Polylactic acid toughened material for 3D printing and preparation method thereof

A 3D printing and polylactic acid technology, applied in the field of 3D printing materials, can solve the problems of PLA shrinkage rate increase, slow cooling, surface roughness, etc., and achieve low shrinkage rate, good roundness of lines, and high regularity of extrusion molding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in combination with preferred embodiments.

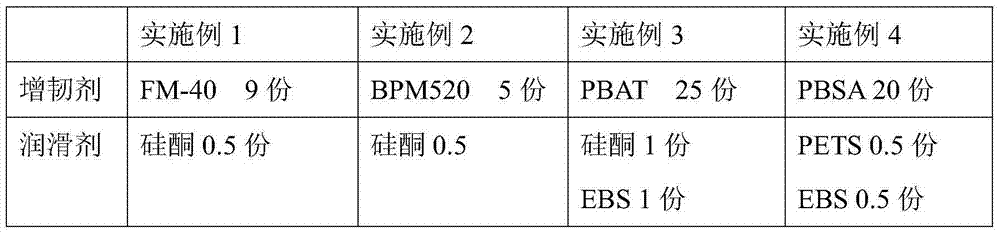

[0053] The present invention provides a polylactic acid toughened material for 3D printing and its preparation method, which is illustrated by the following examples. In each of the following examples, polylactic acid is 100 parts, and the selection of other components is as follows Shown in the table, wherein, in embodiment 1~4, 1 part=50g.

[0054]

[0055]

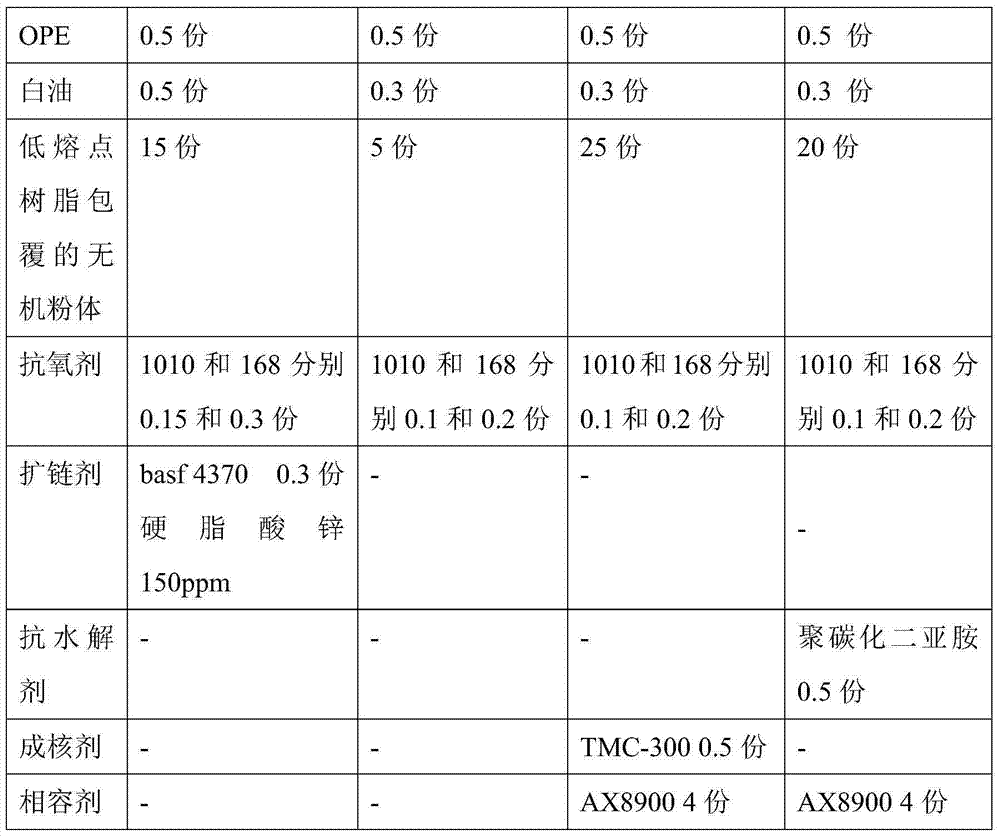

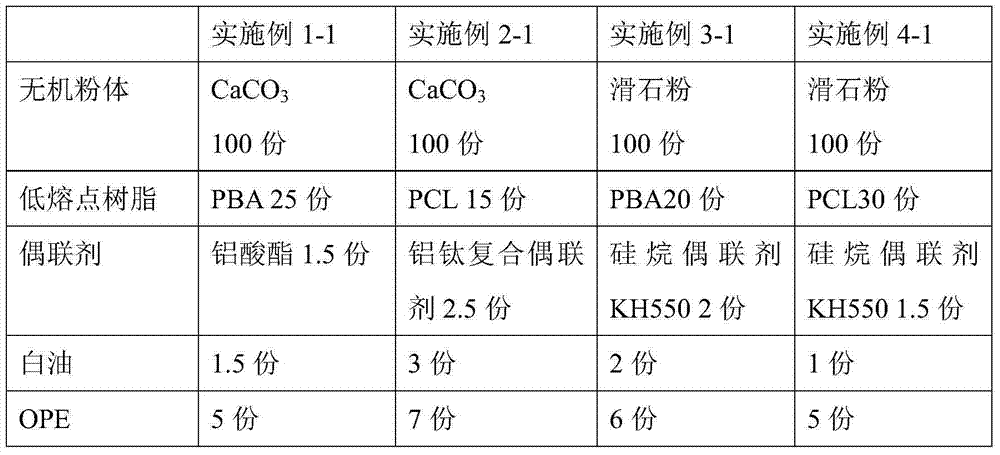

[0056] The low-melting point resin-coated inorganic powder in the above Examples 1 to 4 adopts the schemes shown in the following tables respectively, and in the following Examples 1-1 to 4-1, 1 part = 20 g.

[0057]

[0058] Taking the above example 1-1 as an example, the treatment method of the inorganic powder coated with low melting point resin is as follows:

[0059] 1) Dry 100 parts of calcium carbonate at 105°C until the water content is less than 0.3%, add it to the high mixer, heat the high mixer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com