Dust remover for steel rolling production line

A technology for dust collectors and production lines, applied in chemical instruments and methods, the use of liquid separation agents, the separation of dispersed particles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with embodiment the present invention is described in further detail.

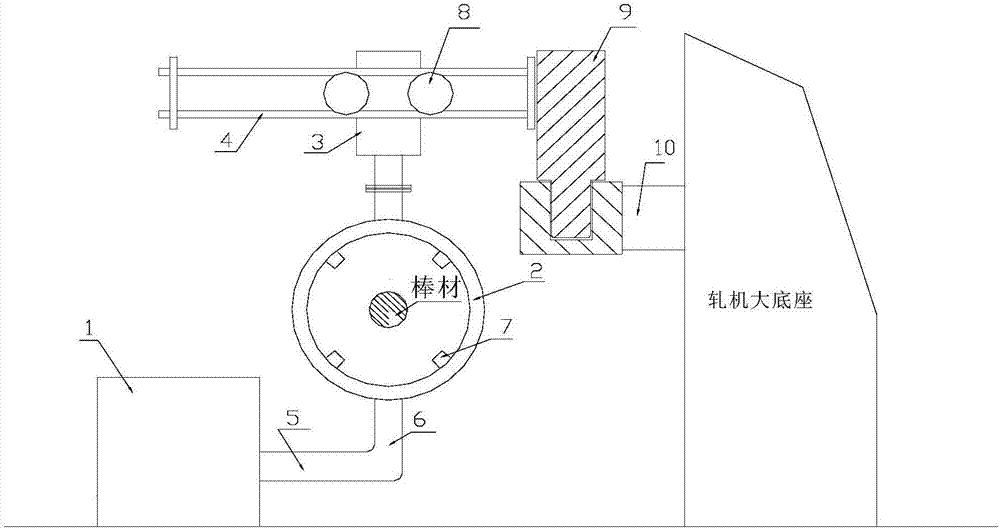

[0026] Such as figure 1 As shown, the present invention relates to a dust collector for a steel rolling production line, which mainly includes a water pump set 1, a water ring 2, a handwheel moving machine 3 and a sliding rod 4, and a soft water pipe 5 is installed at the water outlet of the water pump set 1 , the soft water pipe is convenient to have space to move when the water ring 2 moves, the water pipe 5 is connected with the water inlet of the water ring 2 through the water pipe joint 6, and the cleaning water in the water pump group 1 is passed into the water ring 2, in the A plurality of nozzles 7 are evenly spaced on the inner circumferential surface of the water ring 2, and the plurality of nozzles 7 communicate with the water passage cavity of the water ring 2. In this embodiment, four nozzles are installed on the water ring 2. Nozzles, each nozzle is installed at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com