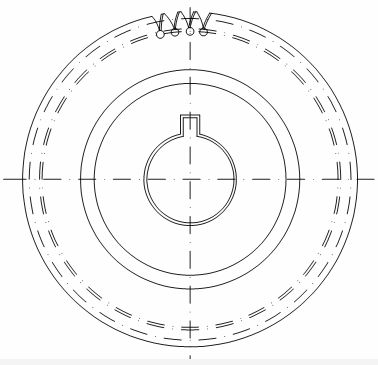

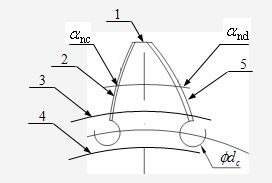

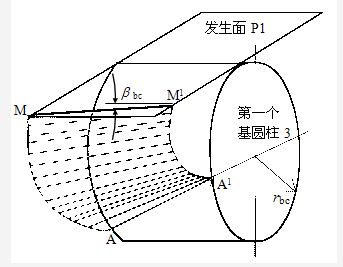

Involute gear-shaving cutter

A technology of shaving cutters and involutes, which is applied in the direction of gear teeth, components with teeth, gear tooth manufacturing tools, etc., can solve the problems of tooth tip thinning and gear tooth impact resistance decline, etc., and achieve a large bearing capacity , good impact resistance and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0097] when , , (mm), , , , Time; ; ; (mm); (mm);

[0098] (mm); (mm); (mm);

[0099] (mm); (mm); (mm);

[0100] (mm); (mm); (mm);

[0101] (mm); (mm); ; ; ;

[0102] ; ; (mm); (mm); (mm);

[0103] ; ; ; ; ; ; ; (mm); (mm); ; ; ; ; (mm);

[0104] (mm); (mm); (mm);

[0105] (mm); (mm); (mm);

[0106] (mm); (mm).

Embodiment approach 2

[0108] when , , (mm), , , , Time; ; ; (mm); (mm);

[0109] (mm); (mm); (mm); (mm); (mm); (mm); (mm);

[0110] (mm); (mm); (mm); (mm); ; ; ; ; ; (mm);

[0111] (mm); (mm); ; ; ;

[0112] ; ; ; ; (mm);

[0113] (mm); ; ; ; ;

[0114] (mm); (mm); (mm); (mm); (mm); (mm); (mm); (mm); (mm).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com