Heat-shrinkable polyester film and packaging

A technology of heat shrinkage and hot water shrinkage rate, applied in the directions of packaging, transportation and packaging, container decoration, etc., can solve the problems of loss of low temperature shrinkage, shrinkage rate decrease, low temperature shrinkage rate decrease, etc., and the shrinkage characteristics will not be affected. The effect of small loss and shrinkage reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

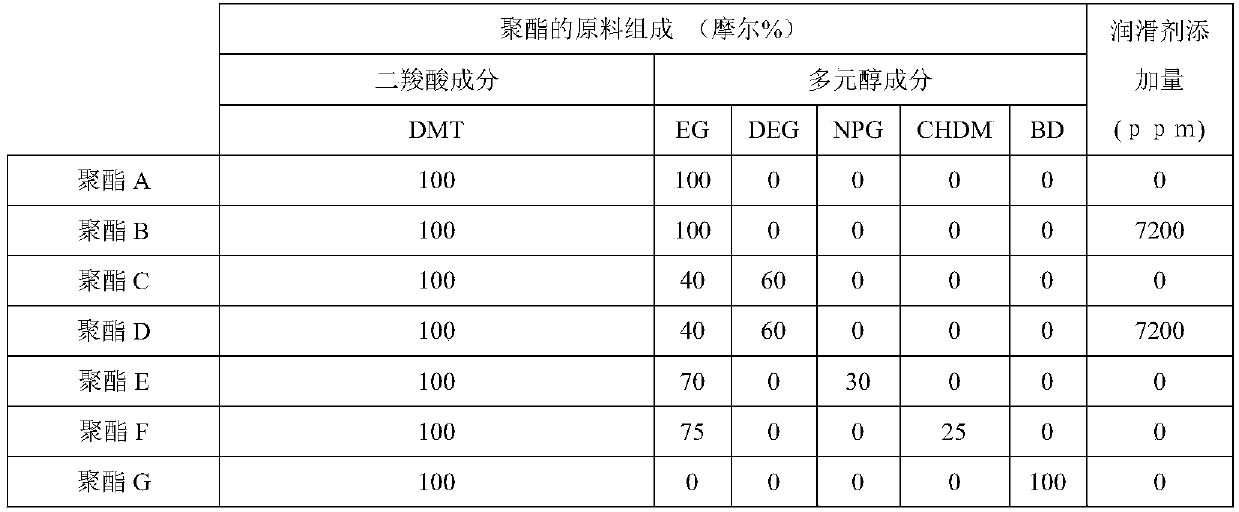

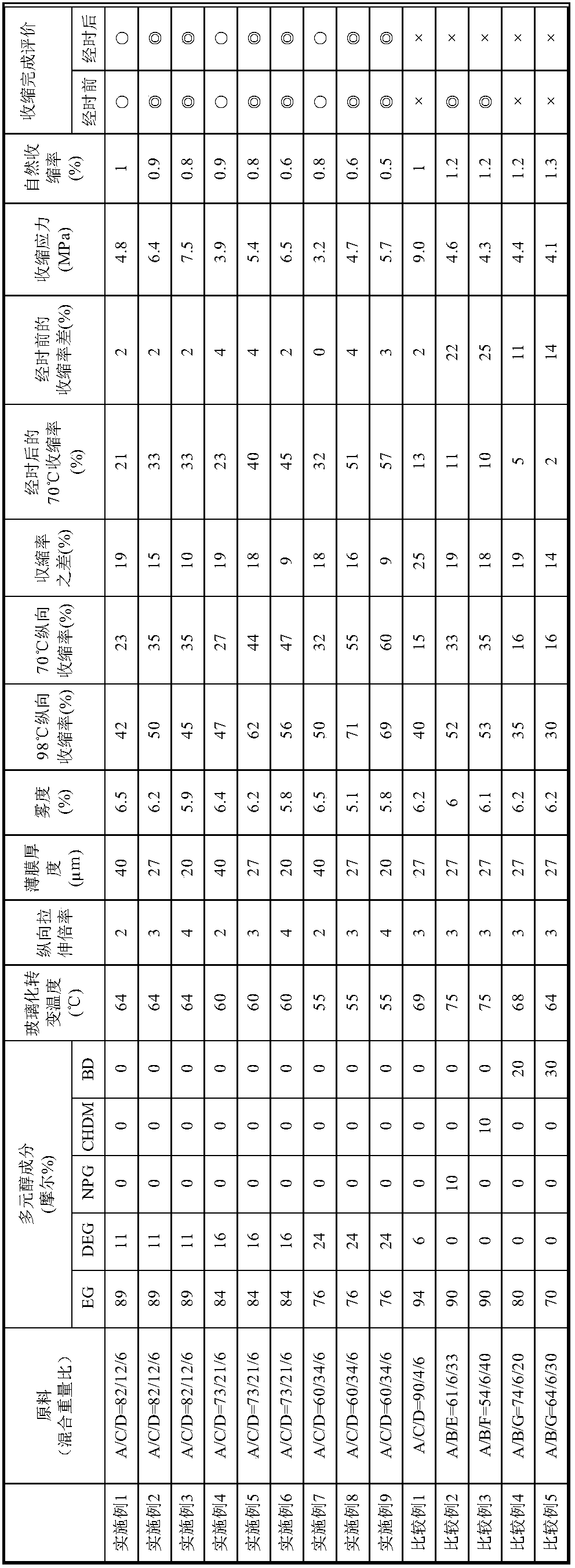

[0070] Hereinafter, although an Example demonstrates this invention in more detail, this invention is not limited to the form of the said Example at all, It can change suitably in the range which does not deviate from the summary of this invention. The compositions of the raw materials used in Examples and Comparative Examples, the production conditions of the thin films in Examples and Comparative Examples, and the evaluation results of the thin films in Examples and Comparative Examples are shown in Table 1 and Table 2, respectively.

[0071] [Table 1]

[0072]

[0073] The abbreviations in the table are as follows.

[0074] ※DMT Dimethyl terephthalate

[0075] ※EG Ethylene glycol

[0076] ※NPG neopentyl glycol

[0077] ※CHDM 1,4-Cyclohexanedimethanol

[0078] ※BD 1,4-butanediol

[0079] [Table 2]

[0080]

[0081] In addition, the evaluation method of the film is as follows.

[0082] [Tg (glass transition point)]

[0083] Using a differential scanning calorime...

Synthetic example A

[0105] Into a stainless steel autoclave equipped with a stirrer, a thermometer, and a partial reflux cooler, 100 mol% of dimethyl terephthalate (DMT) as a dicarboxylic acid component and ethylene glycol (EG) as a diol component were charged. 100 mol%, so that ethylene glycol is 2.2 times that of dimethyl terephthalate in terms of molar ratio, 0.05 mol% of zinc acetate (relative to the acid component) as a transesterification catalyst, and 0.225 mol% of antimony trioxide as a polycondensation catalyst are added. % by mole (relative to the acid component), the transesterification reaction was carried out while distilling the produced methanol out of the system. Thereafter, polycondensation reaction was performed under reduced pressure conditions of 280° C. and 26.7 Pa to obtain polyester A having an intrinsic viscosity of 0.62 dl / g. The composition is shown in Table 1.

Synthetic example B~D

[0107] Polyesters B to D shown in Table 1 were obtained by the same method as in Synthesis Example A. When producing polyesters B and D, add SiO as a lubricant at a ratio of 7200ppm to the polyester 2 (SYLYSIA266 manufactured by Fuji Silysia Chemical Ltd; average particle diameter: 1.5 μm). In the table, DEG is diethylene glycol, NPG is neopentyl glycol, CHDM is 1,4-cyclohexanedimethanol, and BD is 1,4-butanediol. The intrinsic viscosity of each polyester was B: 0.62dl / g, C: 0.65dl / g, D: 0.65dl / g, E: 0.74dl / g, F: 0.64dl / g, G: 1.24dl / g. It should be noted that each polyester is suitably in the form of small flakes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| linear shrinkage | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| hazing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com