Adhesive tape for wafer processing

A wafer processing and adhesive tape technology, which is applied in the direction of adhesives, film/sheet adhesives, electrical components, etc., can solve the environmental load and other problems, and achieve the effect of low environmental load and sufficient shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

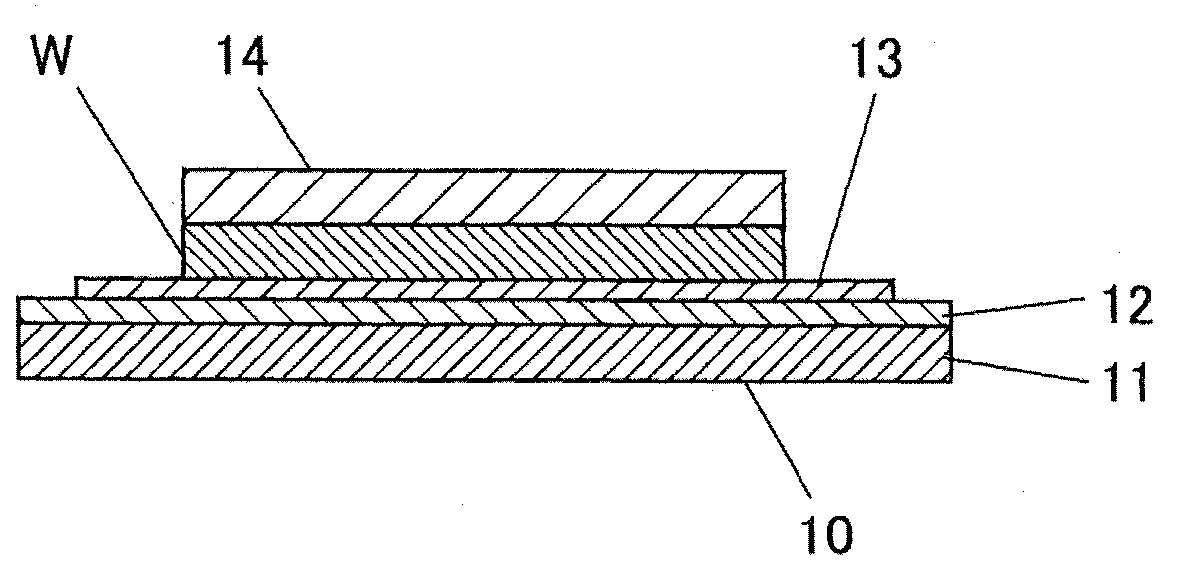

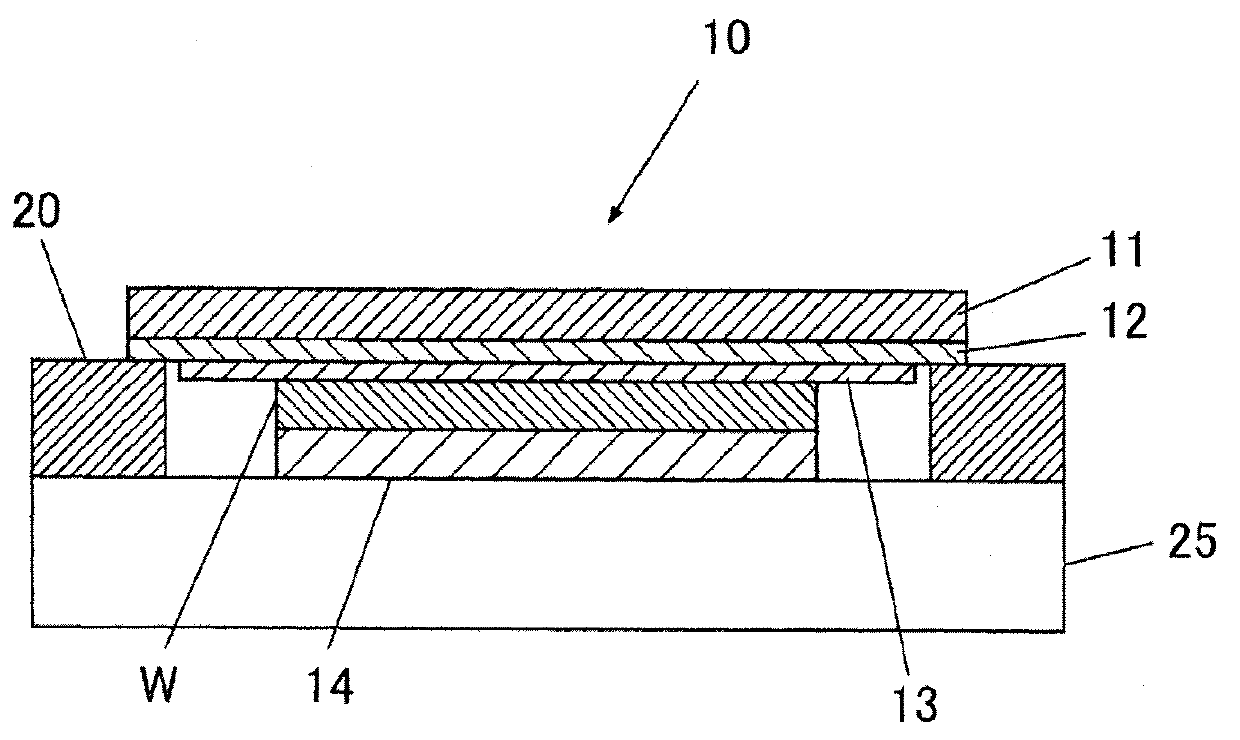

[0192] (Preparation of Base Film 11)

[0193] Zinc ionomer a (density 0.96g / cm3) of ethylene-methacrylic acid-ethyl methacrylate (mass ratio 8:1:1) terpolymer synthesized by free radical polymerization 3 , zinc ion content of 4% by mass, chlorine content of less than 1% by mass, Vickers softening point of 56°C, and melting point of 86°C) were melted at 140°C and molded into a long film with a thickness of 100 μm using an extruder. This produces the supporting substrate 1 for forming the substrate film 11 .

[0194] (Preparation of Adhesive Composition 1)

[0195]An acrylic copolymer (molecular weight: 600,000, hydroxyl value: 4.7 mgKOH / g, acid value: 0.2 mgKOH / g) was obtained by radically polymerizing butyl acrylate, 2-hydroxyethyl acrylate, and acrylic acid. With respect to 100 parts by mass of the acrylic copolymer, 30 parts by mass of trimethylolpropane triacrylate was added as a photopolymerizable cured product, 2 parts by mass of CORONET L (manufactured by Japan Polyure...

Embodiment 2

[0202] (Preparation of Base Film 11)

[0203] Zinc ionomer b (density 0.95g / cm2) of ethylene-methacrylic acid (mass ratio 9.5:0.5) binary copolymer synthesized by free radical polymerization 3 , a zinc ion content of 2% by mass, a chlorine content of less than 1% by mass, a Vickers softening point of 81°C, and a melting point of 100°C) were melted at 140°C and molded into a long film with a thickness of 100 μm using an extruder. This produces the supporting substrate 2 for forming the substrate film 11 .

[0204] Using the support substrate 2 for forming the substrate film 11, the adhesive composition 1, and the adhesive composition 1, the tape 10 for wafer processing was produced by the same method as in Example 1, which was referred to as Example 2. sample.

Embodiment 3

[0206] (Preparation of Base Film 11)

[0207] Ultra-low density polyethylene ULDPEa (density 0.90g / cm2) synthesized by metallocene polymerization 3 , chlorine content less than 1% by mass, Vickers softening point of 72°C, and melting point of 90°C) are melted at 140°C, molded into a long film with a thickness of 100 μm by an extruder, and then used in a medium-energy electron beam accelerator (中ェネルギ-electron beam accelerator) Electron beams were irradiated with an accelerating voltage of 1 MeV and an irradiation dose of 20 Mrad to fabricate the supporting base 3 for forming the base film 11 .

[0208] Using the support substrate 3 for forming the substrate film 11, the adhesive composition 1, and the adhesive composition 1, the tape 10 for wafer processing was produced by the same method as in Example 1, which was referred to as Example 3. sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com