Additive and subtractive compounded manufacturing method for achieving high-precision reference transmission

A manufacturing method and fiducial transfer technology, applied in the field of additive manufacturing process, can solve the problems of inconsistent fiducial transfer and difficult positioning, and achieve the effect of eliminating the influence of dimensional accuracy and deformation, improving consistency and flexible assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

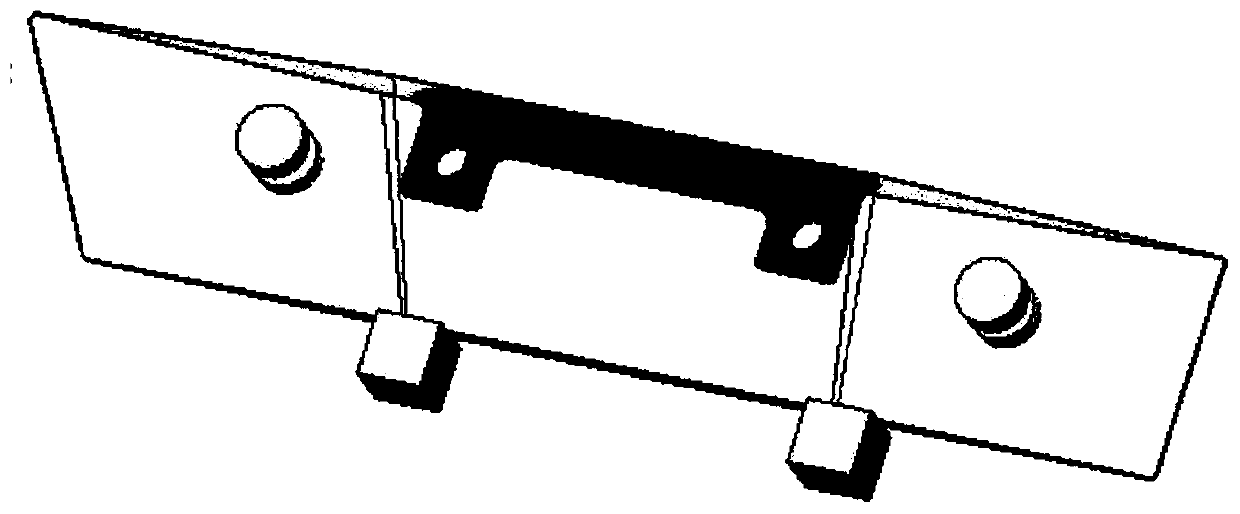

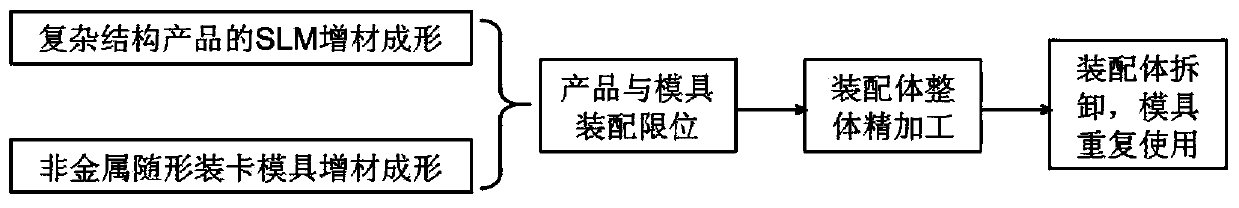

[0026] This embodiment proposes a composite manufacturing method of adding and subtracting materials to realize high-precision reference transfer, and its process is as follows image 3 shown. The additive and subtractive material composite manufacturing method specifically includes the following steps:

[0027] S1. SLM additive forming of complex structural products

[0028] The product categories involved in this embodiment are mainly aimed at products with special-shaped profiles, complex structures that are difficult to process or products with low processing efficiency, such as figure 1 Wing rudder products shown. Select the appropriate SLM process parameters according to its material characteristics, set the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com