A center hole automatic grinding machine for shaft parts

A technology for shaft parts and center holes, which is applied in the field of automatic grinding machines for center holes of shaft parts, can solve problems such as inconsistent requirements, high production costs, and low efficiency, and achieve the effect of convenient adjustment and high-efficiency finishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific embodiments. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

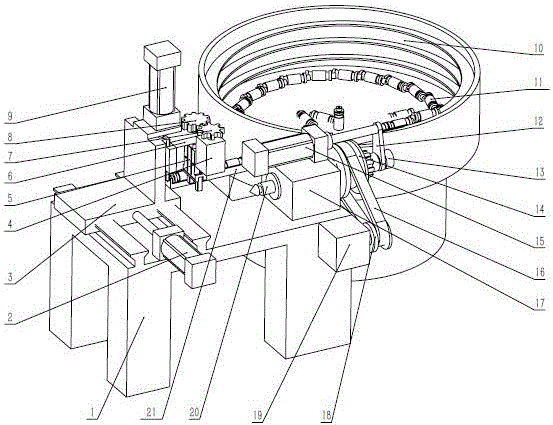

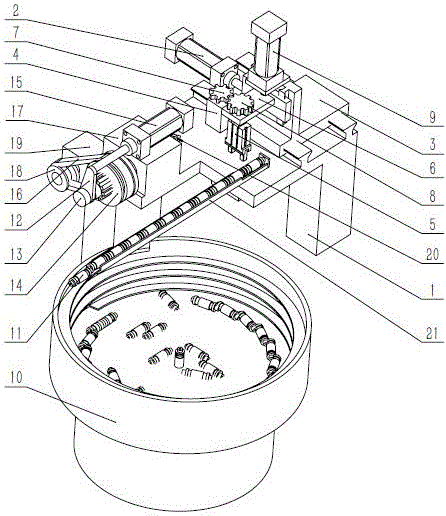

[0015] Such as figure 1 , figure 2 As shown, an automatic center hole grinding machine for shaft parts includes a base 1, a front and rear translation hydraulic cylinder 2, a front and rear translation carriage 3, an up and down translation carriage 6, a pneumatic manipulator 5, a manipulator rotating motor 4, and a main rotating gear 7 And rotation slave gear 8, up and down translation hydraulic cylinder 9, vibration plate 10, grinding main shaft 13, grinding main shaft translation frame 12 and grinding main shaft translation hydraulic cylinder 15, large pulley 14 and small pulley 18, belt 16, grinding main shaft mounting seat 17. Grinding motor 19, grinding head 20, conveyor belt 21, base 1 is a cast iron frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com