Holding surface grinding method

A surface-holding and grinding technology, which is applied in the direction of optical surface grinders, grinding machine parts, grinding/polishing equipment, etc., can solve problems such as wafer thinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

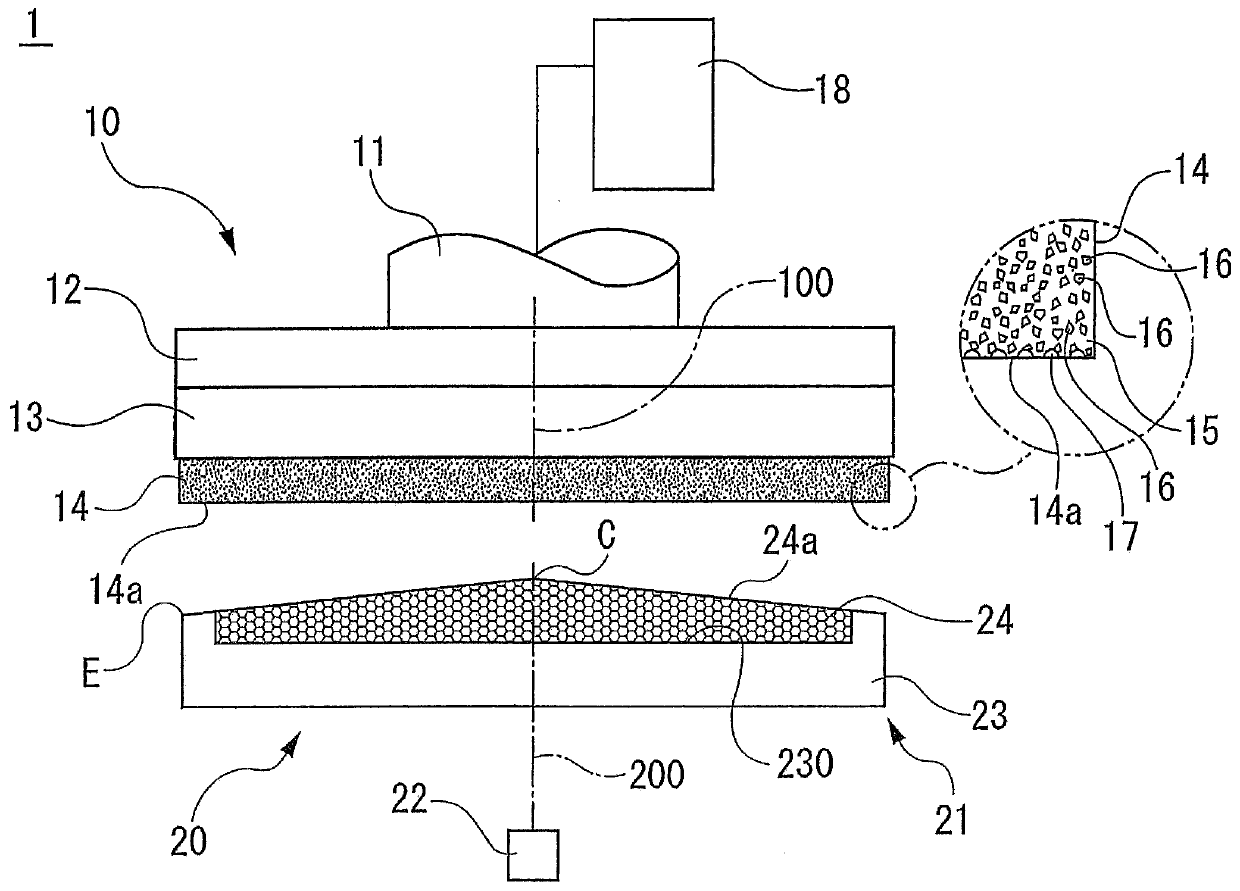

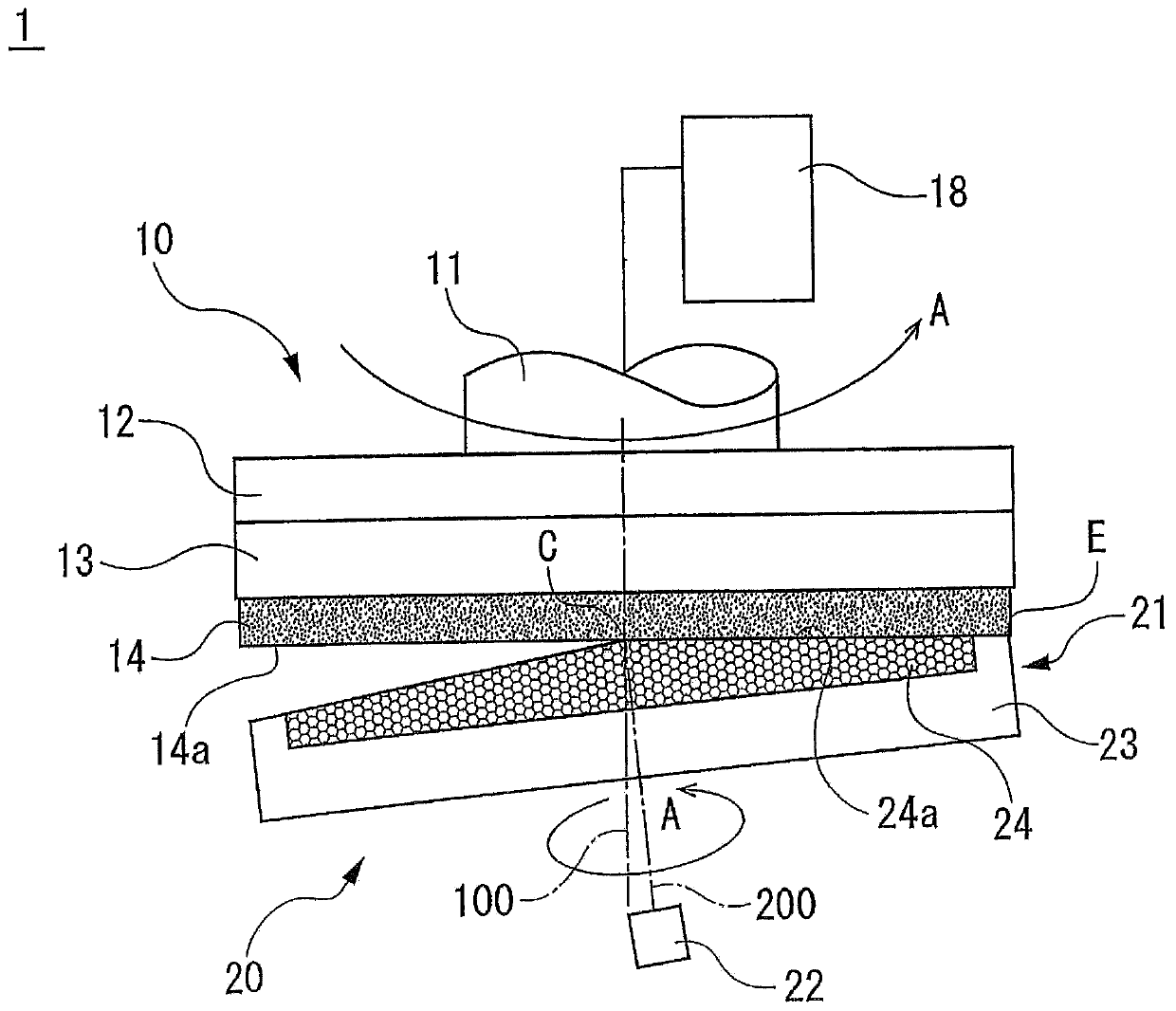

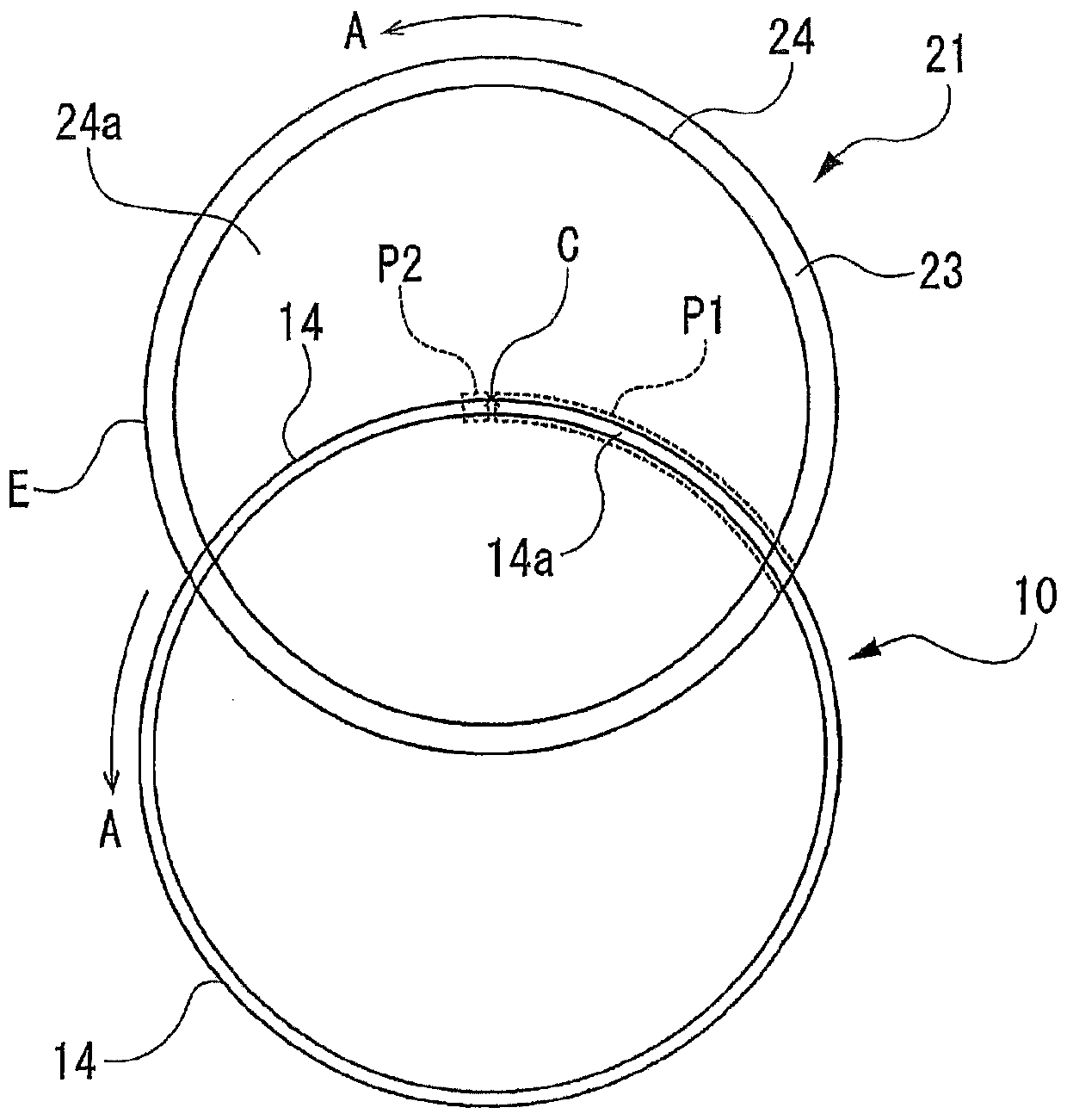

[0018] figure 1 It is an example of the grinding apparatus 1 using the grinding method of the holding surface of this invention. The grinding apparatus 1 has at least: a grinding unit 10 that rotates around a rotating shaft 100 that passes through the center of the grinding wheel 13; and a holding unit 20 that allows the holding table 21 to pass through the holding surface for holding the wafer. The rotation shaft 200 at the center of 24a rotates around.

[0019] Grinding unit 10 has: main shaft 11, and it has the axle center of vertical direction; Grinding grinding wheel 13, it is installed on the lower end of main shaft 11 by mounting seat 12; The lower part of 13. The grinding unit 10 is connected to a lift unit 18 that vertically lifts the grinding unit 10 , and is connected to a motor (not shown) that rotates the main shaft 11 .

[0020] Grinding stone 14 is a vitrified grinding stone obtained by mixing vitrified bond 15 and diamond abrasive grains 16 and sintering the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com