Patents

Literature

36results about How to "Efficient finishing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

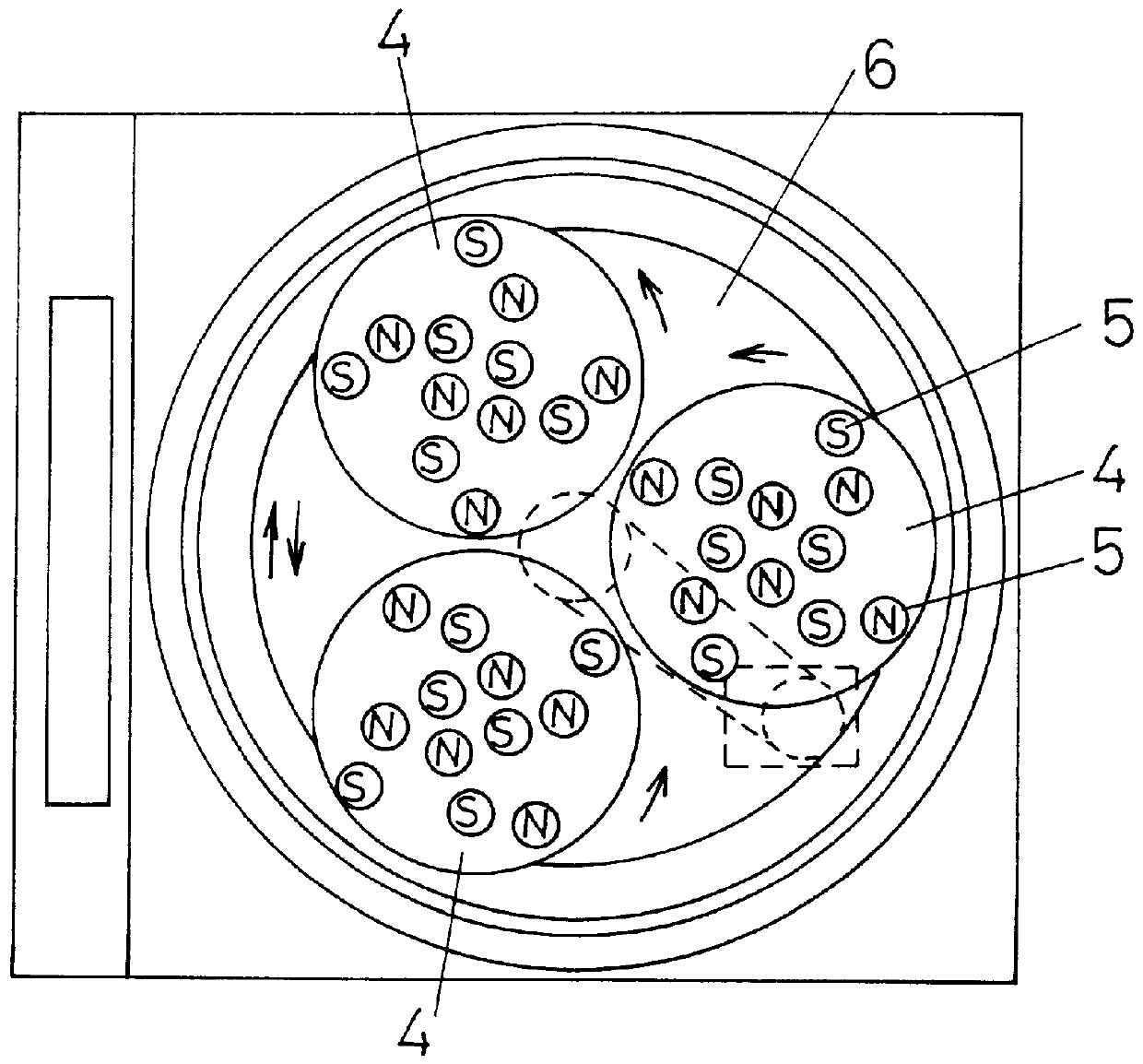

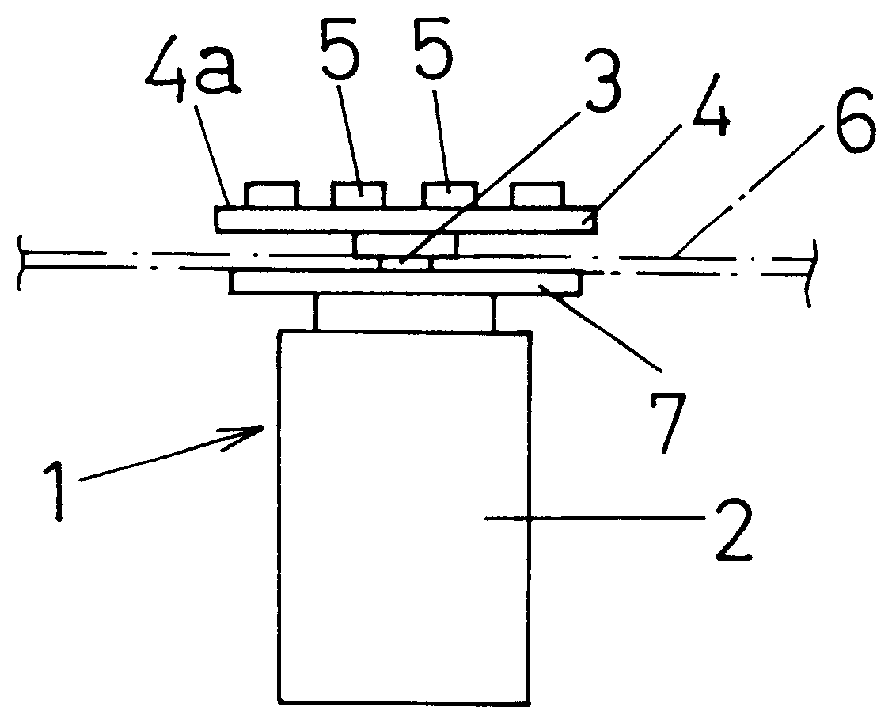

Method and apparatus for finishing works magnetically by generating alternating magnetic fields

InactiveUS6146243AImprove productivityEfficient finishingEdge grinding machinesPolishing machinesEngineeringMagnet

Owner:IMAHASHI MFG

Heat-shrinkable polyester film and process for producing the same

InactiveCN101918196AHigh mechanical strengthHigh Shrinkage PropertiesFlat articlesThin material handlingPolyesterEngineering

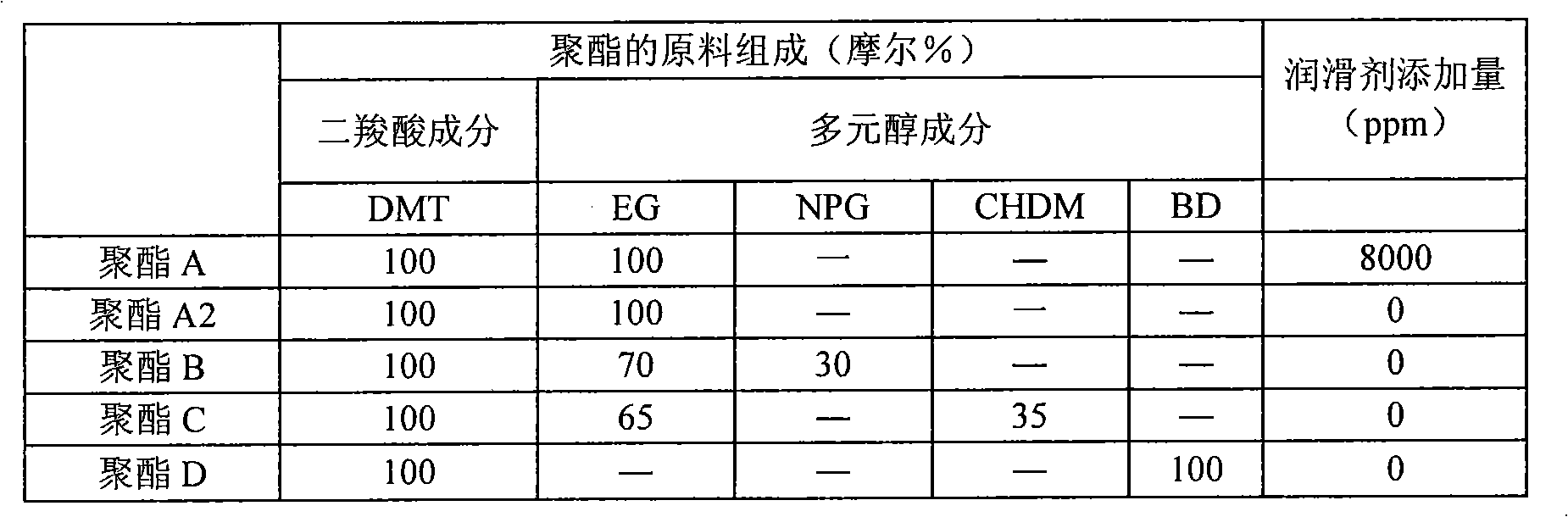

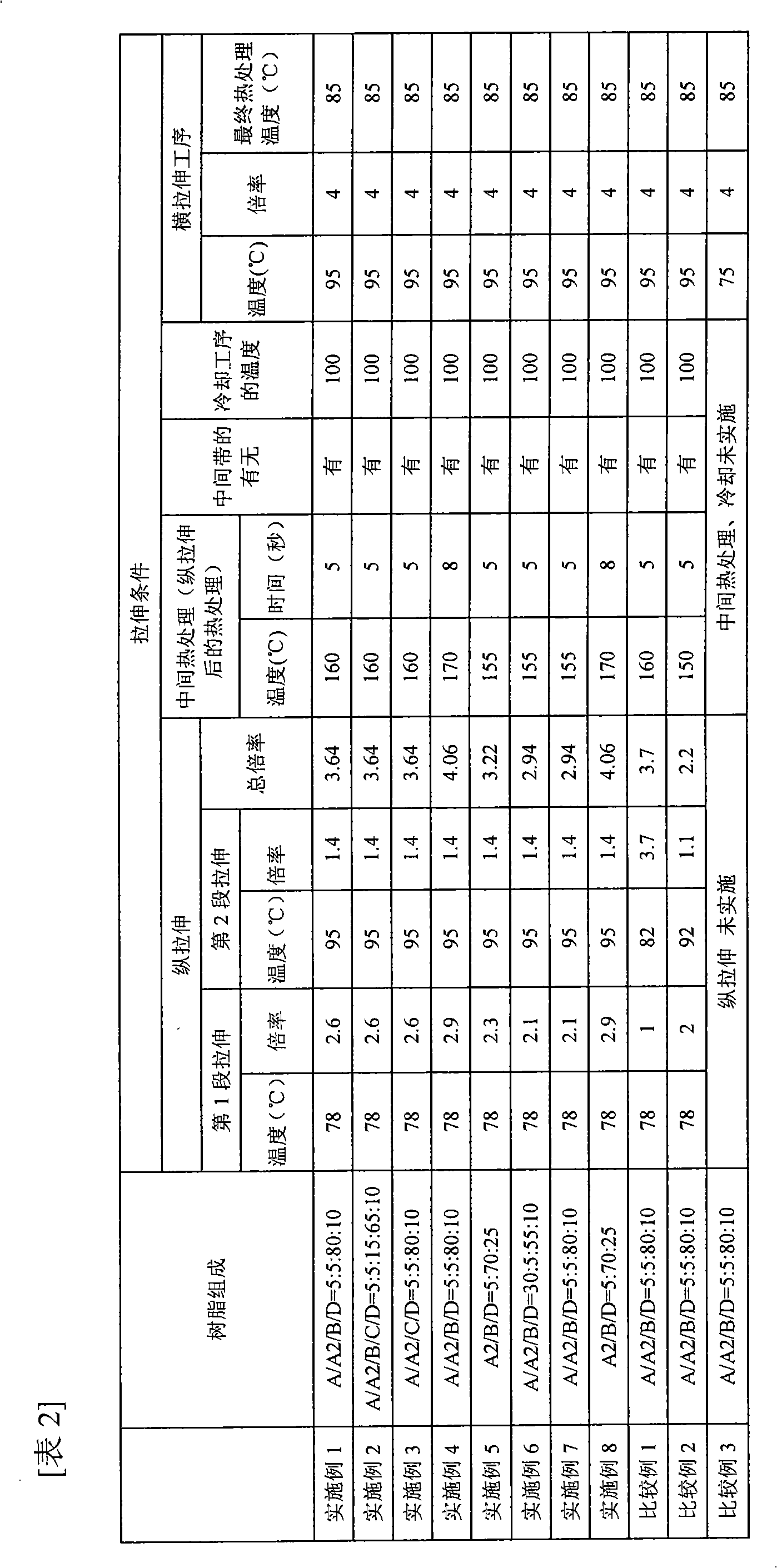

Provided is a heat-shrinkable polyester film whose main shrinkage direction is the machine direction. This film does not shrink in the machine direction in a low-temperature region and, despite this, highly shrinks in a high-temperature region. The film has an extremely high mechanical strength in the transverse direction, which is perpendicular to the main shrinkage direction. The film is suitable for use especially as a film for forming covering labels for dry cells and in applications similar thereto. The heat-shrinkable polyester film shrinks mainly in the machine direction. The film has been regulated so that the degree of machine-direction hot-water thermal shrinkage through 10-second immersion in 80 DEG C water is in a given range and the degree of machine-direction thermal shrinkage and degree of transverse-direction thermal shrinkage through 10-second immersion in a 140 DEG C glycerol bath are in respective given ranges.

Owner:TOYOBO CO LTD +1

Finishing machine

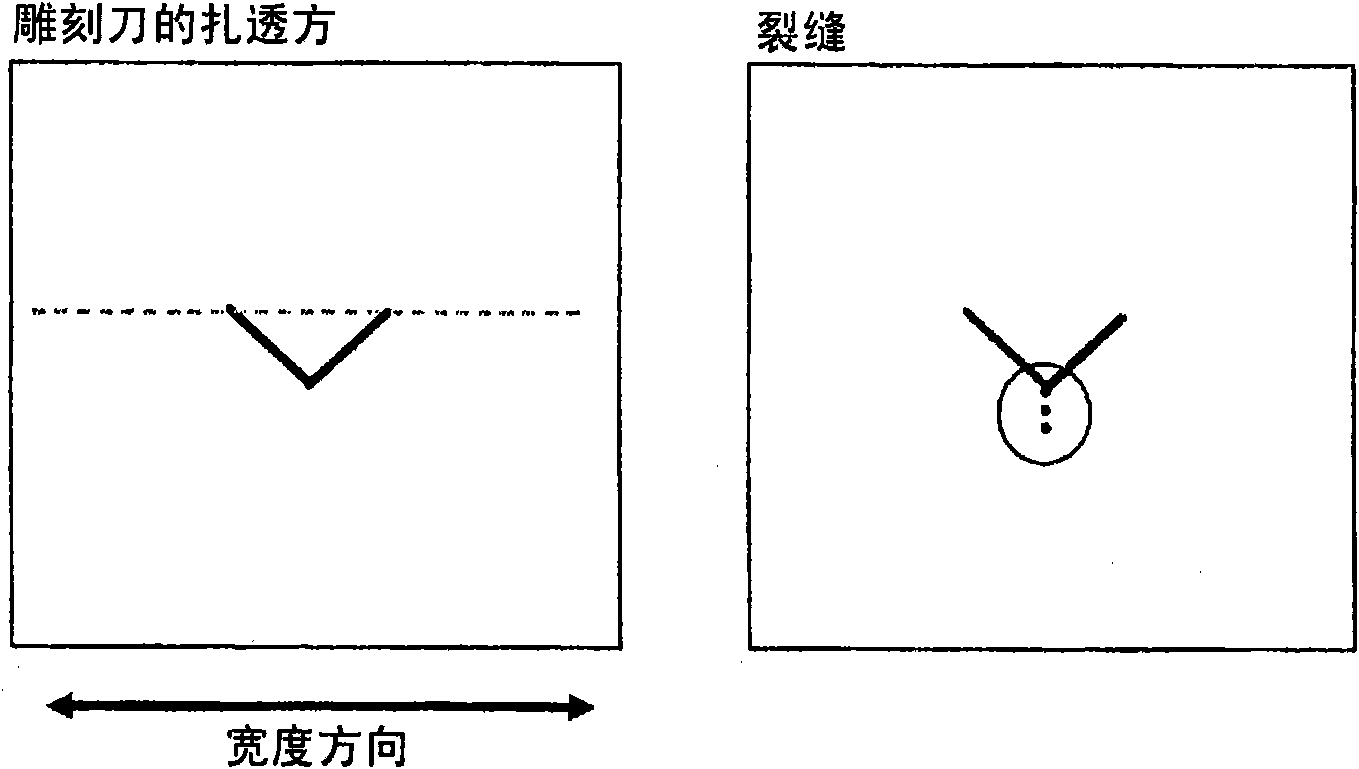

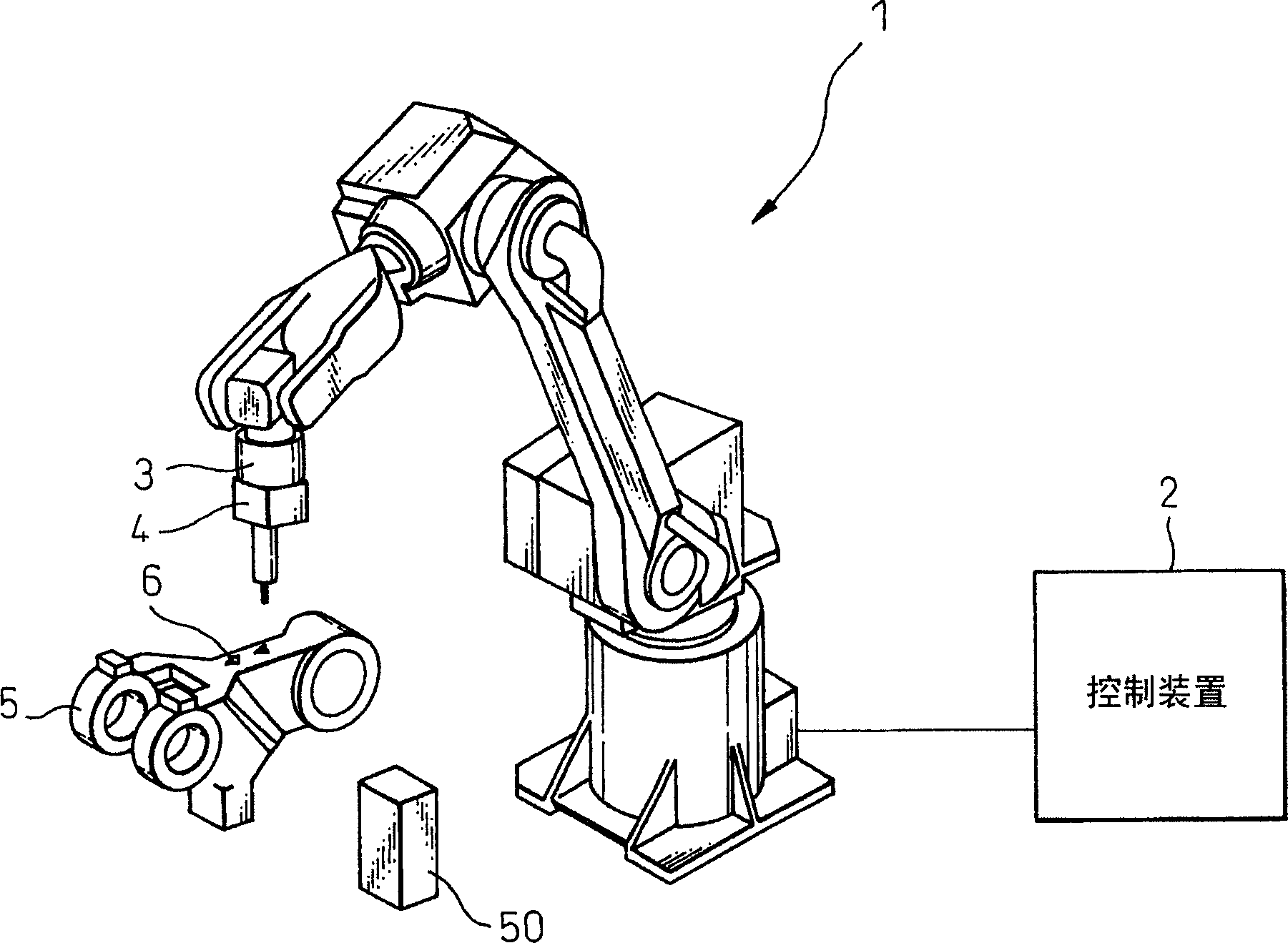

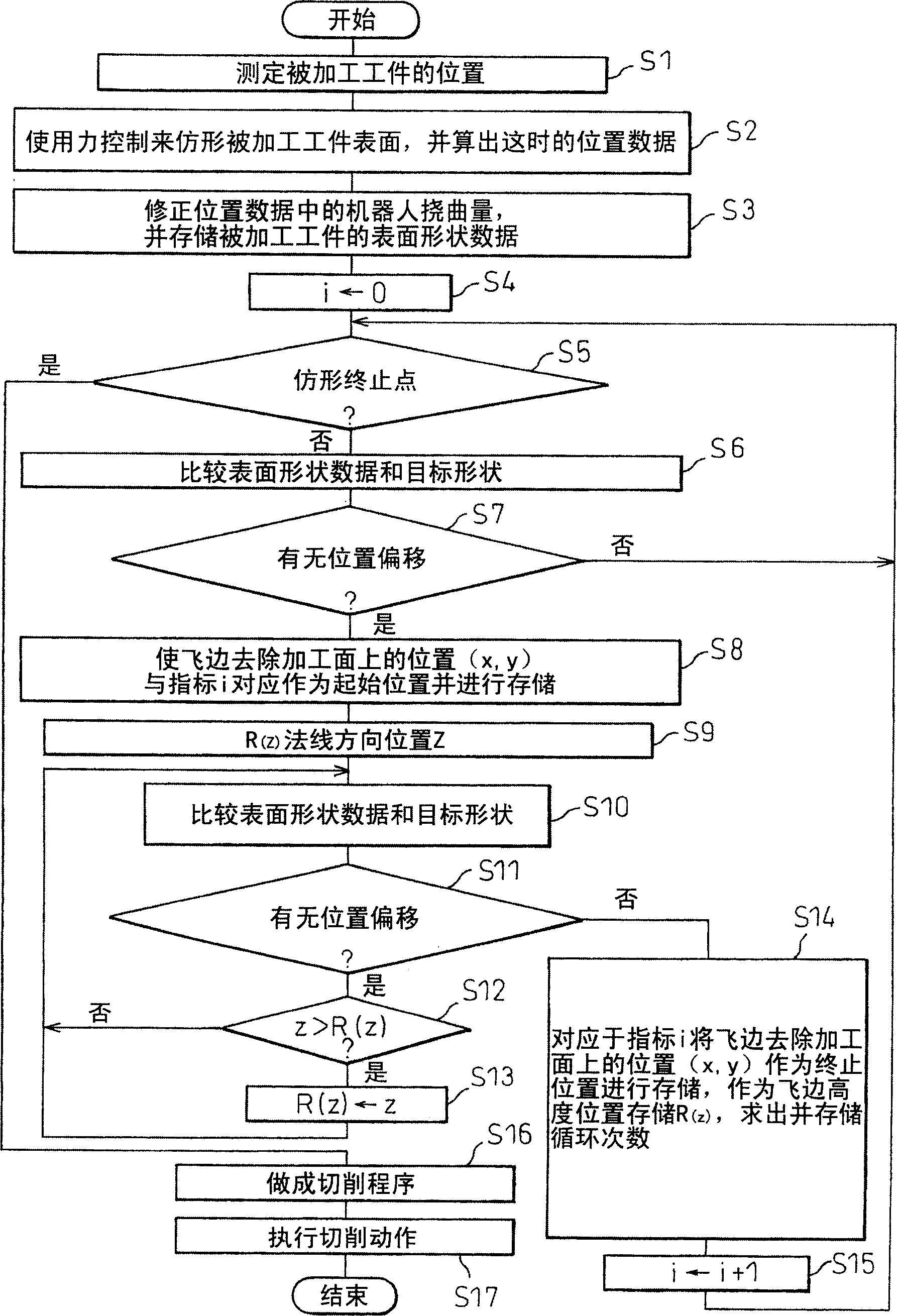

ActiveCN1736660AEfficient finishingProgramme controlAutomatic control devicesMachine toolSurface shape

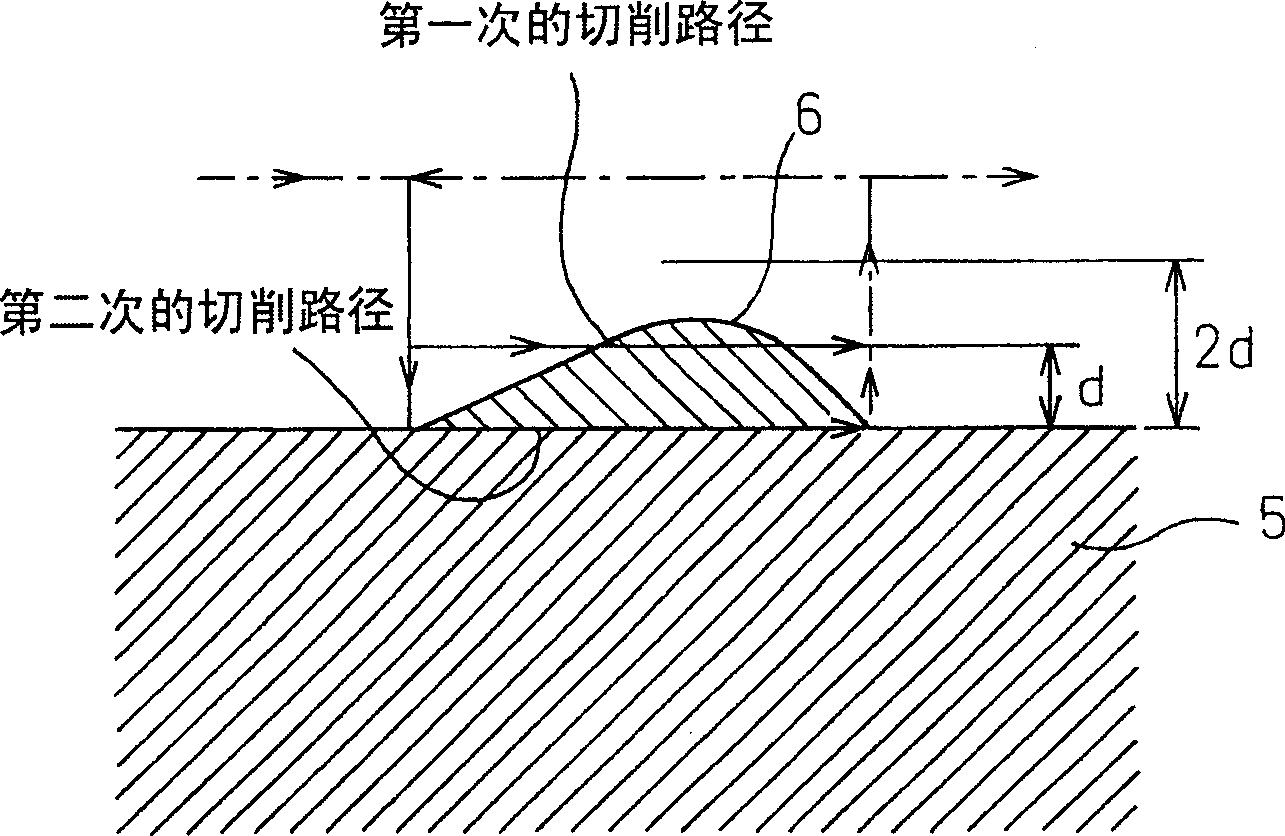

The present invention provides a finishing machine characterized in that useless burr removing actions can be reduced and, further, that the overcutting of a workpiece can be prevented. A surface of a workpiece, from which the burr is removed, is traced when a machining tool is pressed onto the surface of the workpiece under force control so as to find the positional data of the surface shape. This positional data is corrected by an error caused by a bend of a robot. The thus obtained positional data is compared with the target shape of the surface, from which the burr is removed, obtained from CAD data. A shift of the surface shape in the normal line direction is found. The burr generation start position, the burr generation end position and the height of the burr are found by the shift start position, the shift end position and the shift size. A machining program is made which is composed of a pass connecting the burr end position with the burr start position and also composed of a cutting pass for removing the burr, and the thus made machining program is executed. As the burr position is found and the burr is removed when the machining tool is moved to the burr position, the burr can be effectively removed.

Owner:FANUC LTD

Heat-shrinkable polyester film, process for production thereof, and package

ActiveCN101573400AHigh mechanical strengthGood unsealingStampsWrappers shrinkageProduction ratePolyester resin

The present invention provides a heat-shrinkable polyester film which can be easily torn along perforations and which exhibits extremely high productivity. The heat-shrinkable polyester film made from a polyester resin which comprises ethylene terephthalate units as the main constituent and contains at least 15% by mole of units derived from at least one monomer capable of forming a non-crystalline component based on the whole polyester resin and which exhibits specific heat shrinkage characteristics and specific mechanical characteristics after the heat shrinkage.

Owner:TOYOBO CO LTD

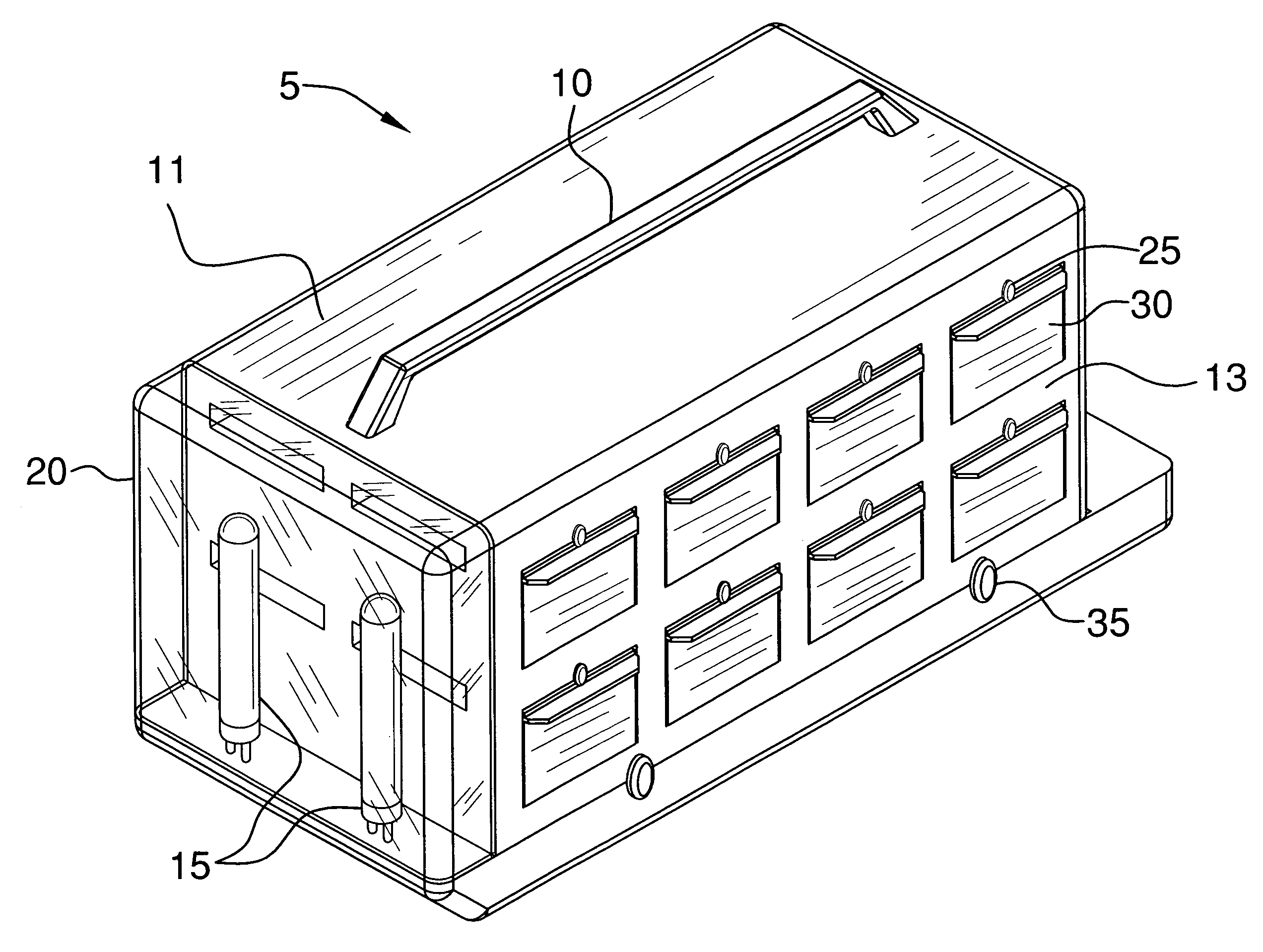

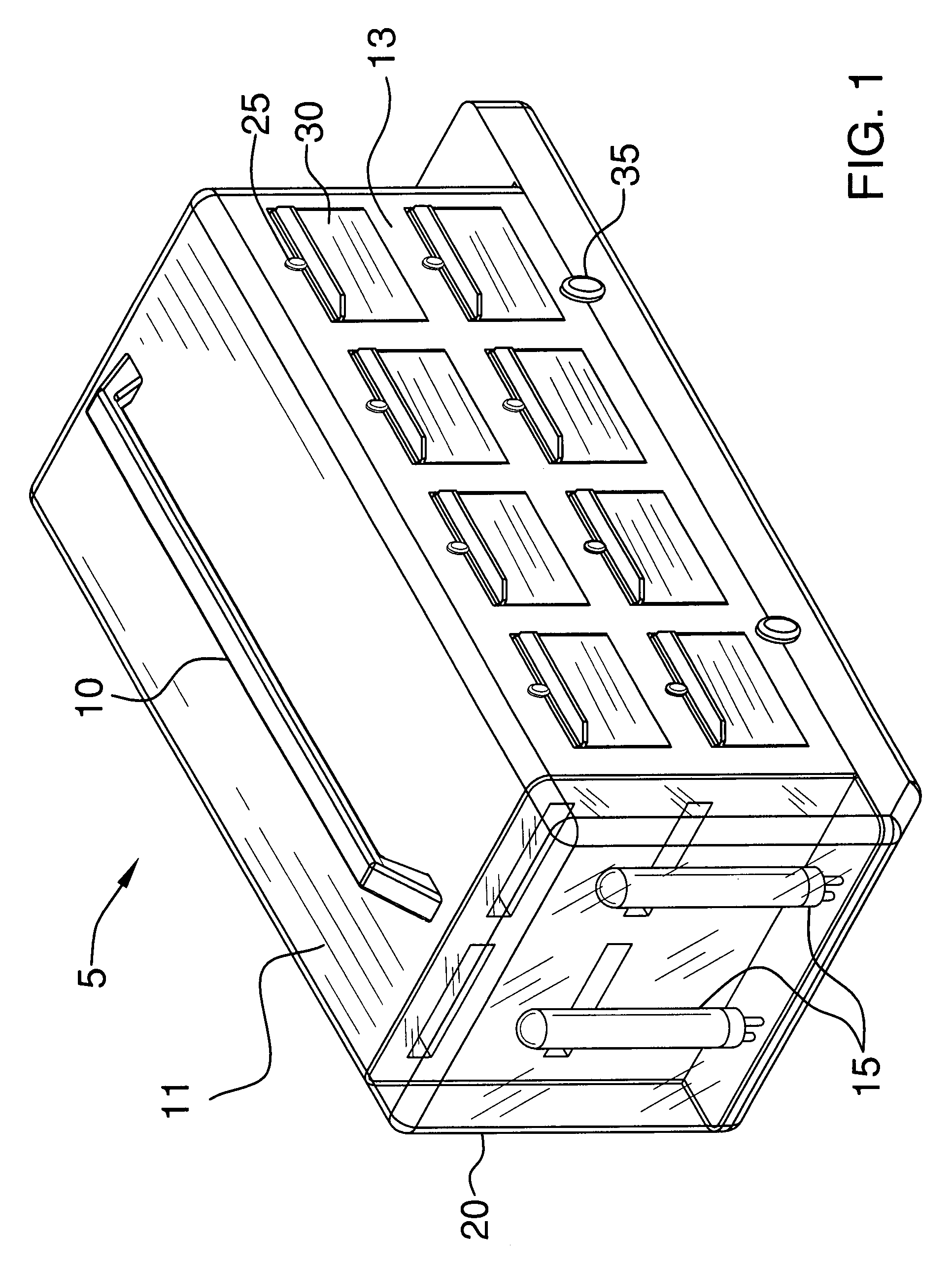

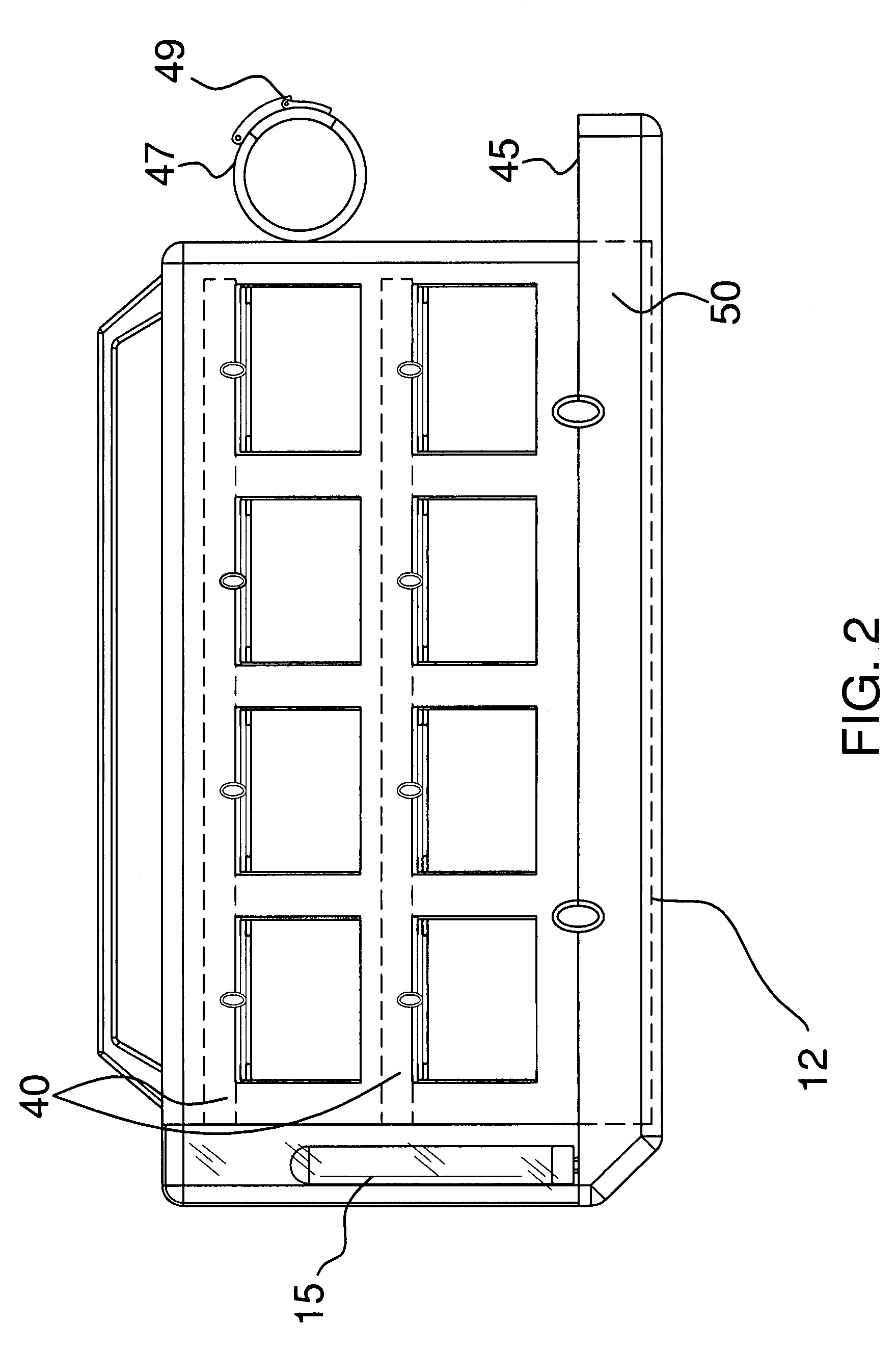

Toolbox with power supply

InactiveUS7252404B1Efficient finishingShorten the timeLighting elementsBed-tablesToolboxElectrical and Electronics engineering

Owner:MESSAMORE DOUGLAS J

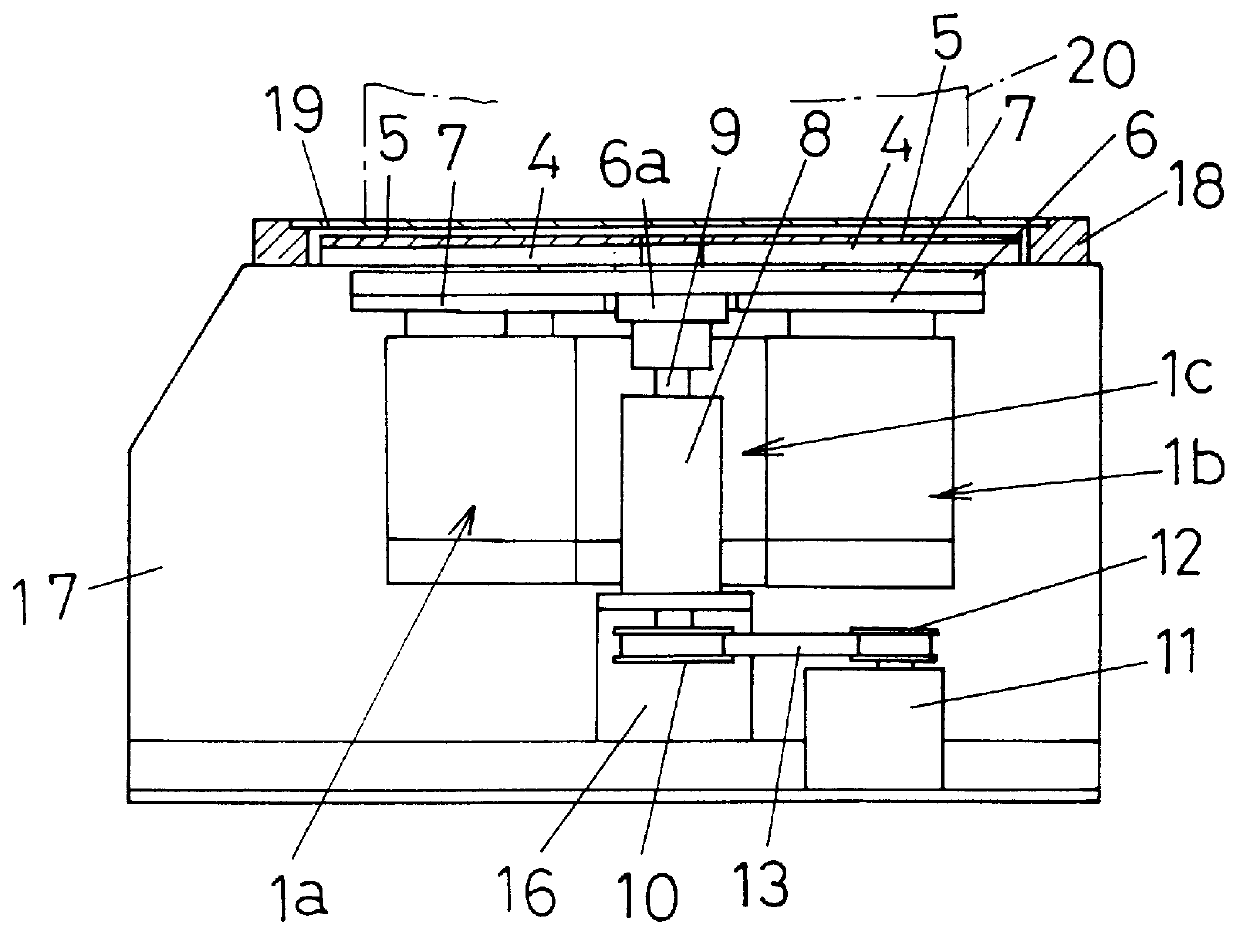

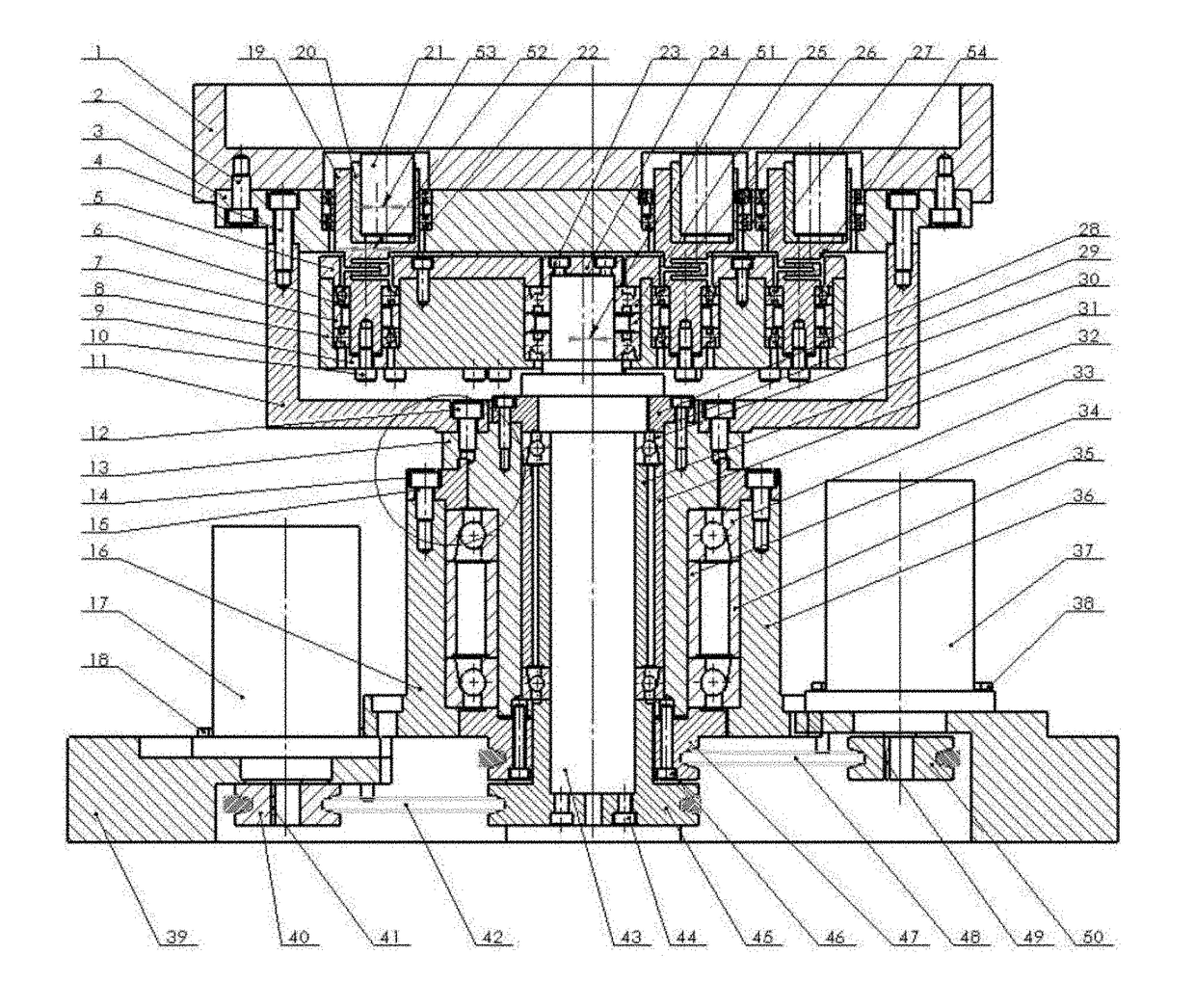

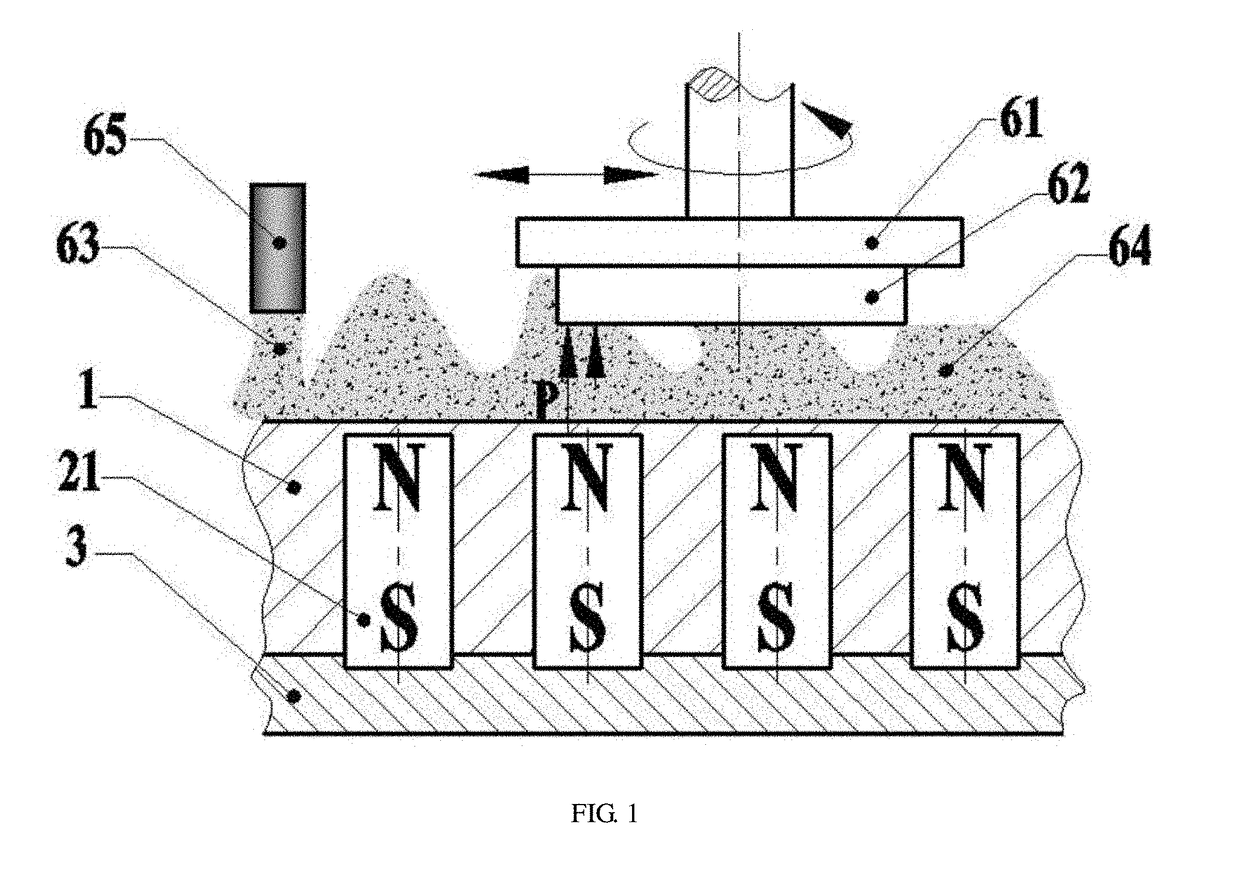

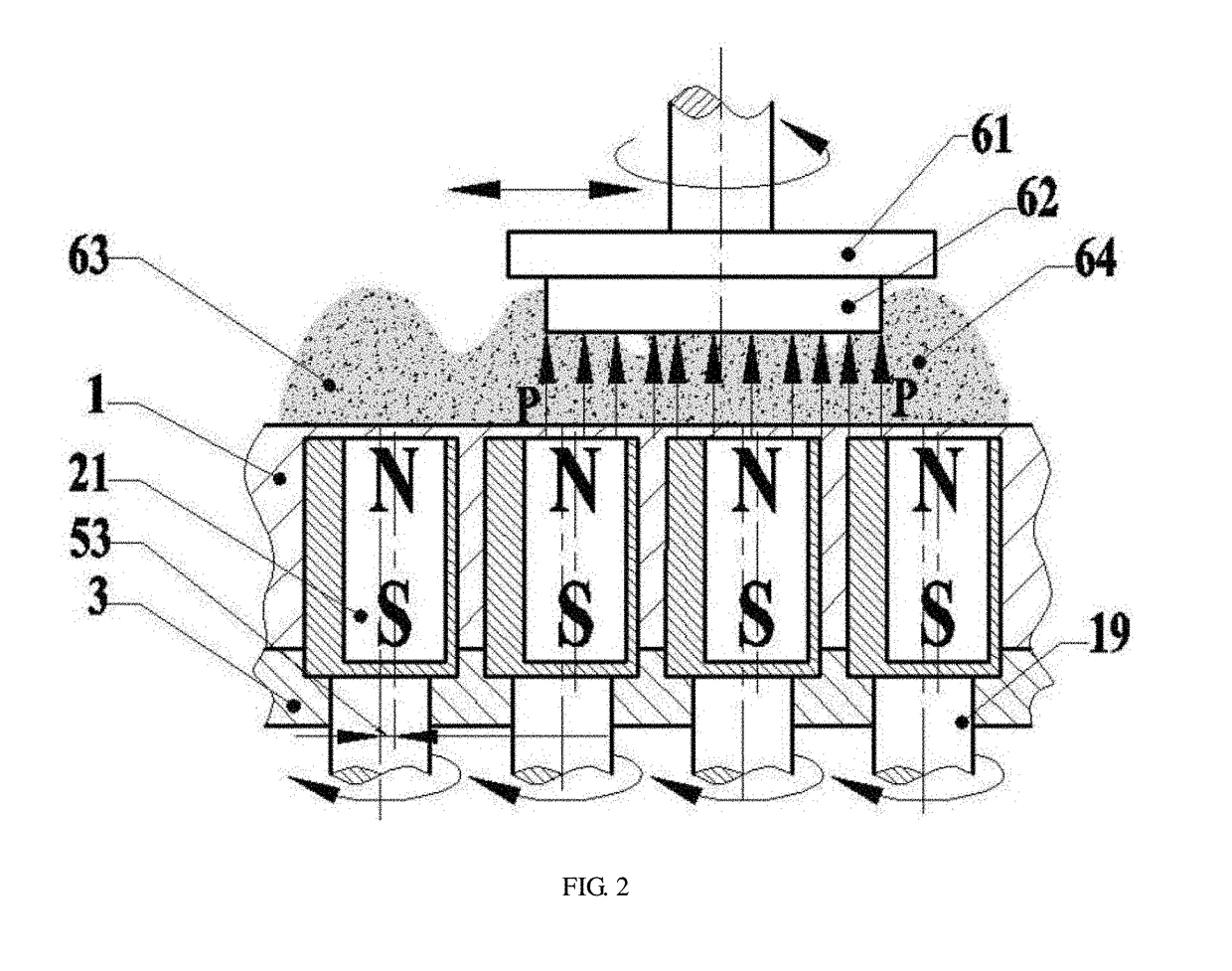

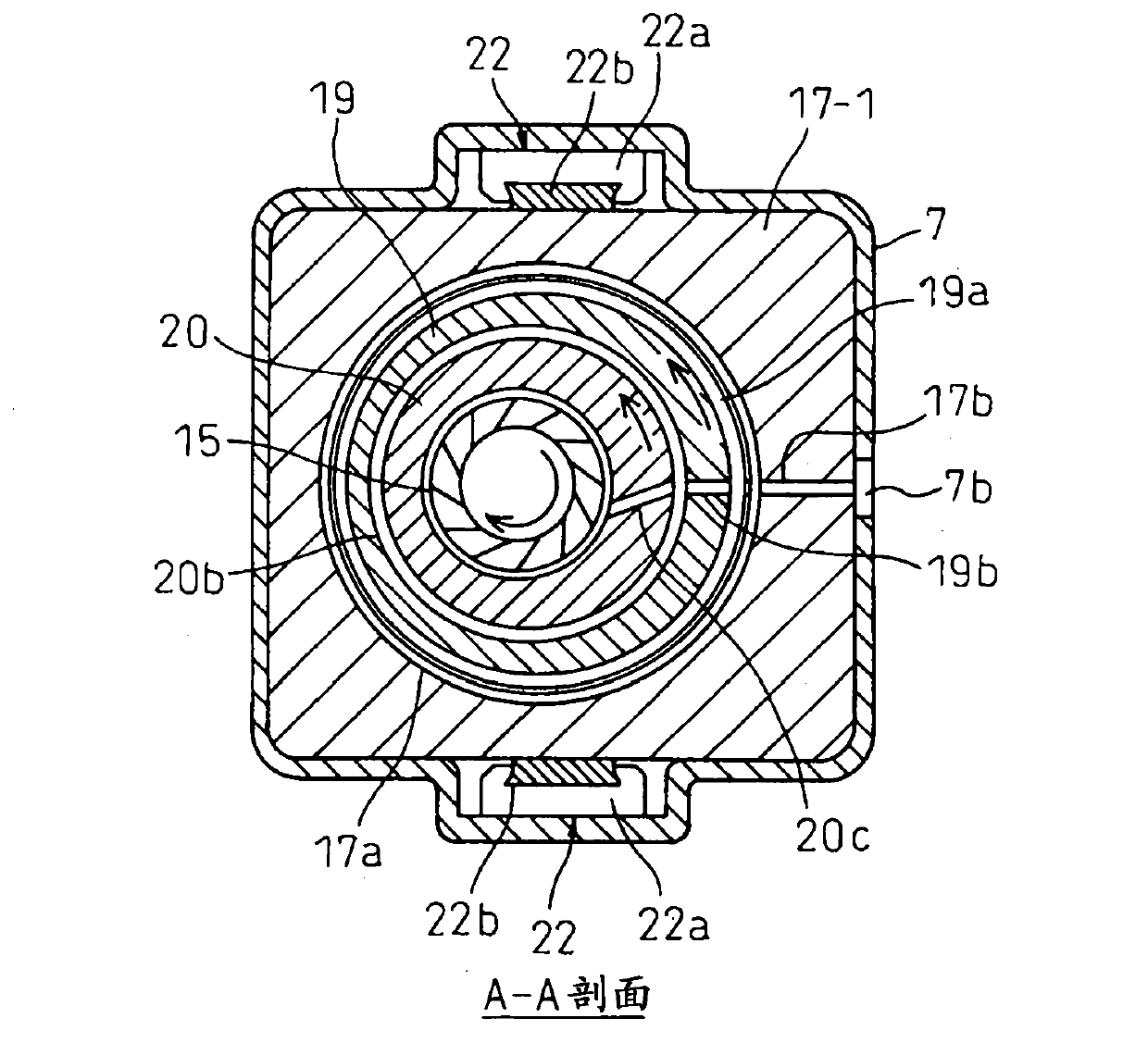

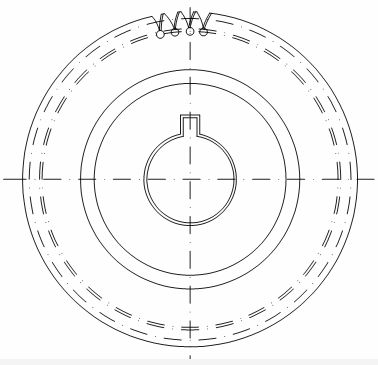

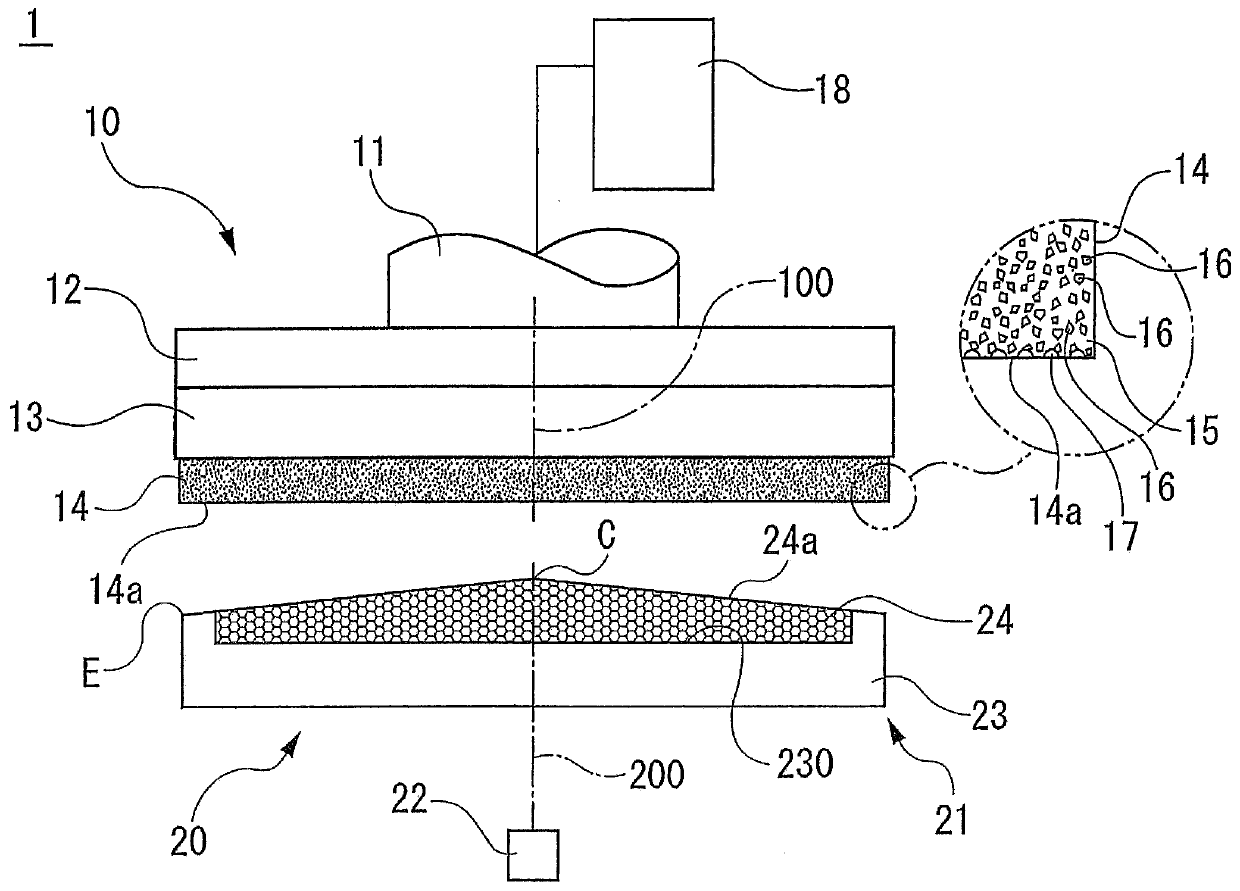

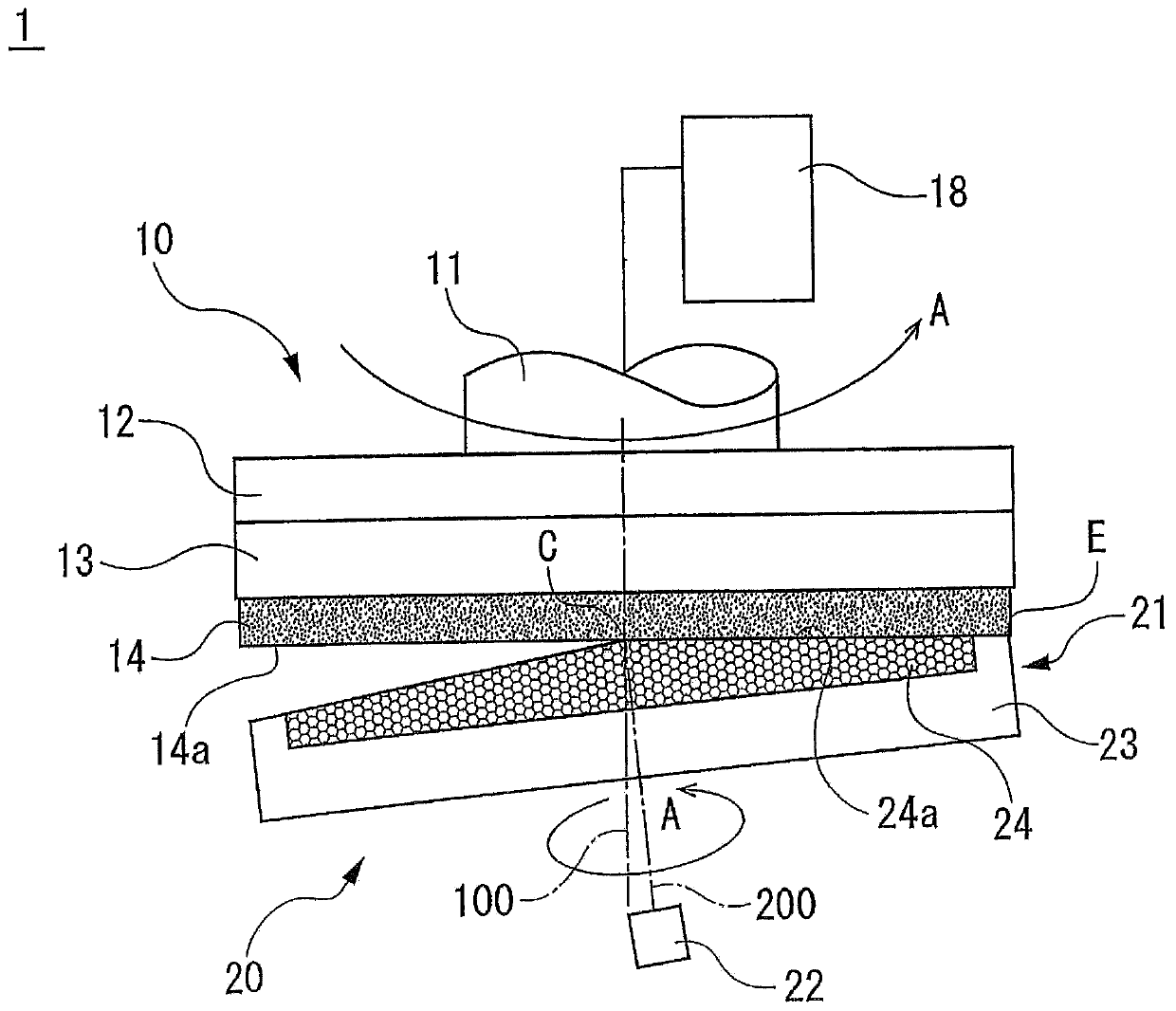

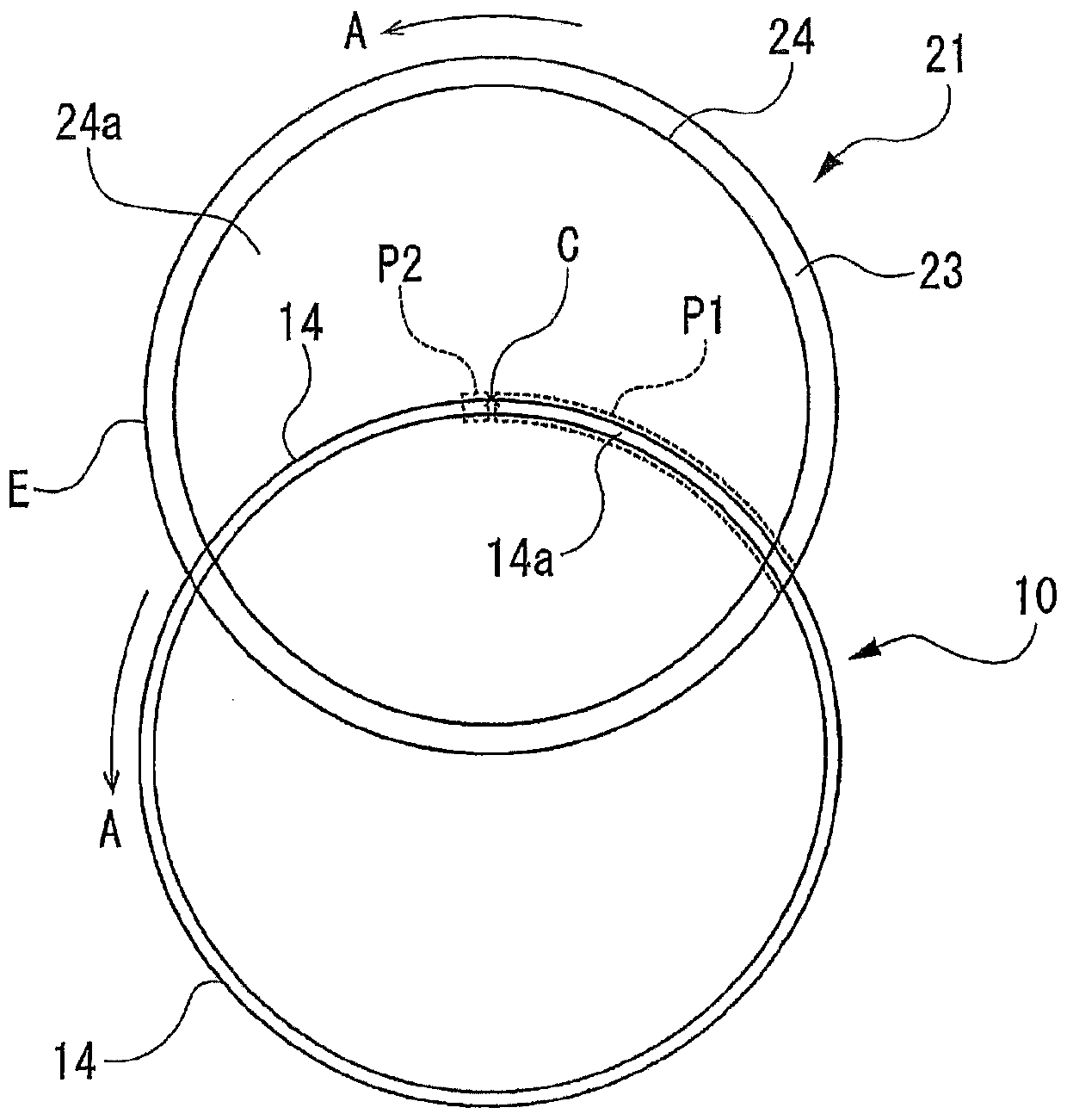

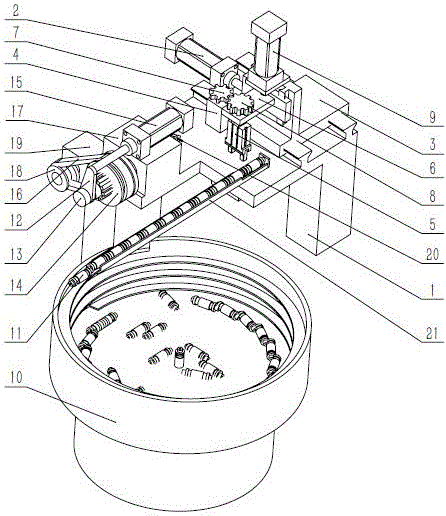

A self-sharpening polishing device with magnetorheological flexible polishing pad formed by dynamic magnetic field and polishing method thereof

InactiveUS20180021910A1Space saveLow costGrinding drivesAbrasive surface conditioning devicesEngineeringMagnetic current

Provided is a self-sharpening polishing device with magnetorheological flexible polishing pad formed by dynamic magnetic field and polishing method thereof. The device includes a polishing disc revolution mechanism and a multi-magnetic-pole synchronous rotary drive mechanism, the polishing disc revolution mechanism including a transmission shaft motor, a transmission shaft, a transfer disc, an eccentric shaft fixing disc, a cup-shaped polishing disc and a transmission shaft transmission mechanism, the multi-magnetic-pole synchronous rotary drive mechanism including an eccentric spindle, a synchronous rotary drive disc, flexible eccentric rotating shafts, eccentric sleeves, magnetic poles, the eccentric shaft fixing disc, and a spindle motor, etc. The device does not need a circulating device to renew magnetorheological fluid and does not need to renew the magnetorheological fluid during the finishing process; in fact the entire process from rough polishing to precise polishing can be done at one time. The device maintains a consistent workpiece surface and delivers a low cost and very efficient polishing process that is eminently suitable for the planes of optical elements with large diameter; it is also suitable for studying the material removal mechanism of planar optical materials and detecting sub-surface damage, as well as other experimental studies.

Owner:GUANGDONG UNIV OF TECH

Boring device

InactiveCN102892538AFree and easy to combineEfficient finishingWorkpiecesTurning toolsEngineeringMechanical engineering

Owner:柳下福藏 +1

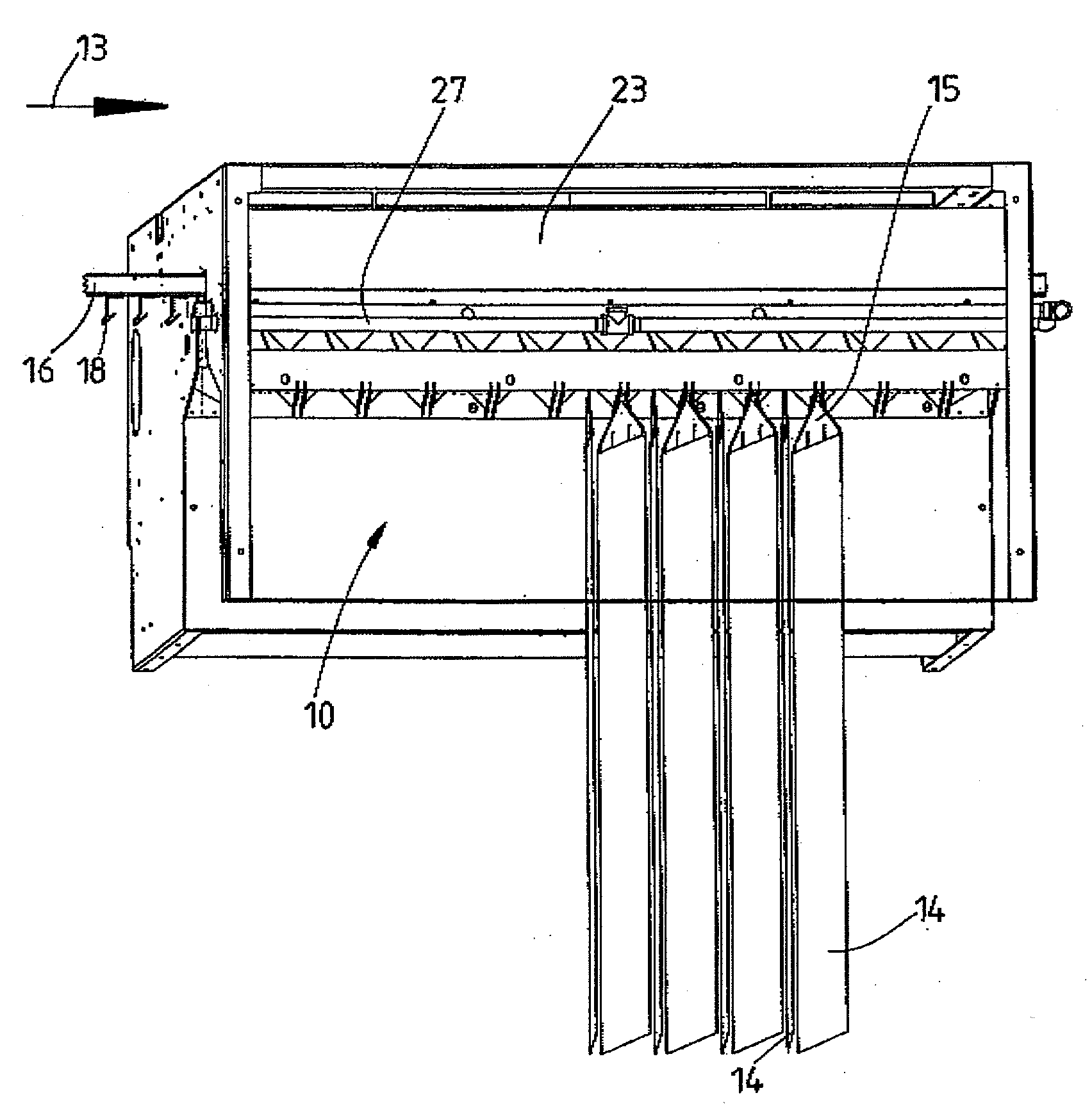

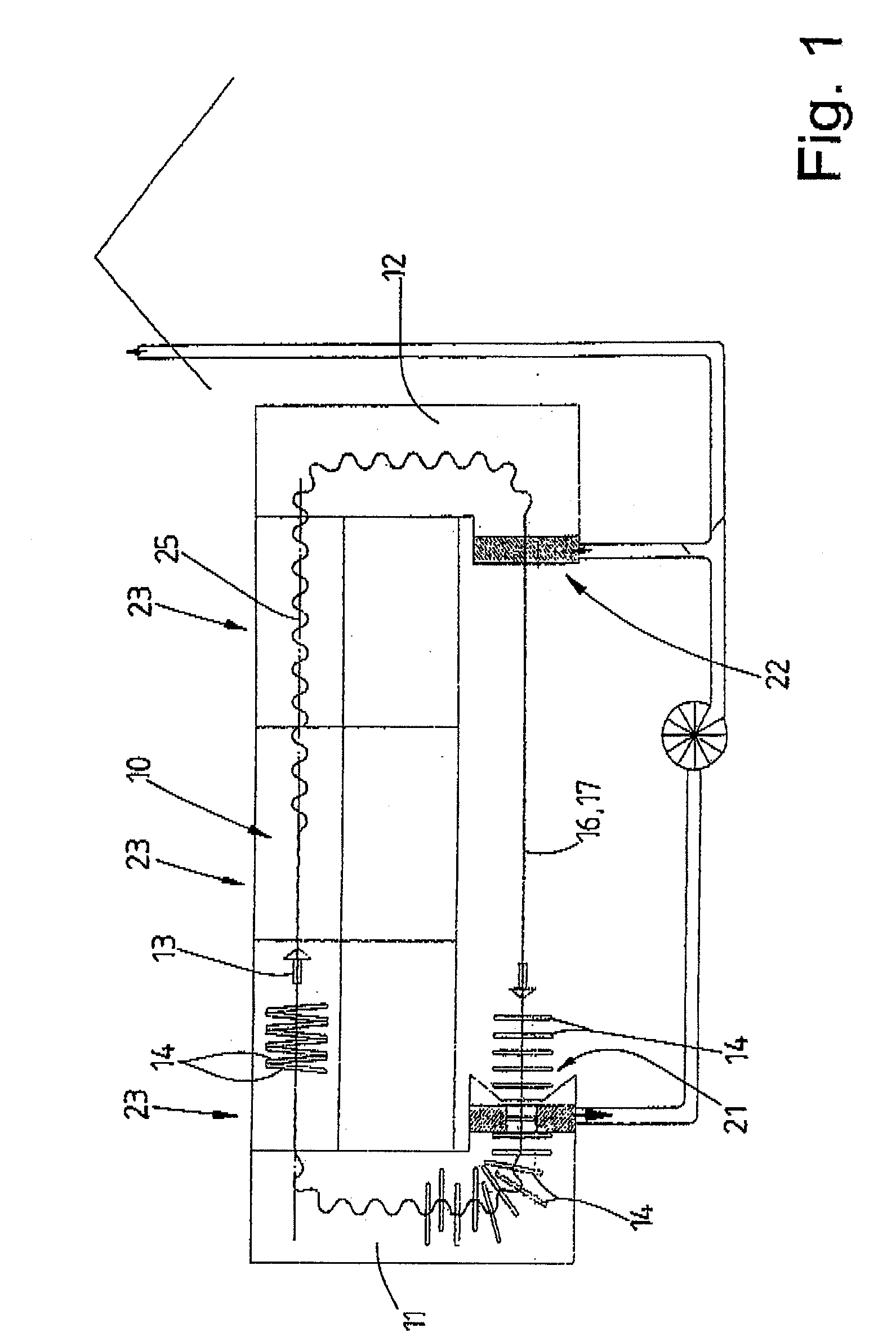

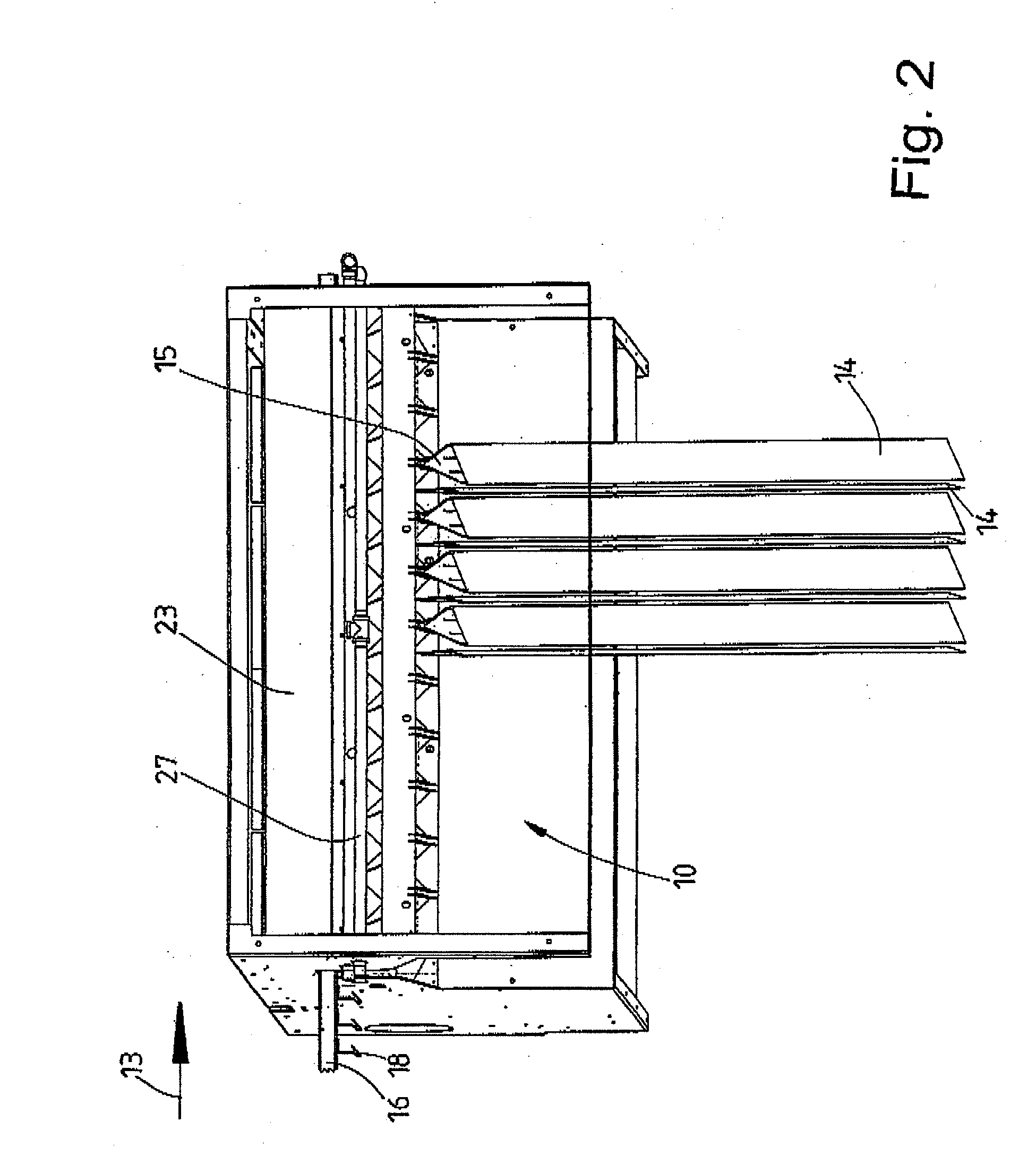

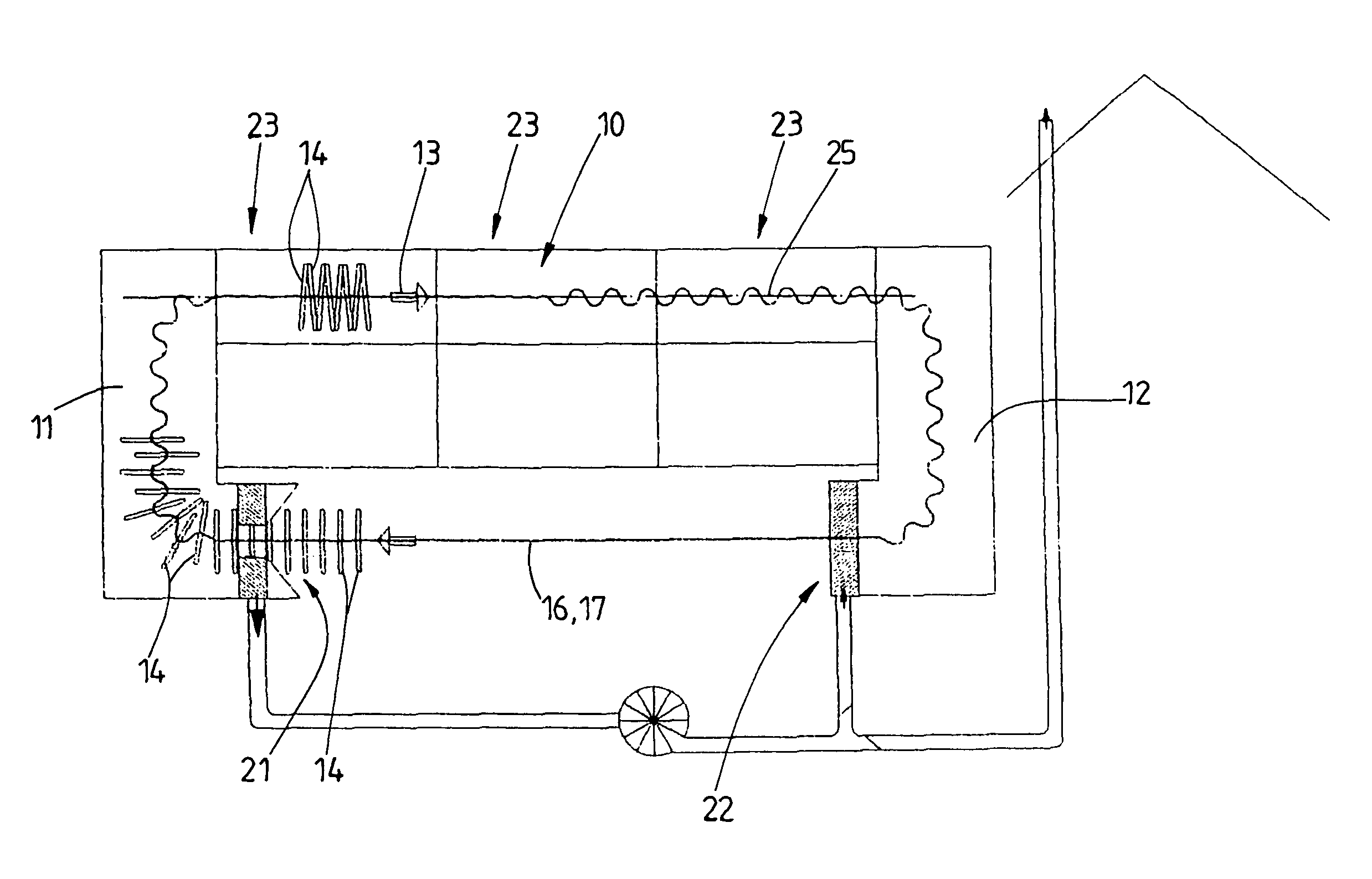

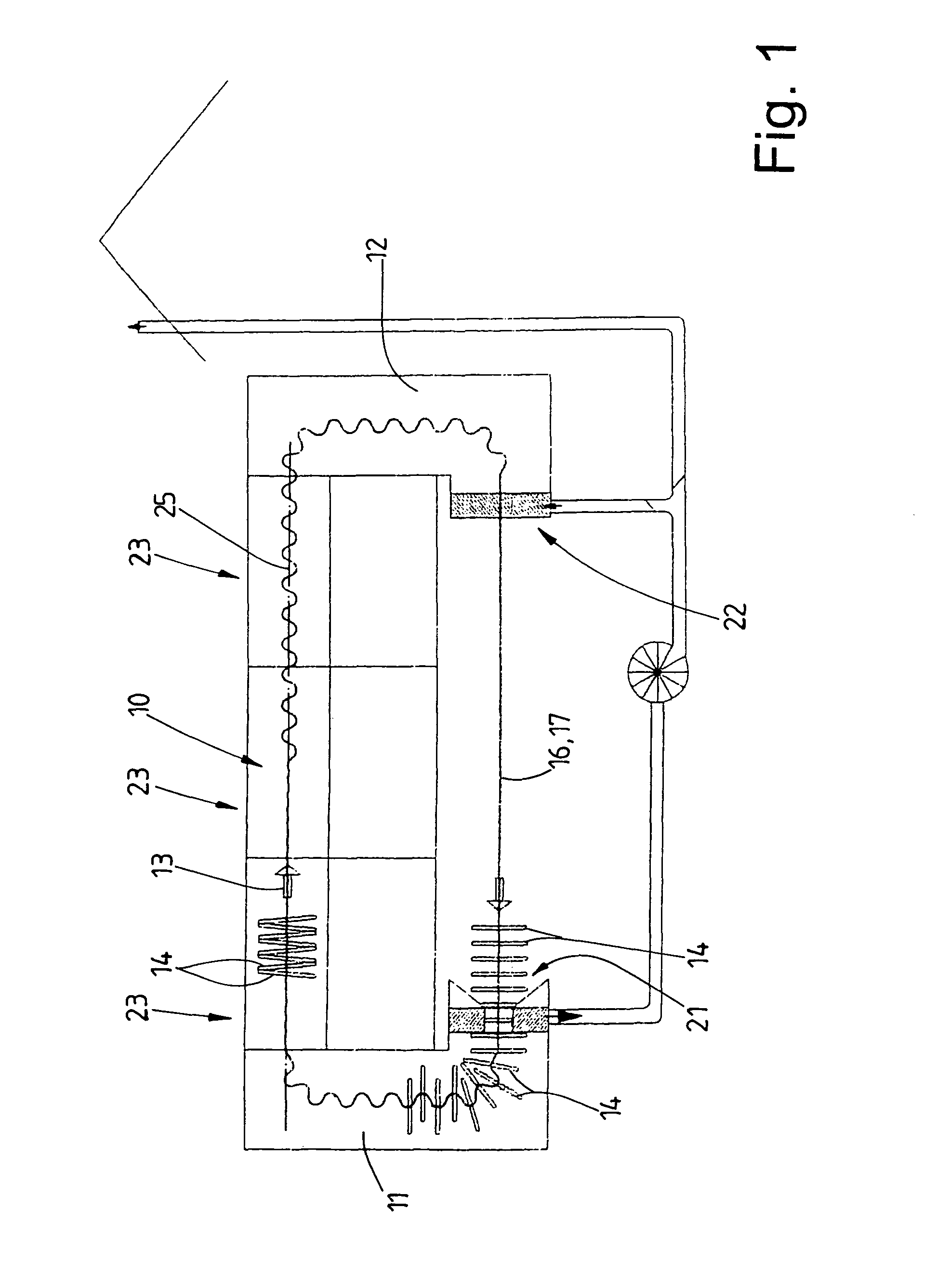

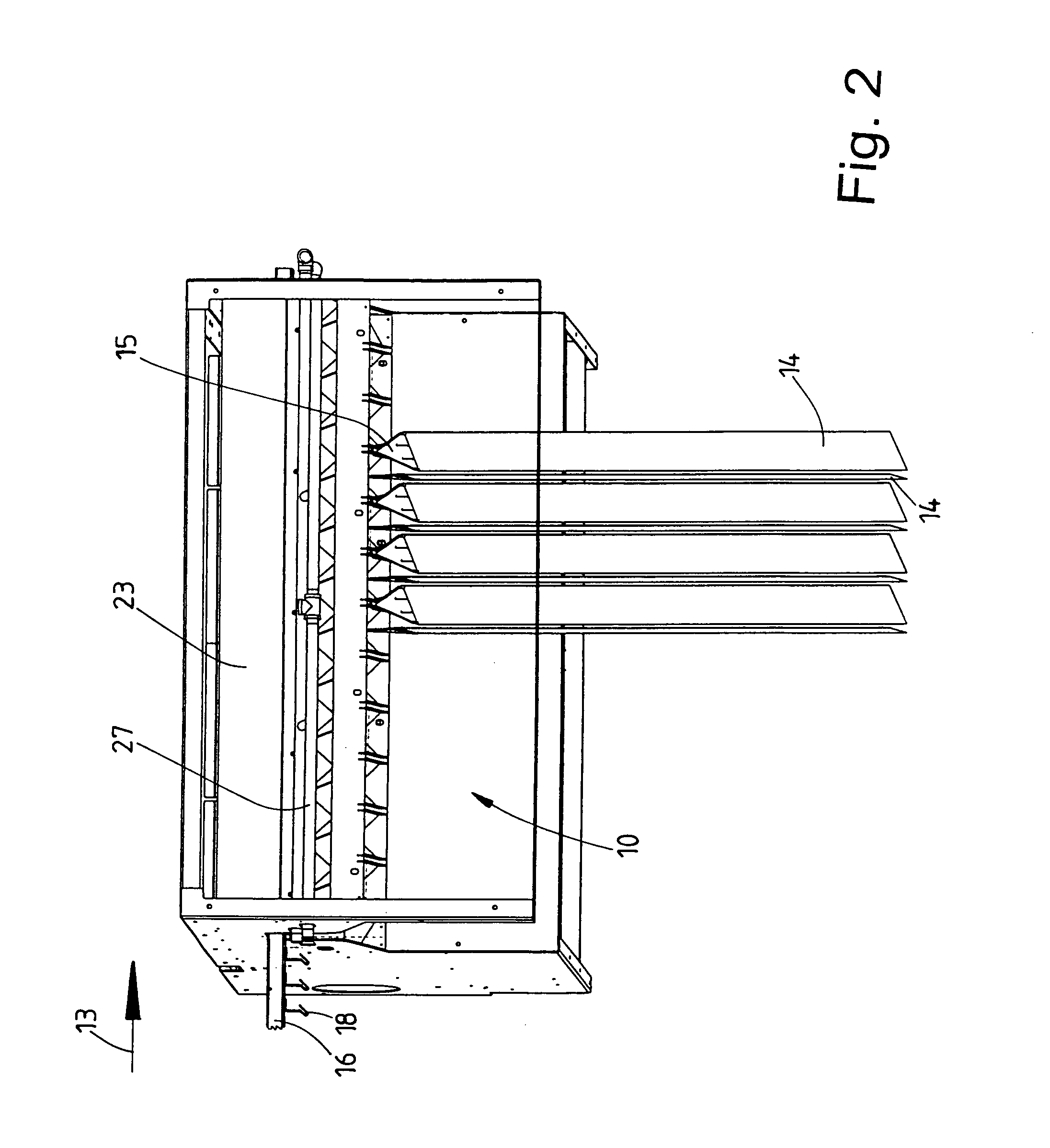

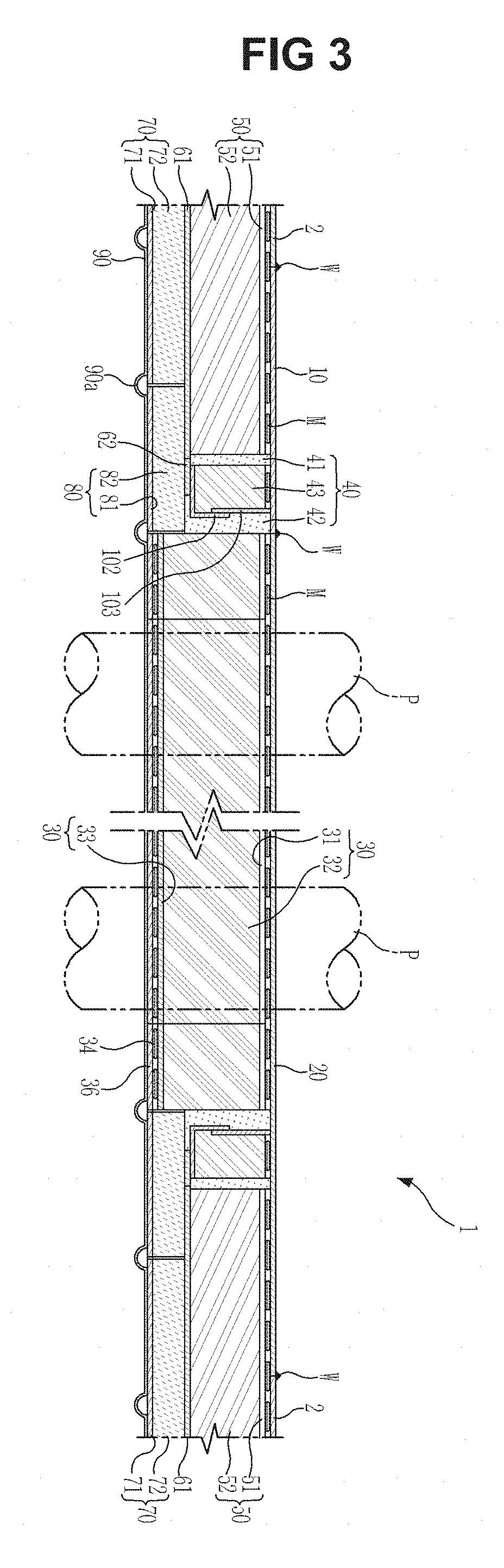

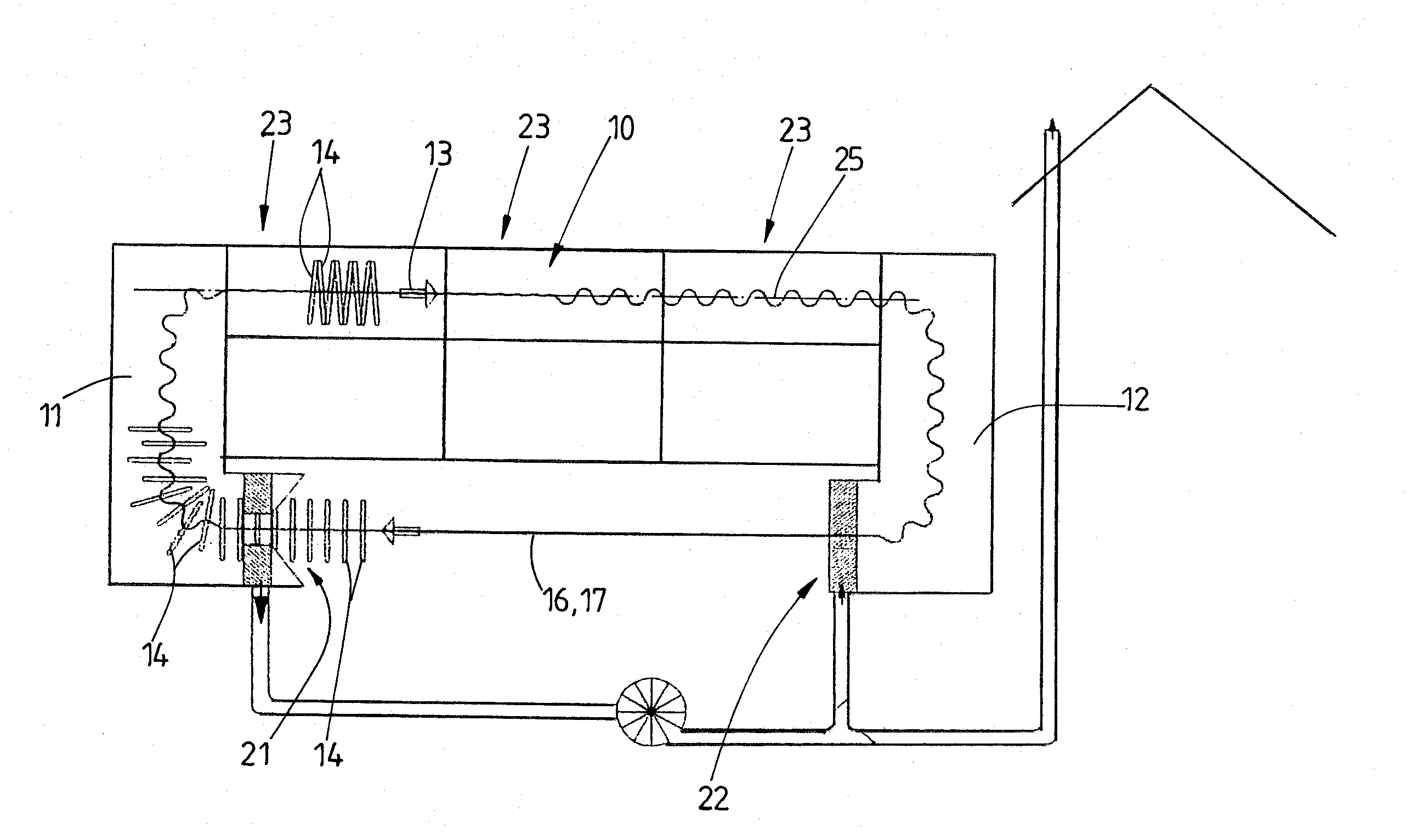

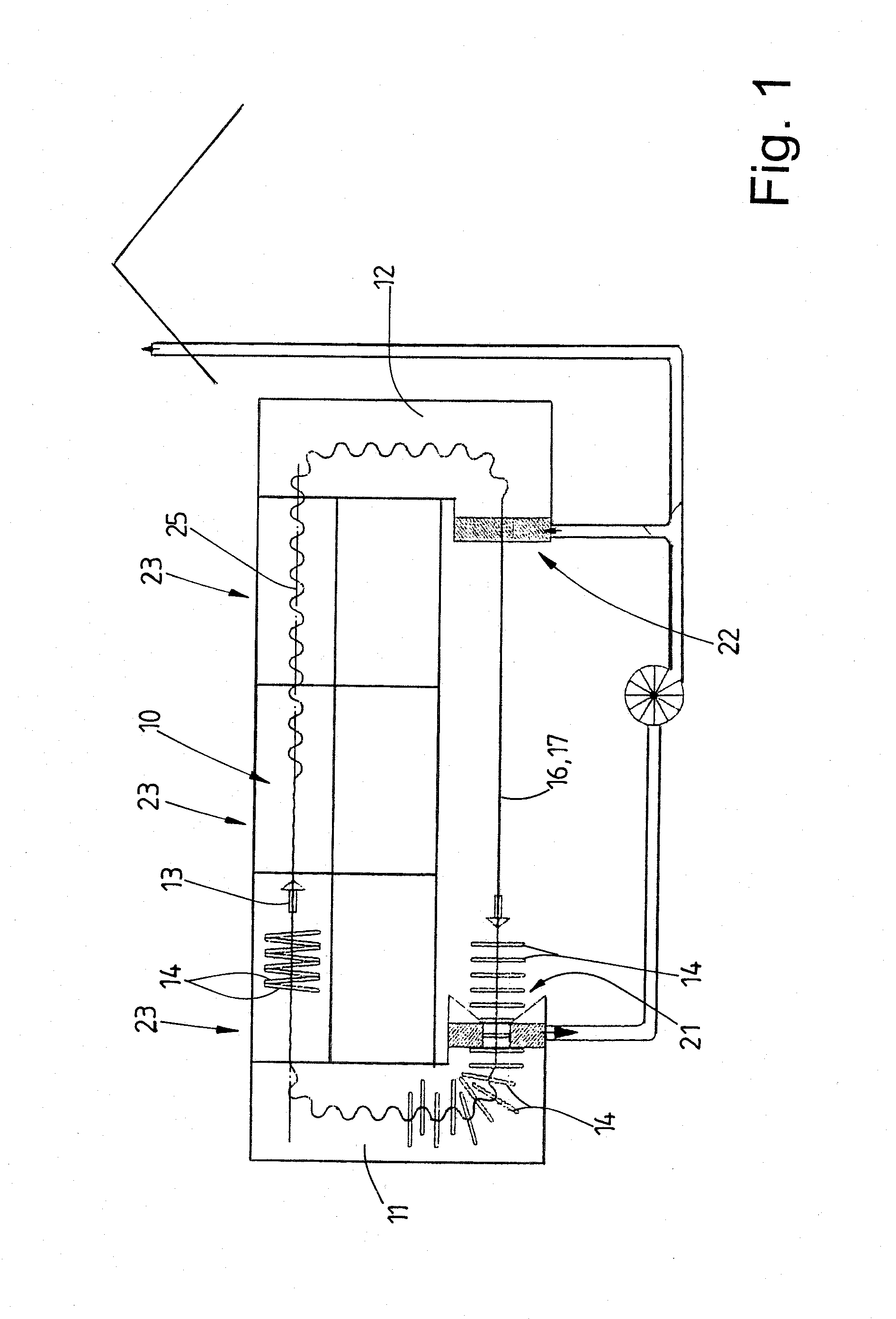

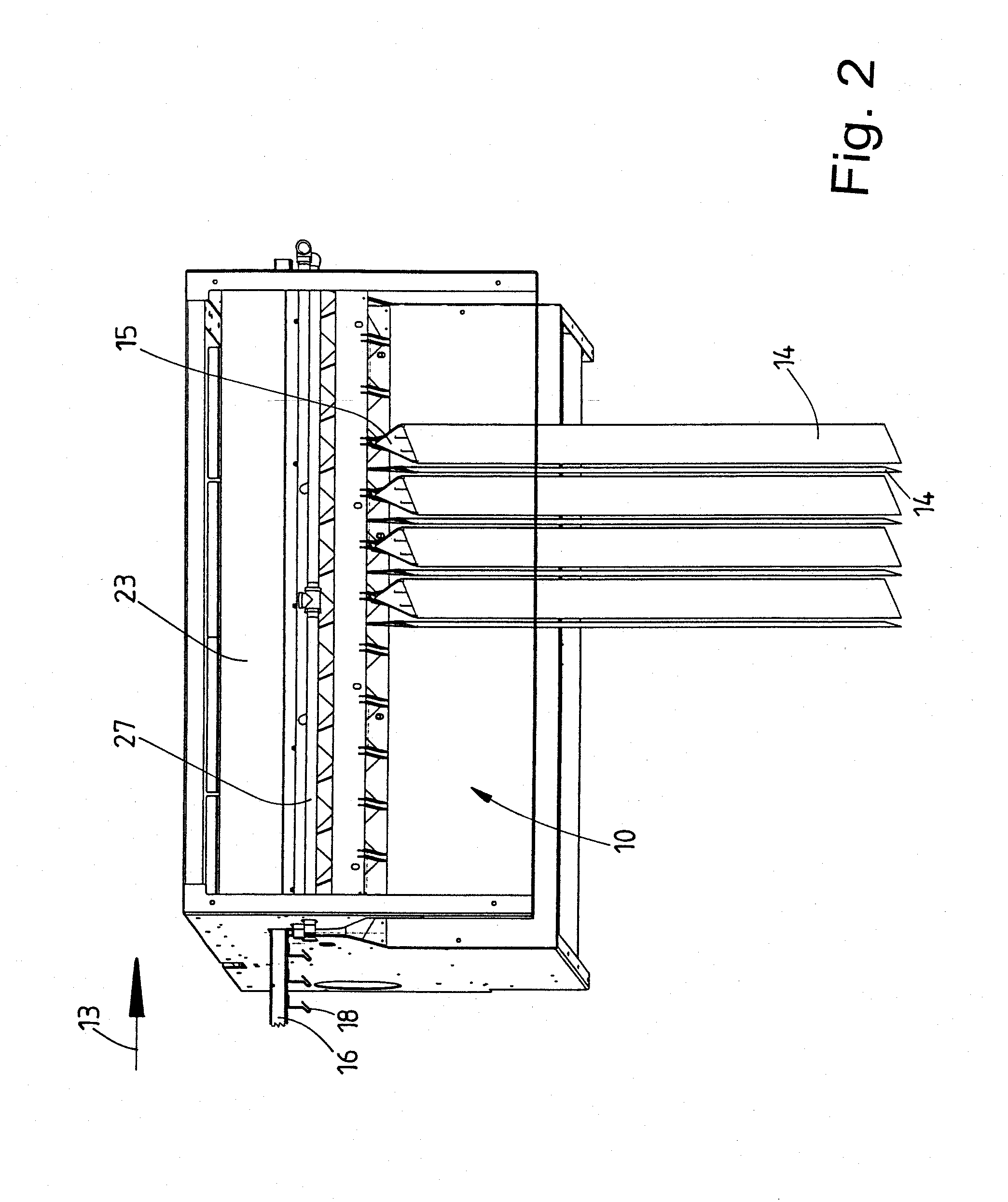

Method for smoothing articles of clothing and tunnel finisher

InactiveUS20080034609A1Meet cutting requirementsEnsure efficient flowIroning apparatusDrying chambers/containersEngineeringMechanical engineering

Owner:KANNEGIESSER GMBH CO HERBERT

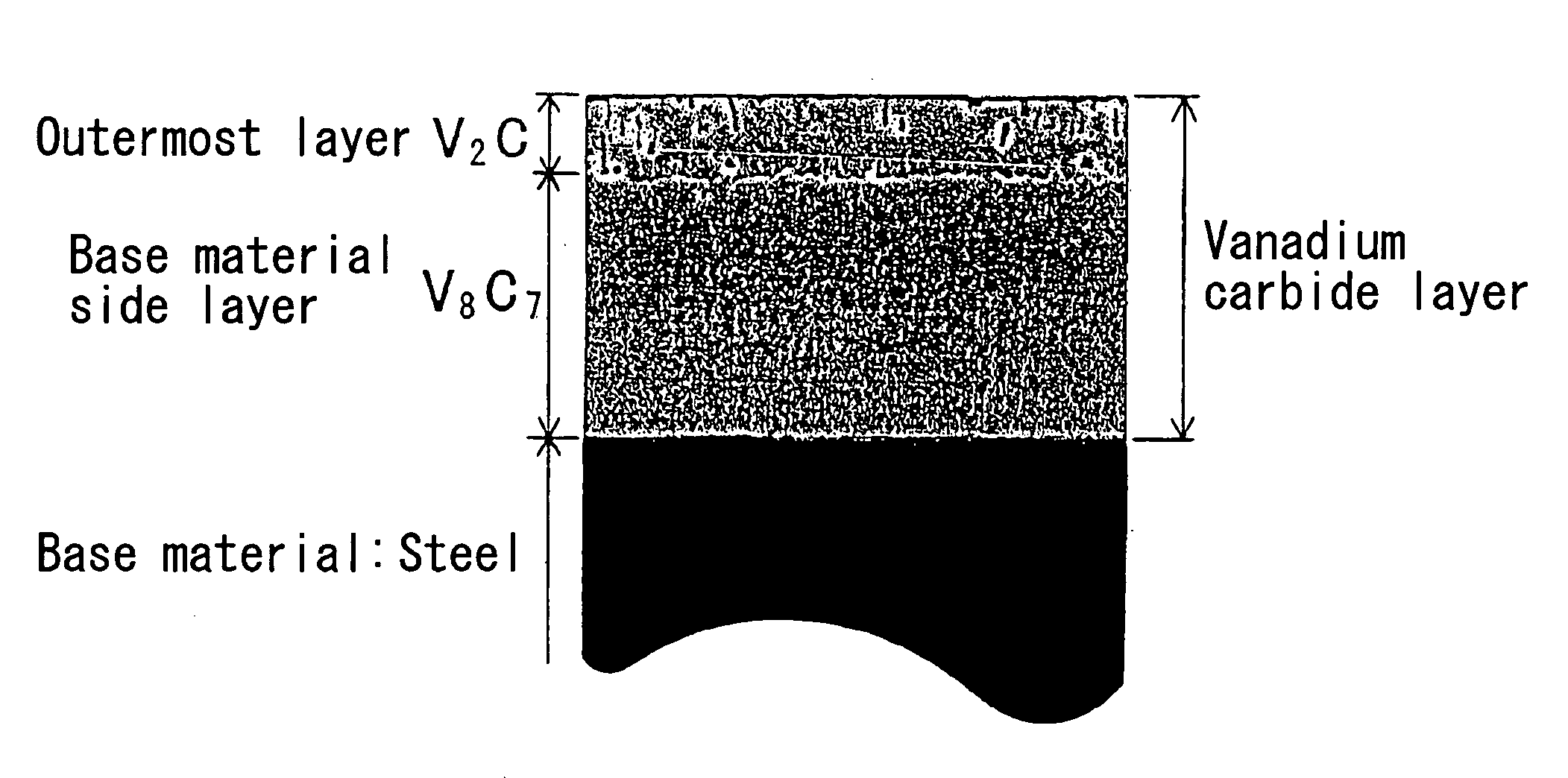

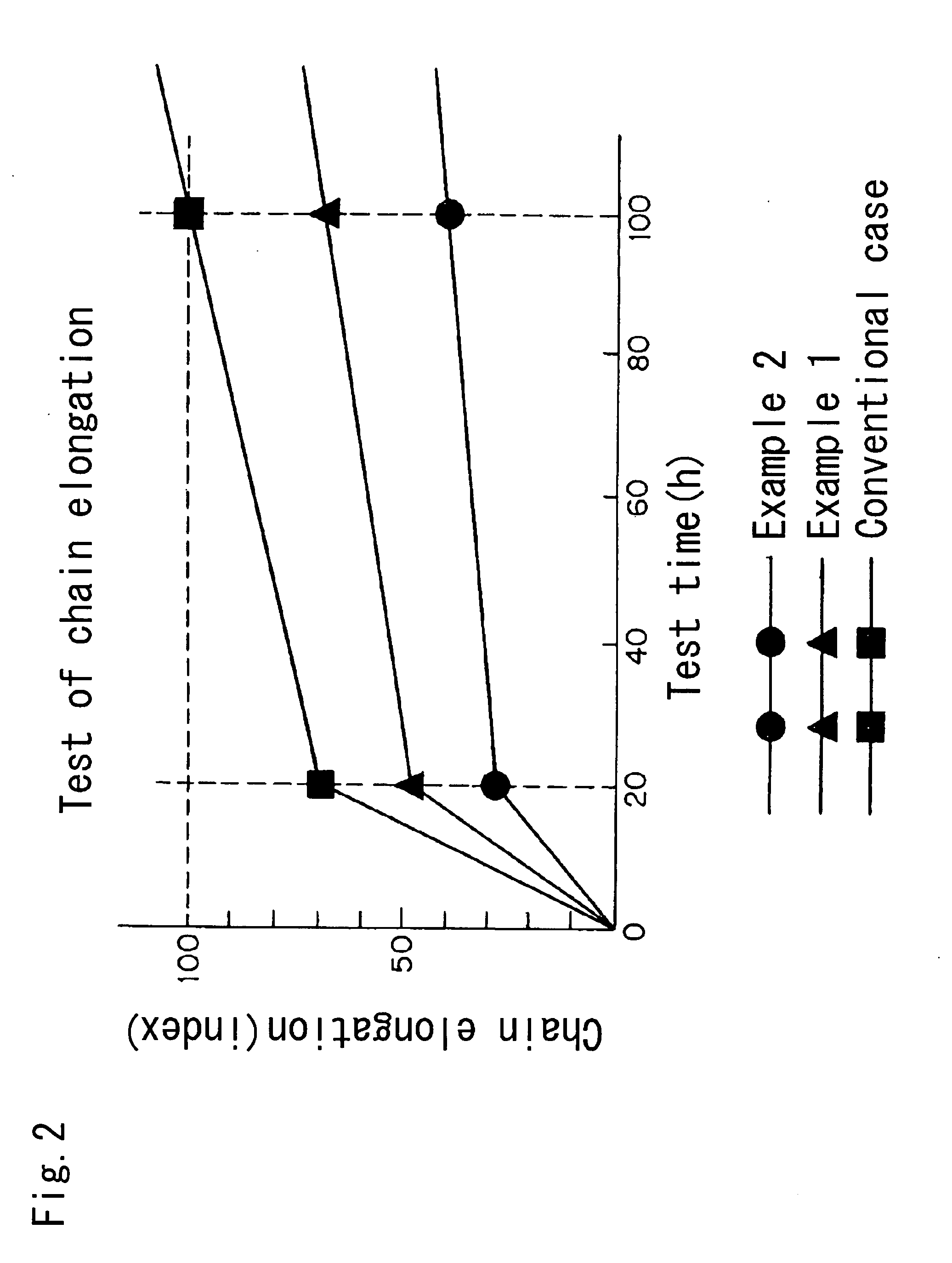

Chain for use in automobile engine

InactiveUS20080020879A1Reduce surface roughnessAbnormal wear elongation is suppressedGearingSolid state diffusion coatingVanadium carbideMaterials science

In a silent chain for an automobile engine timing drive, the pins which interconnect the link plates of the chain have a vanadium carbide layer formed on their surfaces by diffusion penetration. The vanadium carbide layer is composed of two parts: an inner part, on the steel base material of the pin, being a V8C7 layer, and an outermost part being a V2C layer.

Owner:TSUBAKIMOTO CHAIN CO

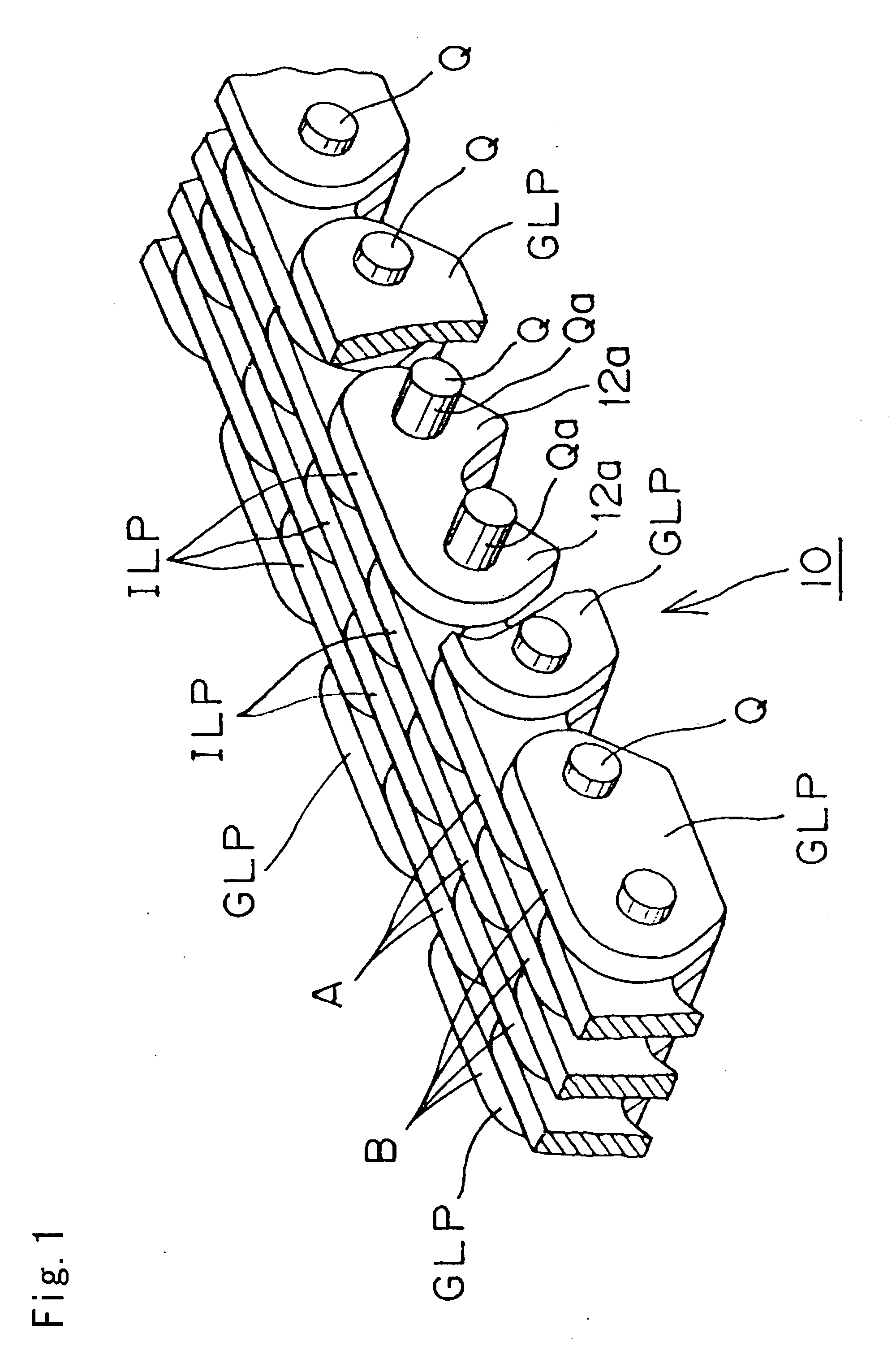

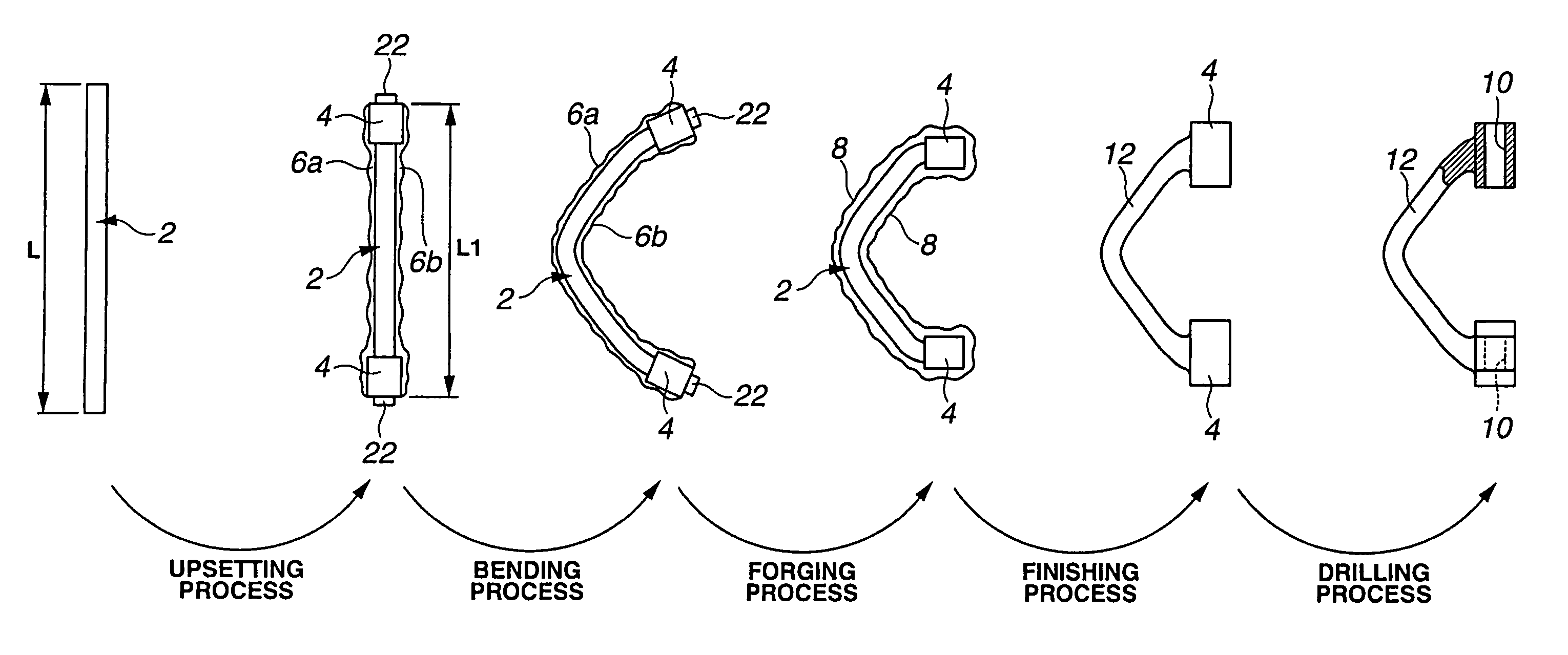

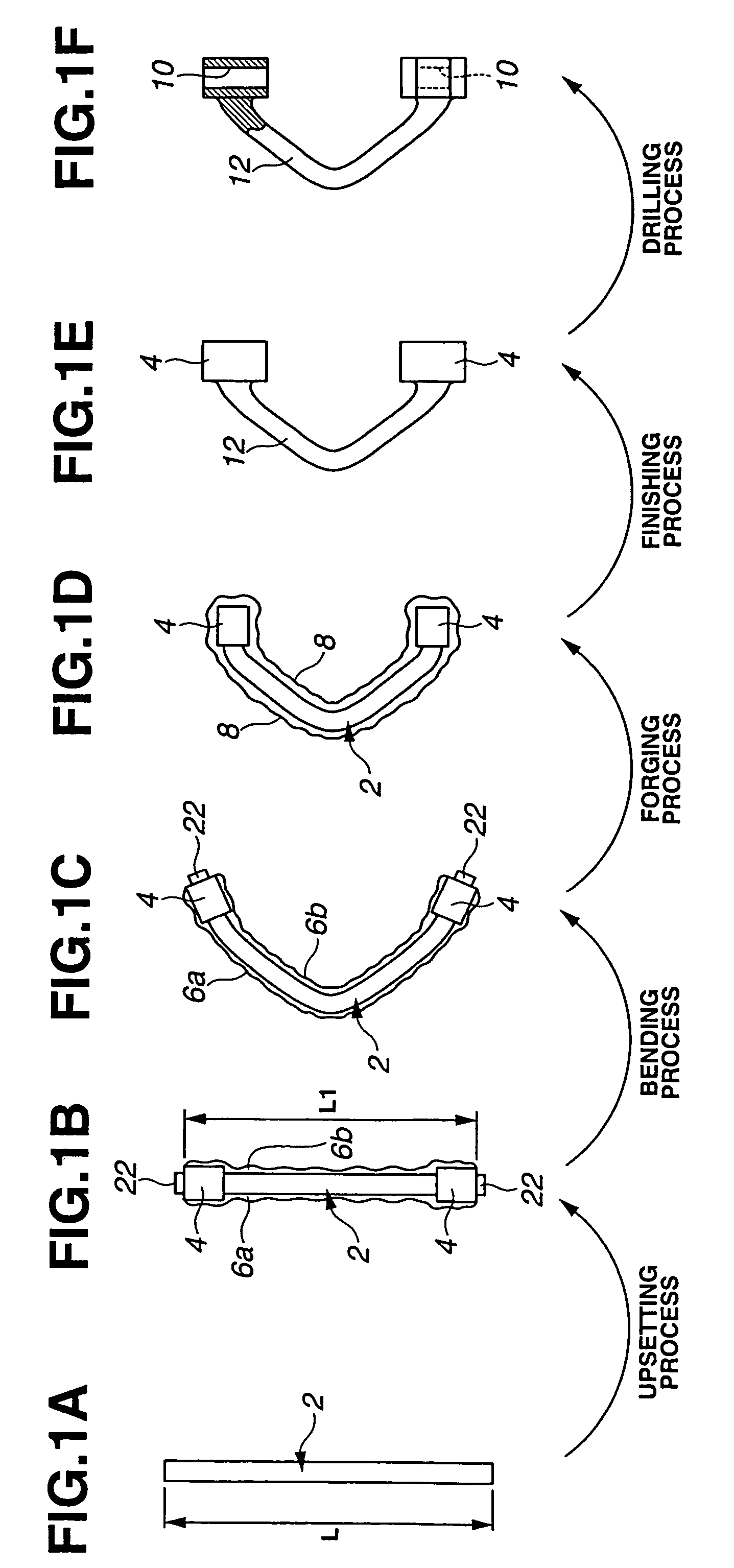

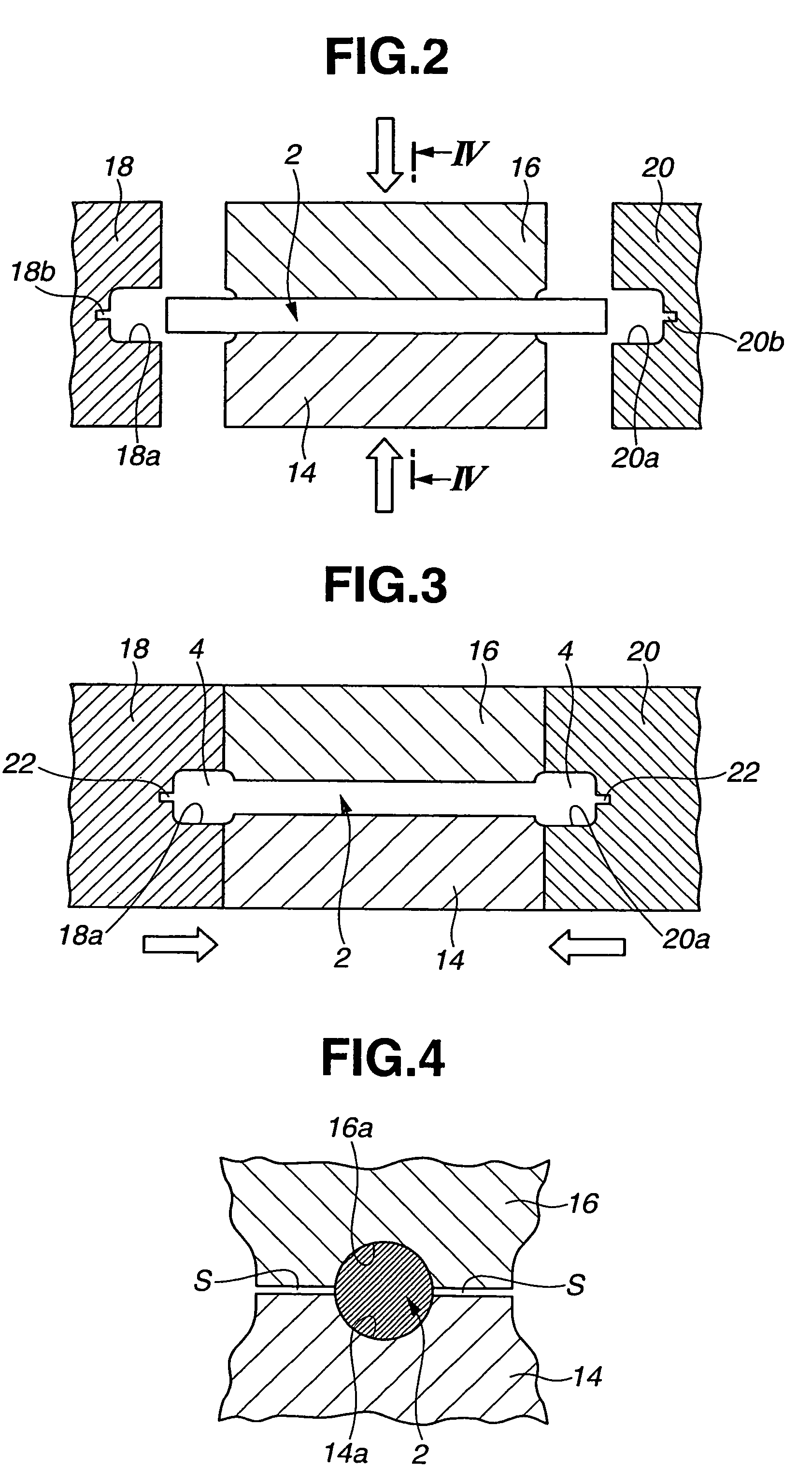

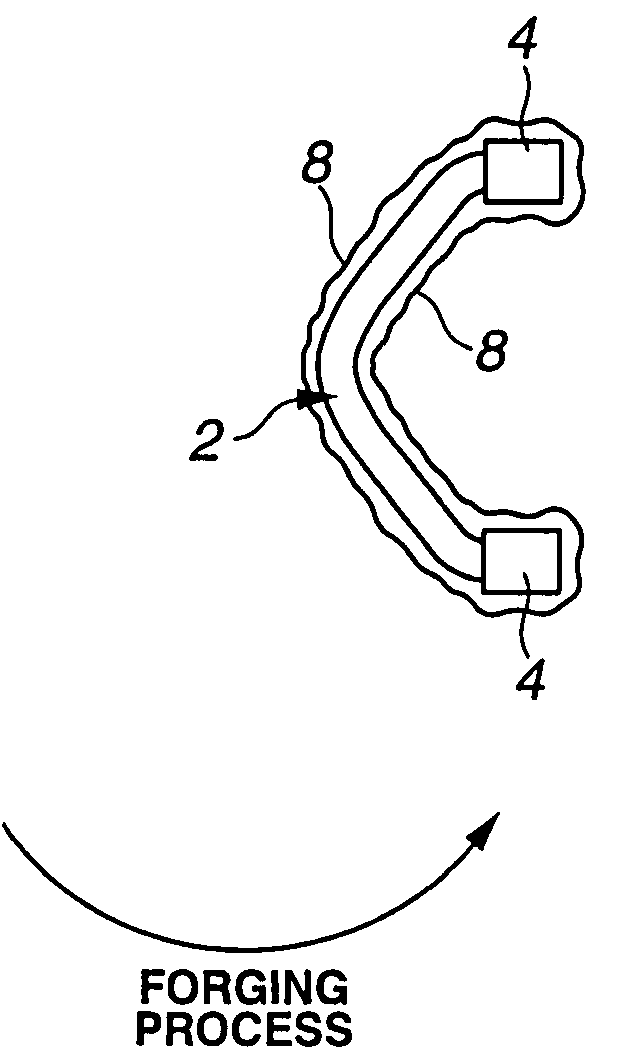

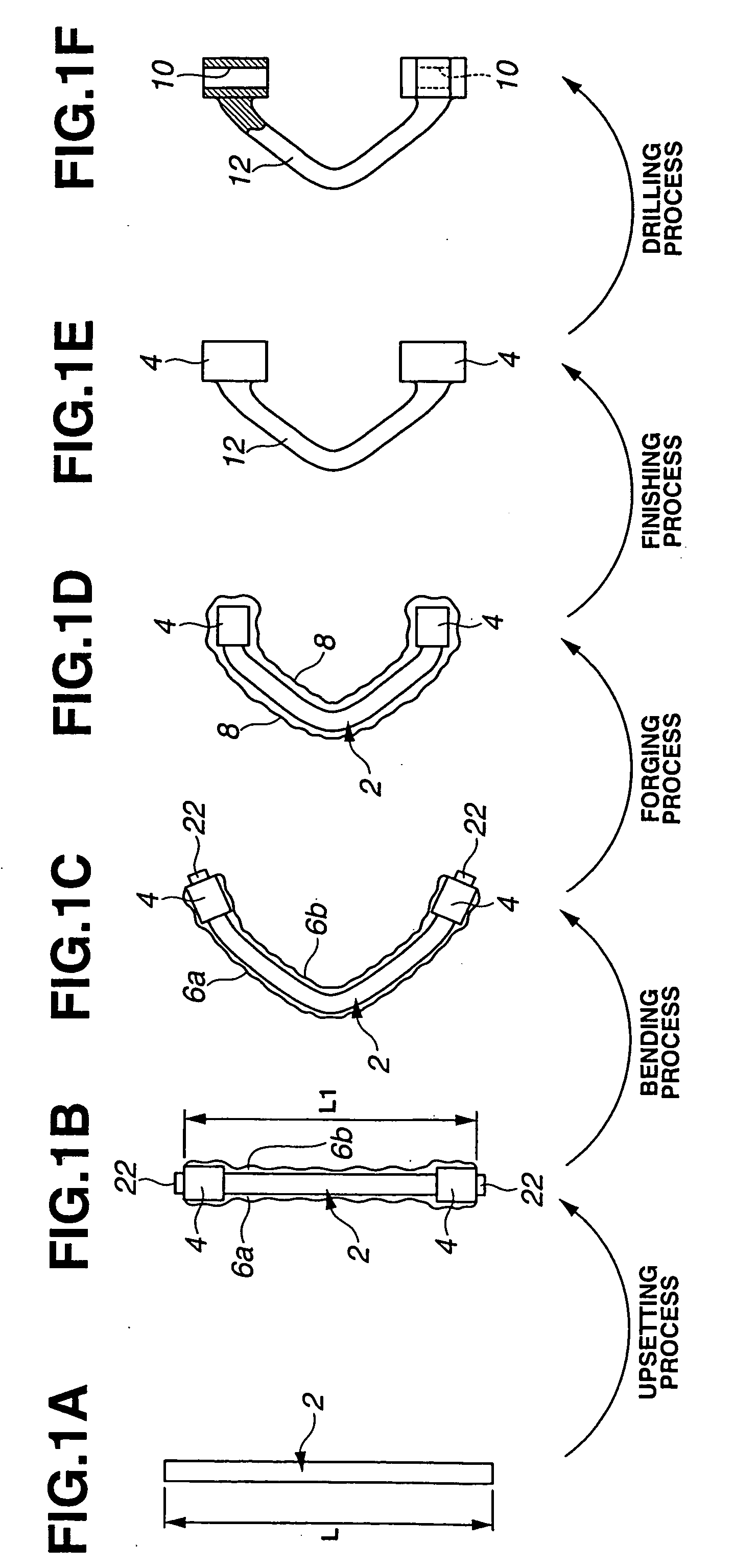

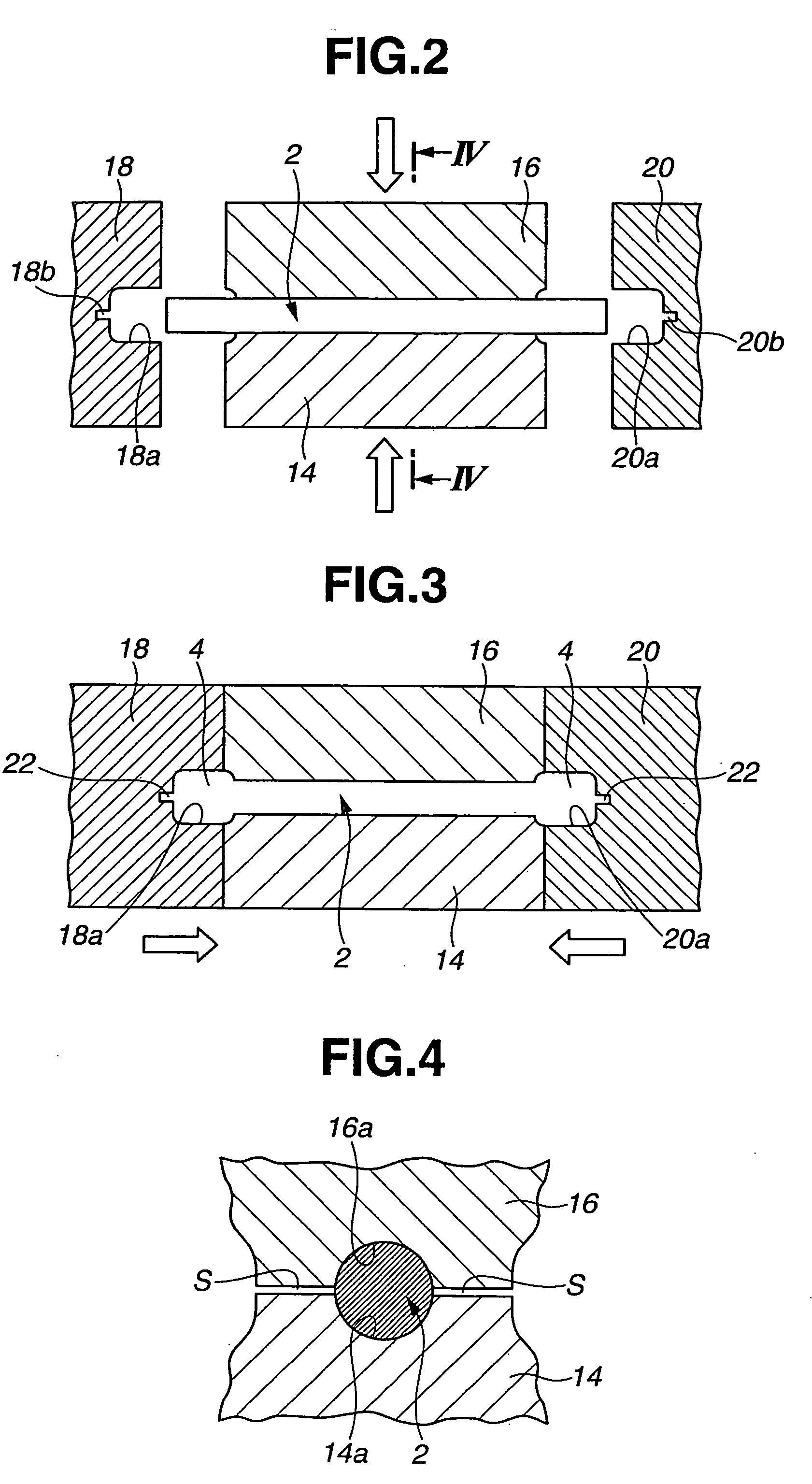

Method of producing forged part and method of producing suspension arm for automotive vehicles

ActiveUS7251979B2Efficient finishingShorten production timeMetal-working apparatusEngine componentsEngineeringMotorized vehicle

A method of producing a forged part includes holding a material by a jig, upsetting the material, held by the jig, to a predetermined length by a pair of upsetting dies disposed on both ends of the material, while pressing the upsetting dies on the material, so as to produce large-diameter portions at the respective axial ends of the material. Next, a bending operation and a forging operation are made to the upset material, in that order. When forging, a direction, in which the material is forged, is set, so that a burr generated on the material by upsetting is included in a burr generated on the material by forging. Next, a finish-machining operation is made to the forged material to remove the burr left on the outer periphery of the material after forging. Thereafter, the finish-machined material is drilled to form bush-mounting holes in the large-diameter portions.

Owner:NISSAN MOTOR CO LTD +1

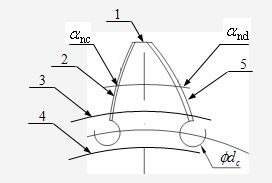

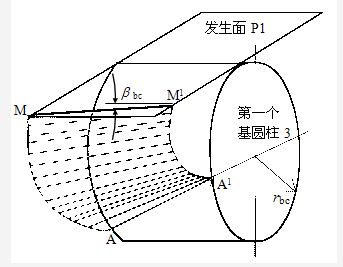

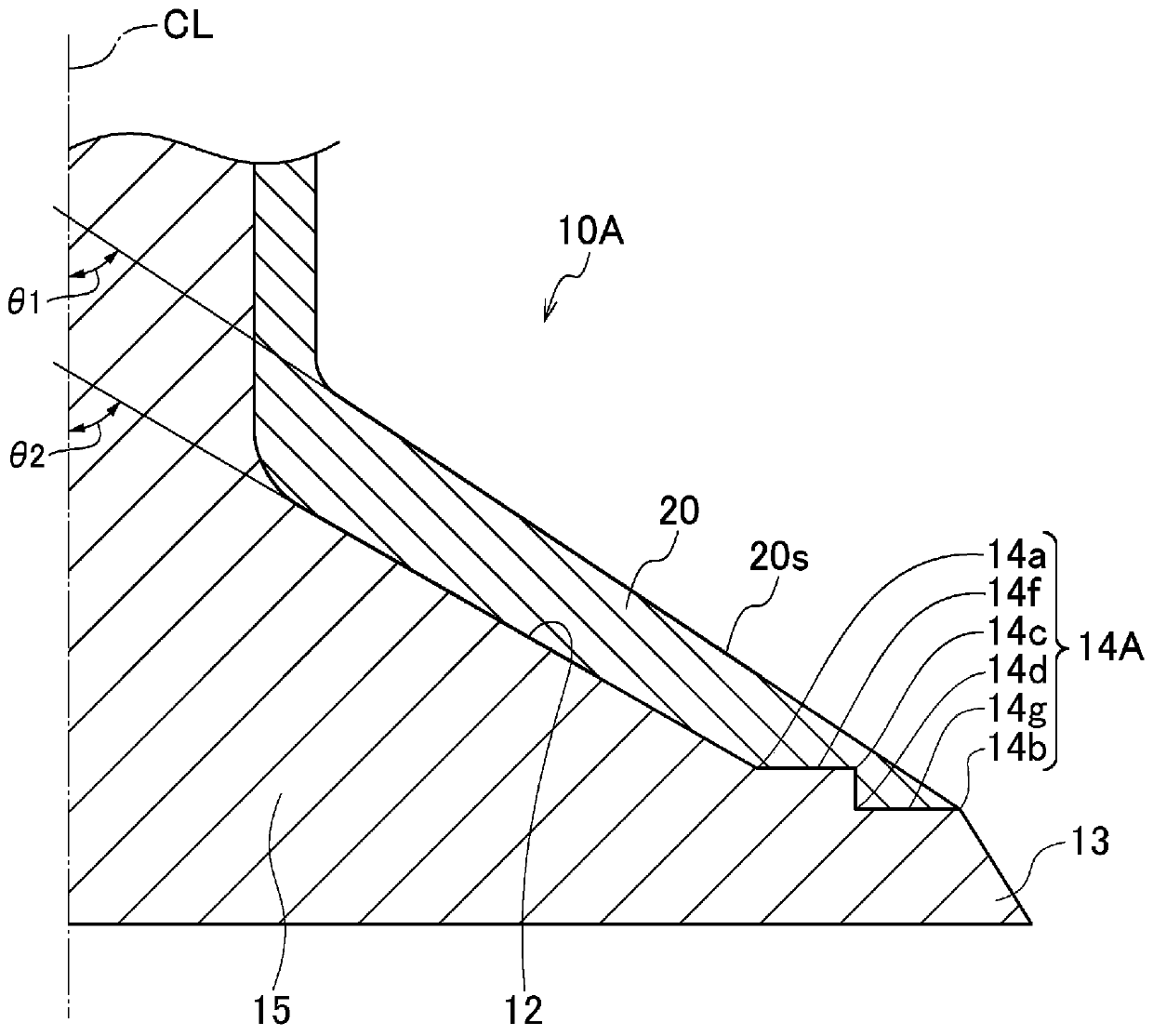

Involute gear-shaving cutter

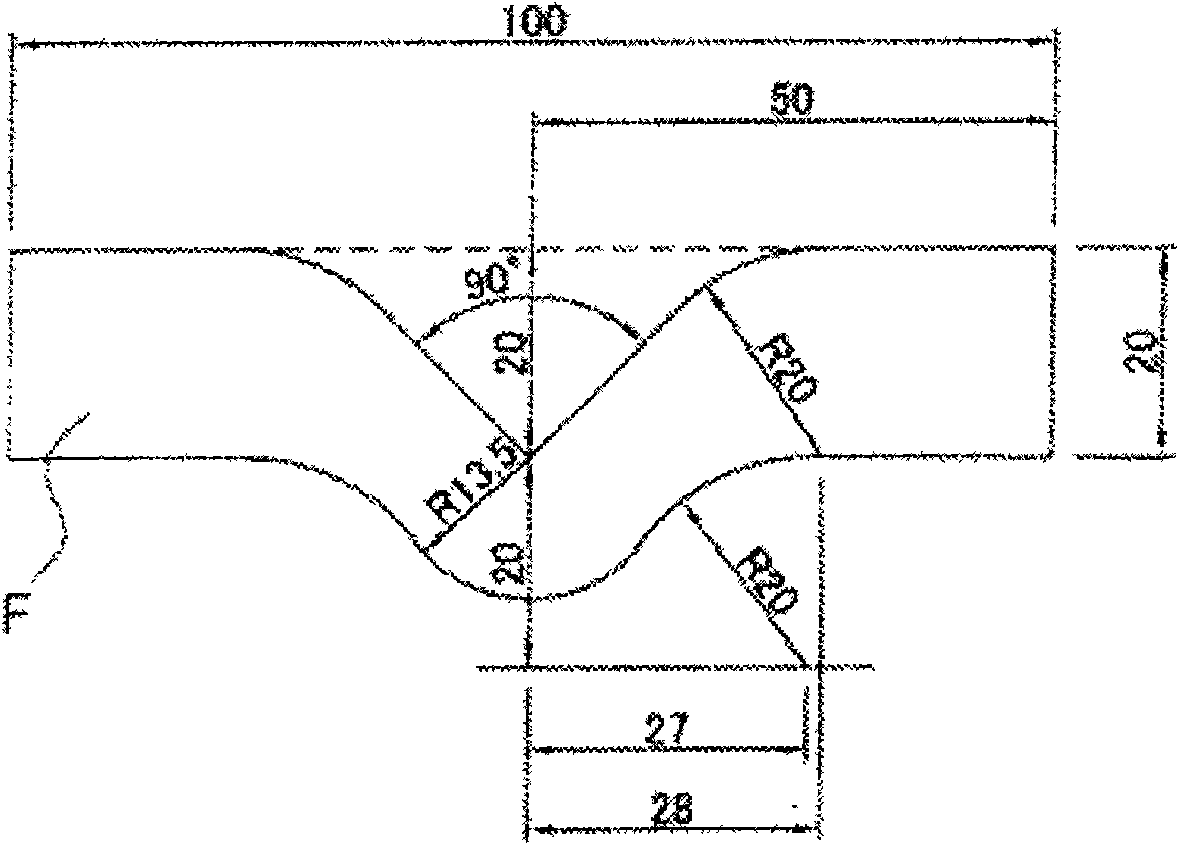

InactiveCN102554365AIncreased pressure angleImprove carrying capacityGear teeth manufacturing toolsGear teethInvolute gearGreek letter alpha

The invention discloses an involute gear-shaving cutter and belongs to the technical field of wheel gears. The involute gear-shaving cutter is characterized in that base cylinders with different diameters are used for generating tooth profile curved surfaces with a respective reference circle pressure angle alpha nc and alpha nd on the two sides of a tooth profile of the nvolute gear-shaving cutter, and the alpha nc is greater than the alpha nd. The gear-shaving cutter is specially designed for an asymmetric involute gear with double pressure angles and can be used for solving the problem that the existing gear-shaving cutter cannot process the asymmetric involute gear with double pressure angles. The tooth profile of the novel gear-shaving cutter mainly comprises a tooth crest 1, a left side tooth surface 2 generated by a first base cylinder 3 and a right side tooth surface 5 generated by a second base cylinder 4. Compared with the existing involute gear-shaving cutter, the involute gear-shaving cutter provided by the invention can carry out finish machining on the asymmetric involute gear with double pressure angles conveniently, rapidly and efficiently, thus the being wide in market prospect and having huge social and economical benefits.

Owner:JIANGSU UNIV

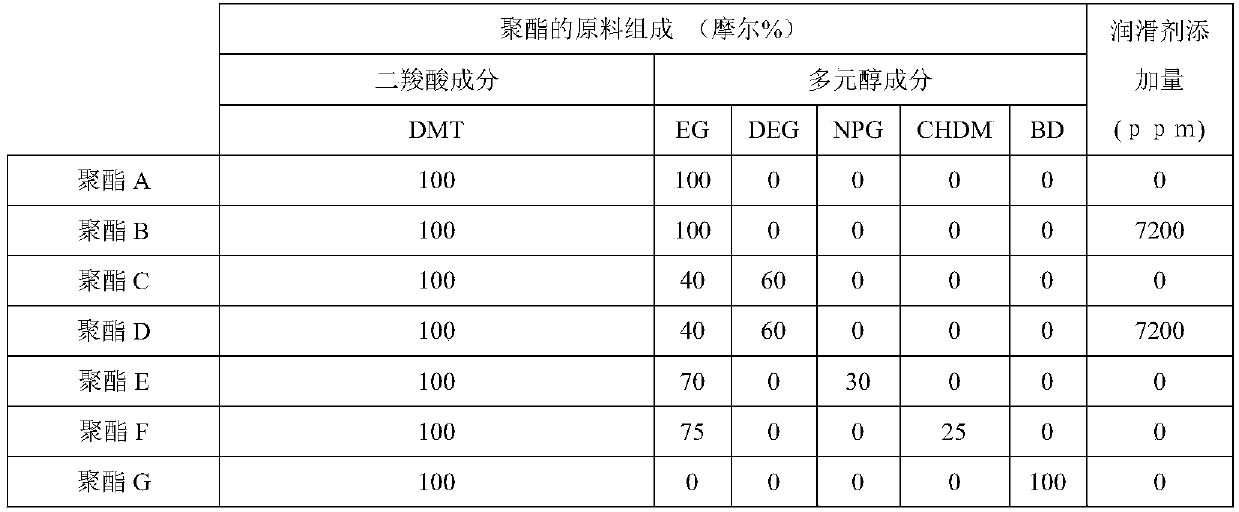

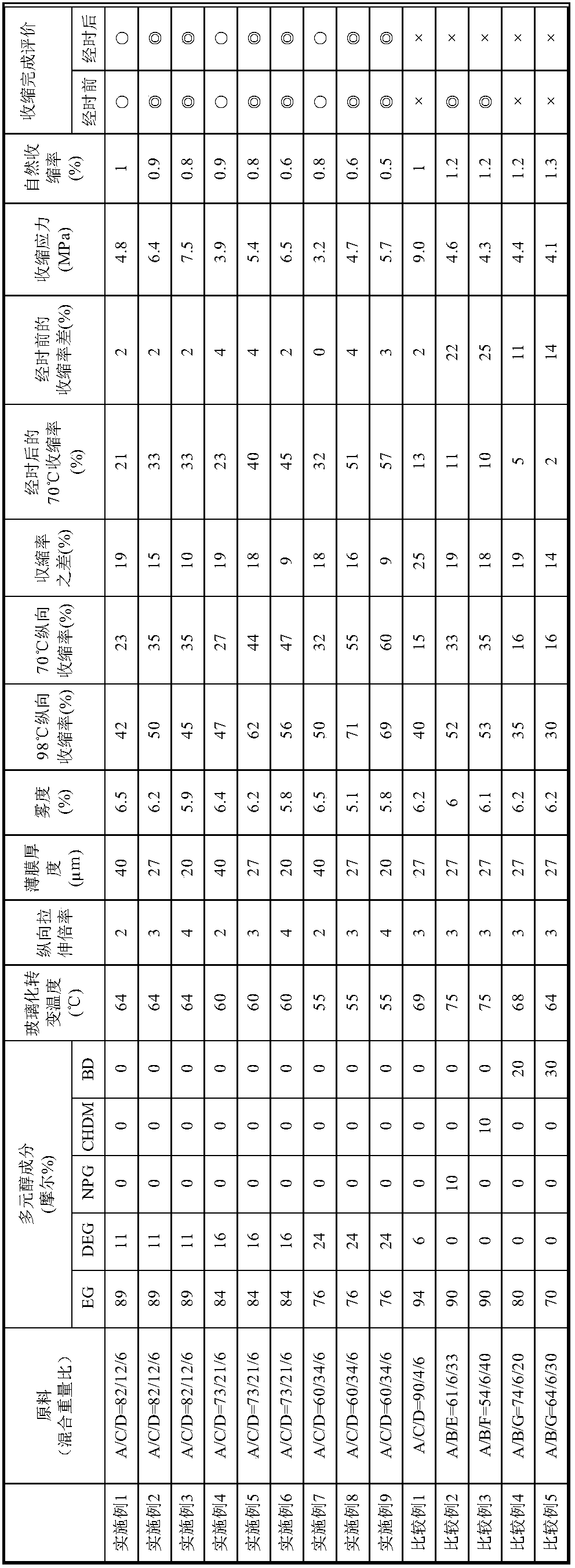

Heat-shrinkable polyester film and packaging

PendingCN109563284AImpaired shrinkage propertiesFully contractileContainer decorationsLevel indicationsPolymer sciencePolyol

The invention provides a heat-shrinkable polyester film of which the longitudinal direction is the main shrinkage direction, which has a high shrinkage ratio in the main shrinkage direction, which isinsusceptible to wrinkles, etc., when used as a label because the difference between the shrinkage ratios at high temperatures and at low temperatures is small, and which undergoes few reductions in shrinkage ratio at low temperatures over time. As a solution, a heat-shrinkable polyester film is characterized by satisfying requirements (1)-(4) below: (1) the hot water shrinkage ratio is 40% or higher in the film main shrinkage direction when the film is immersed in 98 DEG C water for 10 seconds; (2) the difference between the hot water shrinkage ratio in the main shrinkage direction when the film is immersed in 70 DEG C water for 10 seconds and the aforementioned hot water shrinkage ratio in the main shrinkage direction at 98 DEG C is 0-20%; (3) ethylene terephthalate is the main constituent component, and the amount of diethylene glycol (DEG) components is 10-25 mol% out of 100 mol% of polyhydric alcohol components in the entire polyester resin that constitutes the film; (4) the difference between the hot water shrinkage ratio in the main shrinkage direction when the film is immersed in 70 DEG C water for 10 seconds after the film is aged for 28 days at a temperature of 40 DEG C and relative humidity of 85% and the hot water shrinkage ratio under similar conditions before the film is aged is 0-5%.

Owner:TOYOBO CO LTD

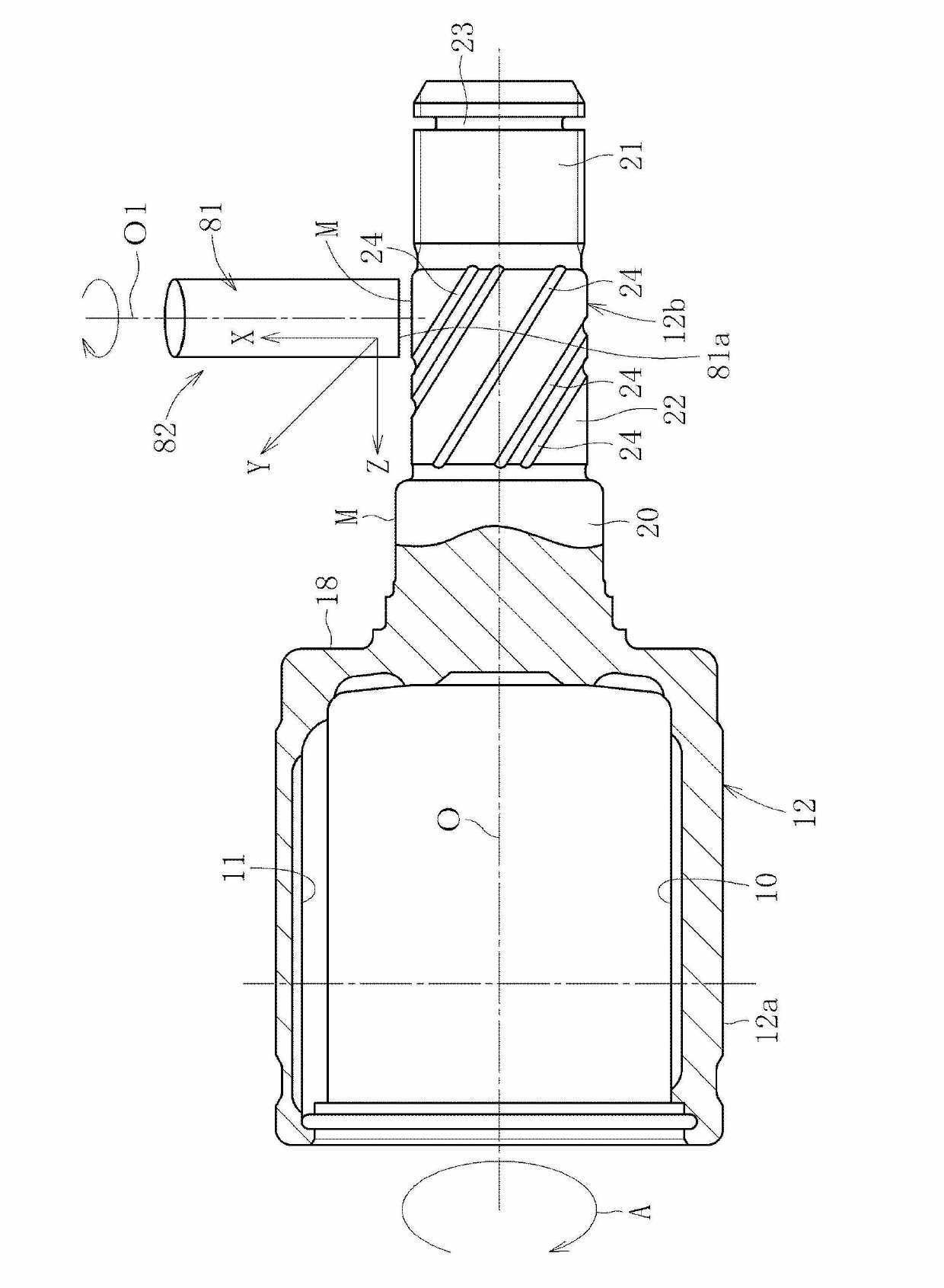

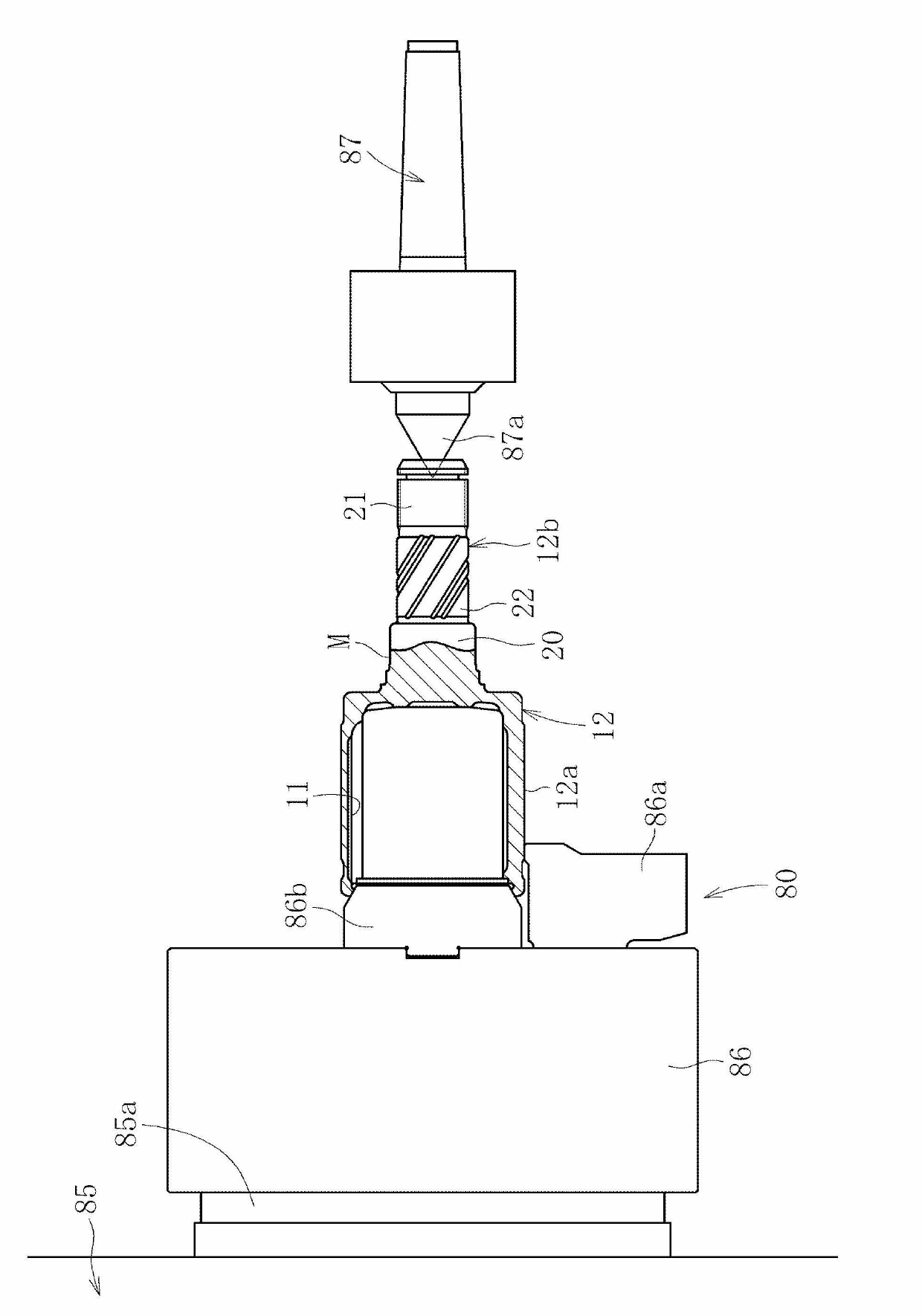

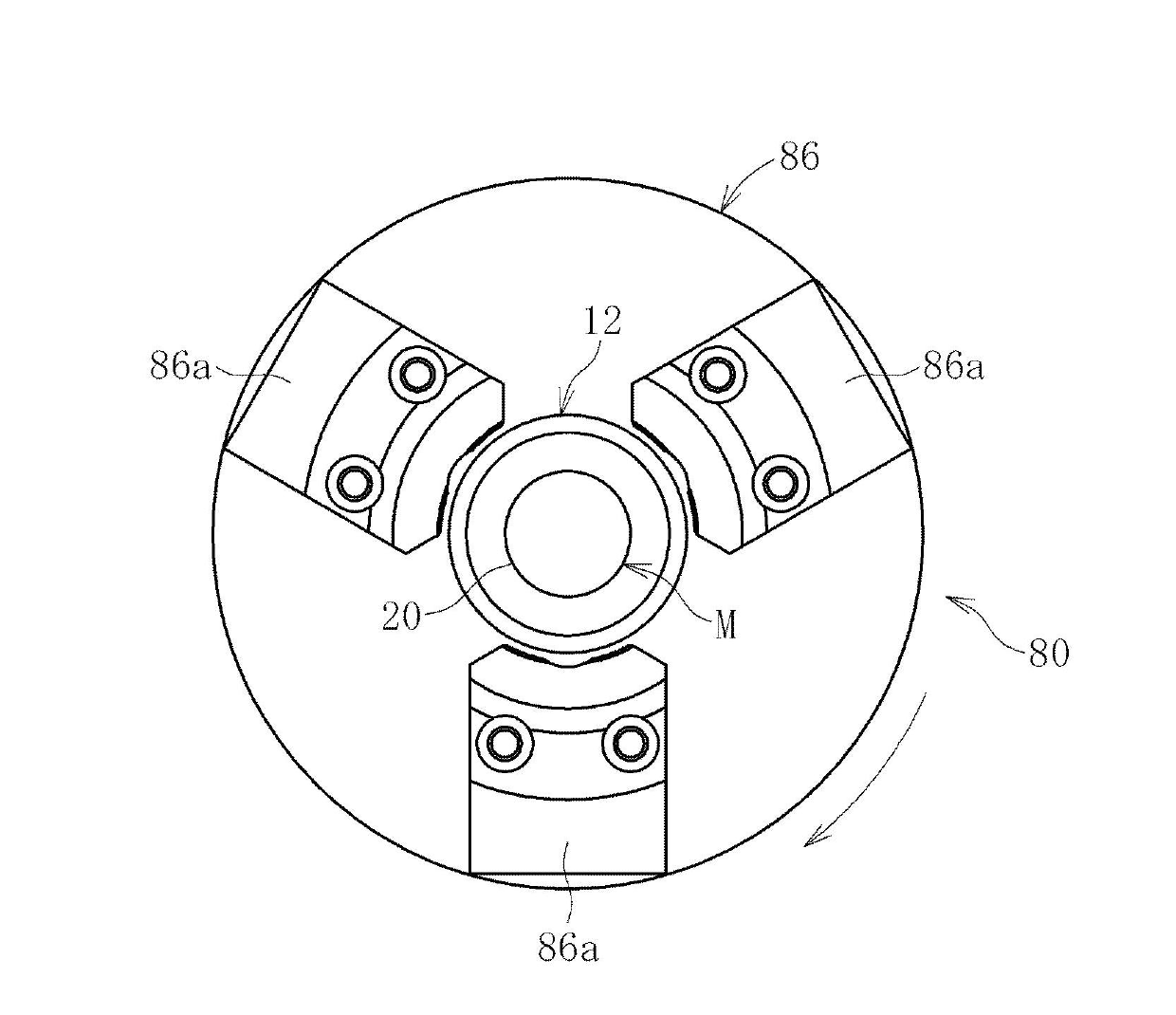

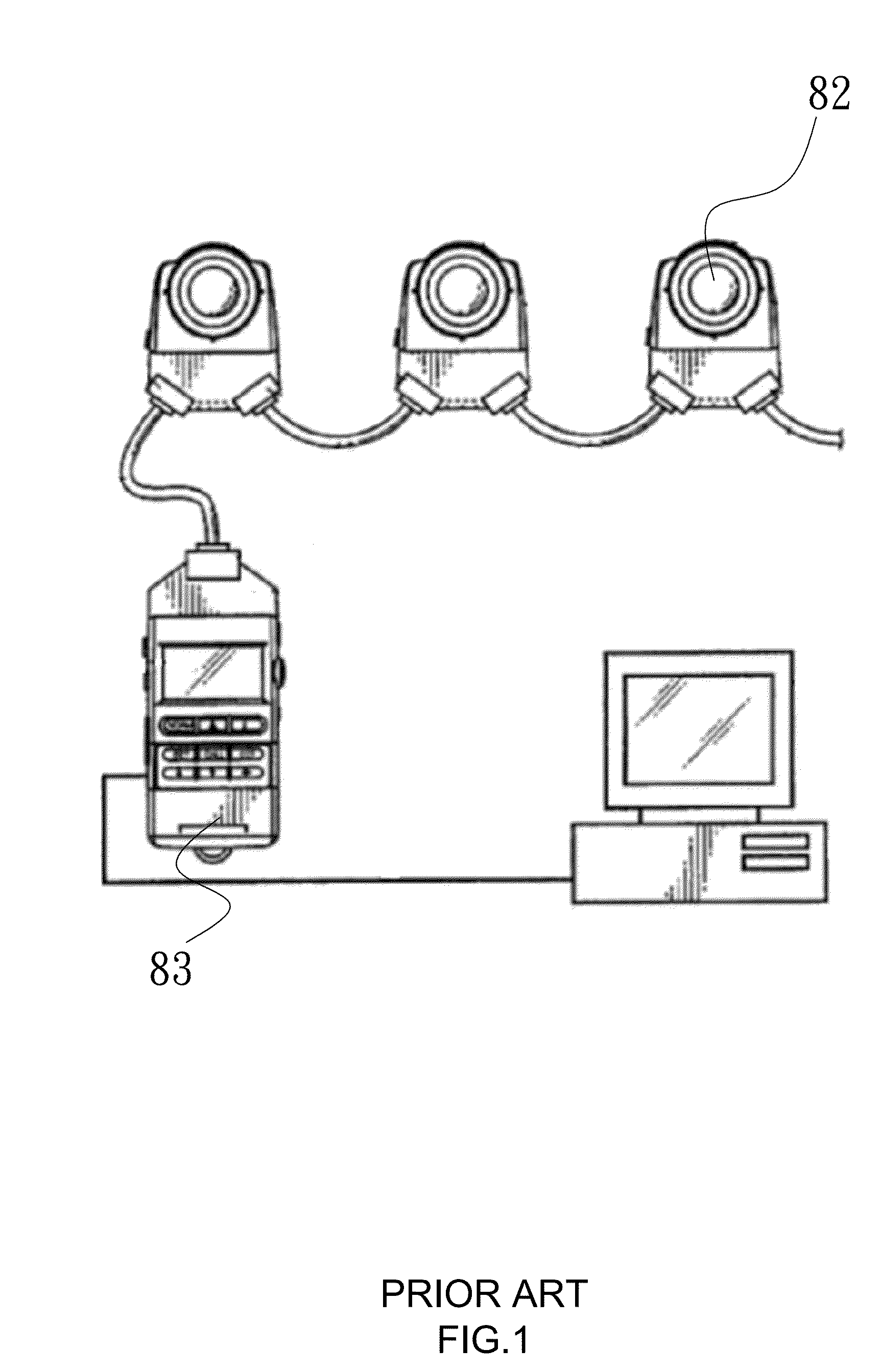

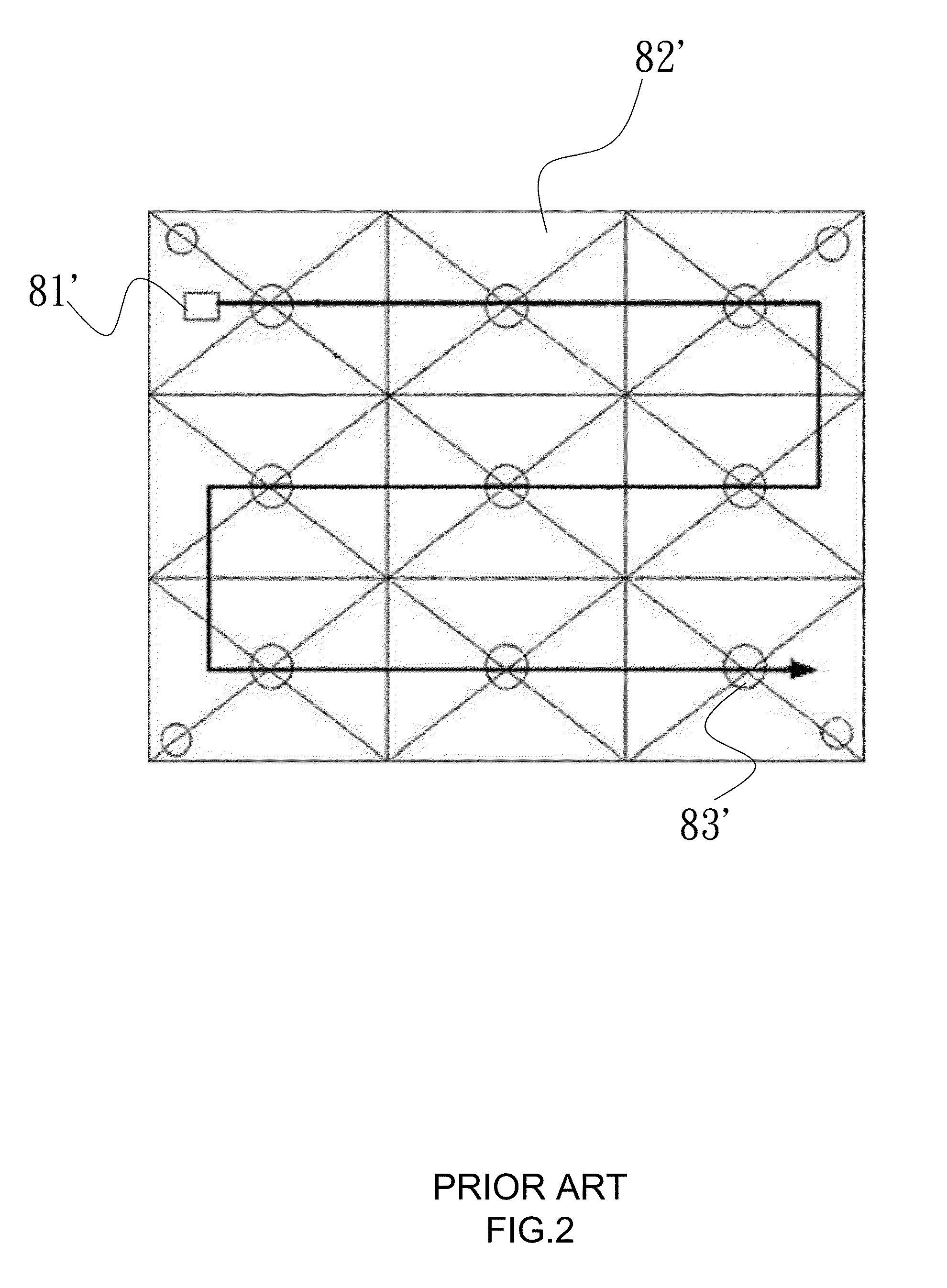

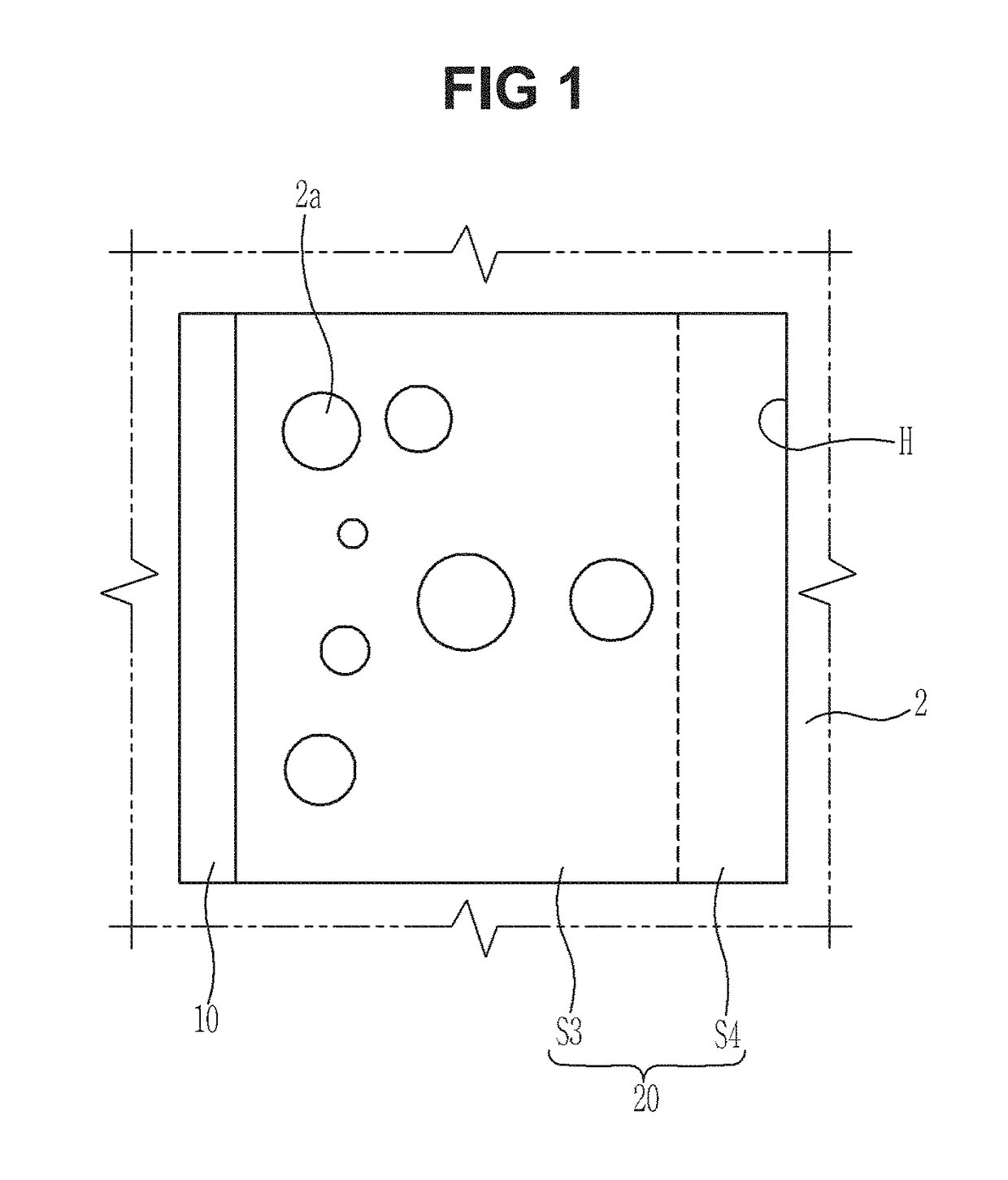

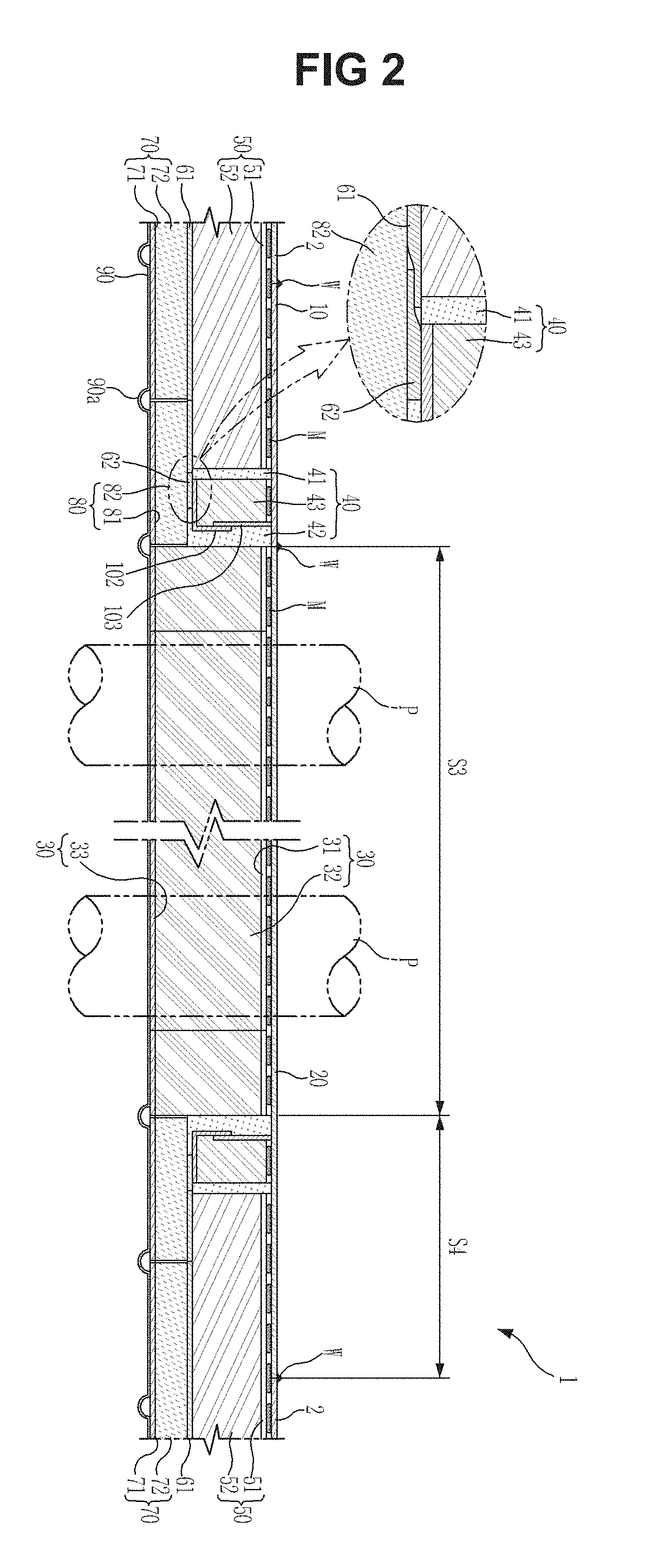

Method of machining sealing surface

InactiveCN102639270AShortening of processing (work) timeImprove air tightnessClutchesYielding couplingEngineeringMechanical engineering

Provided is a method of machining a sealing surface, such that a sealing surface can be finished at low cost and in a short period of time, and such that lead marks can be eliminated and a sealing surface formed with high precision. While a workpiece having sealing surface (M) to be machined is rotated about the axis of the workpiece, the sealing surface (M) is cut and finished with a rotating cutting tool (81). The cutting of the sealing surface (M) by the cutting tool (81) is a type of hardened steel cutting method which generates no lead marks.

Owner:NTN CORP

Optical detection system

InactiveUS20140043310A1Accurate compensationReduce industrial production costCathode-ray tube indicatorsSpectrometry/spectrophotometry/monochromatorsLuminous intensityOptical Module

The invention relates to an optical detection system for detecting the optical distribution of a display device having a light source and a predetermined display range divided into multiple virtual detection regions. The system includes a power module for supplying power to the light source, a monochromatic module for detecting luminous intensity of the light source at various wavelengths within a selected virtual detection region, multiple optical sensor modules, each corresponding to one of the virtual detection regions, a memory module saving wavelength correction parameters of the optical sensor modules, and a processor module receiving the wavelength distribution within the selected virtual detection region of the display device, and for calculating and compensating for expected detection values of the respective optical sensor modules based on the wavelength correction parameters and actual detection values of the optical sensor modules.

Owner:CHROMA ATE

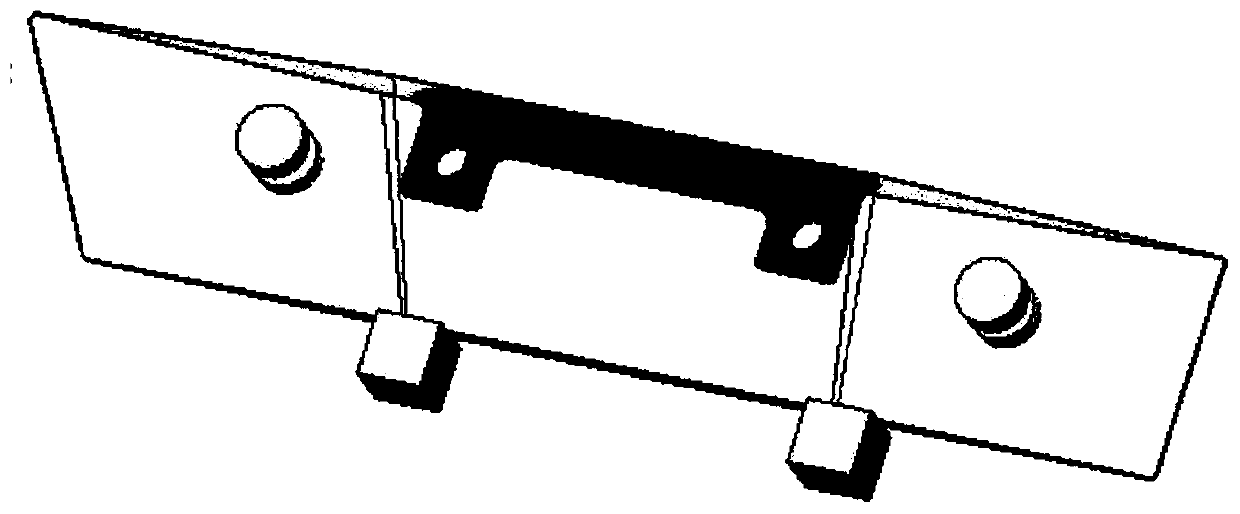

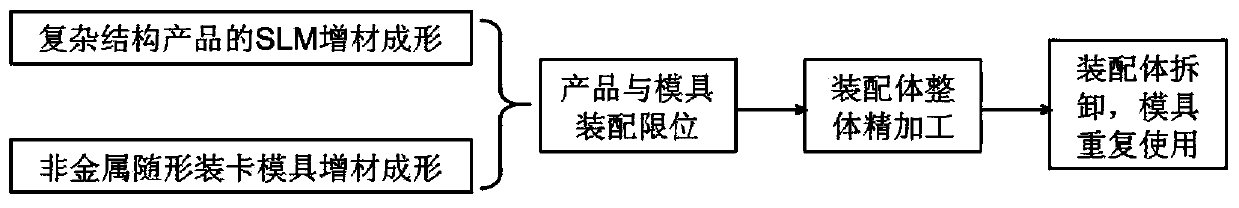

Additive and subtractive compounded manufacturing method for achieving high-precision reference transmission

InactiveCN110625336ARealize product dimensional accuracy controlEliminate dimensional accuracy and deformation effectsFastenerManufacturing engineering

The invention relates to an additive and subtractive compounded manufacturing method for achieving high-precision reference transmission for a special-shaped product of a complex structure. The methodincludes SLM additive forming of the product of the complex structure, additive forming of shape follow-up assembling and clamping molds, integrated assembly conducted on the product and the shape follow-up assembling and clamping molds and integrated finish machining conducted on assemblies. In the additive and subtractive compounded manufacturing method, additional machining of process fasteners for the product is not needed, and the difficulty of control of the structure over the product deformation is lowered; and meanwhile, the product size precision control is achieved, and influences of thick and large fasteners on size precision and deformation of blanks are eliminated; and secondly, the cross section of the product is used as the common reference between different work procedures, the additive process and machining are consistent in reference, manual scribing is omitted, the formulation of the positioning reference is not influenced by subjective factors of people, consistency of product size transmission is improved, and high-precision transmission of the size and the positioning reference in circulation in additive-subtractive working procedures is achieved.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

Holding surface grinding method

ActiveCN110125731AUniform thicknessPrevent over grindingOptical surface grinding machinesAbrasion apparatusWaferingSurface grinding

Owner:DISCO CORP

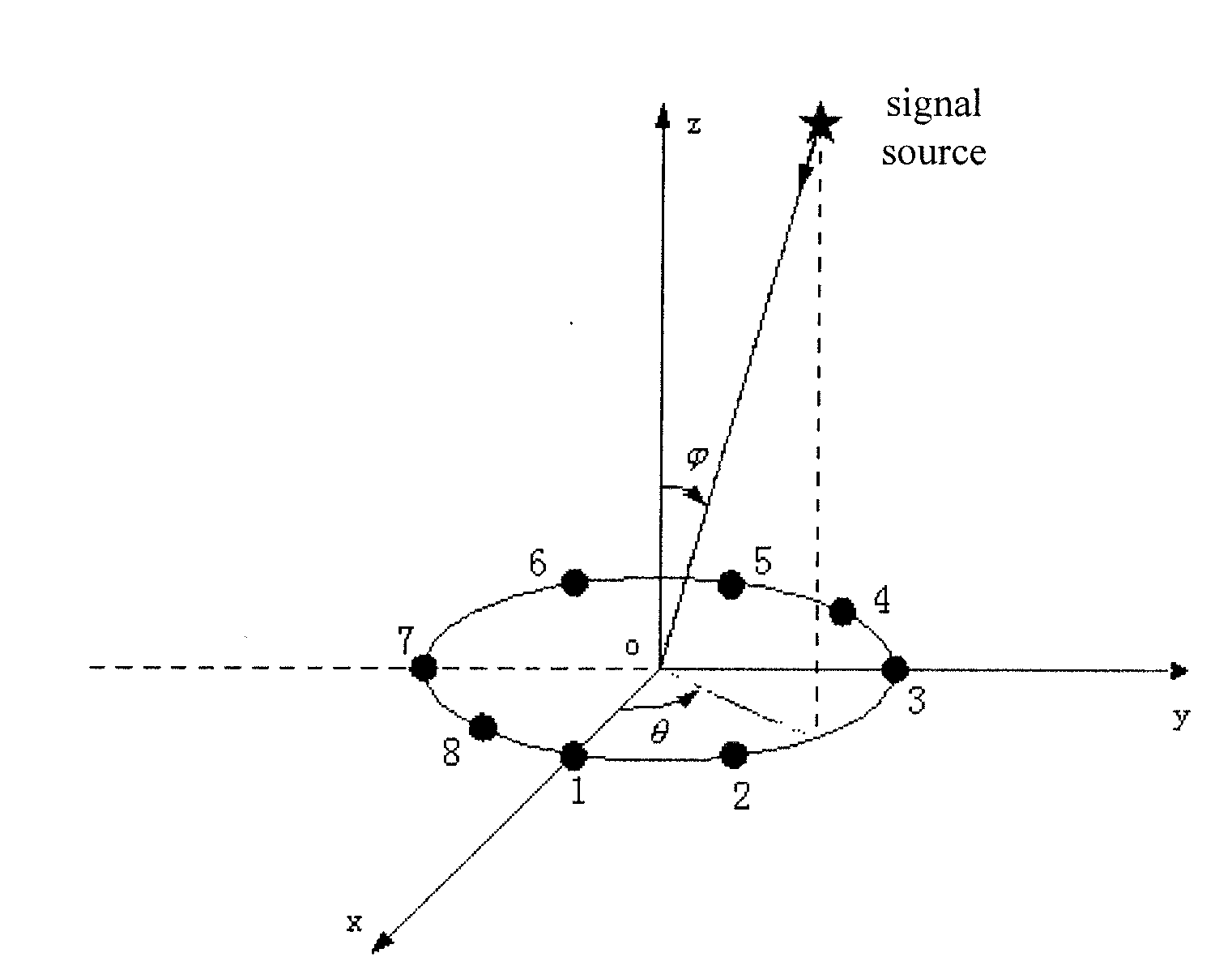

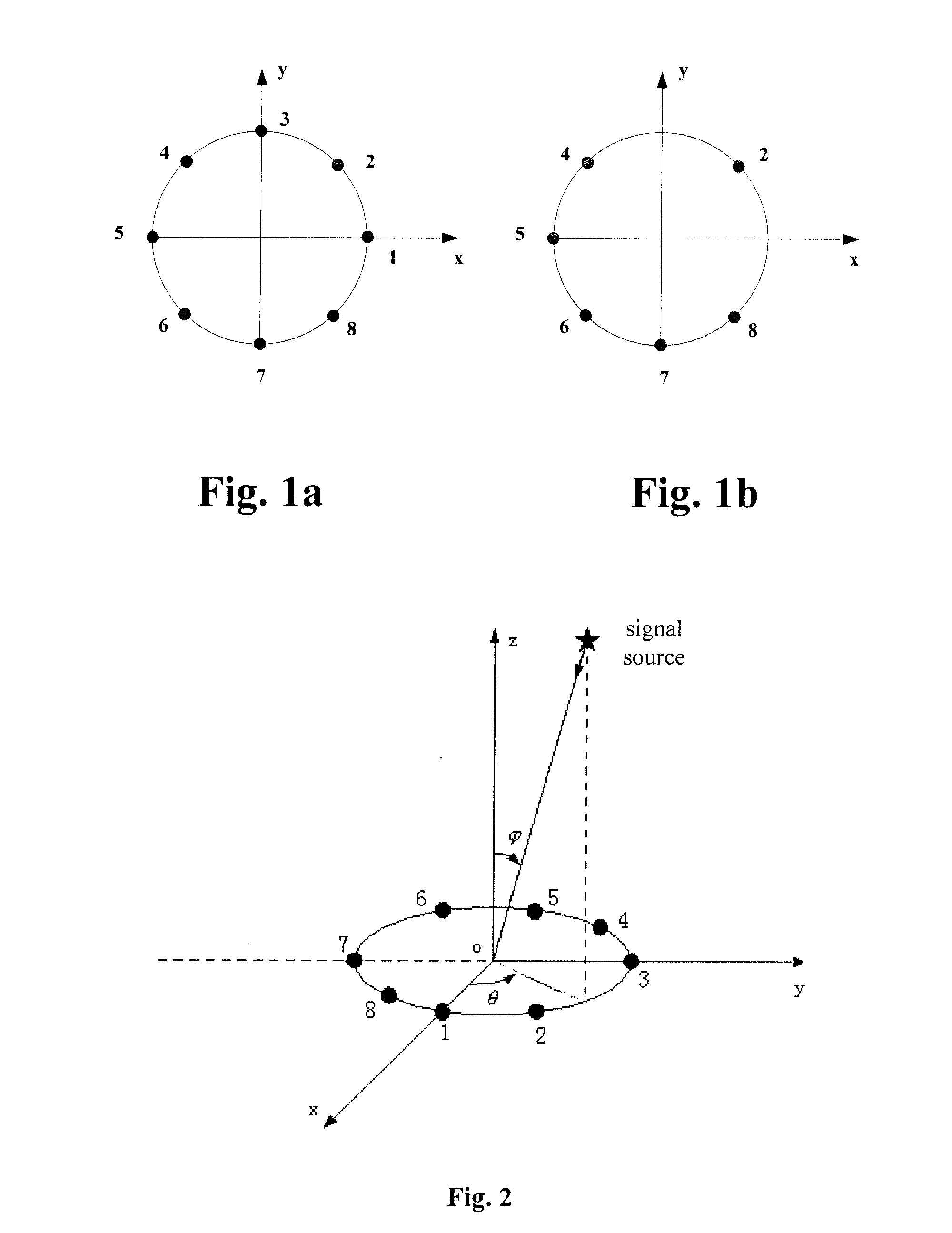

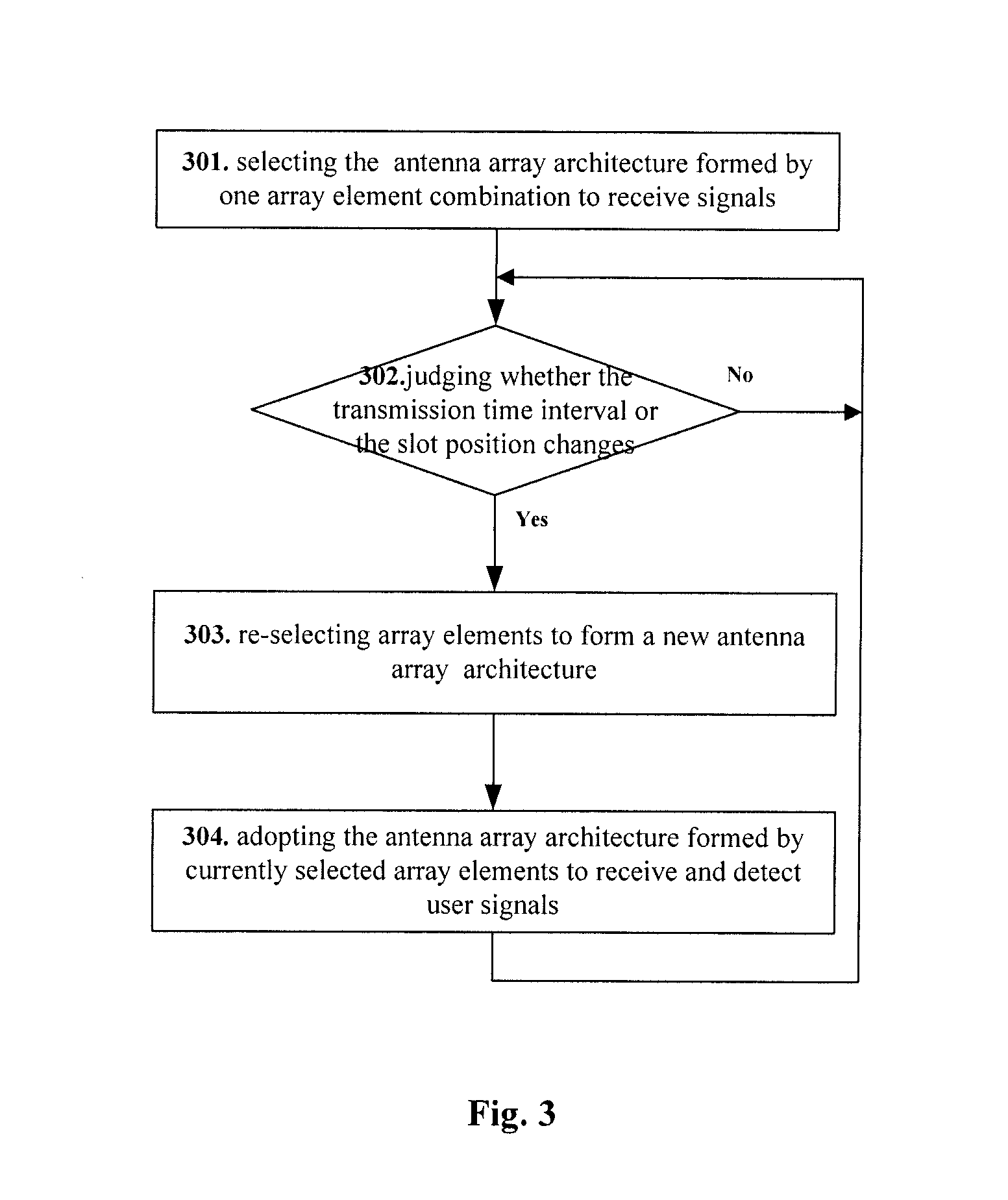

Method For Dynamically Selecting Antenna Array Architecture

InactiveUS20080278374A1Simple to realizeGood flexibilityRadio wave direction/deviation determination systemsSpatial transmit diversityTransmission timeTransmission Time Interval

The present invention discloses a method for dynamically selecting antenna array architecture, deciding a basic antenna array, determining a number of required array elements, selecting determined number of array elements from all the array elements in the basic antenna array to form an antenna array architecture and receiving and detecting signals with the current antenna array architecture, the method further including: determining whether transmission time intervals and / or slot positions of received signals change, if so, re-selecting the determined number of array elements from all the array elements in the basic antenna array to form a new antenna array architecture and receiving and detecting signals with the new antenna array architecture, otherwise, continuing to determine. According to this method, not only the realization is simple but also that each array elements in the antenna array can receive arriving signals more reasonably so that the reliability of the antenna array to receive signals is improved.

Owner:SHANGHAI ULTIMATE POWER COMM TECH

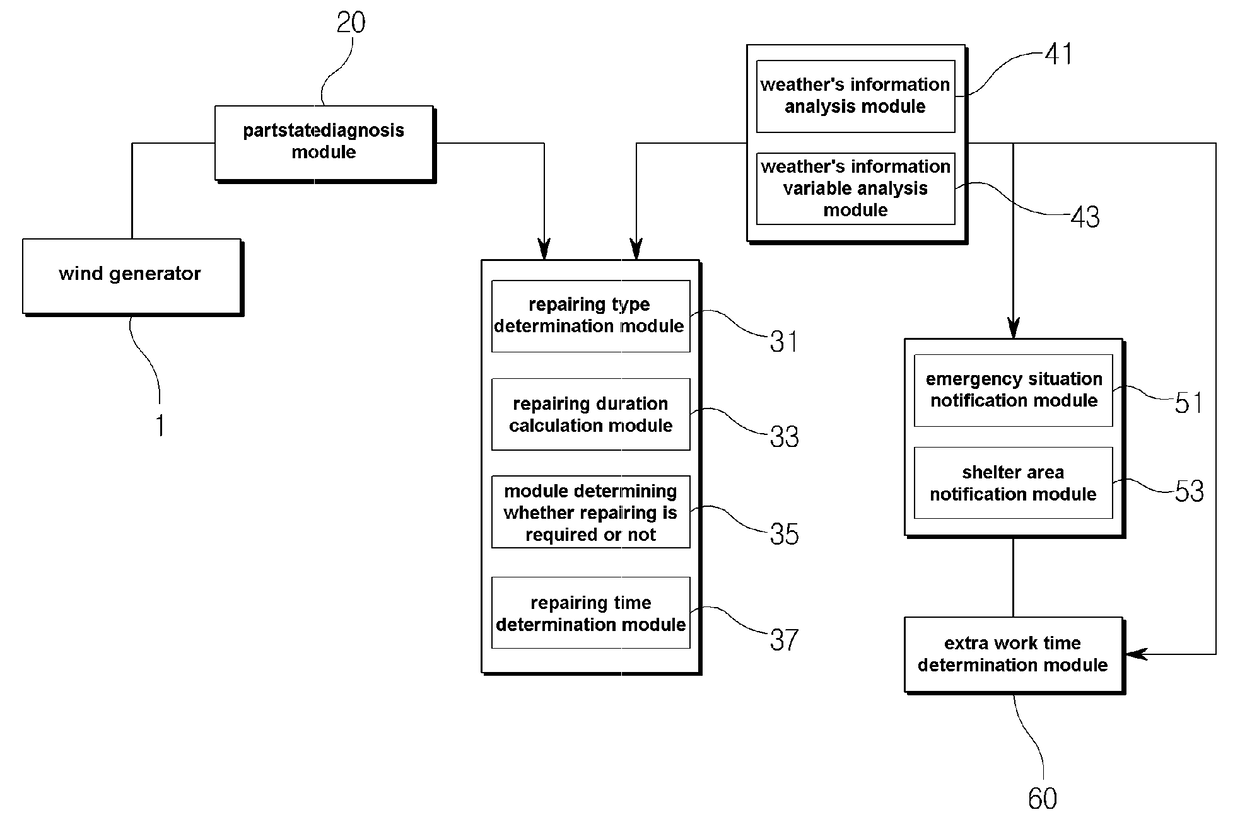

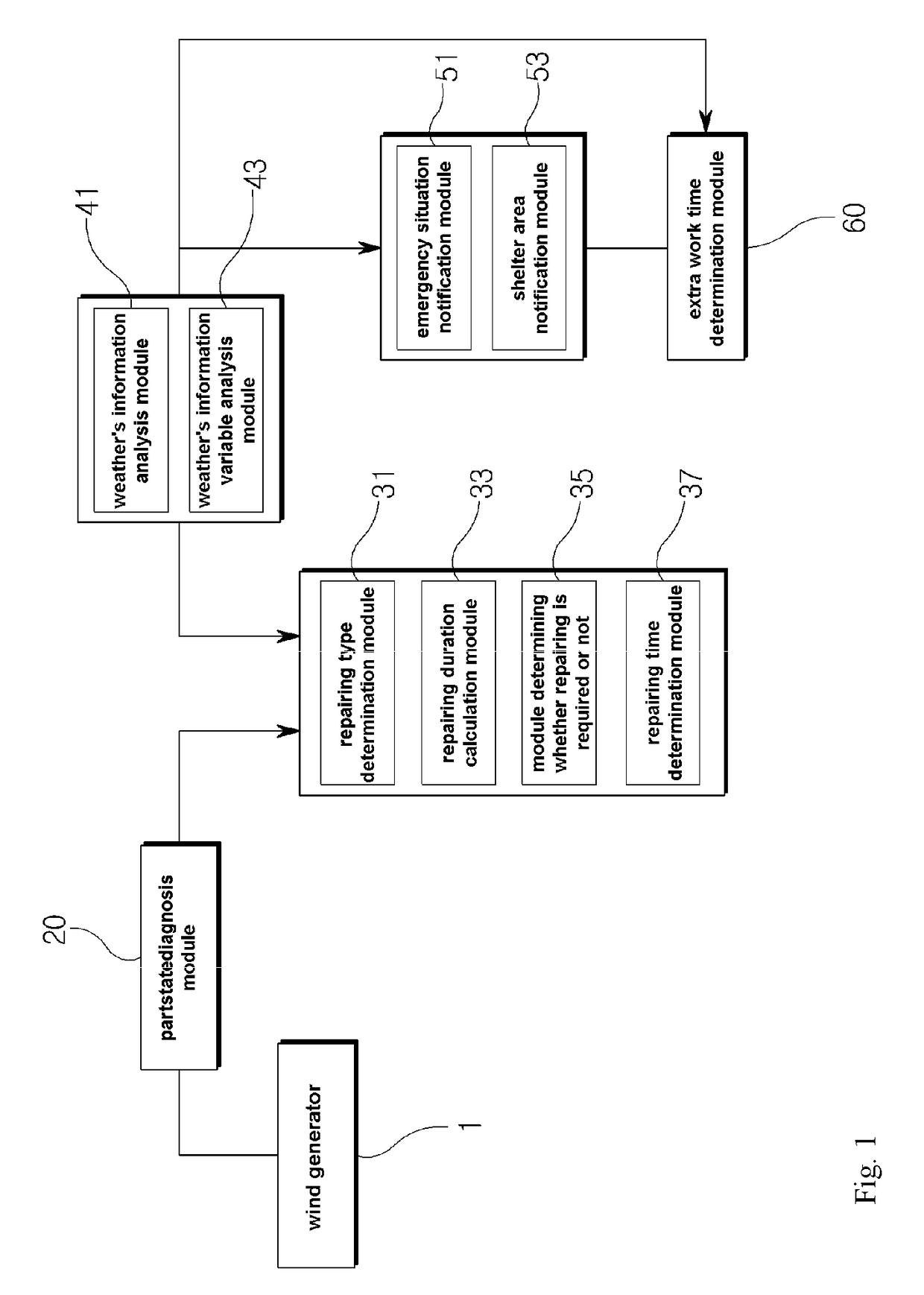

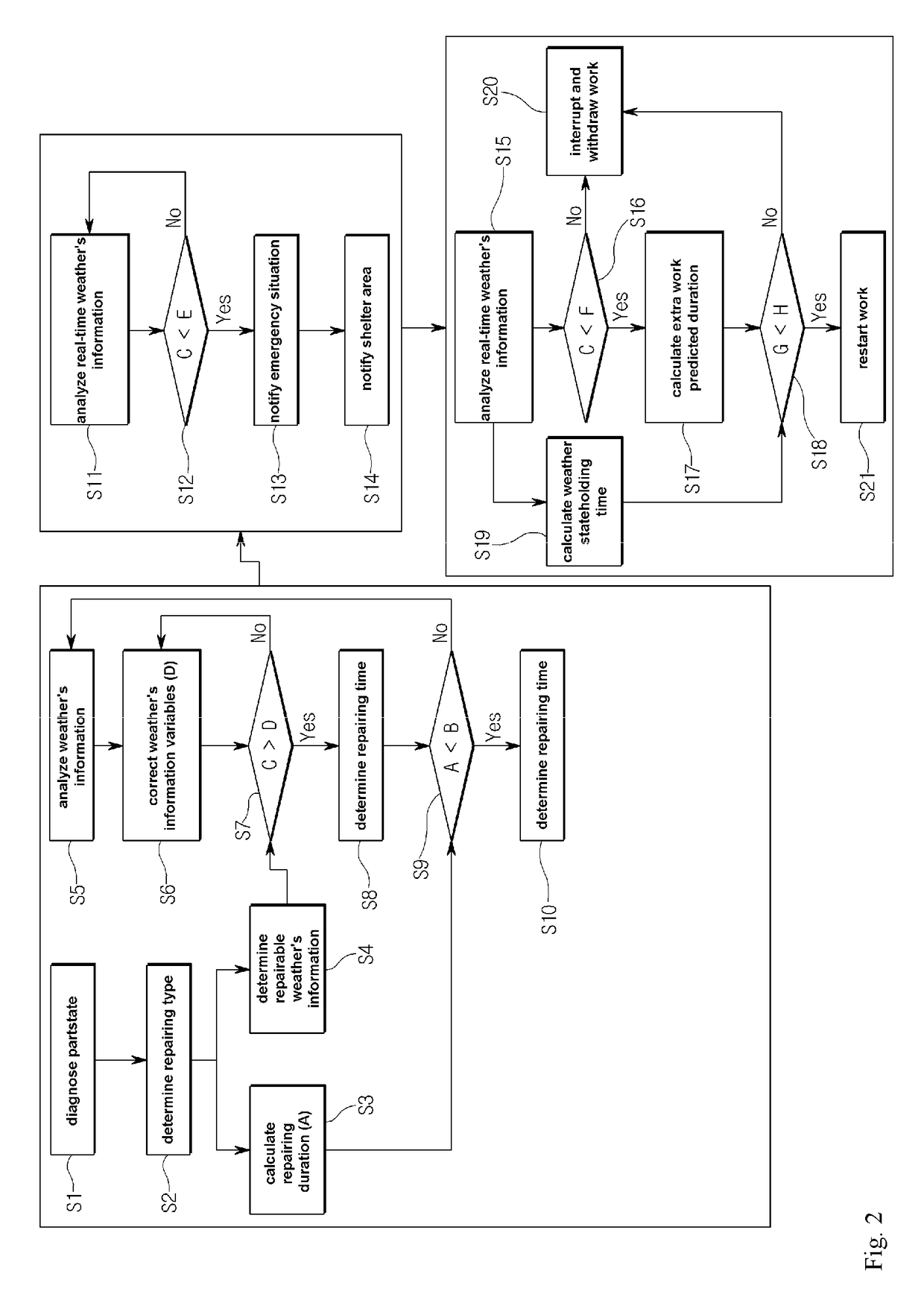

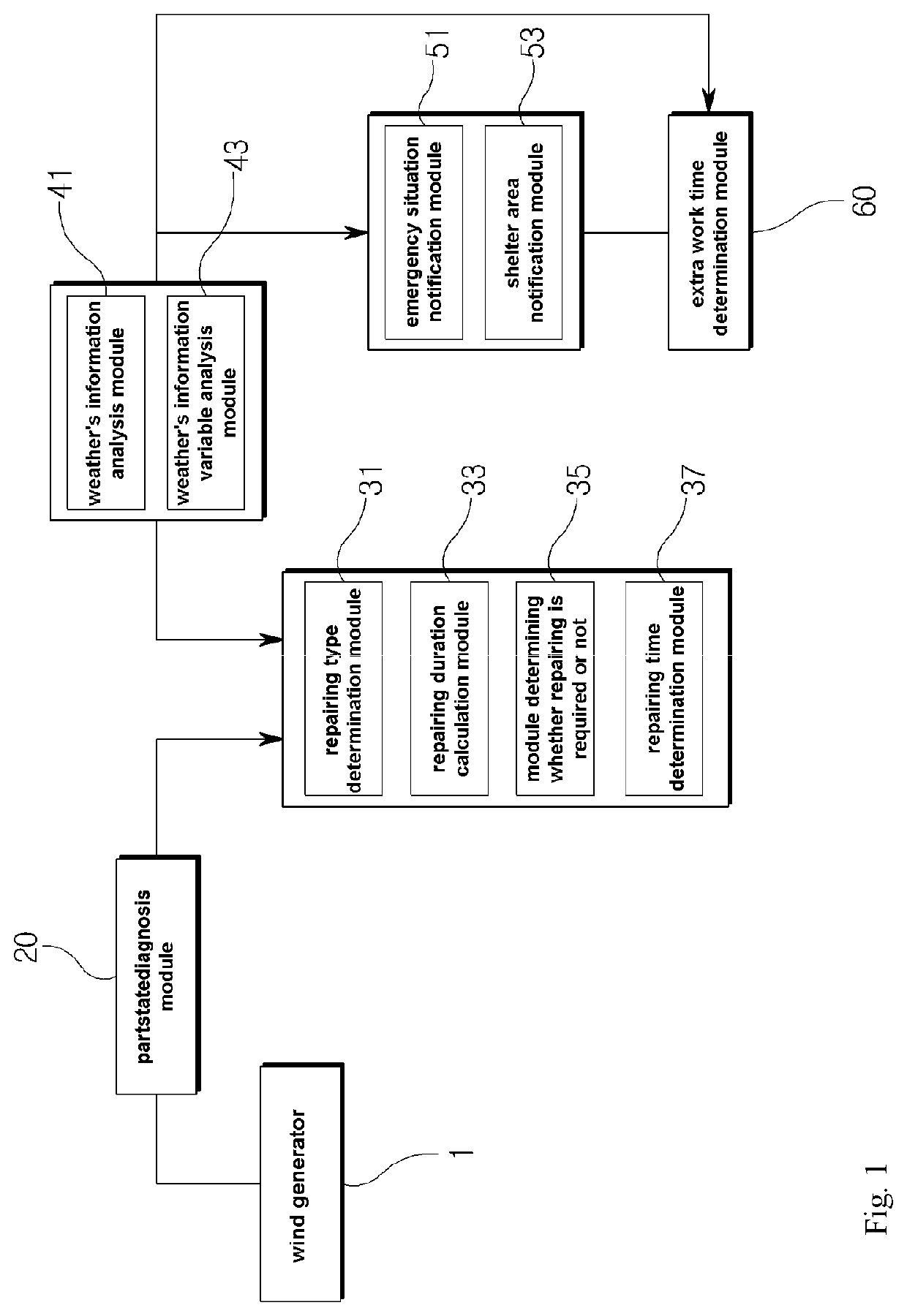

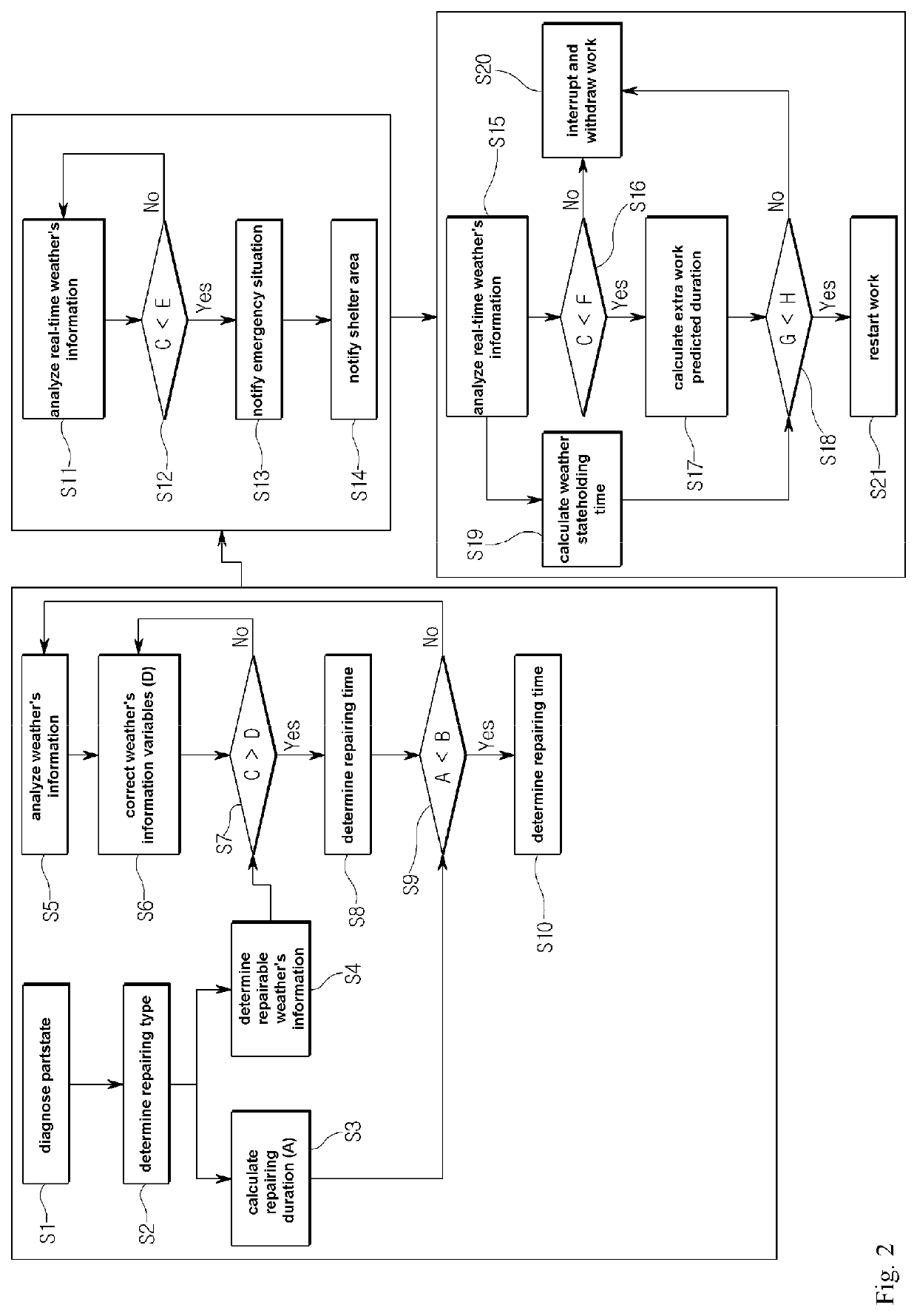

System and method for repairing wind generator based on weather information

ActiveUS20170161671A1Effective calculationRespond quicklyEngine manufactureWeather condition predictionRepair timeEngineering

The present disclosure relates to a method and a system for repairing a wind generator based on weather information. According to an exemplary embodiment of the present disclosure, it is possible to effectively calculate a repairing time of the wind generator based on weather information.

Owner:DOOSAN HEAVY IND & CONSTR CO LTD

Method of producing forged part and method of producing suspension arm for automotive vehicles

ActiveUS20060005596A1Efficient finishingShorten production timeMetal-working apparatusEngine componentsEngineeringMotorized vehicle

A method of producing a forged part includes holding a material by a jig, upsetting the material, held by the jig, to a predetermined length by a pair of upsetting dies disposed on both ends of the material, while pressing the upsetting dies on the material, so as to produce large-diameter portions at the respective axial ends of the material. Next, a bending operation and a forging operation are made to the upset material, in that order. When forging, a direction, in which the material is forged, is set, so that a burr generated on the material by upsetting is included in a burr generated on the material by forging. Next, a finish-machining operation is made to the forged material to remove the burr left on the outer periphery of the material after forging. Thereafter, the finish-machined material is drilled to form bush-mounting holes in the large-diameter portions.

Owner:NISSAN MOTOR CO LTD +1

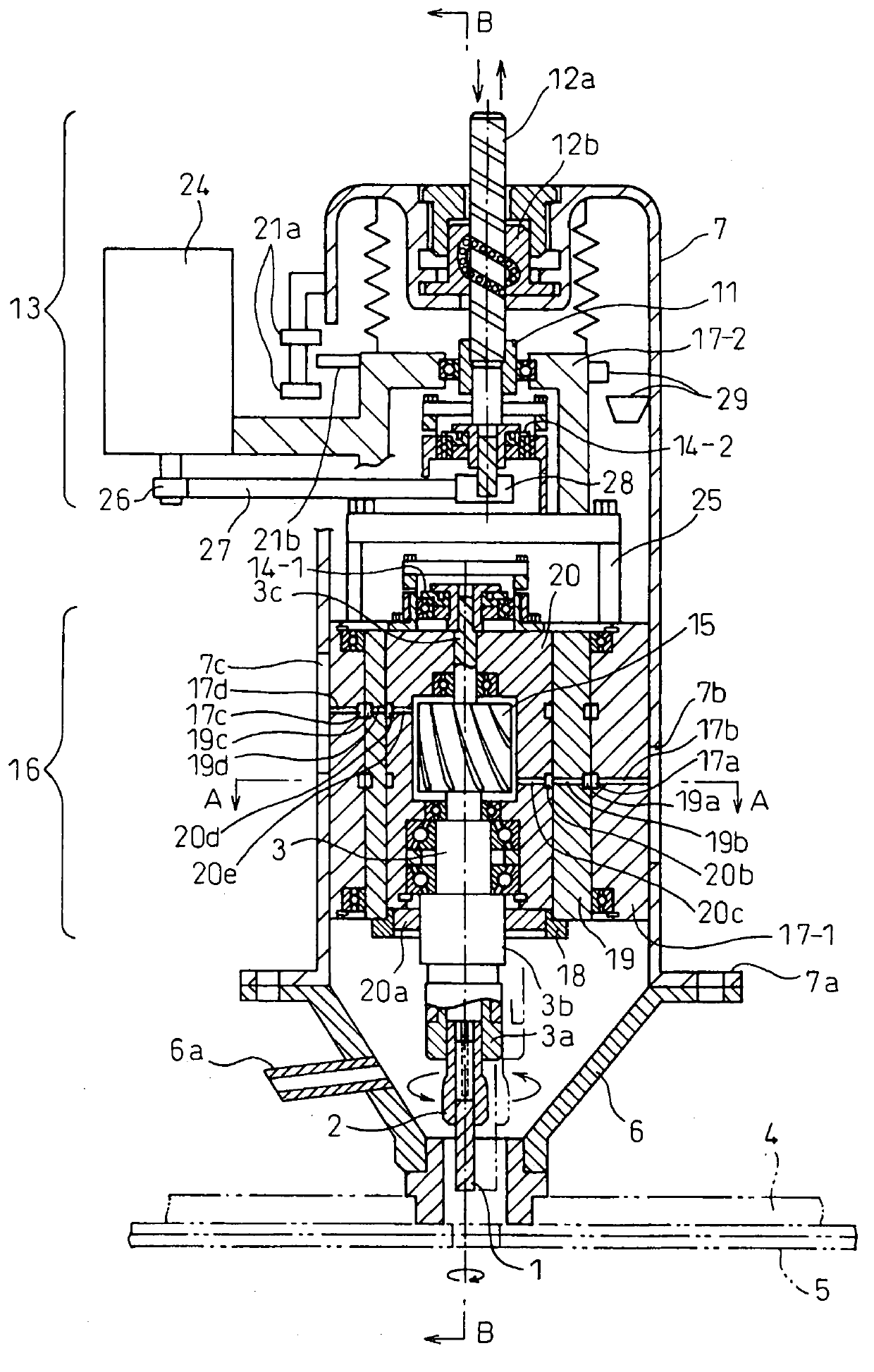

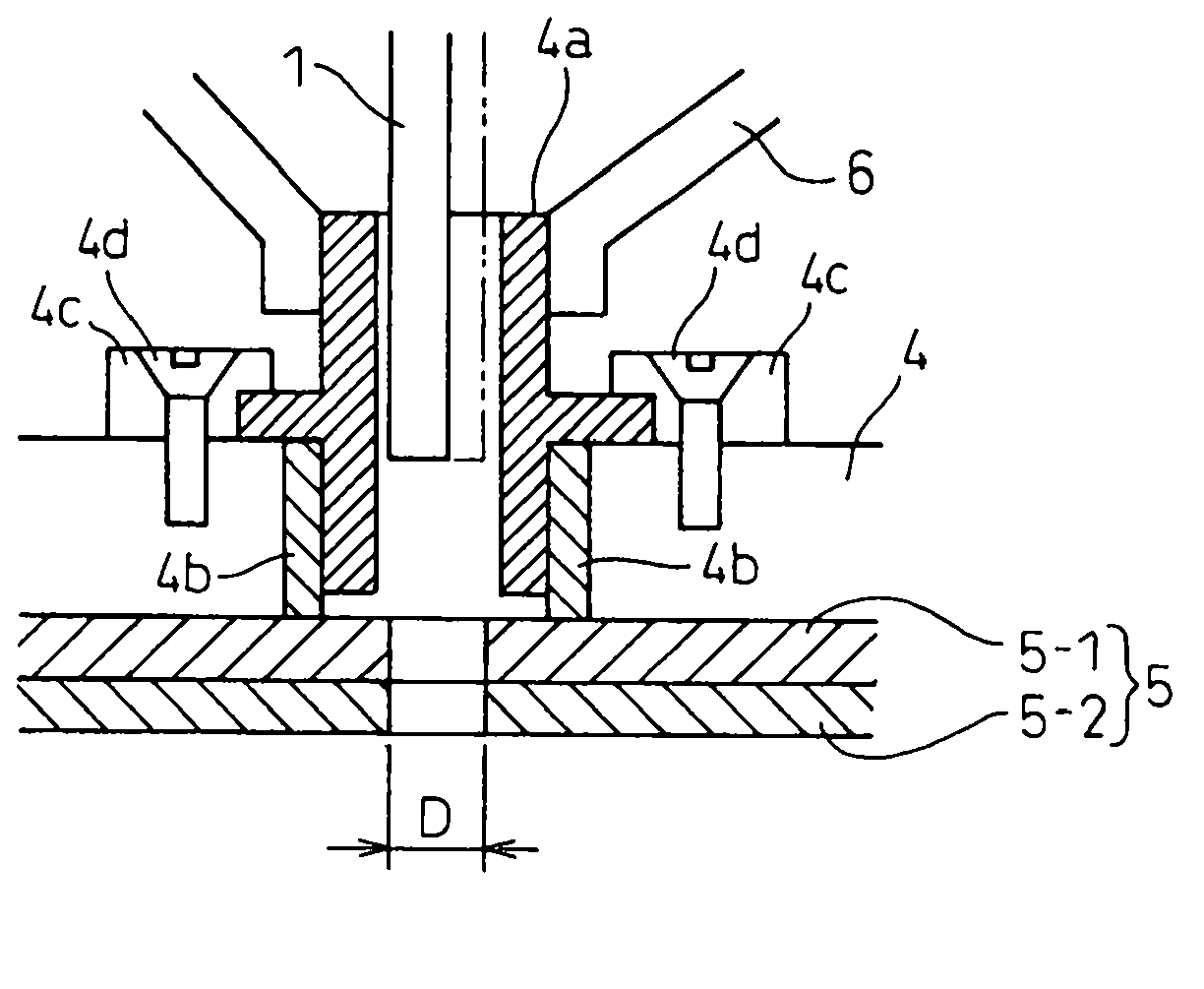

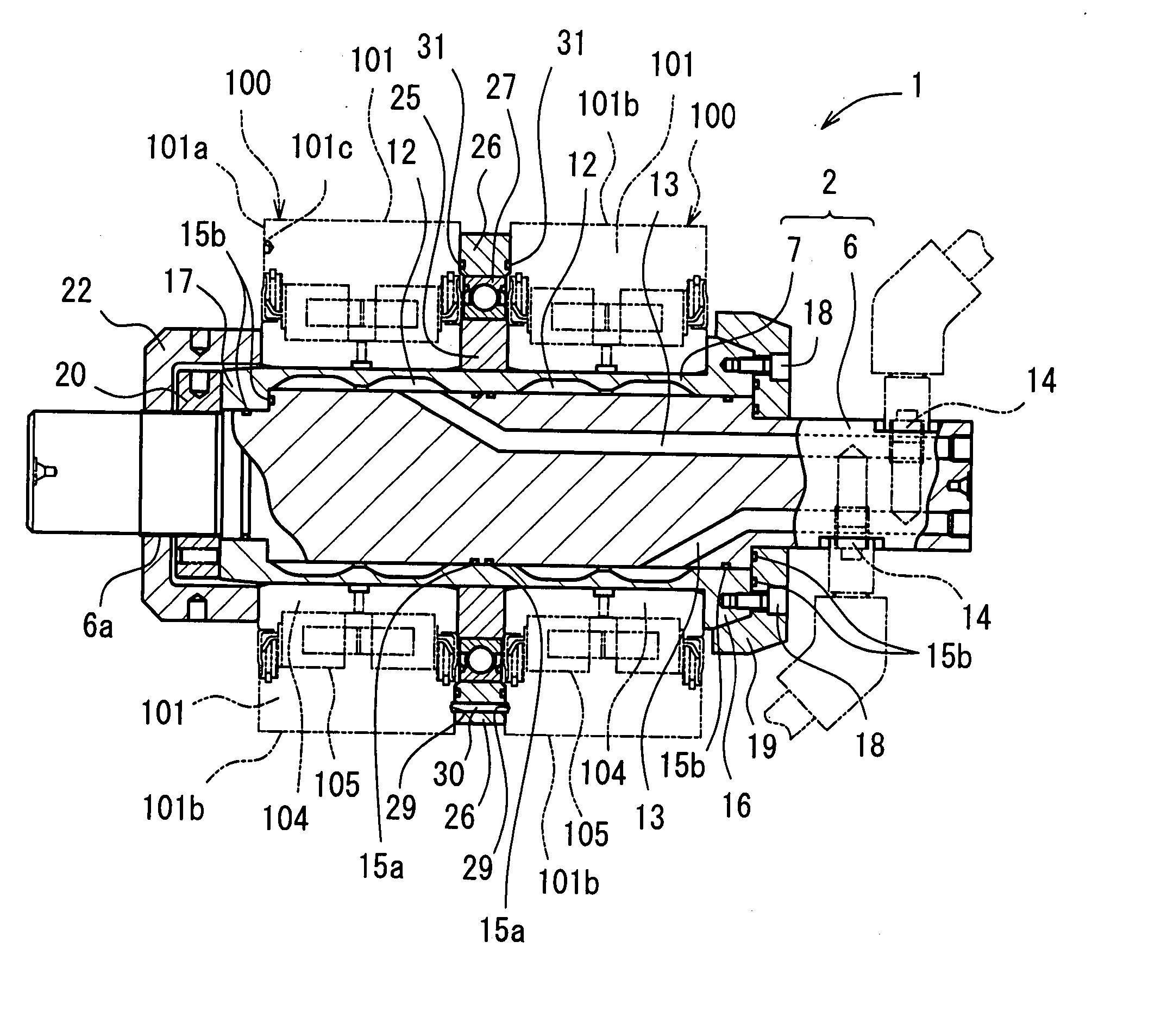

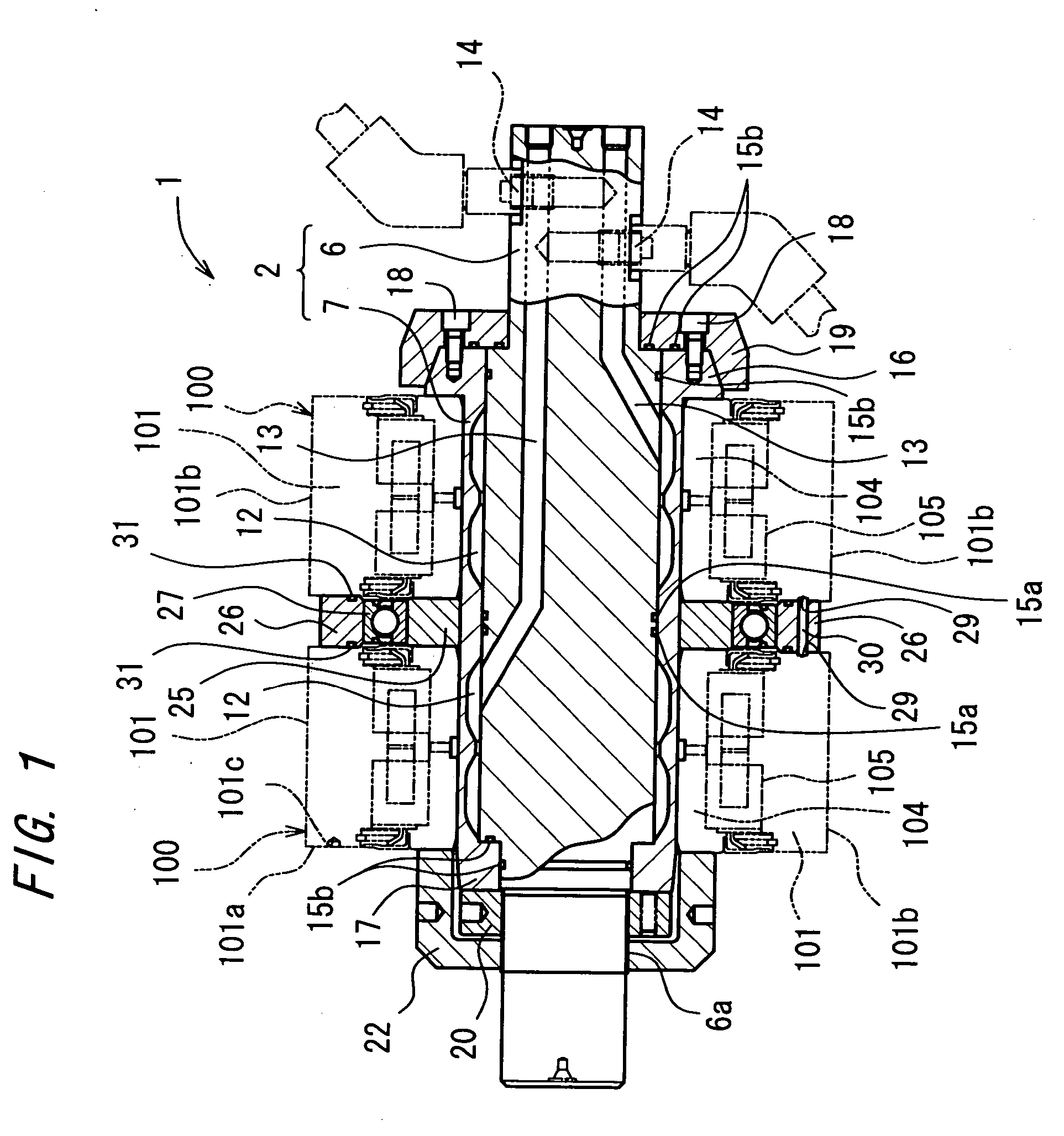

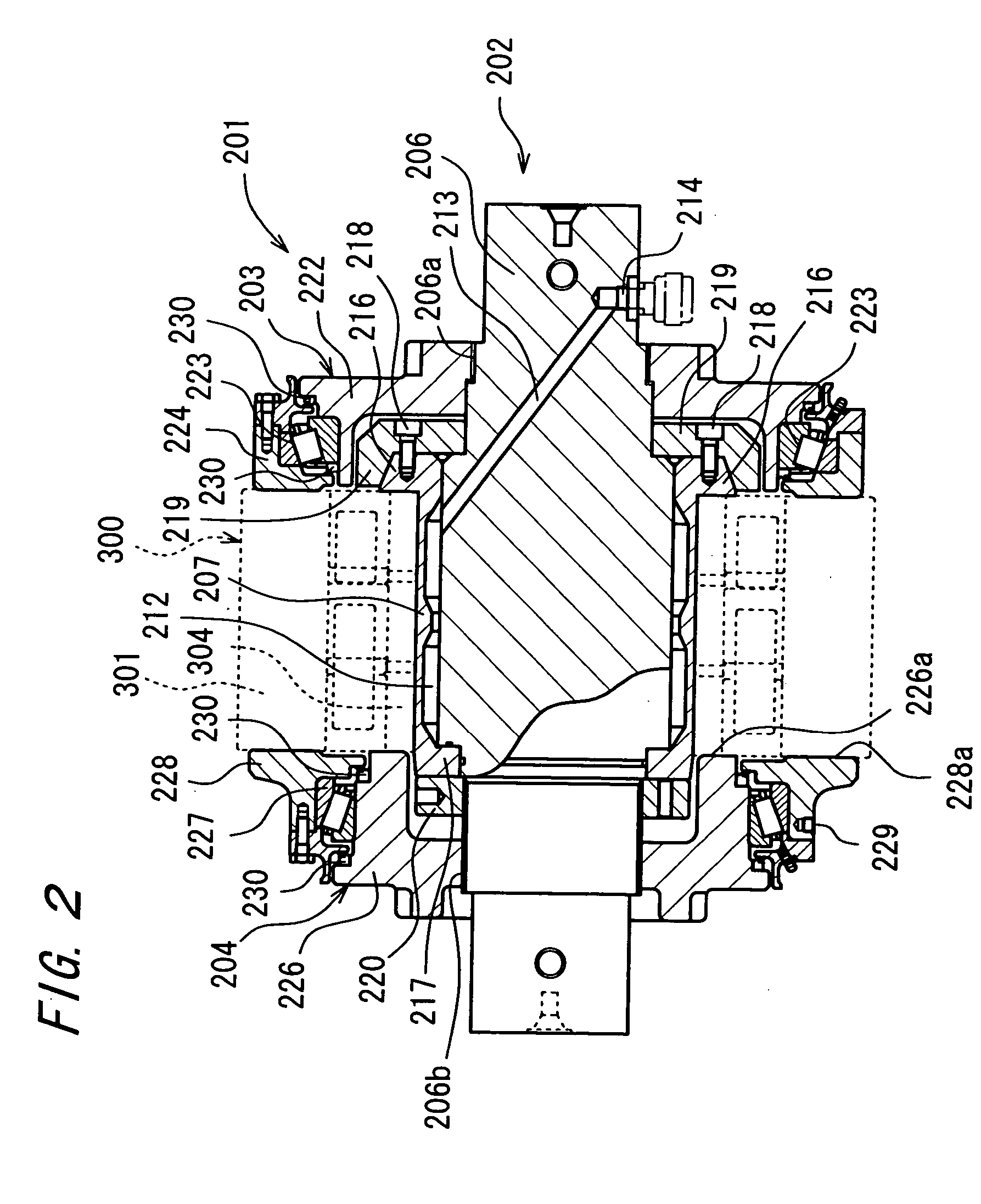

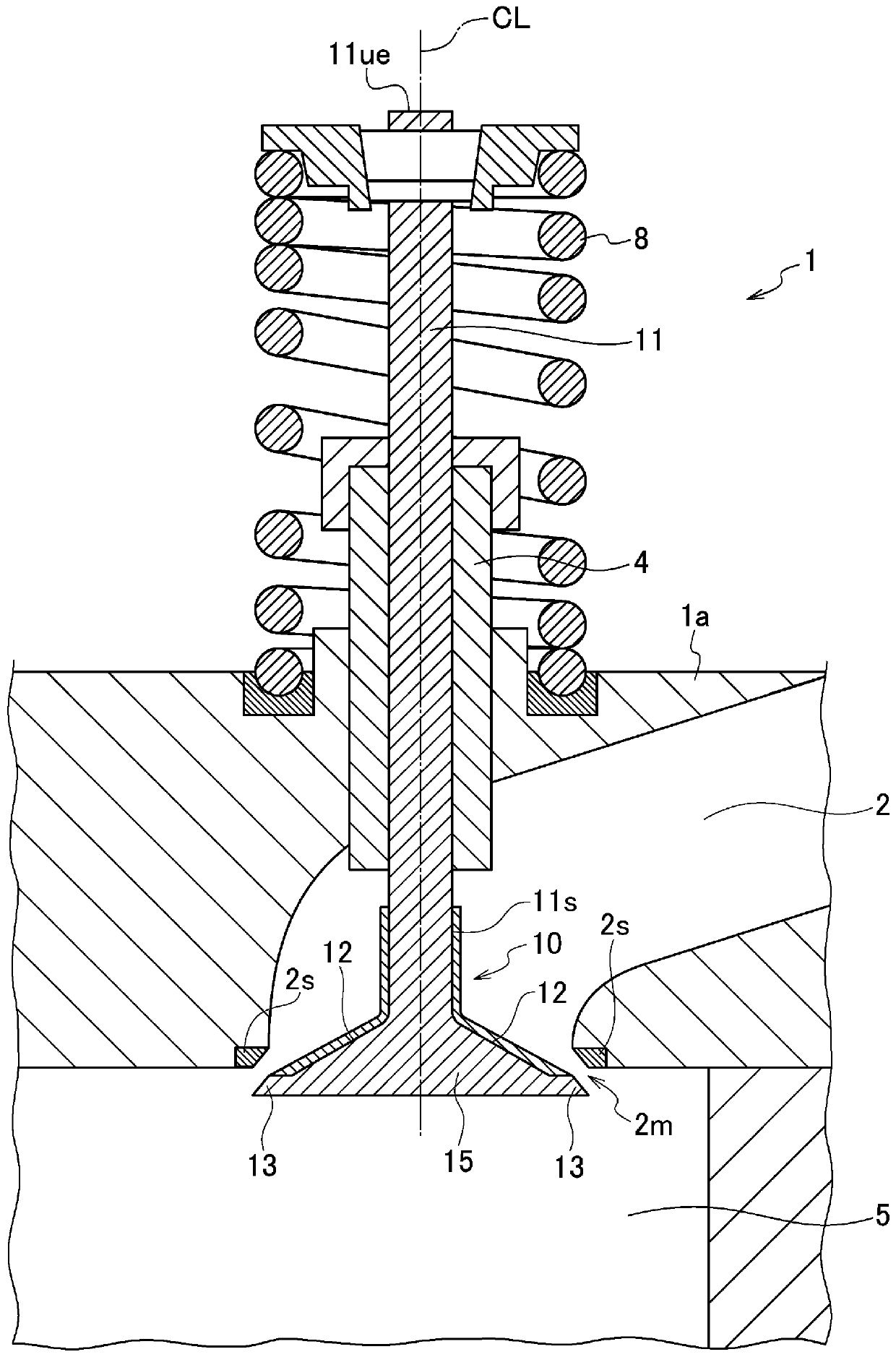

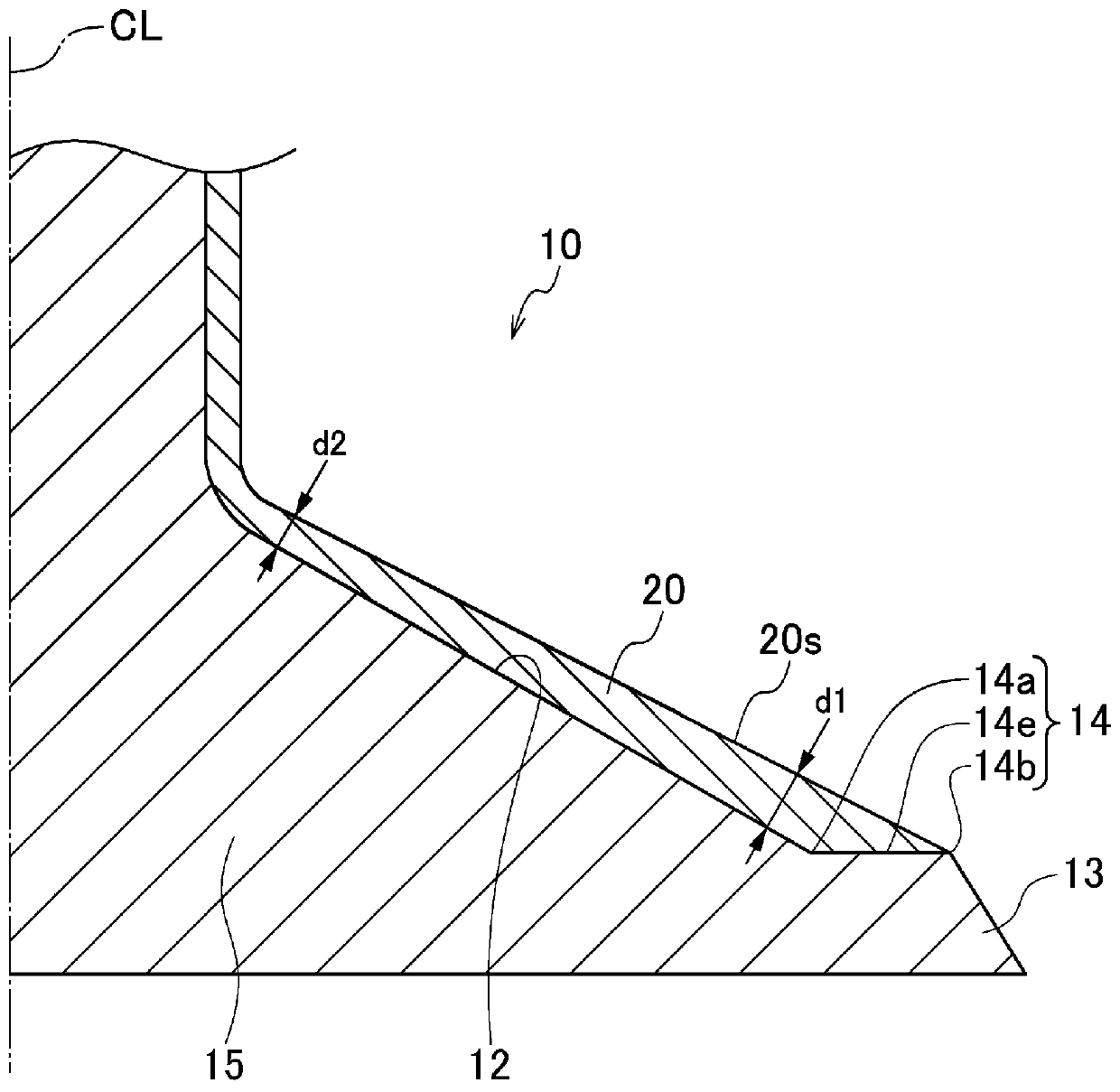

Polishing jig for rolling mill backup roll bearing

InactiveUS20040198201A1Improve efficiencyImprove versatilityRevolution surface grinding machinesMetal rolling stand detailsEngineeringBackup roll

A polishing jig of a hydraulic integral system is improved to increase efficiency. A polishing jig 1 for bearing for use in back-up roll of rolling mill including a shaft member 2 on which an inner ring 104 of a bearing 100 for use in back-up roll of rolling mill is fitted; and a pressure-oil chamber 12 operative in association with the feeding of a pressure oil into the shaft member 2 to protrude an outer circumferential part of the shaft member 2 radially outwardly, the polishing jig includes an inner-ring fixing portion 16 for axially fixing individual inner rings 104 of a plurality of the bearings 100 fitted on the shaft member 2 as axially arranged, wherein a plurality of the pressure-oil chambers 12 are formed internally of the shaft member 2 in correspondence to the plural bearings 100 fixed on the shaft member 2.

Owner:KOYO SEIKO CO LTD

Editing systems and methods

InactiveUS20130219253A1Efficient finishingNatural language data processingSpecial data processing applicationsOperational systemDigital content

Editing systems and methods to be used in a digital content / e-book editing environment are provided. An editing interface in a use interface (for example, a browser picture) in a development platform structured on a cloud network has a universal interactive component frame. At least one user selects required editing components / editing tools to design e-book content and / or digital content, and various interactive program codes are automatically integrated, thus to efficiently finish the required e-book content and / or digital content. The finished e-book content and / or digital content comprising interactive webpage and / or content is packed into a form of application according to the format of an operating system used for packing, wherein the packed application can be downloaded for use and / or published to a shopping mall of application software.

Owner:CHIDOPI

intake valve of internal combustion engine

ActiveCN108266244BReduced hermeticity reductionReduce accumulationMachines/enginesLift valveCombustion chamberInlet valve

Owner:HONDA MOTOR CO LTD

Method for smoothing articles of clothing and tunnel finisher

InactiveUS7966682B2Meet cutting requirementsEnsure efficient flowTextile treatment machine partsOther washing machinesMechanical engineeringEngineering

Owner:KANNEGIESSER GMBH CO HERBERT

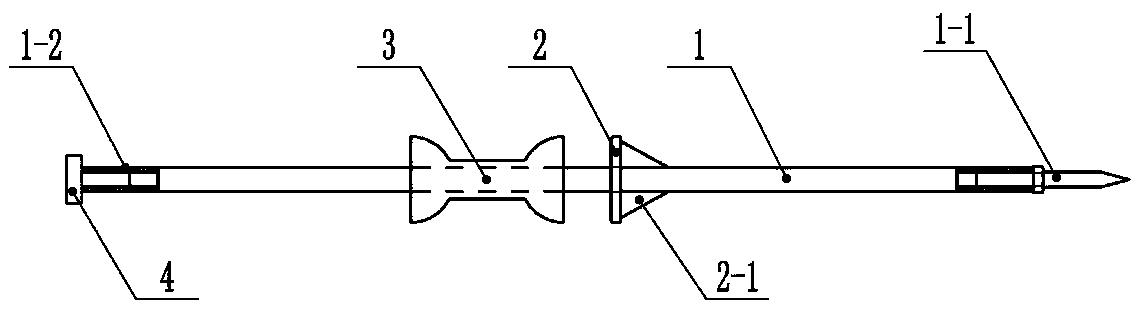

Iron notch mud sleeve finishing tool

PendingCN108977602AReduce labor intensityEfficient finishingBlast furnace componentsBlast furnace detailsHot blastBlast furnace smelting

The invention discloses an iron notch mud sleeve finishing tool, and relates to the technical field of the blast furnace smelting tool manufacture. The iron notch mud sleeve finishing tool comprises adrill rod provided with a drill bit and a drill shank. A middle position of the drill rod is provided with a beating baffle. A beating sliding weight is throughout installed between the beating baffle and the drill shank. The beating sliding weight is sheathed on the drill rod. The drill shank is provided with a tail baffle. The tail baffle is connected with the drill shank through a screw rod. Atriangular rib plate is installed between the beating baffle and the drill bit. The triangular rib plate is fixed on the drill rod and the beating baffle. The drill bit is welded on a bolt, and connected with the drill rod through the bolt. Problems that a current iron notch mud sleeve needs to be operated by multiple persons and a finishing speed of the iron notch mud sleeve is slow are solved.

Owner:LIUZHOU IRON & STEEL

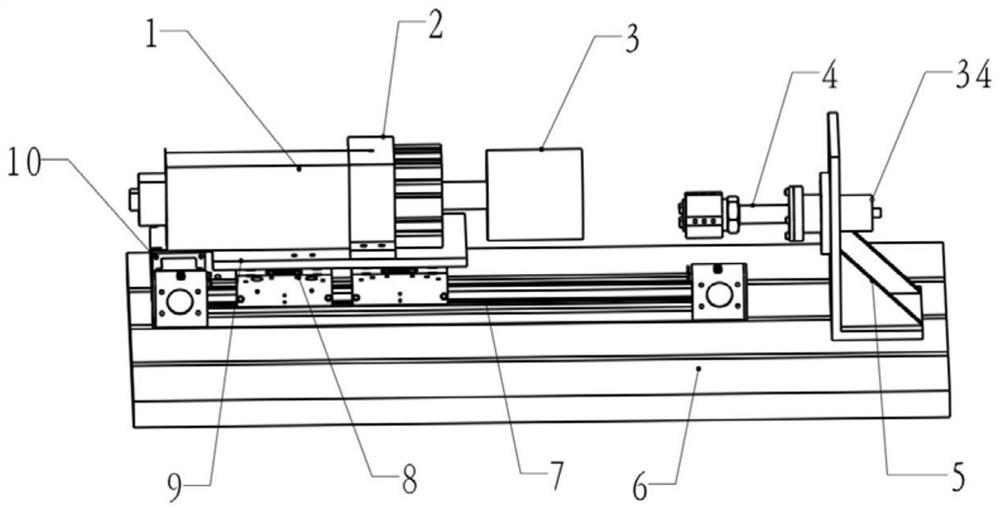

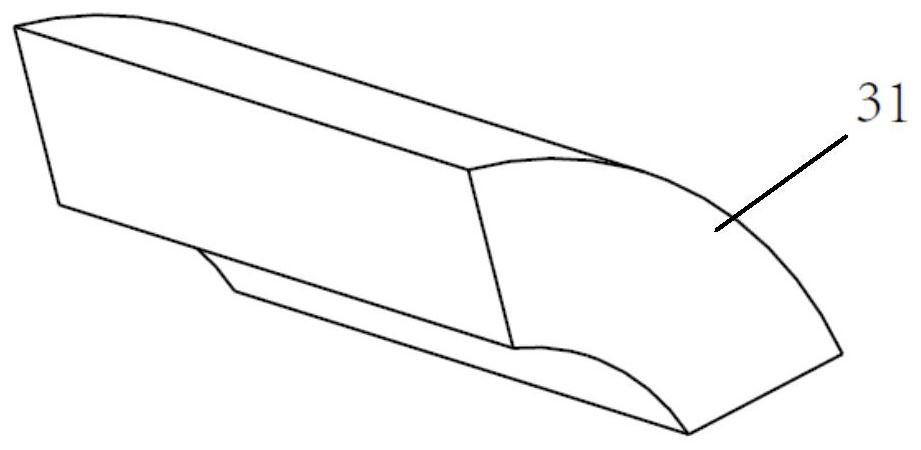

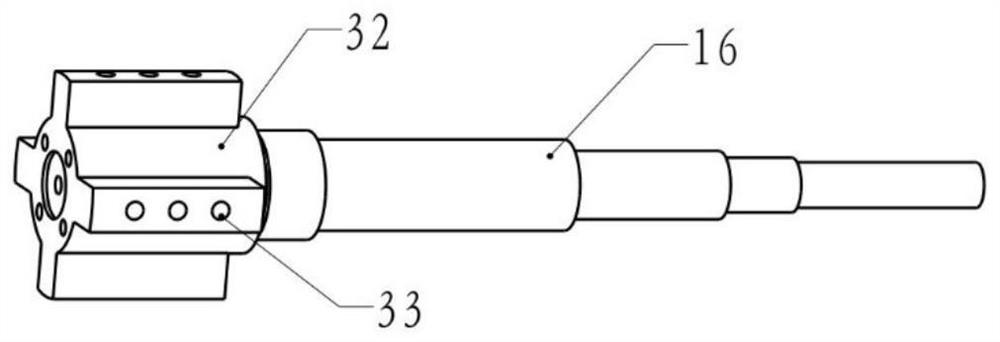

A kind of magnetic grinding device and method of ultrasonic composite high-pressure air flow

A magnetic grinding device and method for ultrasonic composite high-pressure airflow, characterized in that the device includes an installation platform (6), one end of the installation platform (6) is installed with a timing belt guide rail (7), and the timing belt guide rail (7) is installed There is a slider (8), the ultrasonic vibrator (1) is installed on the slider (8), the cylindrical workpiece (3) is installed on the ultrasonic vibrator (1), and the other end of the installation platform (6) is installed with Bending plate support (5), the hollow motor (34) driving the polishing spindle assembly (4) is fixed on the bending plate support (5), the high-pressure air flow enters the hollow rotating shaft (16) through the rotary joint, and passes through the holes Enter the processing area. The invention combines the effects of multiple physical fields to make the grinding track of abrasive particles more complex and uniform, and the device has reasonable design, simple structure, high processing efficiency, and is easy to adjust and assemble.

Owner:南京航太机电有限公司 +1

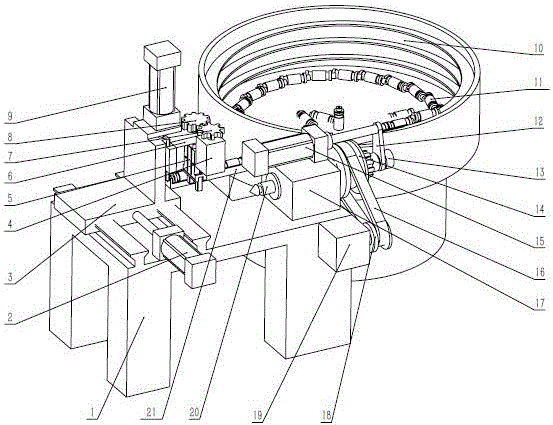

A center hole automatic grinding machine for shaft parts

InactiveCN105127878BAdjust working positionEfficient finishingGrinding drivesLapping machinesHydraulic cylinderGear wheel

The invention discloses an automatic grinding machine for a shaft part central hole. The automatic grinding machine comprises a base, a front-and-back transverse moving hydraulic cylinder, a front-and-back transverse moving drag plate, a vertical transverse moving drag plate, a pneumatic mechanical arm, a mechanical arm rotating motor, a rotating driving gear, a rotating driven gear, a vertical transverse moving hydraulic cylinder, a vibration disc, a grinding main shaft, a grinding main shaft transverse moving frame, a grinding main shaft transverse moving hydraulic cylinder, a large belt wheel, a small belt wheel, a belt, a grinding main shaft mounting seat, a grinding motor, a grinding head and a conveying belt; the mechanical arm rotating motor is mounted on the vertical transverse moving drag plate, and the rotating driving gear is mounted on a mechanical arm rotating motor main shaft; the grinding main shaft mounting seat is mounted on the base, and the grinding main shaft is mounted on the grinding main shaft mounting seat; and the grinding main shaft transverse moving hydraulic cylinder is mounted on the grinding main shaft mounting seat. Hydraulic driving control parts in the front-and-back direction and the up-and-down direction, the pneumatic mechanical arm and the grinding main shaft are arranged, so that the working position of the pneumatic mechanical arm is conveniently and rapidly adjusted, and the aim of high efficiency and fine machining of the shaft part central hole is achieved.

Owner:庄亚琼

Pump tower installation structure of liquefied natural gas storage tank and manufacturing method thereof

ActiveUS10208895B2Effectively fixedEfficient finishingContainer filling methodsContainer discharging methodsTowerLNG storage tank

Disclosed herein are a pump tower installation structure of a liquefied natural gas (LNG) storage tank and a manufacturing method thereof. The pump tower installation structure of the LNG storage tank includes an adaptor disposed at a predetermined area of an opening portion formed at an inner hull disposed on an upper side of the LNG storage tank, and a cover having through-holes corresponding to pipes of the pump tower installed at the storage tank, and disposed at a remaining area of the opening portion to be connected with the adaptor.

Owner:SAMSUNG HEAVY IND CO LTD

Method for smoothing articles of clothing and tunnel finisher

ActiveUS20110252674A1Meet cutting requirementsEnsure efficient flowFibre treatmentIroning machinesMechanical engineeringEngineering

Owner:KANNEGIESSER GMBH CO HERBERT

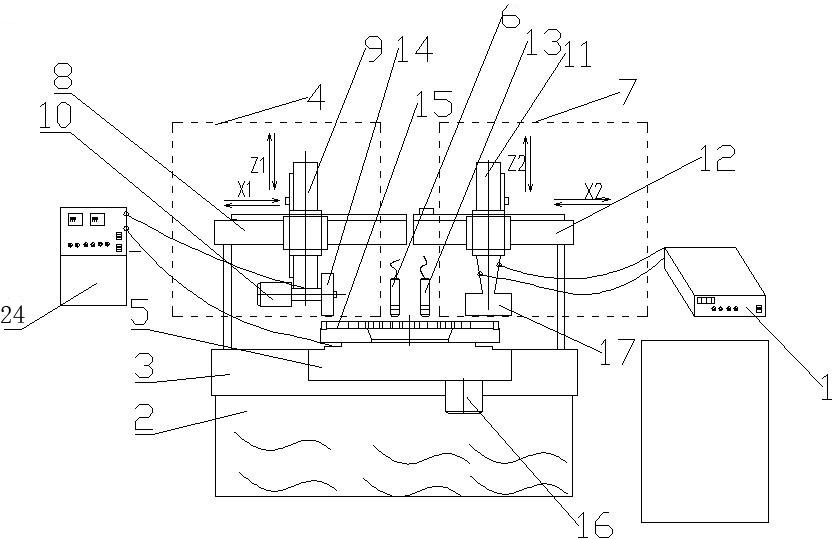

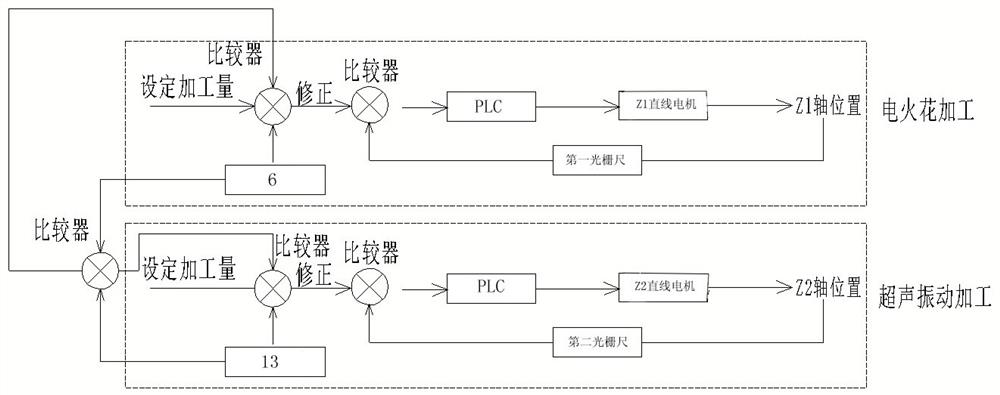

Composite bond grinding wheel dressing device and method

ActiveCN112405351BHigh melting pointAvoid knocking off blocksGrinding feed controlAbrasive surface conditioning devicesCrazingGrating

The invention discloses a composite bond grinding wheel dressing device and method, including a high-precision turntable and a control system. An electric spark dressing module and an ultrasonic dressing module are respectively arranged above the two sides of the high-precision turntable, and the electric spark module includes a Z1 linear motor. , X1-axis linear motor, pulse power supply, electrode motor, electrode, first grating ruler and first laser positioner. In the present invention, high-temperature discharge and carbonization are first performed on the composite bond grinding wheel by a pulse power supply, but the ceramic materials and wear-resistant inorganic fillers in the composite bond have high melting points and carbonization adhesion, and the carbonization residue adhesion after electric processing is not easy to throw away; then use ultrasonic The cavitation phenomenon of the method removes the carbonized adhesion layer on the end face of the composite bond grinding wheel block, and then performs further electrical machining and trimming, which is non-contact machining. The invention solves the problems that the grinding wheel of the composite bonded grinding wheel is dropped due to processing, internal cracks are generated, and the internal structure is damaged by processing heat.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

System and method for repairing wind generator based on weather information

ActiveUS10949781B2Effective calculationRespond quicklyEngine manufactureWeather condition predictionEngineeringAtmospheric sciences

Owner:DOOSAN HEAVY IND & CONSTR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com