Finishing machine

A technology for processing and processing tools, applied in feeding devices, metal processing, automatic control devices, etc., and can solve problems such as uselessness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] An embodiment of the present invention will be described below with reference to the drawings.

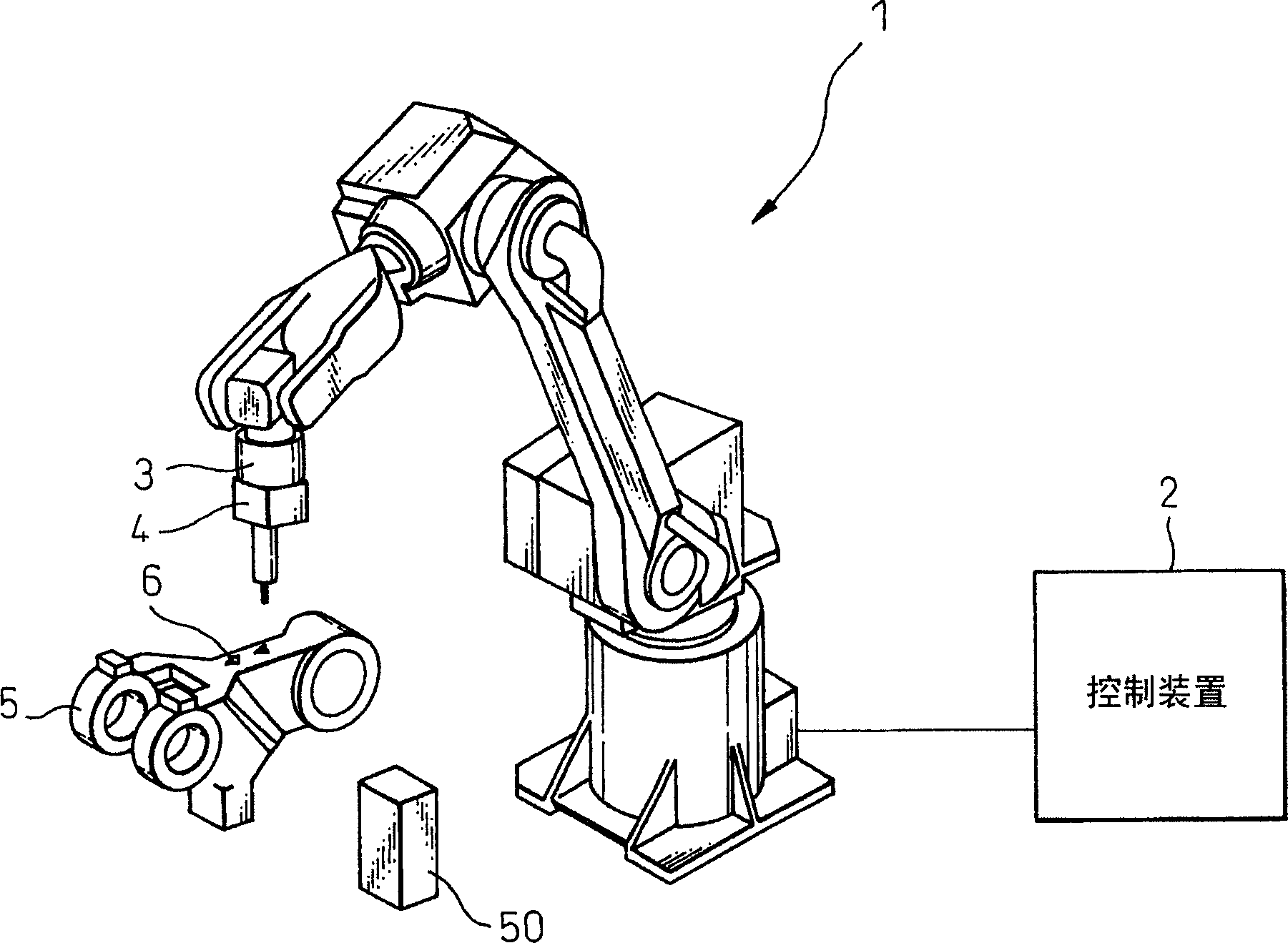

[0019] figure 1 It is a schematic diagram of one embodiment of the present invention. In this embodiment, a machined workpiece 5 such as a machine part is fixed at a predetermined position on a table (not shown), and a machining tool 4 is attached to the front end of the arm of the robot body 1 via a force sensor 3 . The finishing device of the present invention uses the machining tool 4 to remove the flash 6 on the workpiece 5 to be machined. In addition, in figure 1 In , mark 2 is the control device of the robot, and the robot main body 1 is controlled and operated by the control device 2 . In addition, the cutting edge of the machining tool 4 is in a rotating form, and the driving control of the machining tool 4 is also performed by the control device 2 .

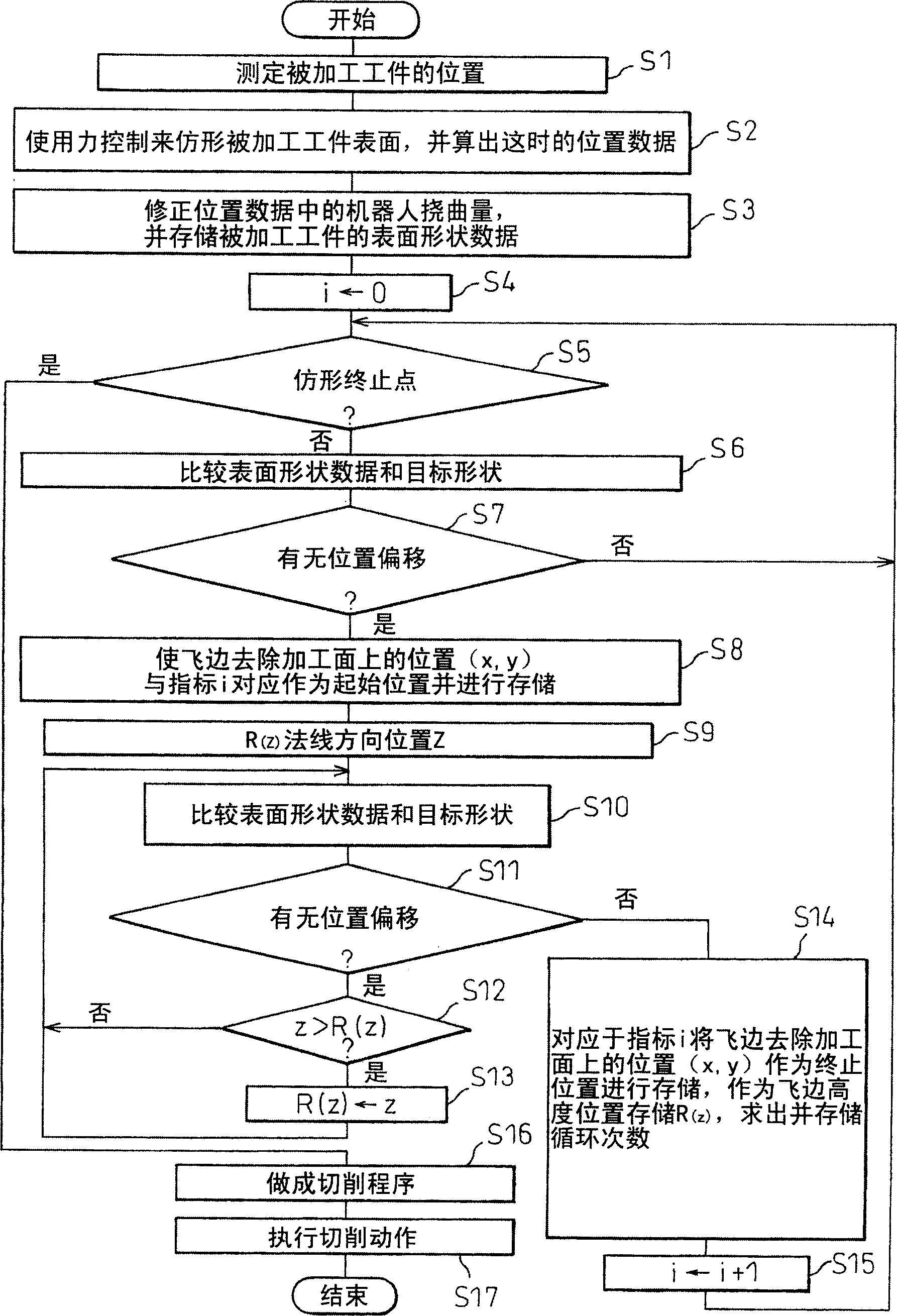

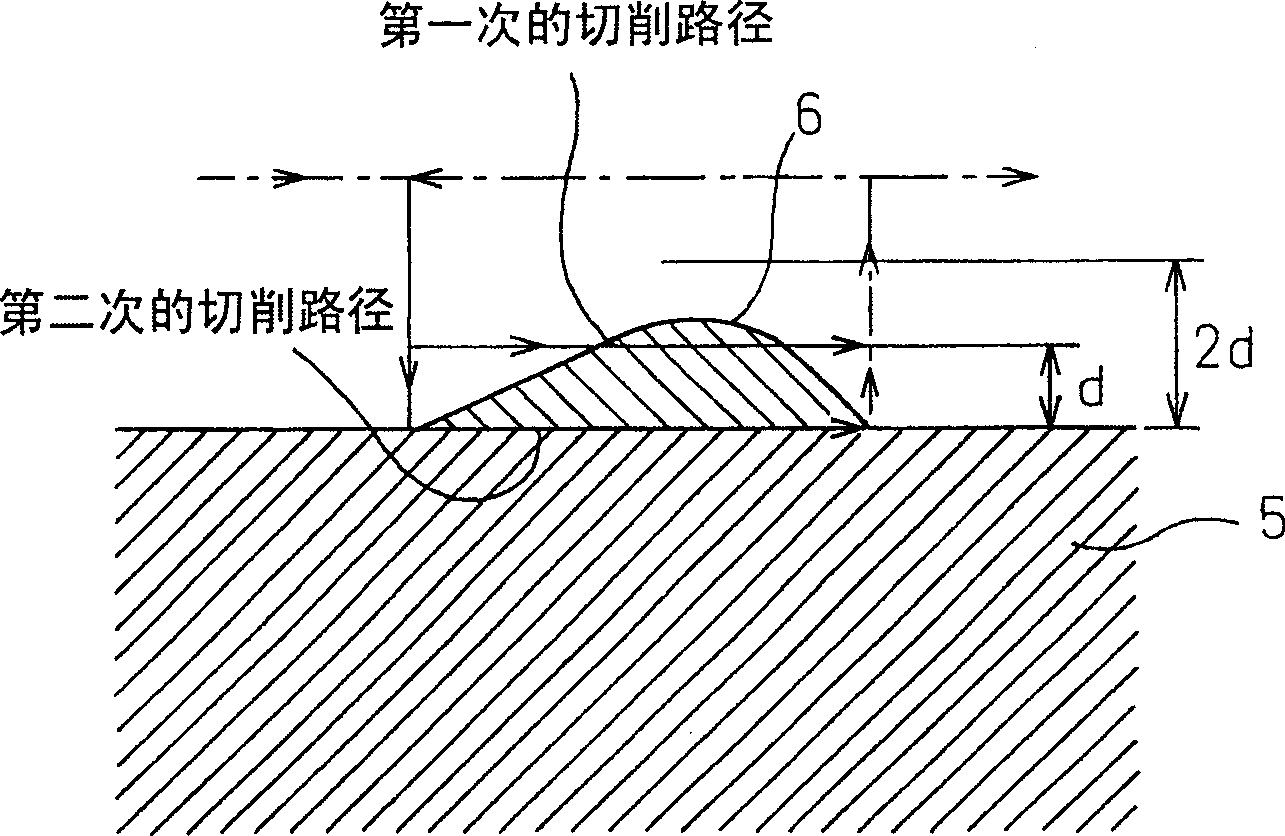

[0020] The force sensor 3 detects the pressing force of the machining tool 4 during machining and when profiling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com