Impact-resistant composite structure based on uhmwpe secondary hybrid weaving

A composite structure and secondary mixing technology, which is applied in the field of protection and safety, can solve the problems of low single-layer protection effect, affecting the impact resistance effect of composite protection structures, and poor impact resistance effect of two-dimensional fabrics, etc., to achieve excellent impact resistance. Effect of reducing delamination damage and increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

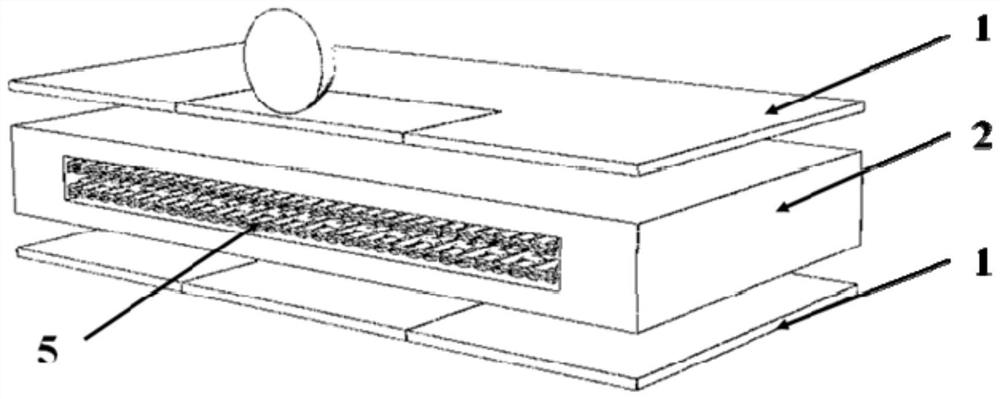

[0037] The impact-resistant composite structure based on UHMWPE secondary mixed weaving, the impact-resistant composite structure includes composite material plate 1, aluminum alloy frame 2, fiber braid I5 and polyurethane soft rubber, such as figure 1 shown;

[0038] The composite material plate 1 is prepared by injecting epoxy resin into the fiber braid II by using the RTM vacuum glue injection process, and then heat-pressing and cooling, with a thickness of 4.25mm;

[0039] The aluminum alloy frame 2 is a hollow structure made of 2024 aluminum alloy, and a cavity with a length of 96mm, a width of 80mm and a height of 6mm is processed inside;

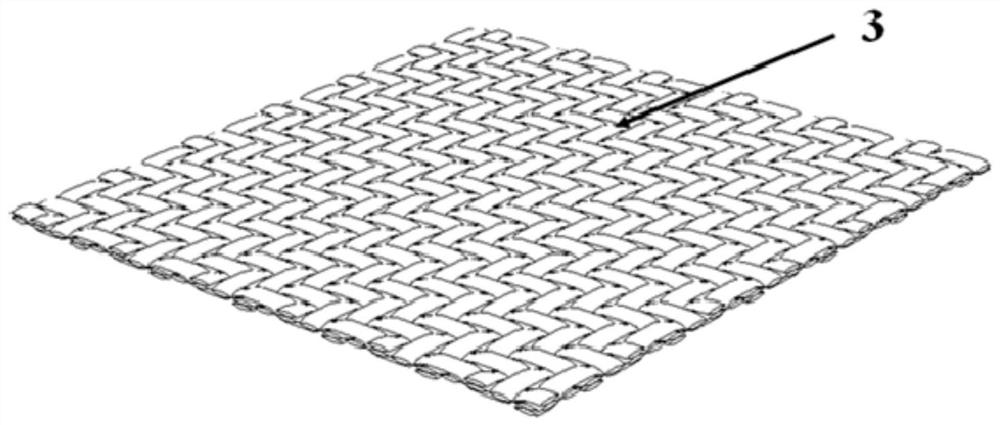

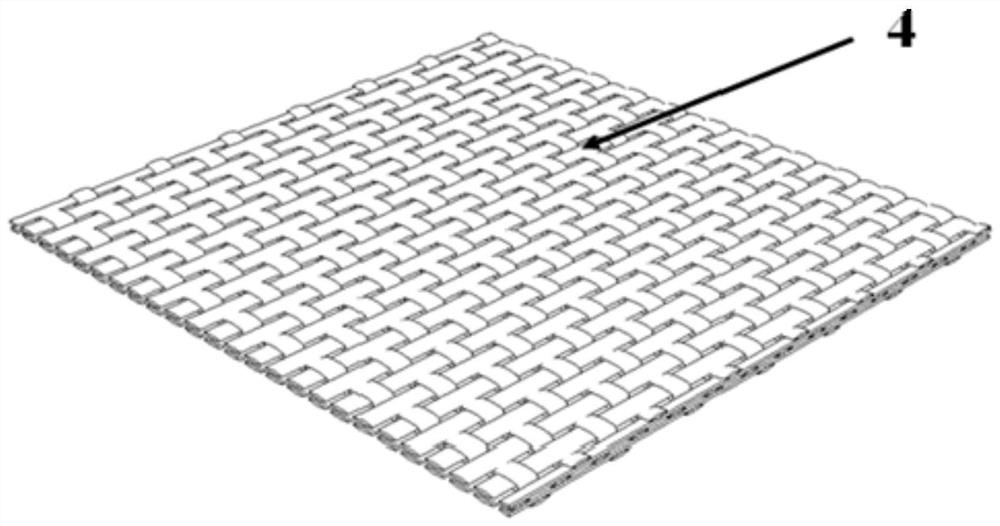

[0040] The fiber braid I5 and the fiber braid II are prepared by the following method: UHMWPE yarns are used to weave two-dimensional three-directional UHMWPE fabric 3 and three-dimensional orthogonal UHMWPE fabric 4, such as figure 2 and image 3 shown; then the two-dimensional three-directional UHMWPE fabric 3 and the three-dimensi...

Embodiment 2

[0044] The impact-resistant composite structure based on UHMWPE secondary mixed weaving, the impact-resistant composite structure includes composite material plate 1, aluminum alloy frame 2, fiber braid I5 and polyurethane soft rubber, such as Figure 5 shown;

[0045] The composite material plate 1 is prepared by injecting epoxy resin into the fiber braid II by using the RTM vacuum glue injection process, and then cooling by hot pressing, with a thickness of 8.5mm;

[0046] The aluminum alloy frame 2 is a hollow structure made of 2024 aluminum alloy, and two cavities are processed inside, each cavity has a length of 96 mm, a width of 90 mm and a height of 8 mm, and two adjacent cavities The wall thickness between them is 2mm;

[0047] The fiber braid I5 and the fiber braid II are prepared by the following method: UHMWPE yarns are used to weave two-dimensional three-directional UHMWPE fabric 3 and three-dimensional orthogonal UHMWPE fabric 4, such as figure 2 and image 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com