Plastic bevel gear

A technology of helical gears and plastics, applied in the field of plastic helical gears, can solve the problems of thinning of the tooth tip and the reduction of the impact resistance of the gear teeth, and achieve the effects of easy molding, weight reduction and volume reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

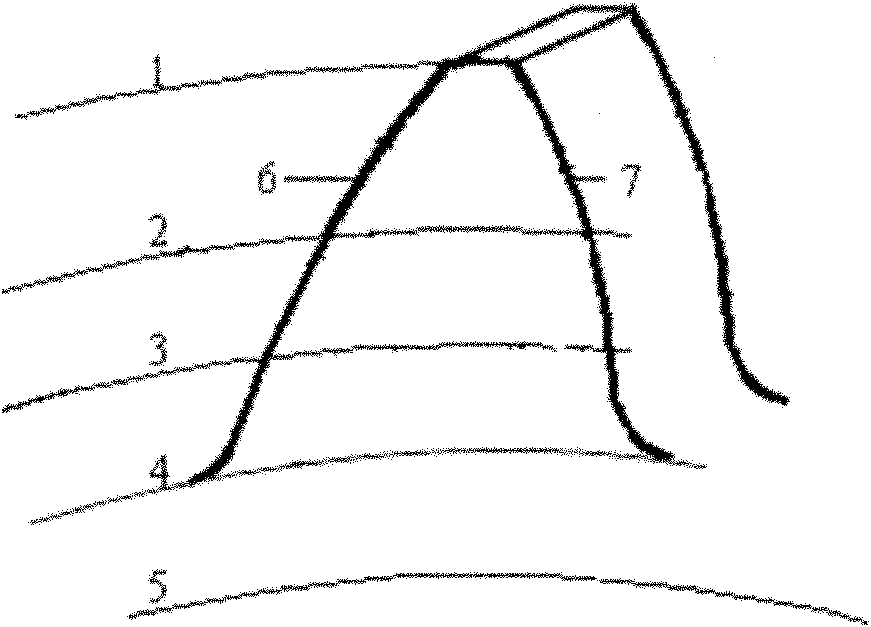

[0018] See Figure 1-2 , the tooth shape of the plastic helical gear in this embodiment mainly includes the tooth top 1, the left tooth surface (that is, the left involute tooth profile) 6 generated by the second base cylinder 5, and the right tooth surface generated by the first base cylinder 3. The side tooth surface (that is, the right involute tooth profile) 7 and the dedendum 4. When the gear is working, the left tooth surface 6 with a large pressure angle participates in meshing, and the right tooth surface 7 with a small pressure angle does not participate in meshing.

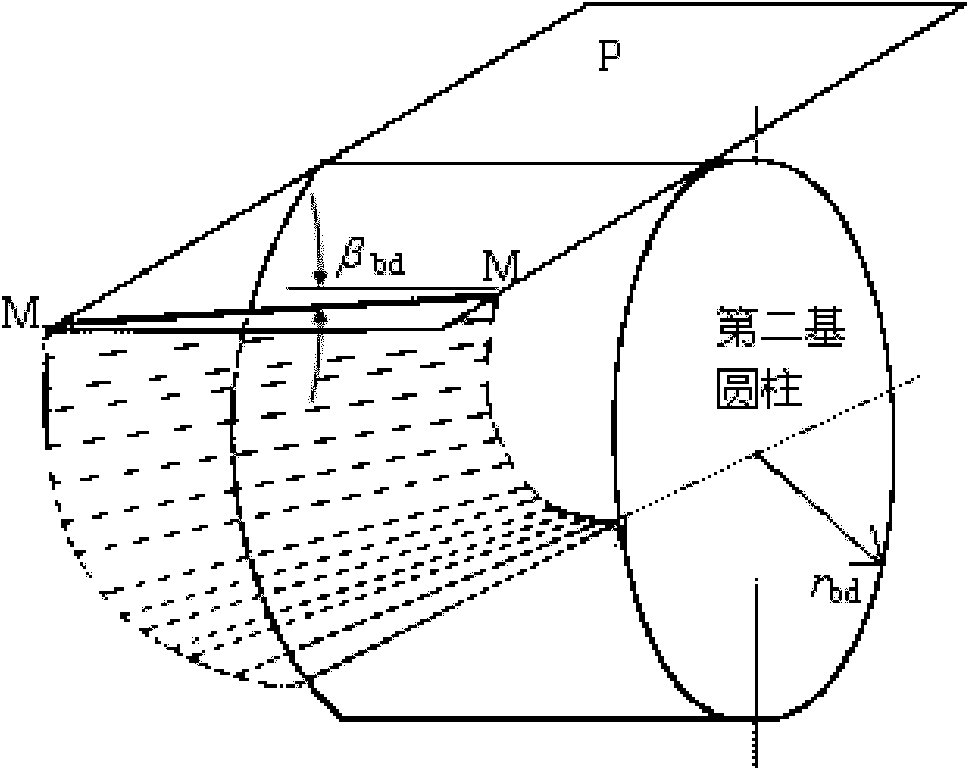

[0019] The formation of the tooth profile surface of the non-meshing side of the helical gear: take the line segment r bc Draw the first base cylinder surface of the helical gear as the radius, and there is a first occurrence surface Q that is tangent to the first base cylinder surface, and the angle between the first line segment KK on the first occurrence surface Q and the axis of the first base cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com