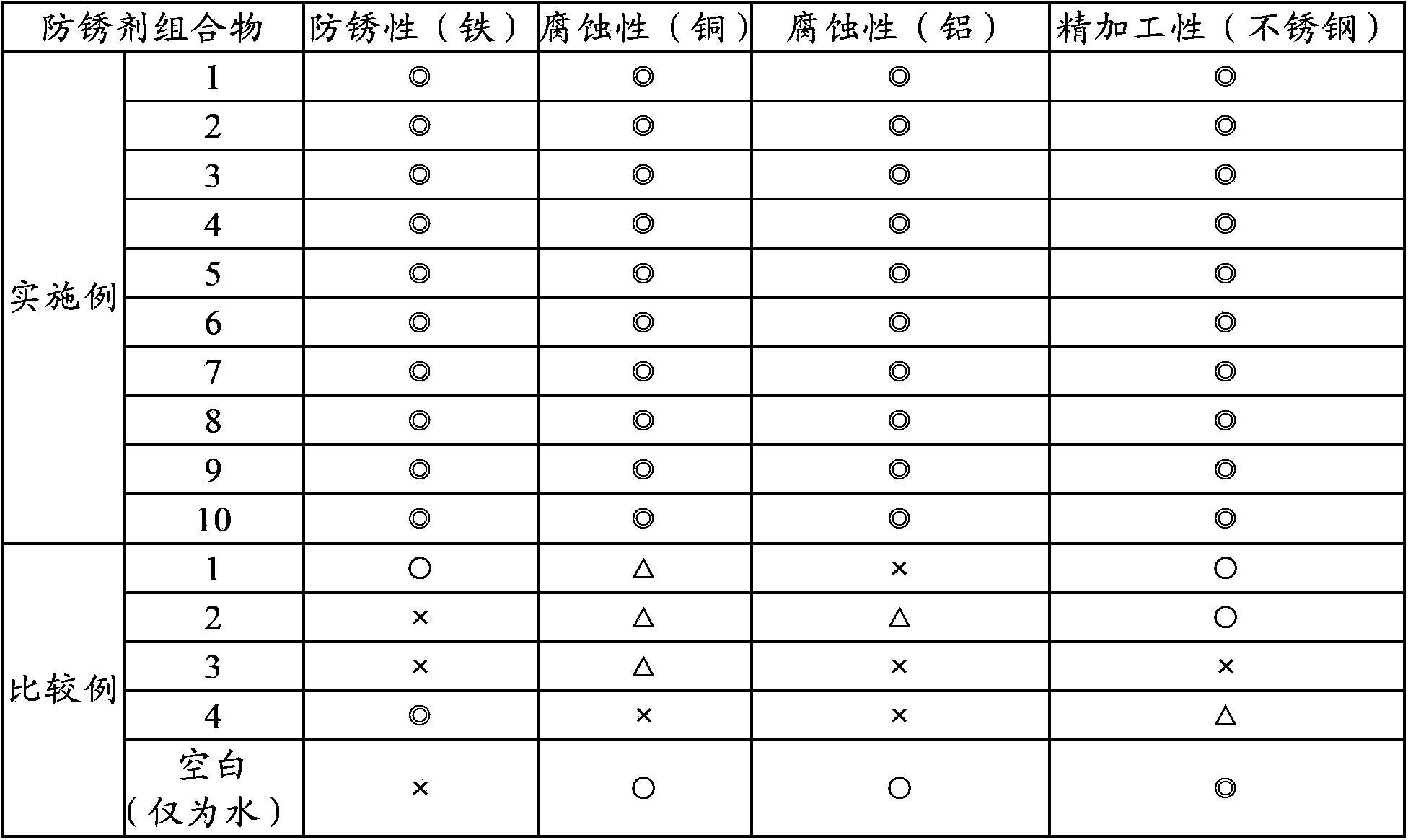

[0035] A rust preventive composition was prepared according to the formulation shown in Table 1 below, and the following evaluations were performed. The results are shown in Table 2.

[0036] [Table 1]

[0037]

[0038] 1. For iron rust resistance

[0039] A 50-fold dilution in water of each rust preventive composition was prepared as a rust preventive liquid. Spread cast iron powder (FC200) in a petri dish, add 2 ml of the obtained antirust solution dropwise to 2 g of the cast iron powder, check the state of rust at room temperature within 24 hours, and compare with the following criteria Rust resistance.

[0040] ◎: no rust

[0041] ○: less than 5% rust

[0042] △: 5% or more to less than 25% of rust

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com