Splittable conjugate fiber, fiber structure using the same, and wiping cloth

A composite fiber and fiber structure technology, applied in the direction of fiber treatment, conjugated synthetic polymer artificial filament, fabric, etc., to achieve the effect of high density, high shrinkage performance and excellent wiping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

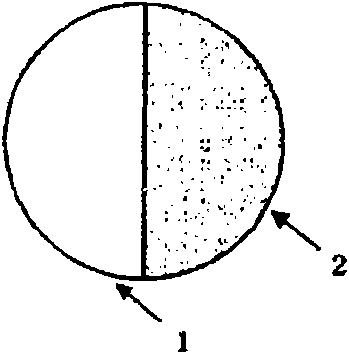

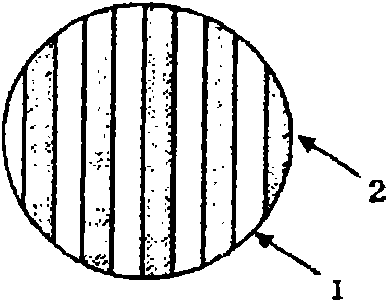

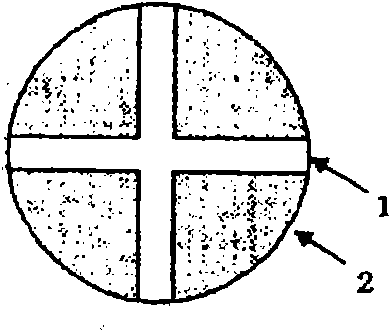

[0124] Nylon MXD6 having a relative viscosity of 2.7 and nylon 6 having a relative viscosity of 3.0 were mixed at a weight ratio of 50:50 to obtain a polyamide resin composition as component A. In addition, polyethylene terephthalate having an intrinsic viscosity of 0.61 was used as the B component.

[0125] According to the ratio of A component: B component volume ratio is 1: 2, under the condition of spinning temperature 295 ℃, spinning speed 1500m / min, carry out melt composite spinning in the mode that A component constitutes the radial part, obtain almost the same as Figure 4 Undrawn filaments of the same cross-section. At this time, component A is supplied to a metering pump through a static mixer after being melted. Then, the obtained undrawn yarn was drawn under the conditions of a roller heater of 85°C, a plate heater of 150°C, and a drawing speed of 2.50 times to obtain a split-type conjugate fiber of 110dtex / 50f.

[0126] Then, using this drawn yarn, a tube knitti...

Embodiment 2、3

[0129] [Example 2, 3, Comparative Example 1, 2]

[0130] Except for changing the weight ratio of nylon MXD6 and nylon 6 which are polyamide components, fibers were produced by the method described in Example 1, and various evaluations were performed.

[0131] [Table 1]

[0132]

Embodiment 4

[0144] Except that the B component was made of polypropylene, and the treatment method was immersion in 98° C. hot water for 10 minutes, fibers were produced according to the method described in Example 1, and various evaluations were performed. The results are shown in Table 2.

[0145] Due to the low adhesion between polyolefin and polyamide, it is easy to use hot water to cut fiber and shrink. Moreover, a product with soft touch and good bulkiness was obtained.

[0146] "Example of wiping performance"

[0147] Examples regarding wiping performance are further specifically cited. However, the present invention is not limited to the Examples described below.

[0148] A. Intrinsic viscosity of polyester

[0149] Intrinsic viscosity [η] is measured in a mixed solvent of phenol / tetrachloroethane=6 / 4 (weight ratio) at 20° C. using an automatic viscometer by a usual method.

[0150] B. Relative viscosity of polyamide

[0151] The relative viscosity ηrel is measured in a sulfur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com