Patents

Literature

34results about How to "Low roundness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

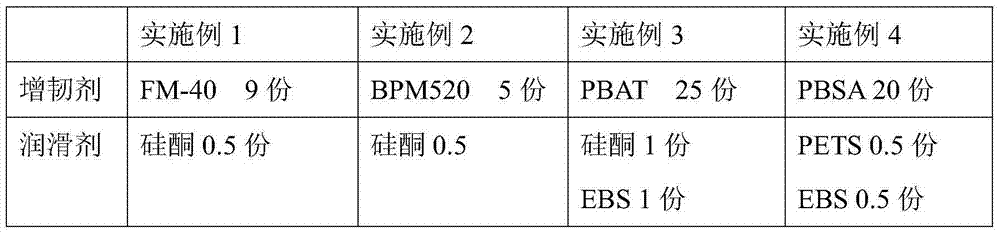

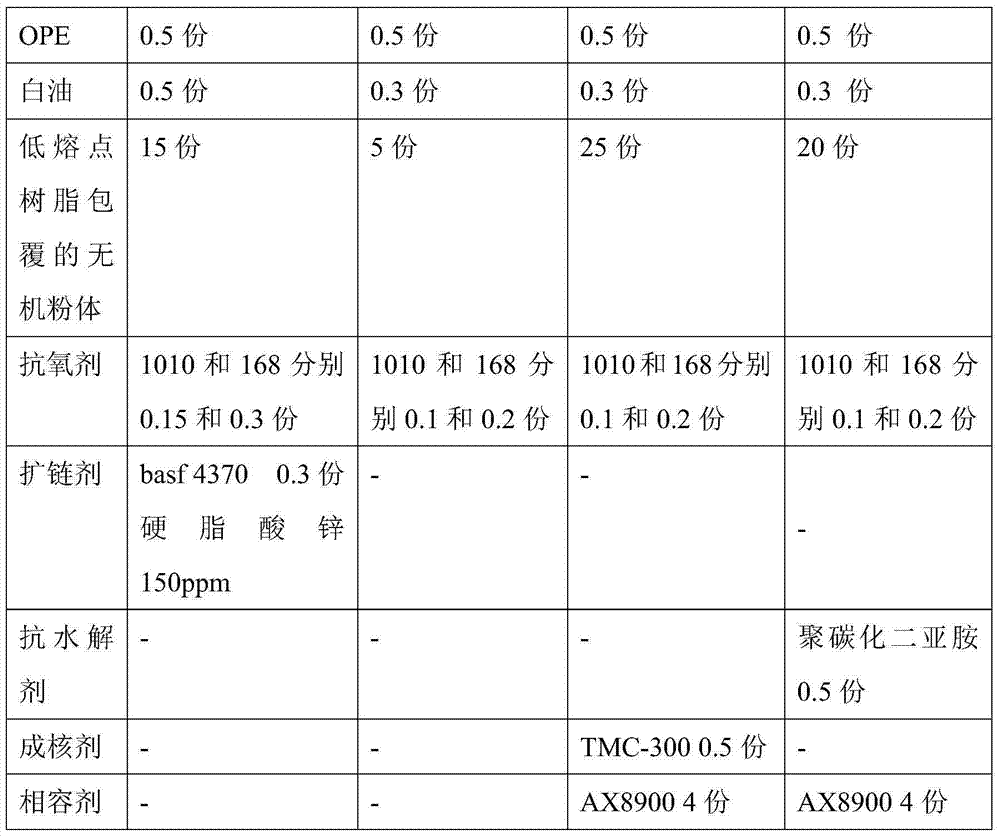

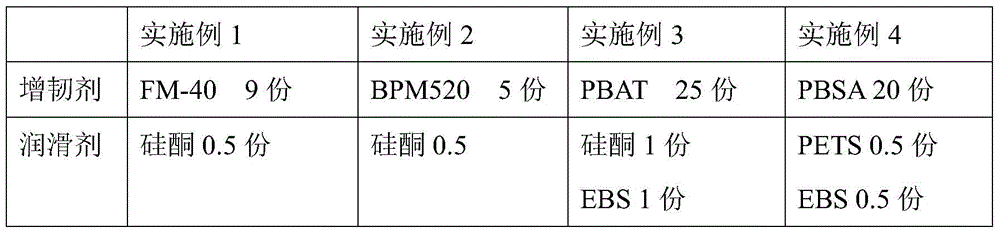

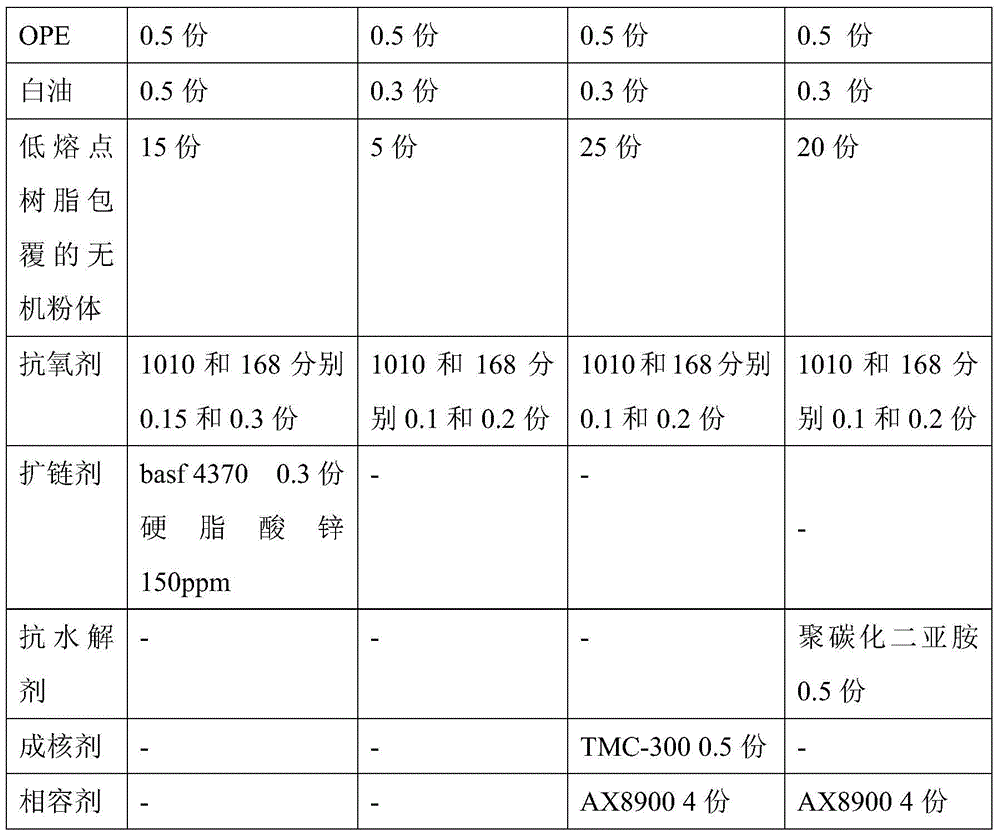

Polylactic acid toughened material for 3D printing and preparation method thereof

ActiveCN104725806AImprove toughnessImprove shrinkageAdditive manufacturing apparatusPolymer scienceAntioxidant

The invention discloses a polylactic acid toughened material for 3D printing, which comprises polylactic acid and the following components in percentage by mass (on the basis of polylactic acid): 5-25% of toughener, 0.5-2.0% of lubricant, 0.5-2.0% of oxidized polyethylene wax, 0.3-1.0% of white oil, 5-25% of low-melting-point resin-coated inorganic powder and 0.3-0.9% of antioxidant. The material prepared by the technical scheme has the advantages of favorable toughness, high extrusion forming regularity and favorable line roundness. The printing proves that the product has the advantages of low shrinkage, no edge lifting, no cracking, high cooling speed and favorable appearance and has wide printing application range.

Owner:SHENZHEN ESUN IND

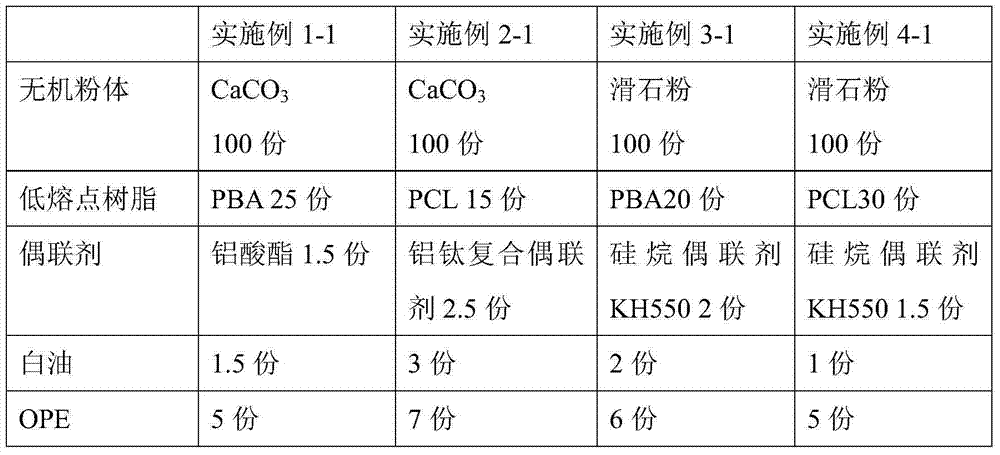

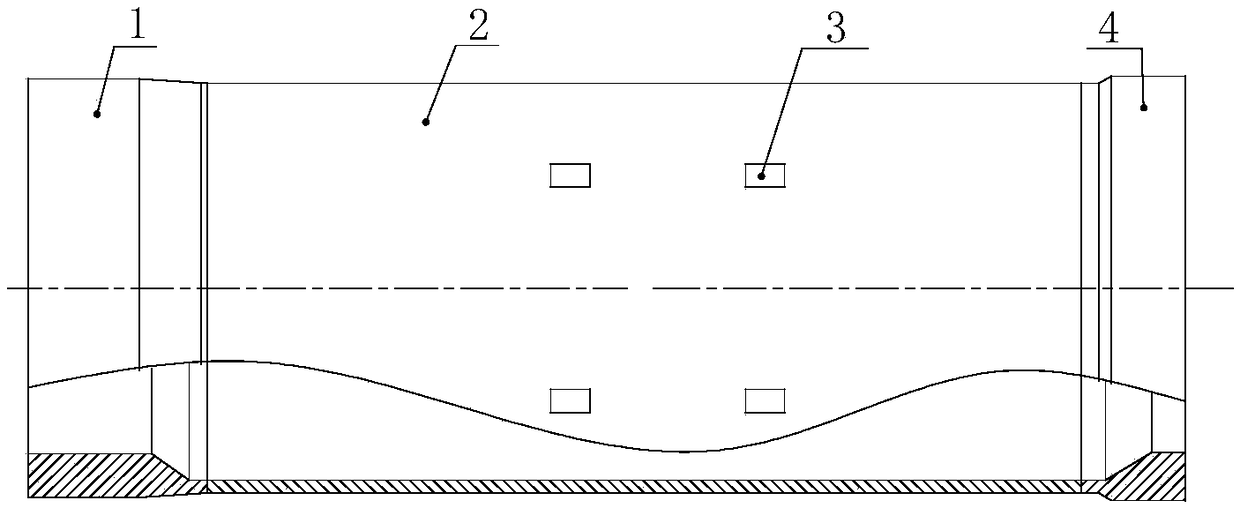

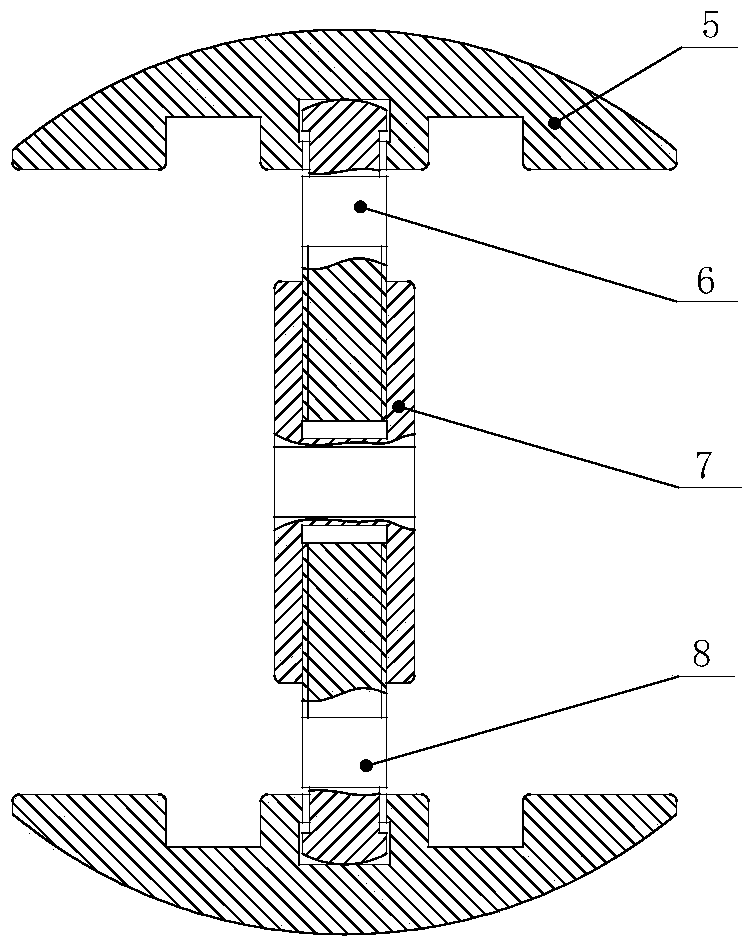

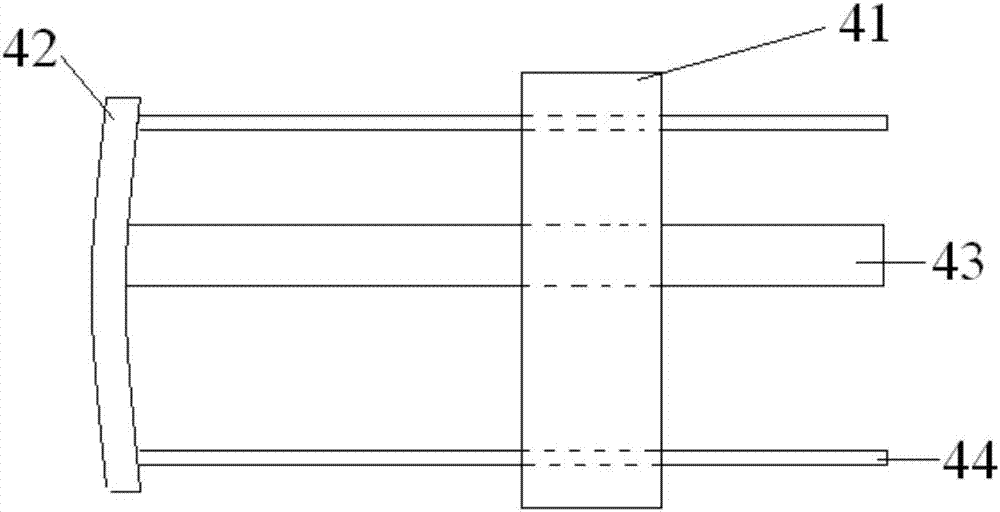

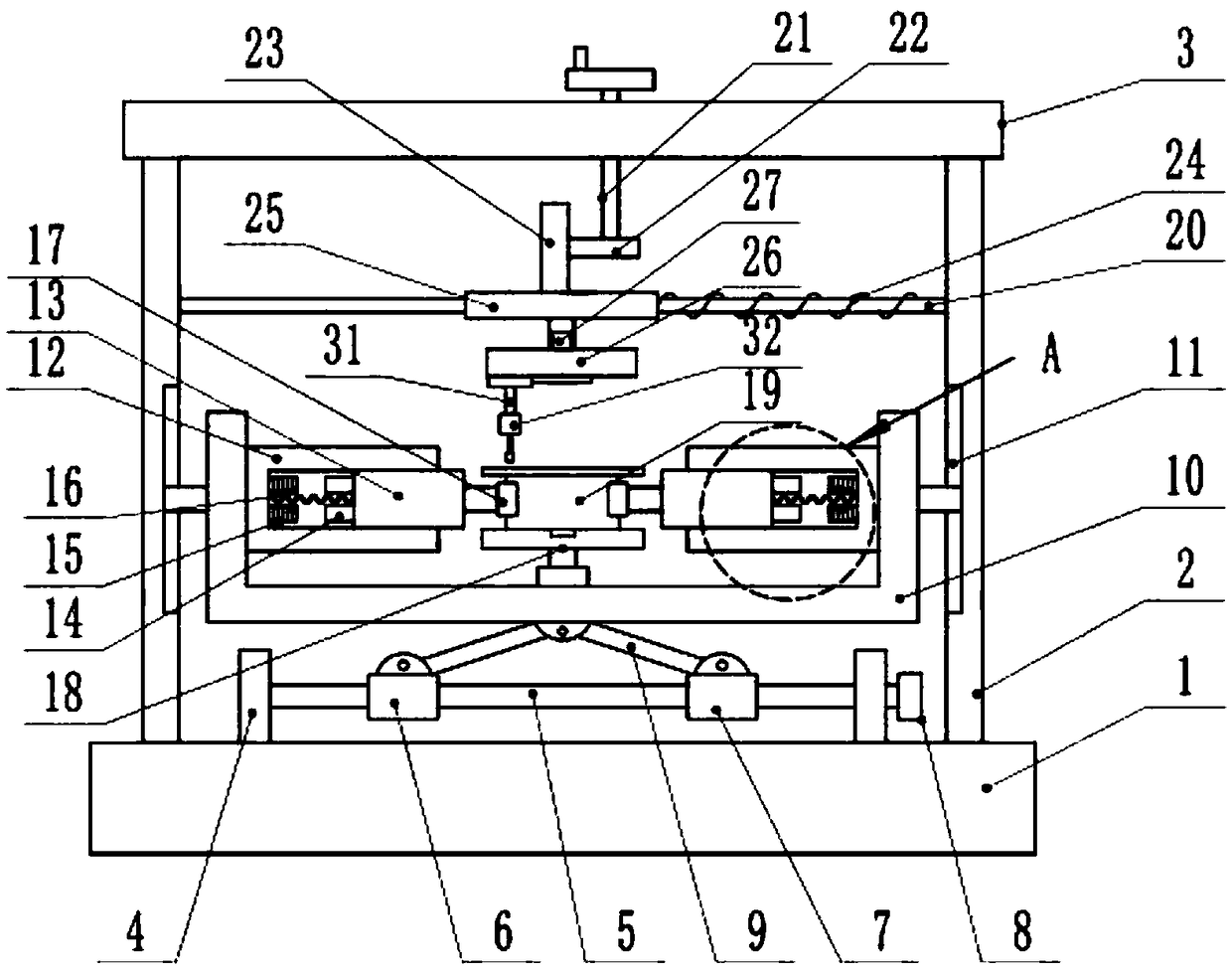

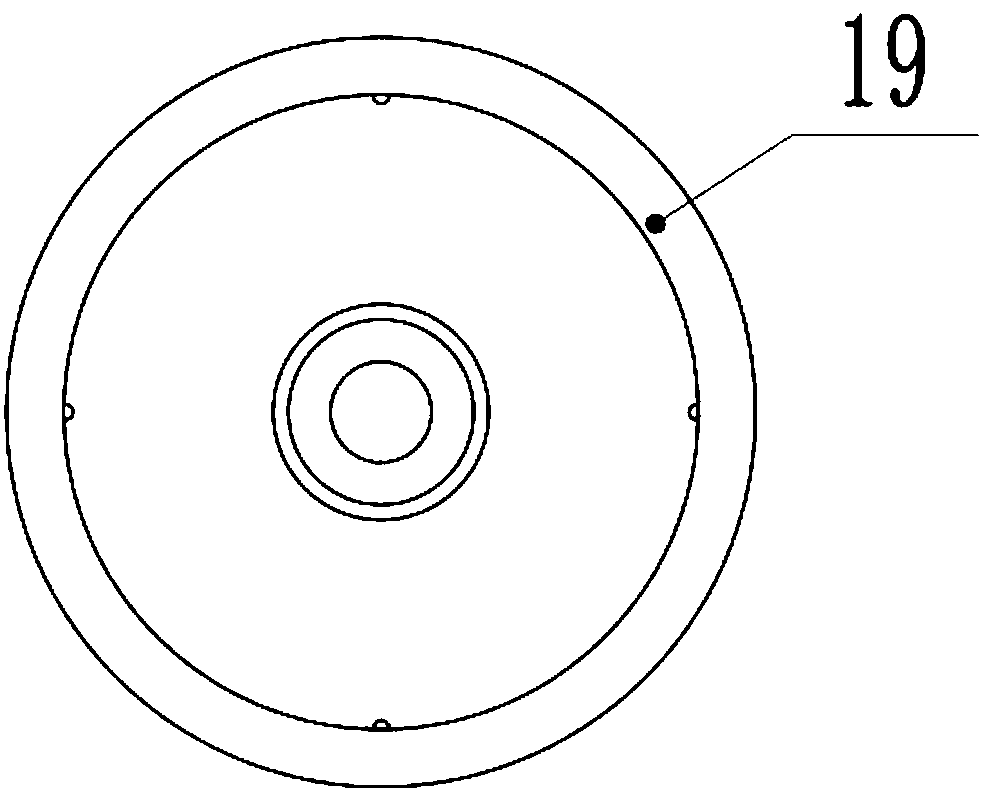

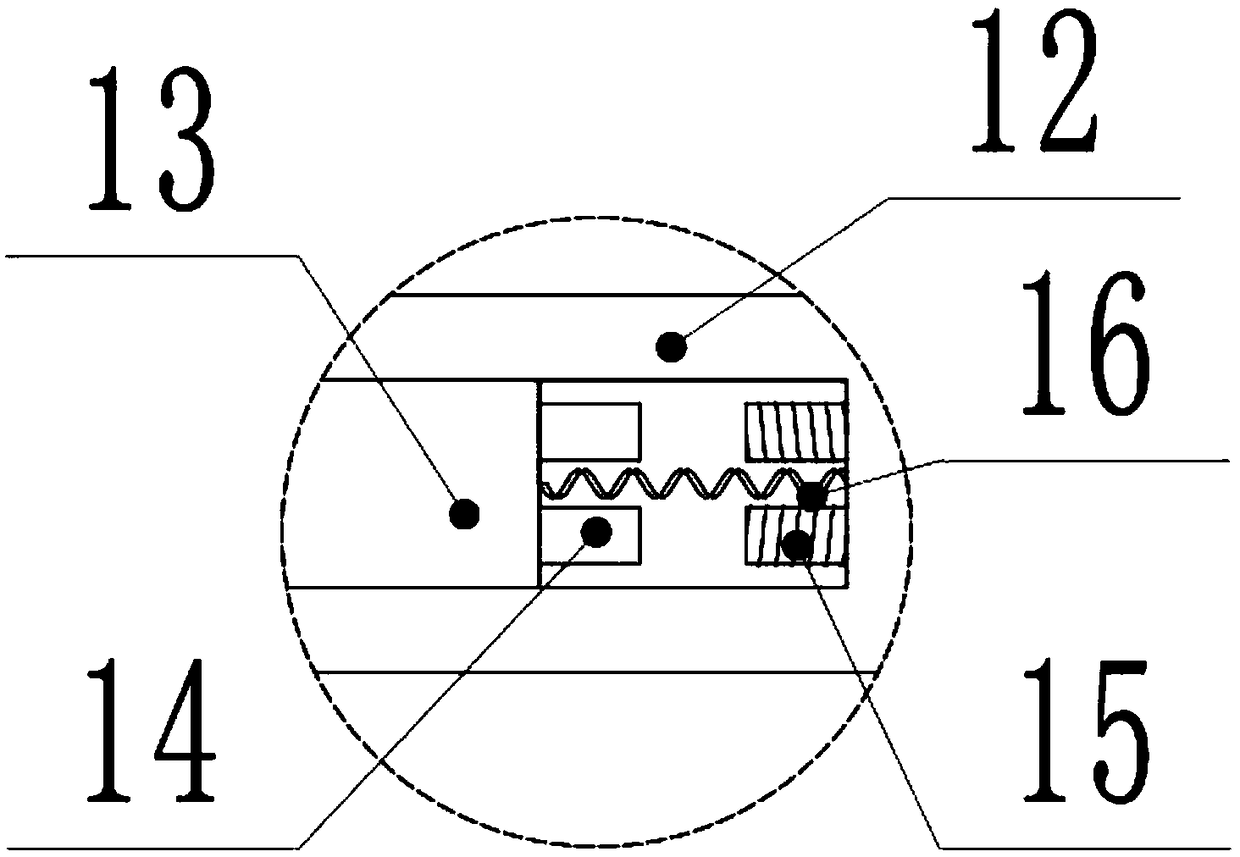

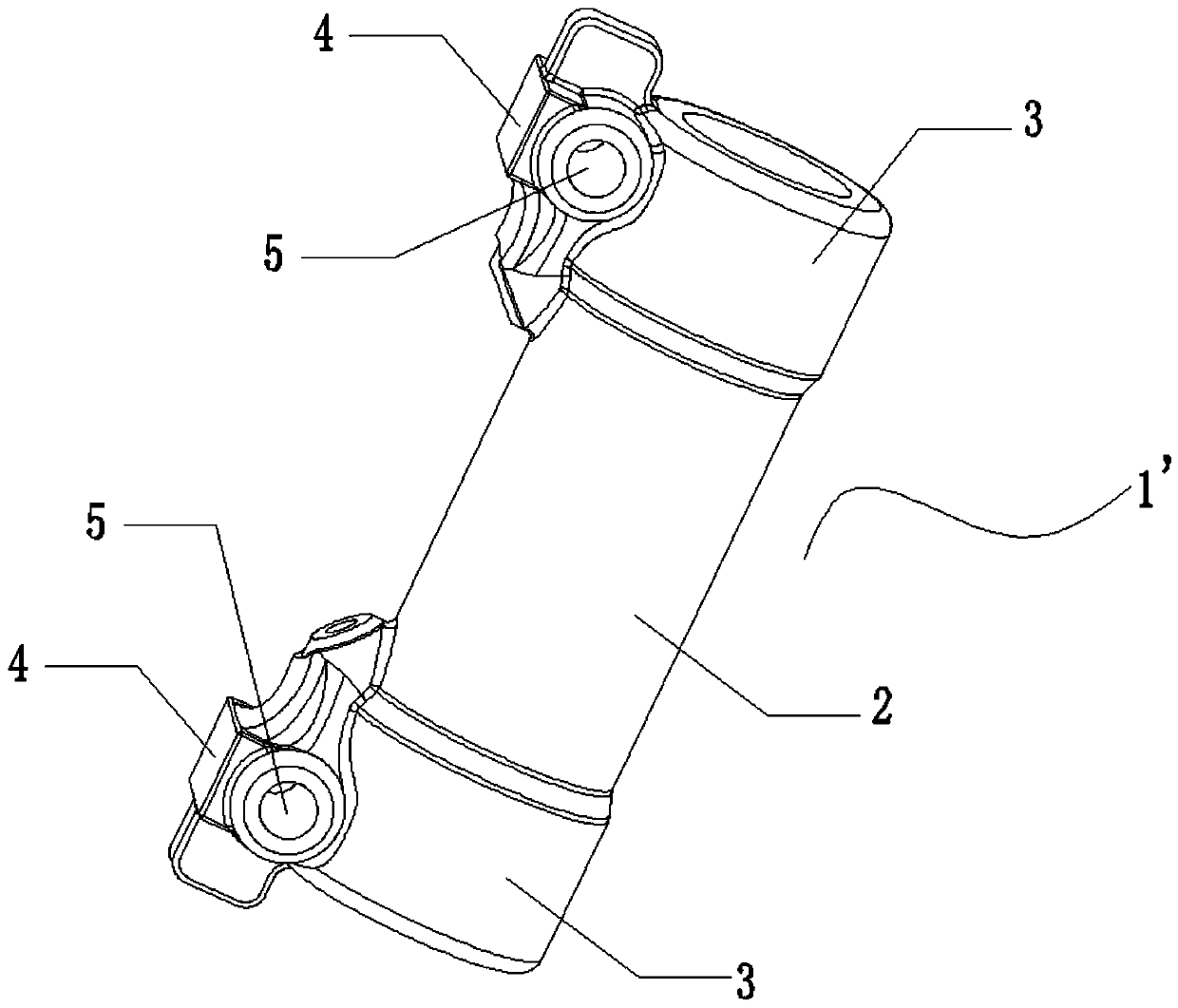

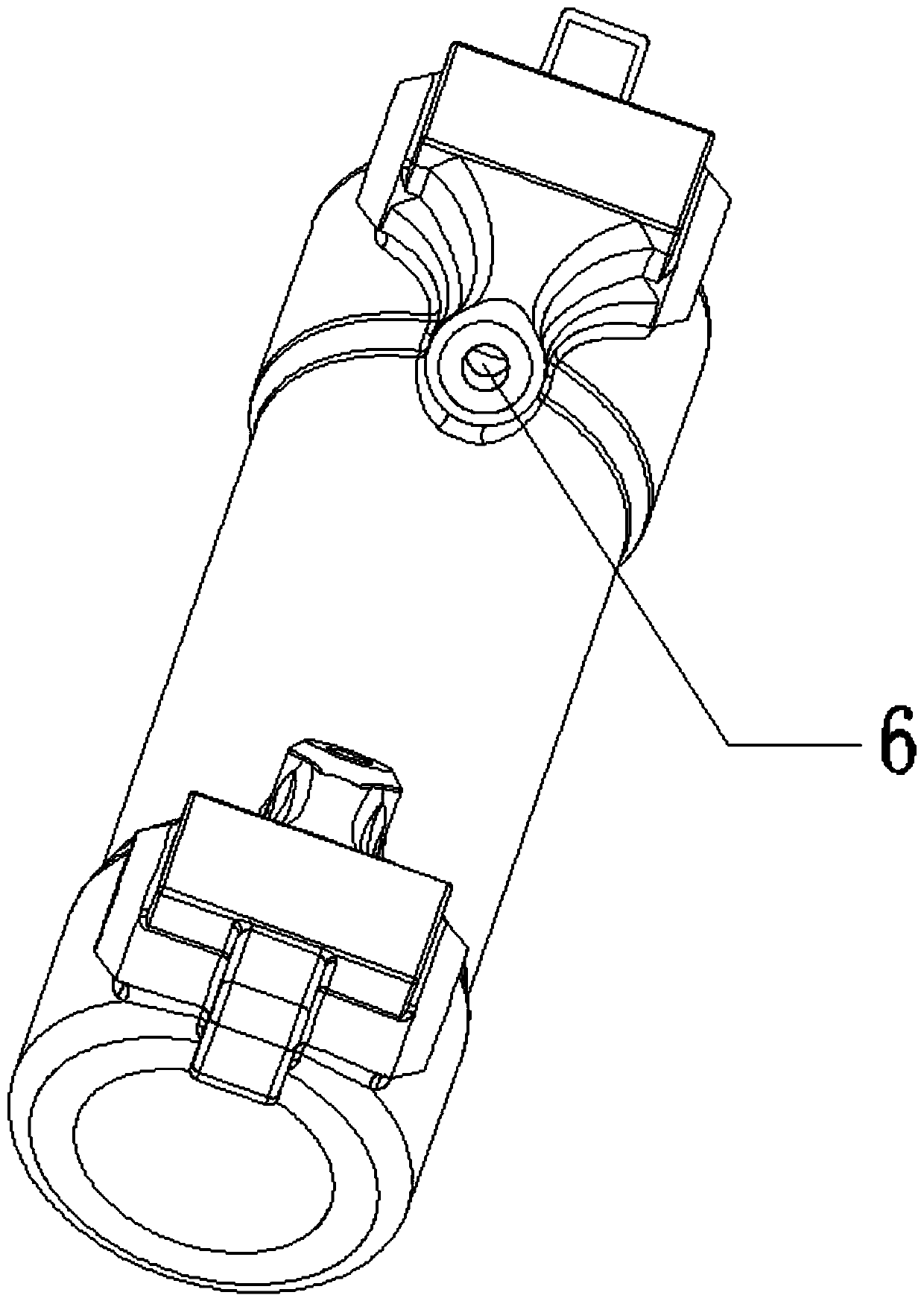

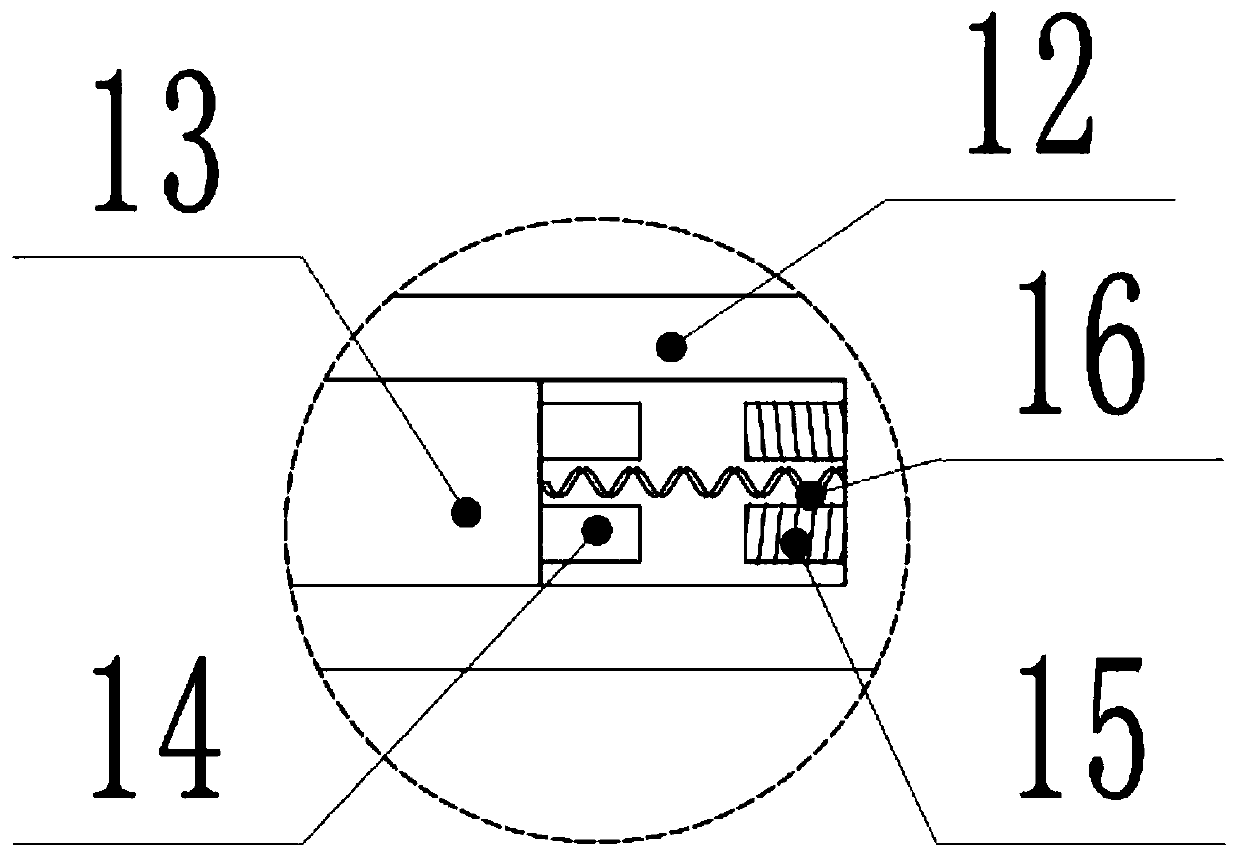

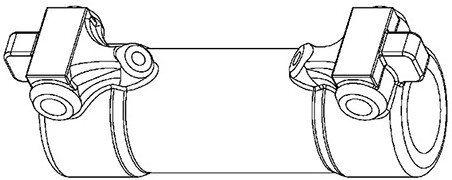

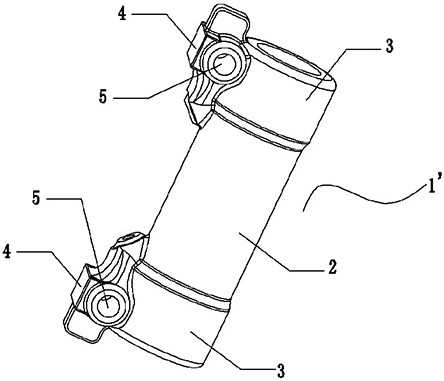

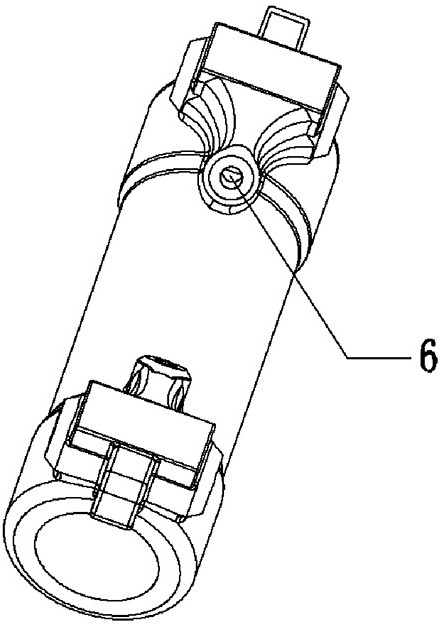

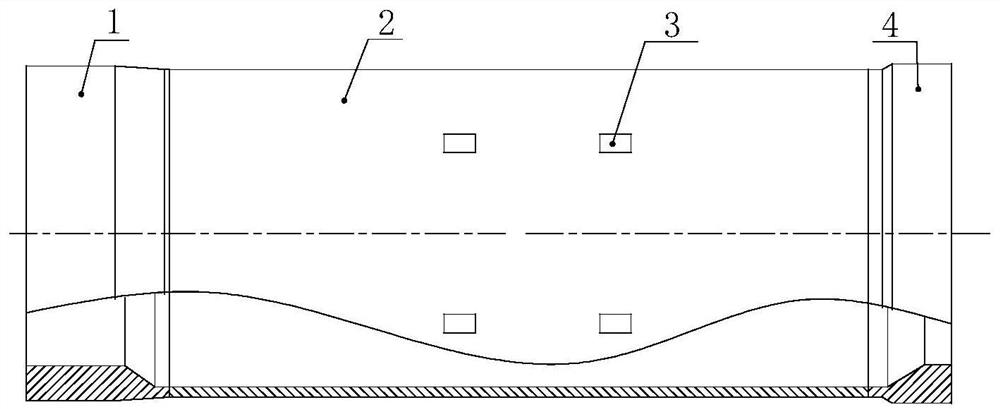

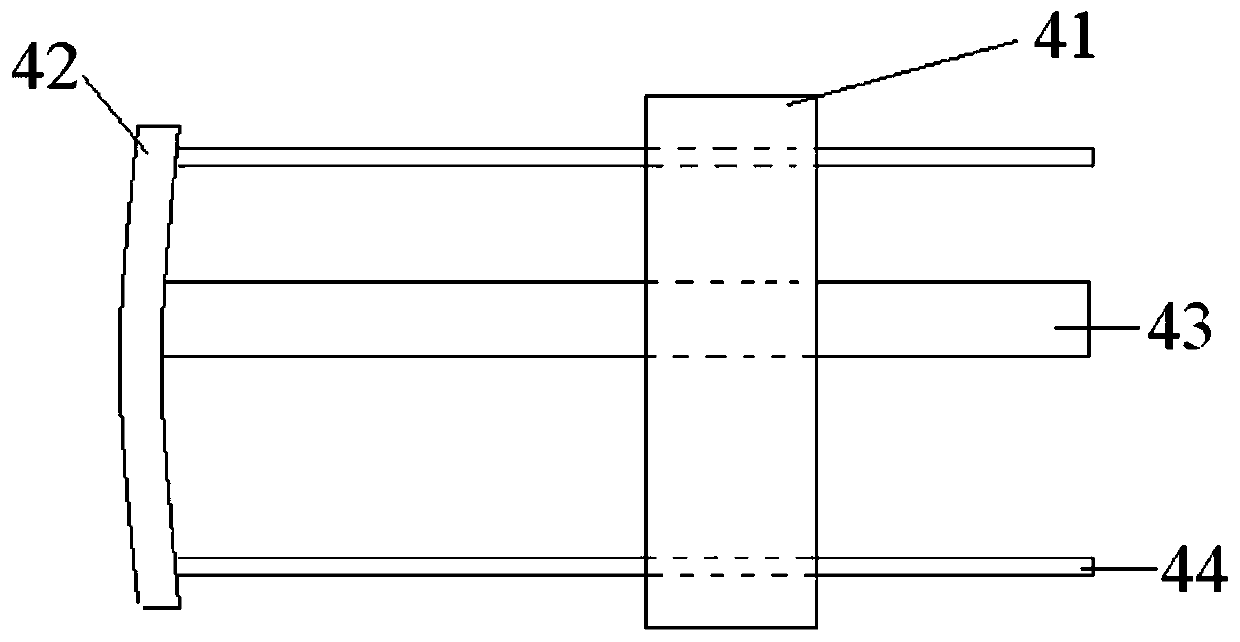

Extensible and retractable inner supporting tool

ActiveCN109366052ALarge stretchEasy accessWelding/cutting auxillary devicesAuxillary welding devicesEngineeringStress relief

The invention discloses an extensible and retractable inner supporting tool. One end of a left-handed screw is installed in a screw installation hole in the plane geometric center of a supporting plate, and the left-handed screw is in rotating fit with the screw installation hole. A left-hand thread at the other end of the left-handed screw is installed in a threaded hole in the center at one endof a sleeve. One end of a right-handed screw is installed in a screw installation hole in the plane geometric center of the other supporting plate, and the right-handed screw is in rotating fit with the screw installation hole. A right-hand thread at the other end of the right-handed screw is loaded in a threaded hole in the center at the other end of the sleeve. The extensible and retractable inner supporting tool has extending and retracting functions; in a shortened state, the extensible and retractable inner supporting tool can be put into a shell and then extends to support a cylinder, rigid restraining to the cylinder is achieved, and the welding deformation is reduced; and by means of stress relief annealing heat treatment through the belt tool, deformation stress is eliminated, andtherefore the cylinder circular degree after welding is guaranteed, and the circular degree of the shell is reduced to 2.5 mm from 10 mm.

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

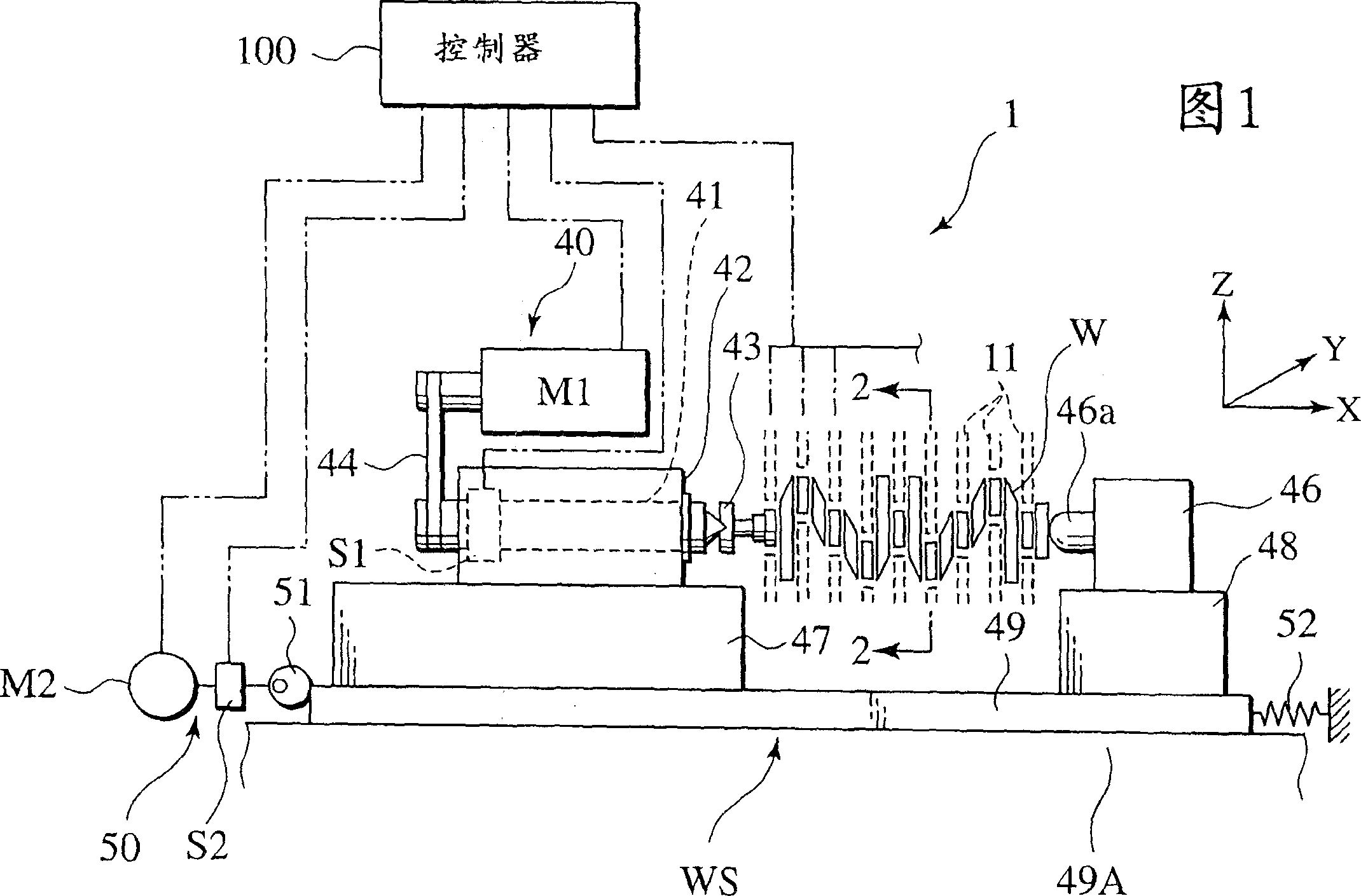

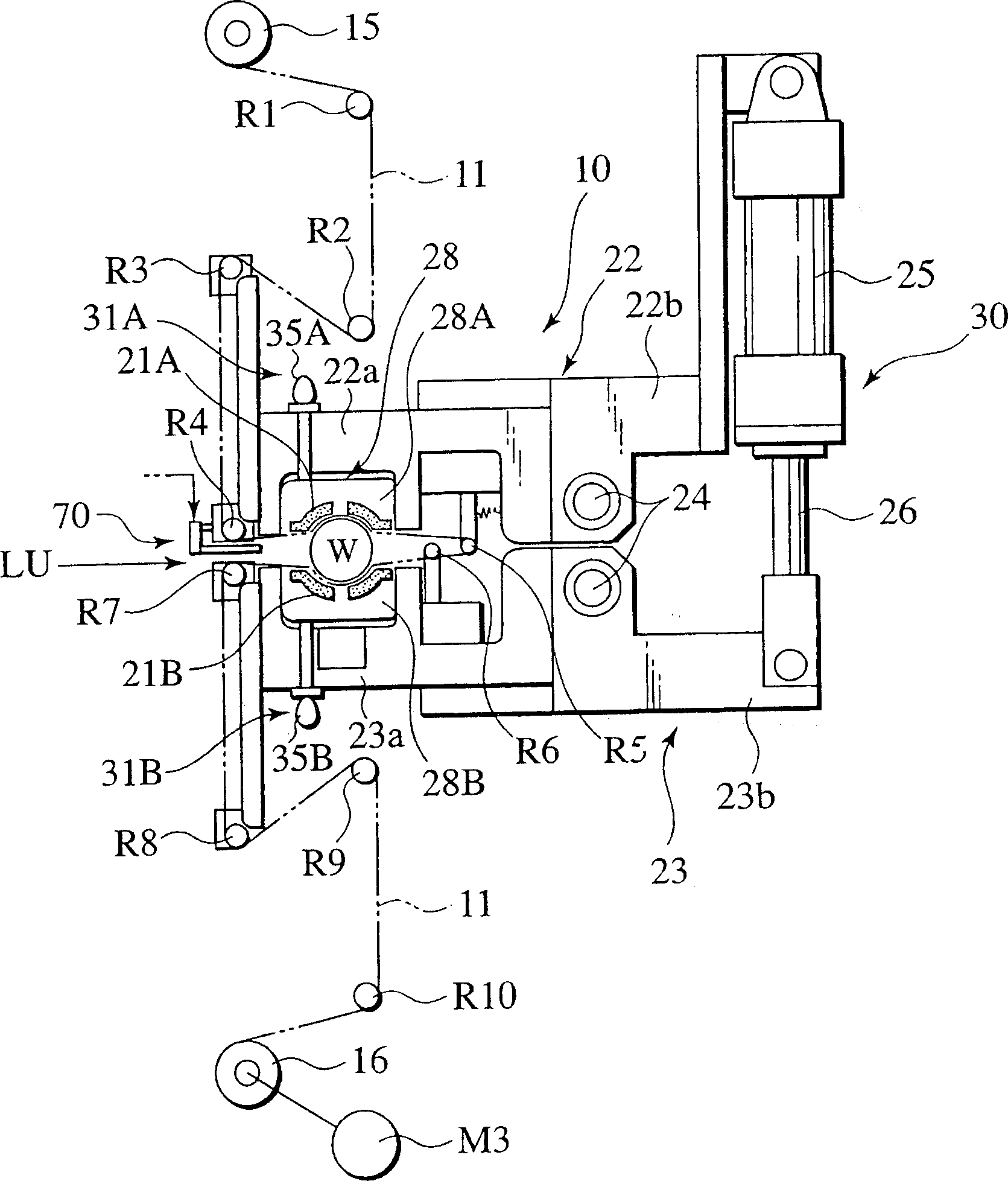

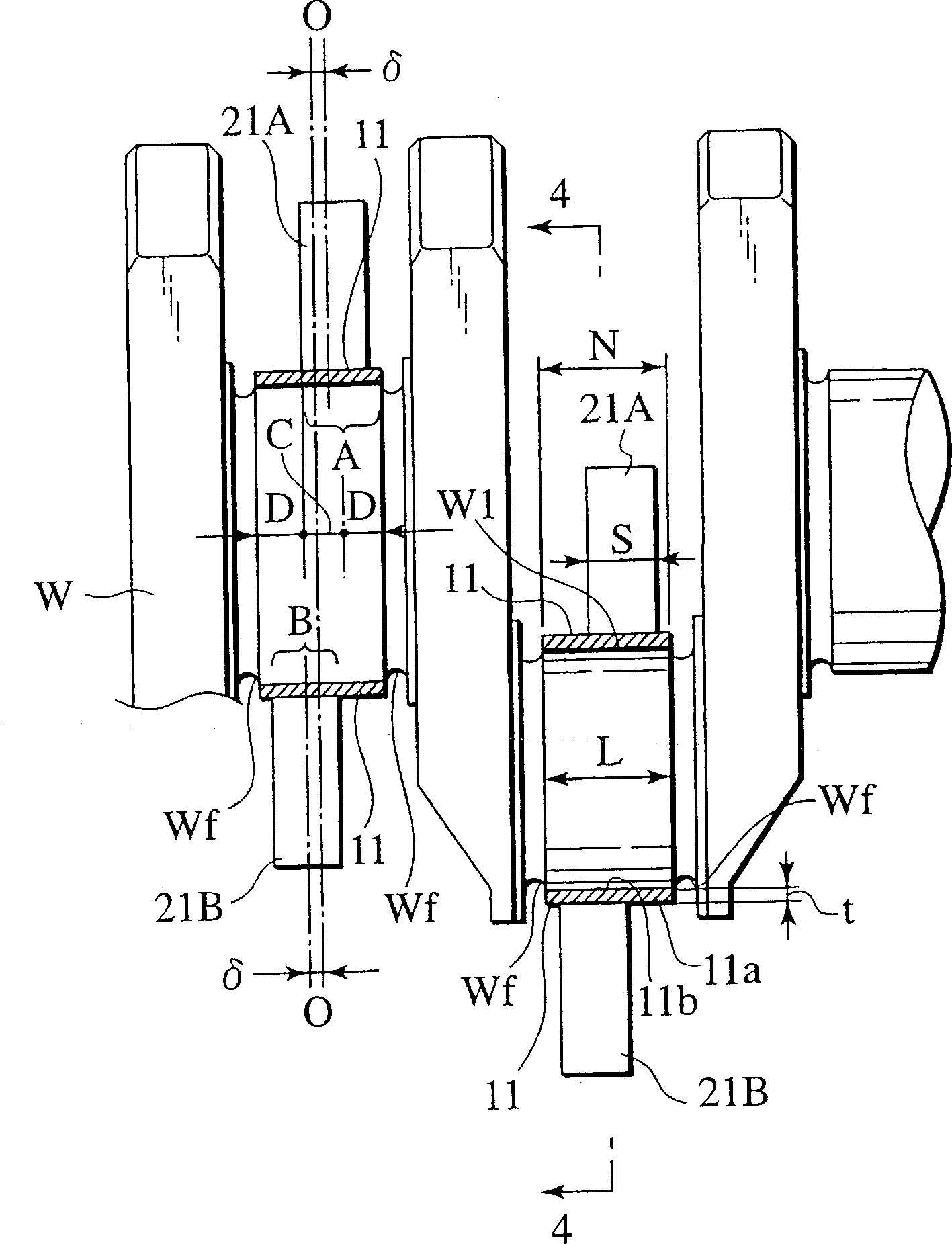

Surface finishing apparatus and related method

InactiveCN1520962AHigh strengthLow roundnessRevolution surface grinding machinesBelt grinding machinesSurface finishDistribution pattern

An apparatus and method for surface finishing a workpiece is disclosed as including a workpiece supporting mechanism supporting a workpiece having a target shaped periphery with a given width to be surface finished and a tool holder holding a surface finish tool in abutting contact with the target shaped periphery of the workpiece. A pressure applying mechanism is operative to apply a pressure force to the surface finish tool through the tool holder to cause the surface finish tool to be held in pressured contact with the target shaped periphery, with the pressure force exhibiting a given distribution pattern depending upon an axial direction of the workpiece. A drive mechanism rotates the workpiece to allow the surface finish tool to surface finish the target shaped periphery into a given geometrical profile, variably contoured along an axis of the workpiece depending on the given pressure distribution pattern.

Owner:NISSAN MOTOR CO LTD

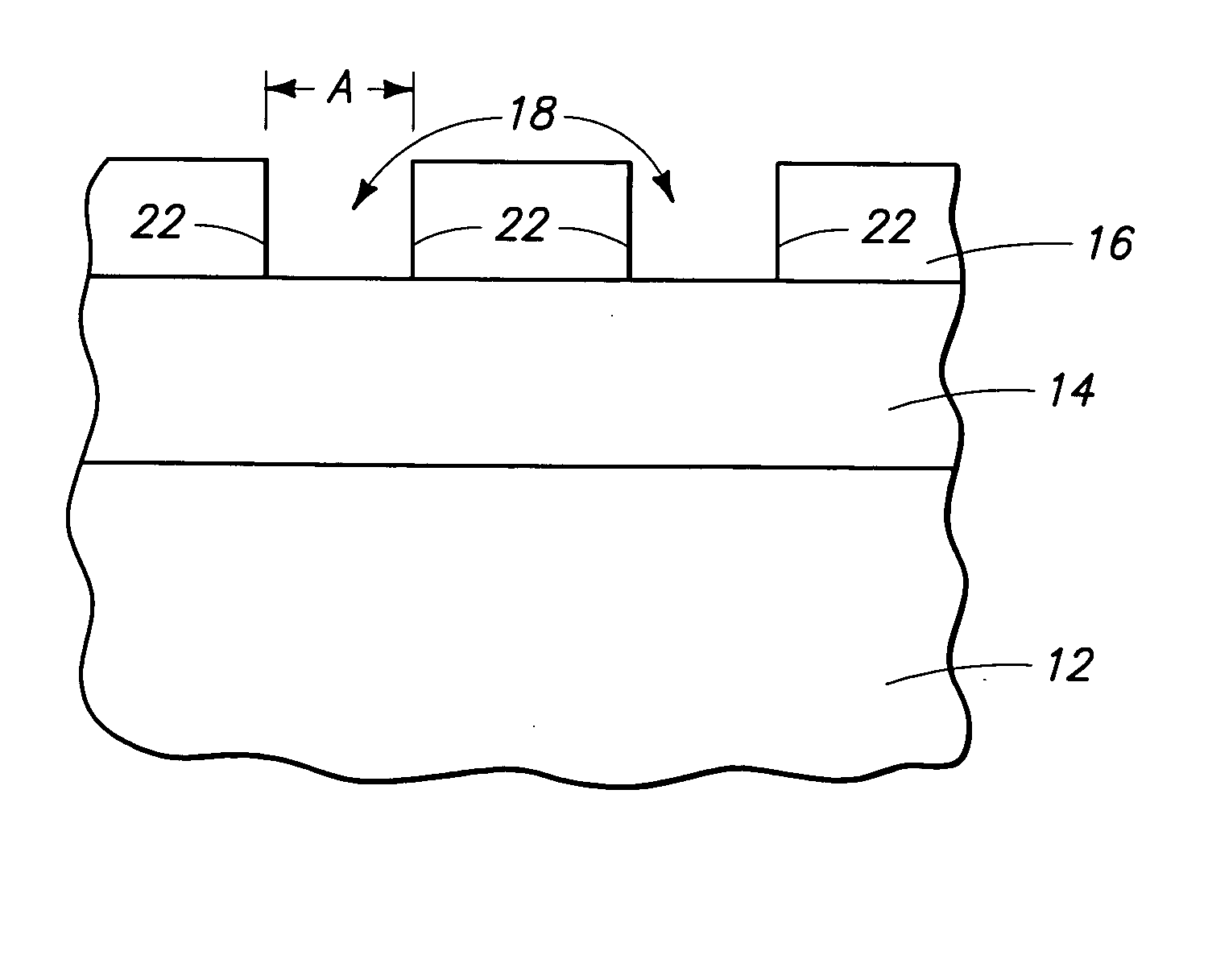

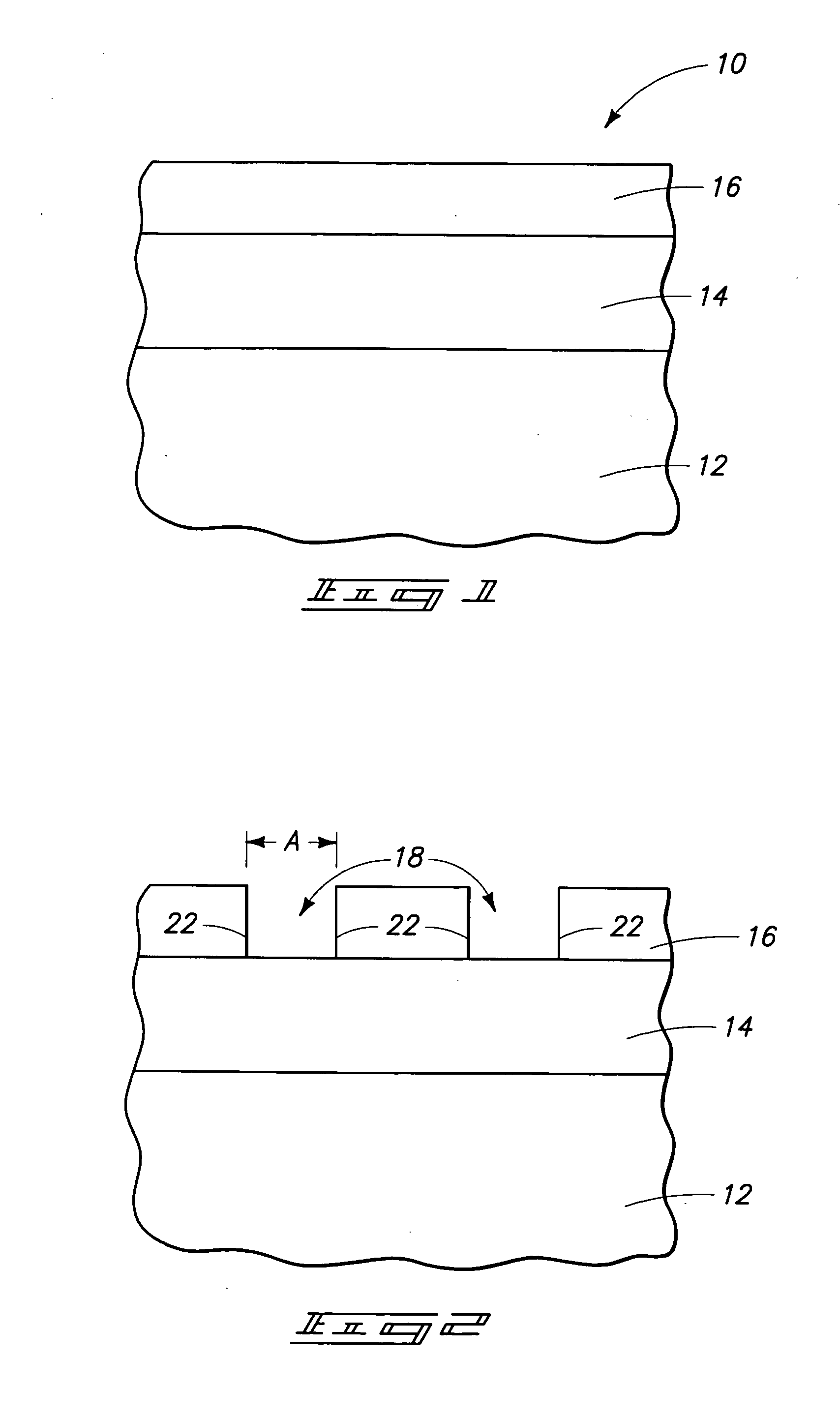

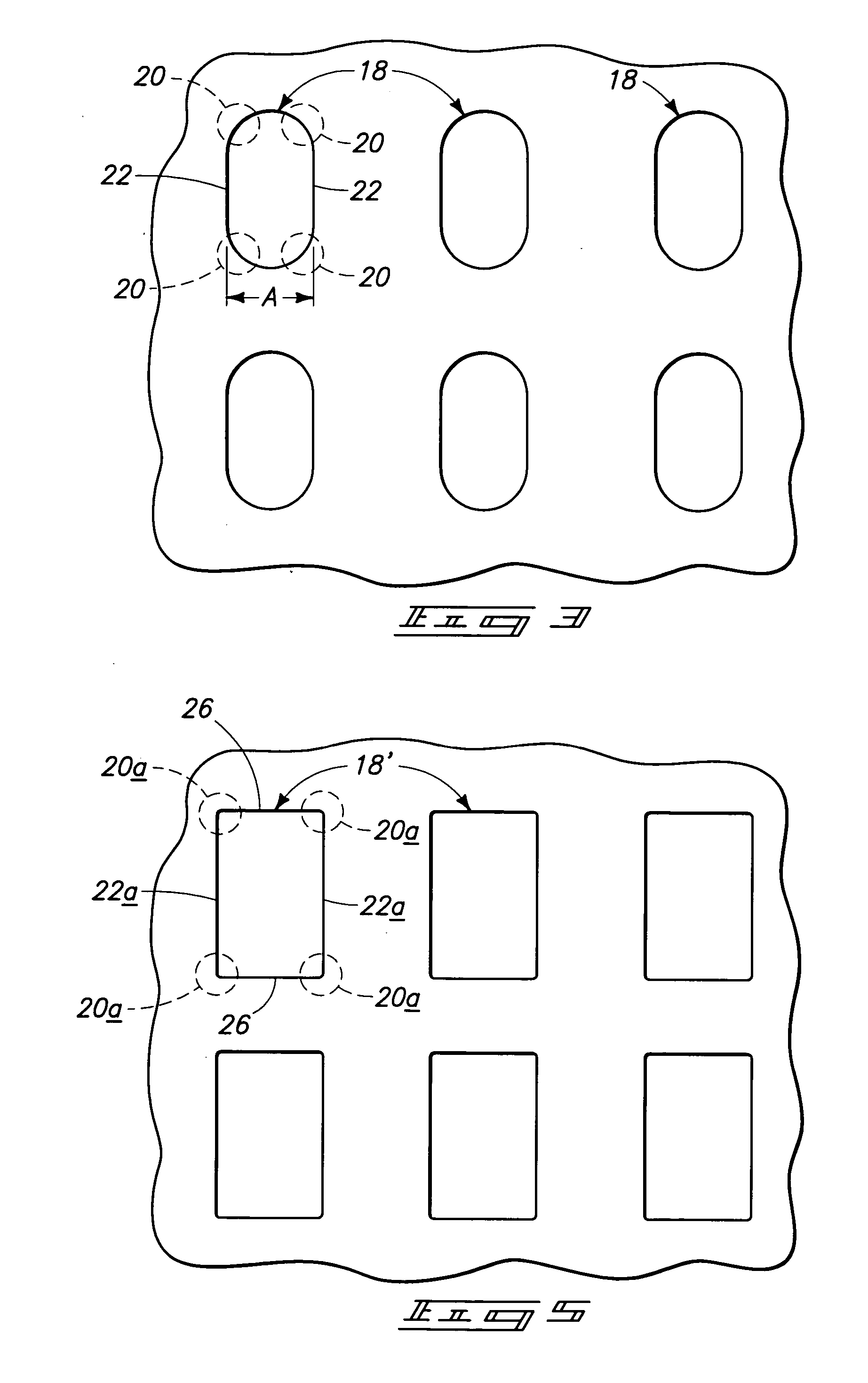

Methods of forming a capacitors -

InactiveUS20060024904A1Low roundnessIncrease the number ofSolid-state devicesSemiconductor/solid-state device manufacturingEngineering physicsCapacitor

A carbon containing masking layer is patterned to include a plurality of container openings therein having minimum feature dimensions of less than or equal to 0.20 micron. The container openings respectively have at least three peripheral corner areas which are each rounded. The container forming layer is plasma etched through the masking layer openings. In one implementation, such plasma etching uses conditions effective to both a) etch the masking layer to modify shape of the masking layer openings by at least reducing degree of roundness of the at least three corners in the masking layer, and b) form container openings in the container forming layer of the modified shapes. Capacitors comprising container shapes are formed using the container openings in the container forming layer. Other implementations and aspects are disclosed.

Owner:MICRON TECH INC

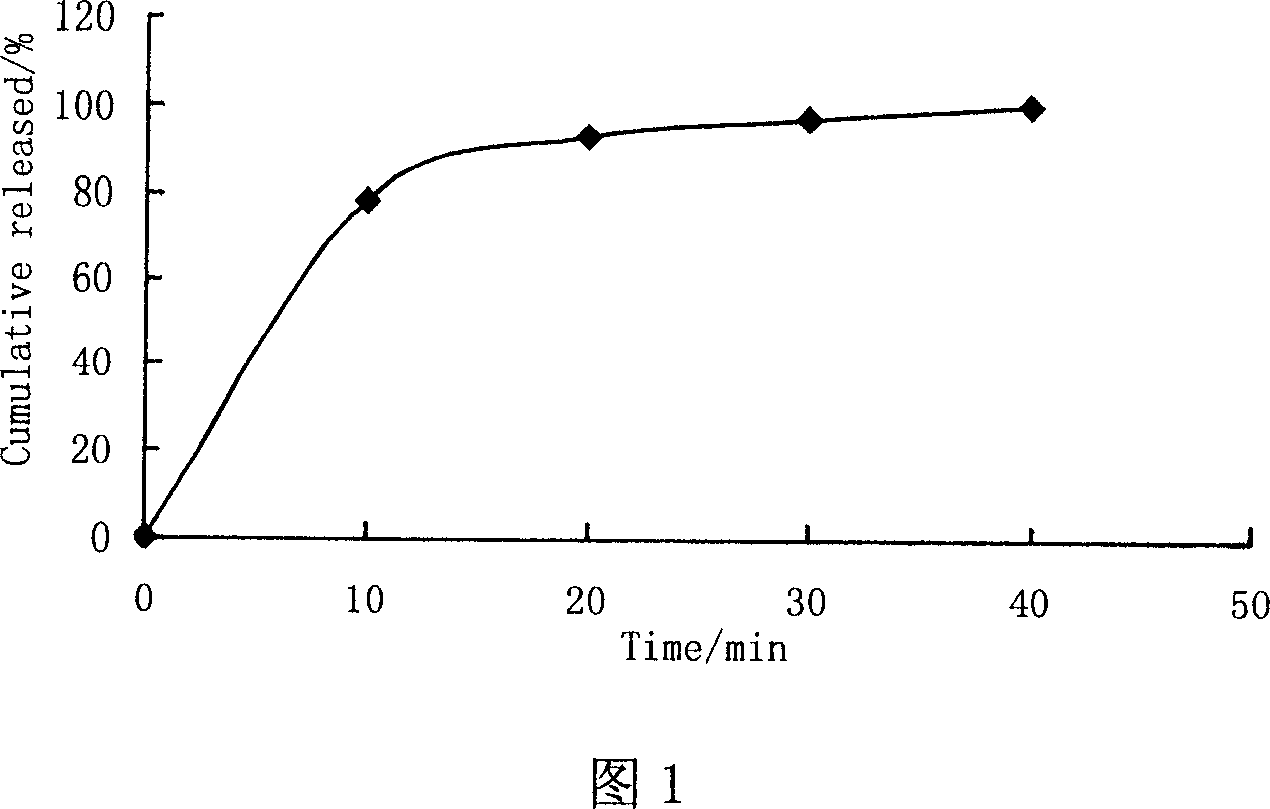

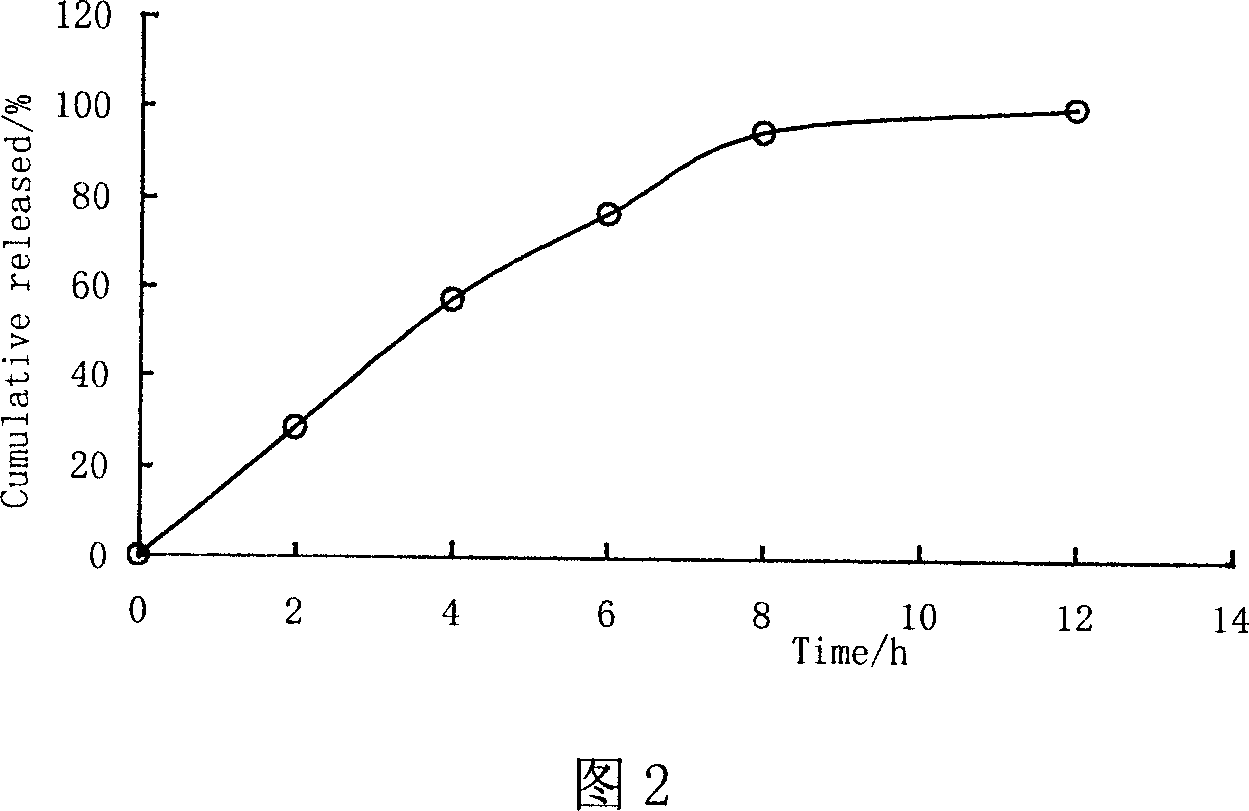

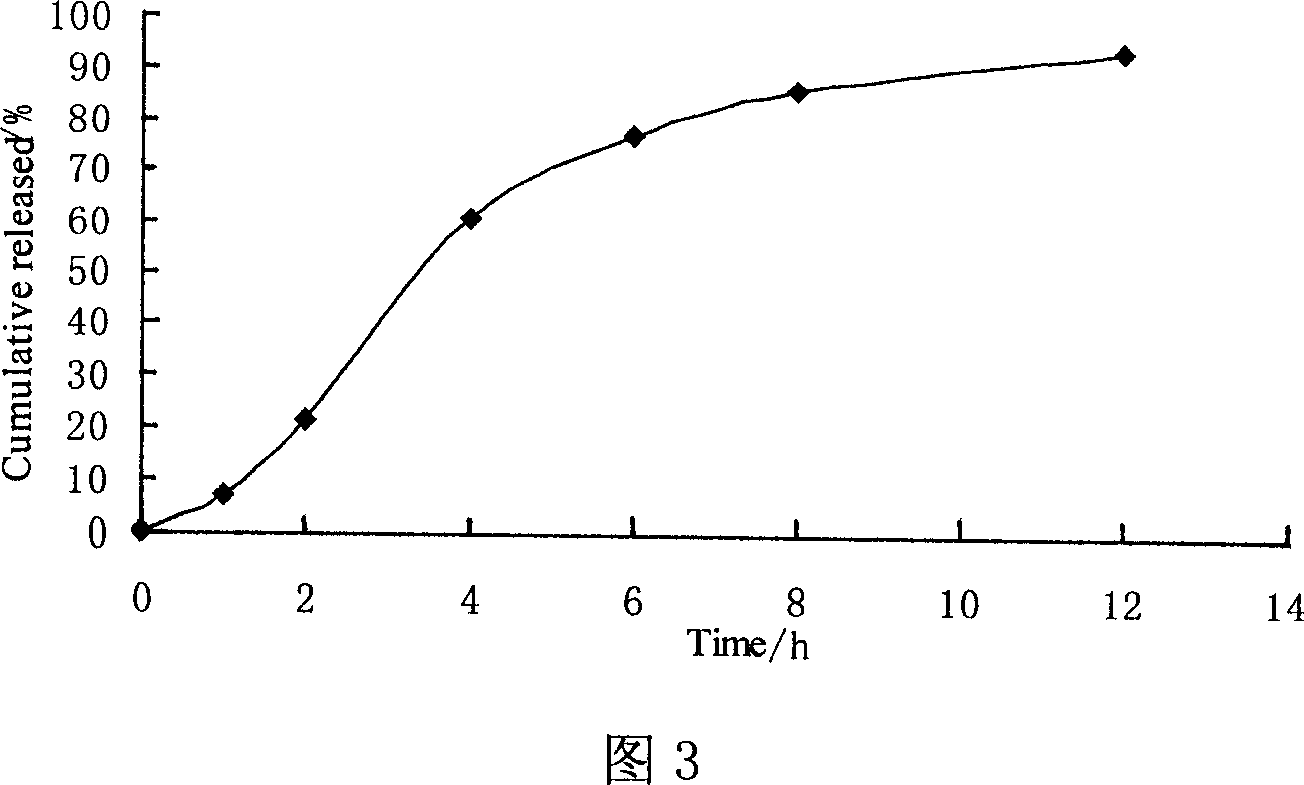

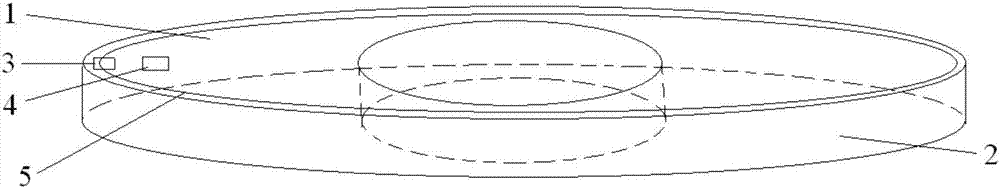

Slow-releasing micro-pills of sophocarpidine and its preparing method

InactiveCN101045053AImprove liquidityImprove stabilityOrganic active ingredientsDigestive systemSophocarpidineFluidized Bed Coating Method

Owner:SHANDONG INST OF PHARMA IND

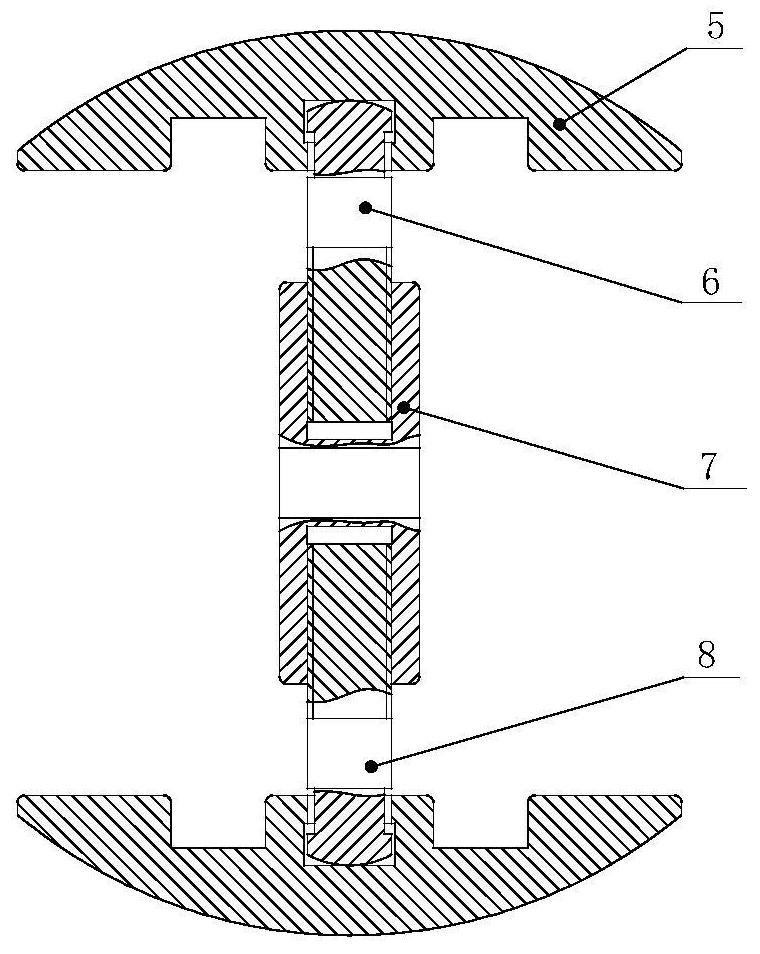

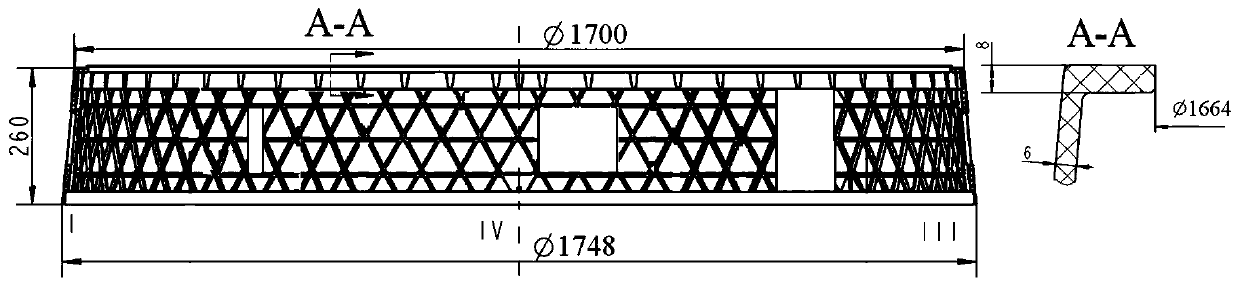

Tool and method for correcting shape of composite cabin section

The invention relates to a tool and method for correcting the shape of a composite cabin section and belongs to the technical field of composite component curing deformation. In the method, the shape of the composite cabin section is corrected by using the tool at set temperature so as to reduce the problems that the deformation of a composite component causes product scrap, or too-concentrated stress on the following processing and assembly and the like.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

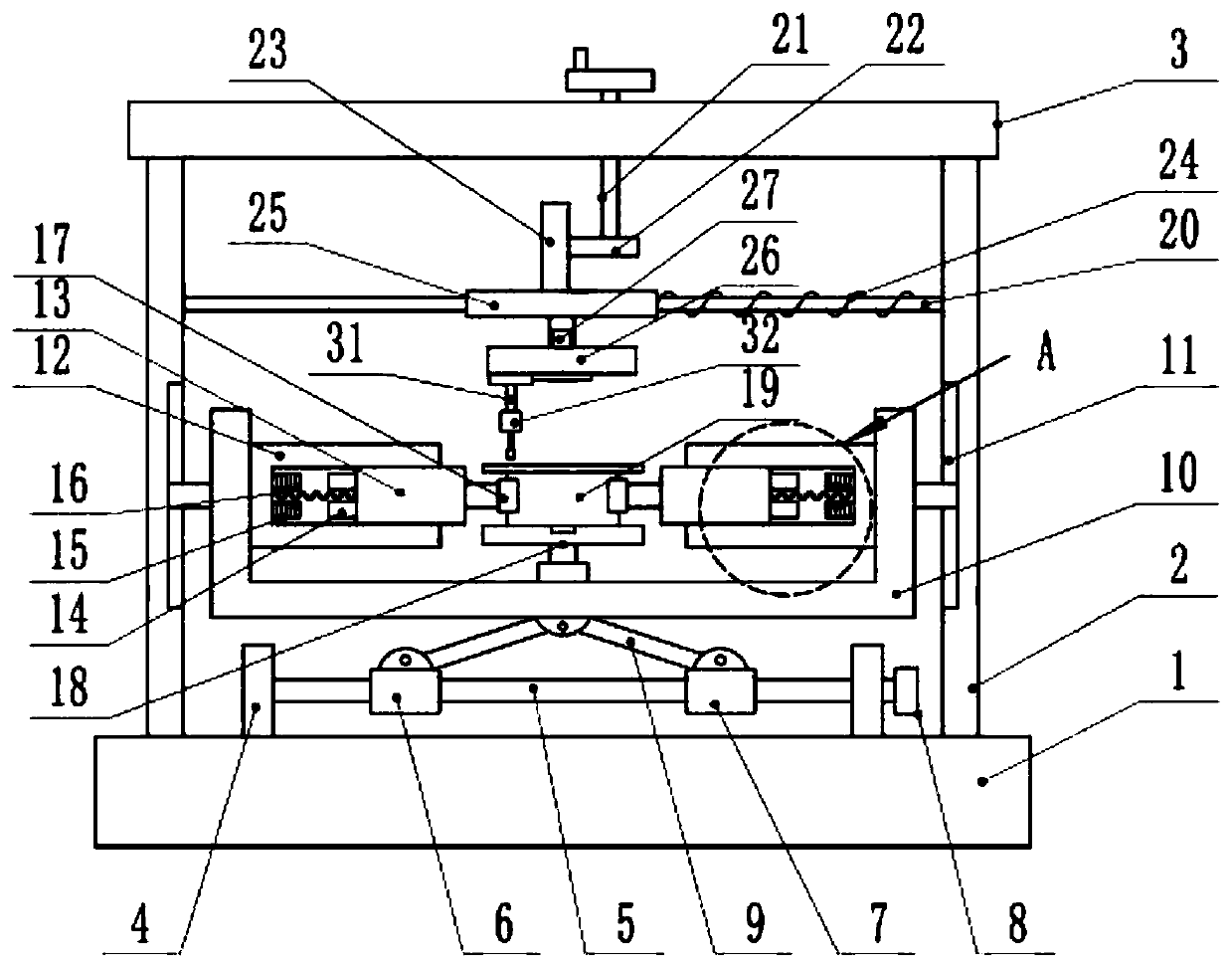

Grinding and removing device for spigot of adjustable galvanized plate end cover

ActiveCN108161653AImprove versatilityLower acquisition costsGrinding machinesGrinding work supportsInterference fitEngineering

The invention discloses a grinding and removing device for a spigot of an adjustable galvanized plate end cover. The grinding and removing device comprises a base, clamping devices, an inner gear disc, a rotating motor and a grinding device, wherein the clamping devices are arranged on the left side and the right side of the inside of a lifting table, the inner gear disc is fixedly welded to the lower side of a sliding strip through a connecting rod, a connecting shaft is arranged at the center wheel core of a second gear in an interference fit mode, and a grinding device is arranged at the lower end of the connecting shaft. According to the grinding device, the end covers with different diameters can be clamped, so that the universality of the device is greatly improved, and the purchasing cost of equipment is saved; a grinding head on the grinding device is driven to carry out planetary rotation, and the spigot in the end cover is ground, so that compared with manual grinding, the grinding speed of the grinding and removing device is higher; the intensity of grinding each spigot can be the same, the degree of roundness of the end cover caused by different grinding strength is avoided, and the single-machine noise of a motor during final assembly is guaranteed.

Owner:NANTONG XINXIANG ZINC IND

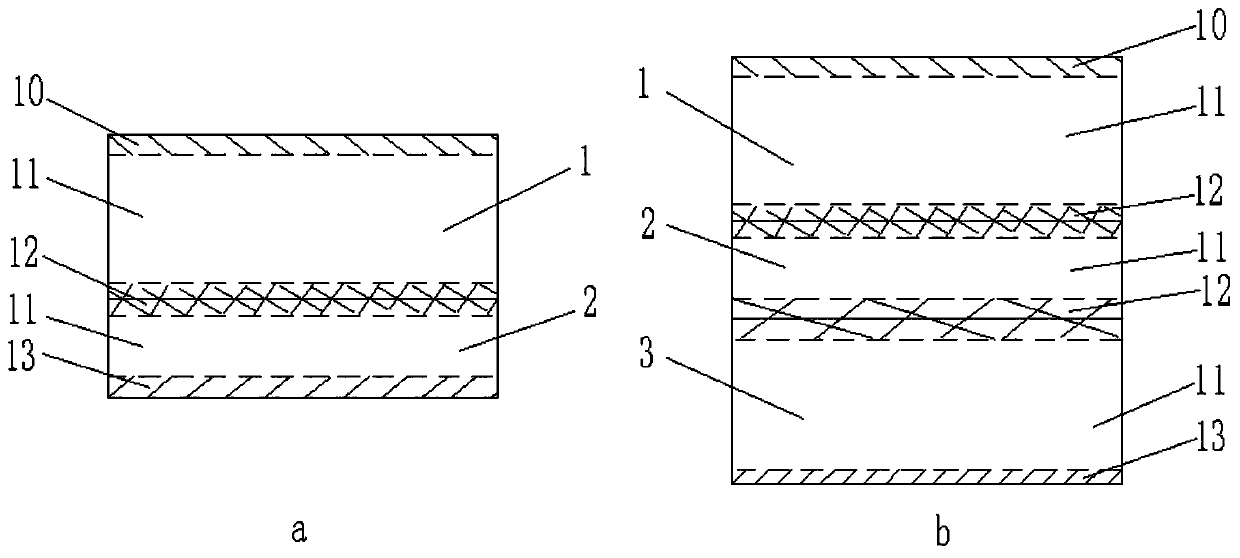

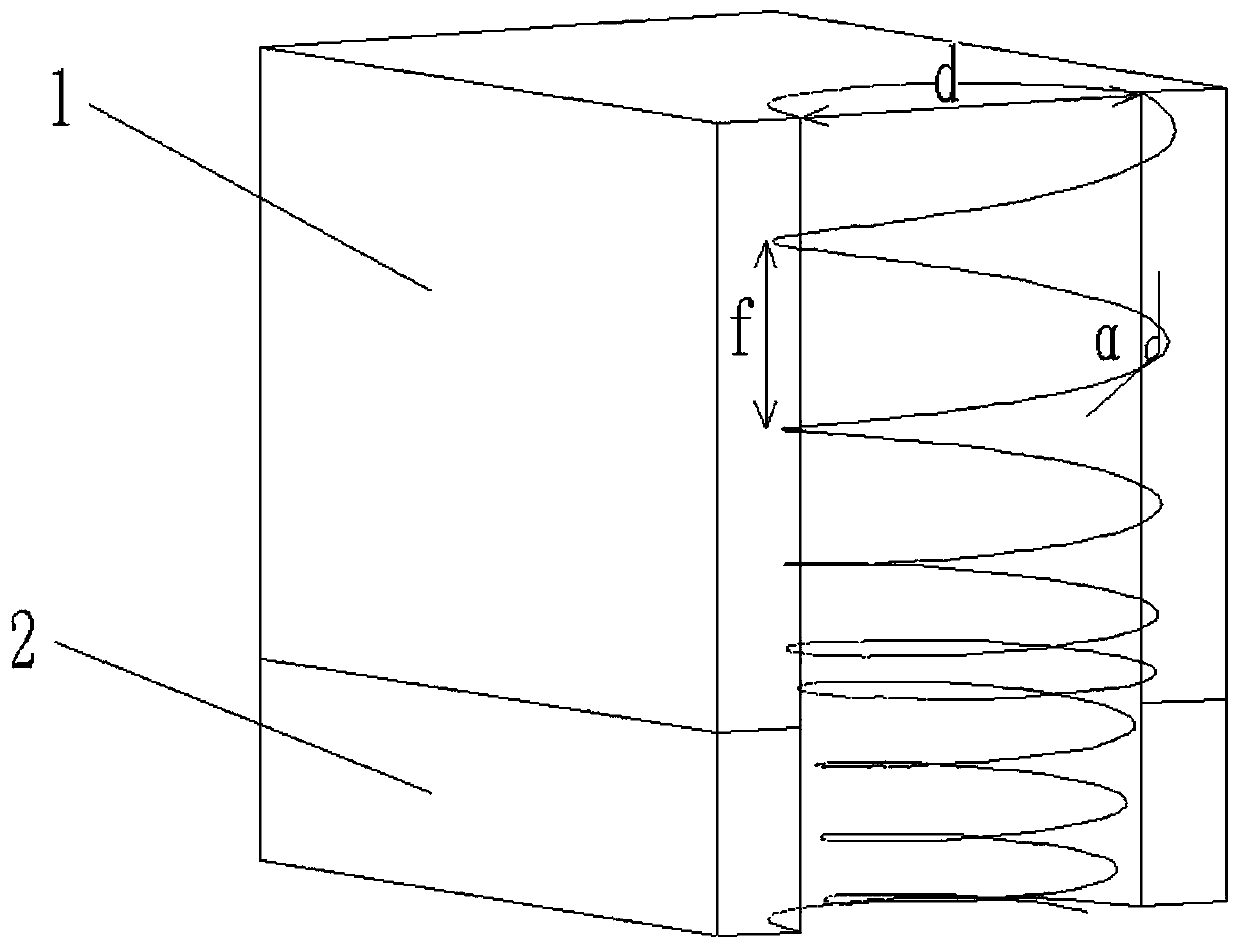

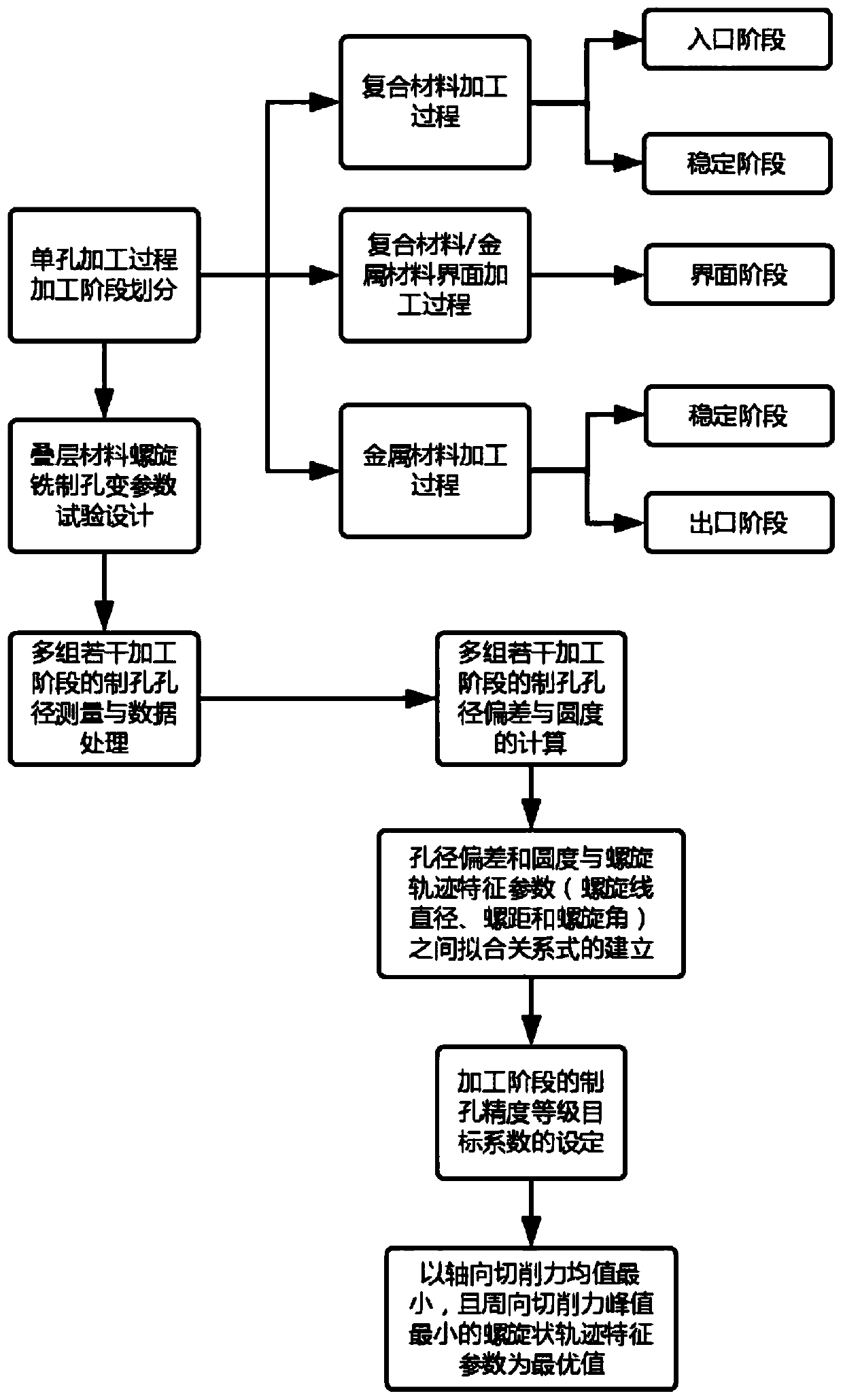

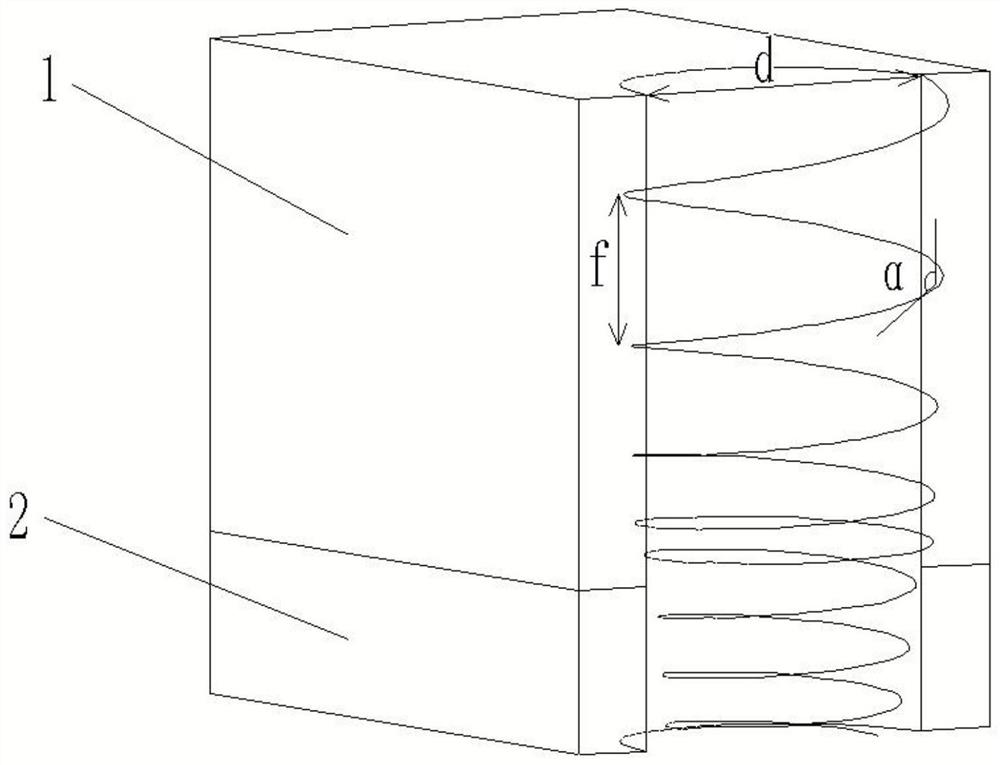

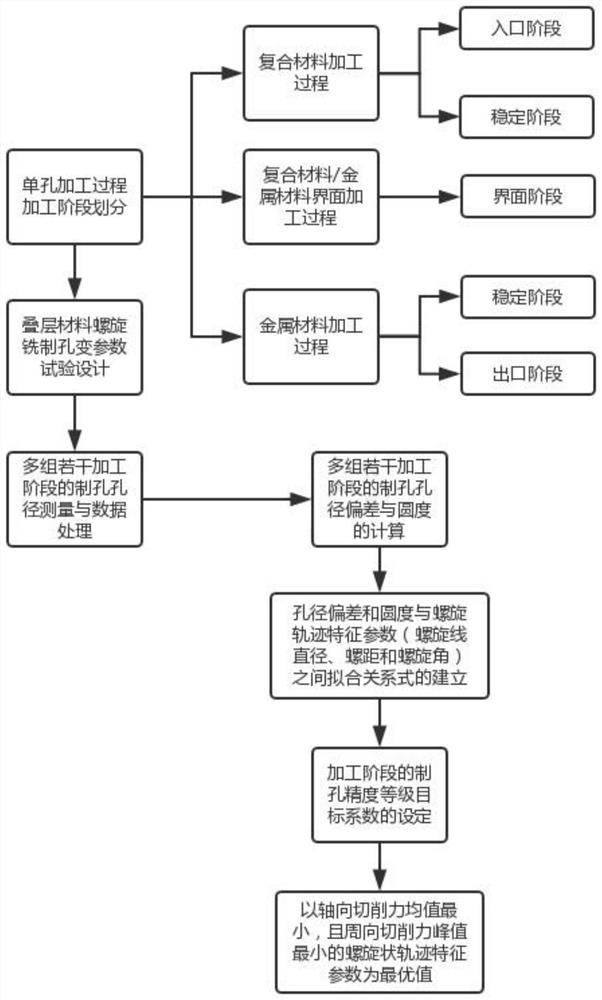

Laminated material hole-making machining track planning method

ActiveCN111390253AAvoid processing defectsImprove processing qualityMilling equipment detailsCutting forceMachining process

The invention discloses a laminated material hole-making machining track planning method. The method comprises the following steps of 1) dividing a laminated material machining process into an inlet machining stage, a stabilizing machining stage, an interface machining stage, an outlet machining stage and the like in the axial direction; 2) measuring and arranging hole-making precision data; 3) analyzing a change rule of the hole-making precision at each stage, and establishing a fitting relational expression among the aperture deviation, the roundness and the spiral track characteristic parameter; and 4) taking the minimum axial cutting force mean value and the minimum circumferential cutting force peak value as targets to obtain the optimal value of the spiral track characteristic parameter. According to the method, a way is provided for solving the problem that machining of a laminated material through hole is in an ''inverted-cone shape'', spiral motion track planning is carried out by analyzing the hole-making precision change rule of the key stage in the single-hole machining process and taking the requirement for the precision grade of the outlet stage as the core target, finally technological parameter optimization is achieved, in this way, the overall hole-making precision in the single-hole machining process can be improved, the overall cutting force level can be lowered, and the service life of a tool is prolonged.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

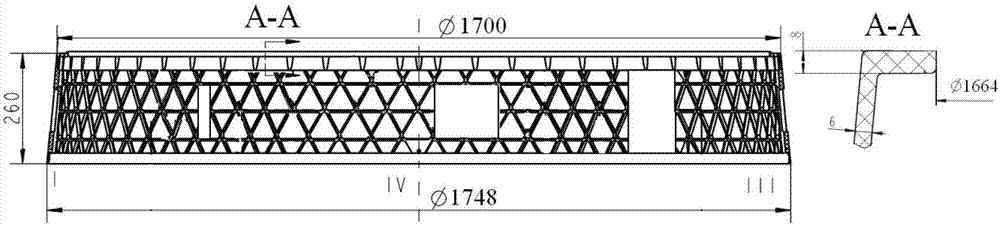

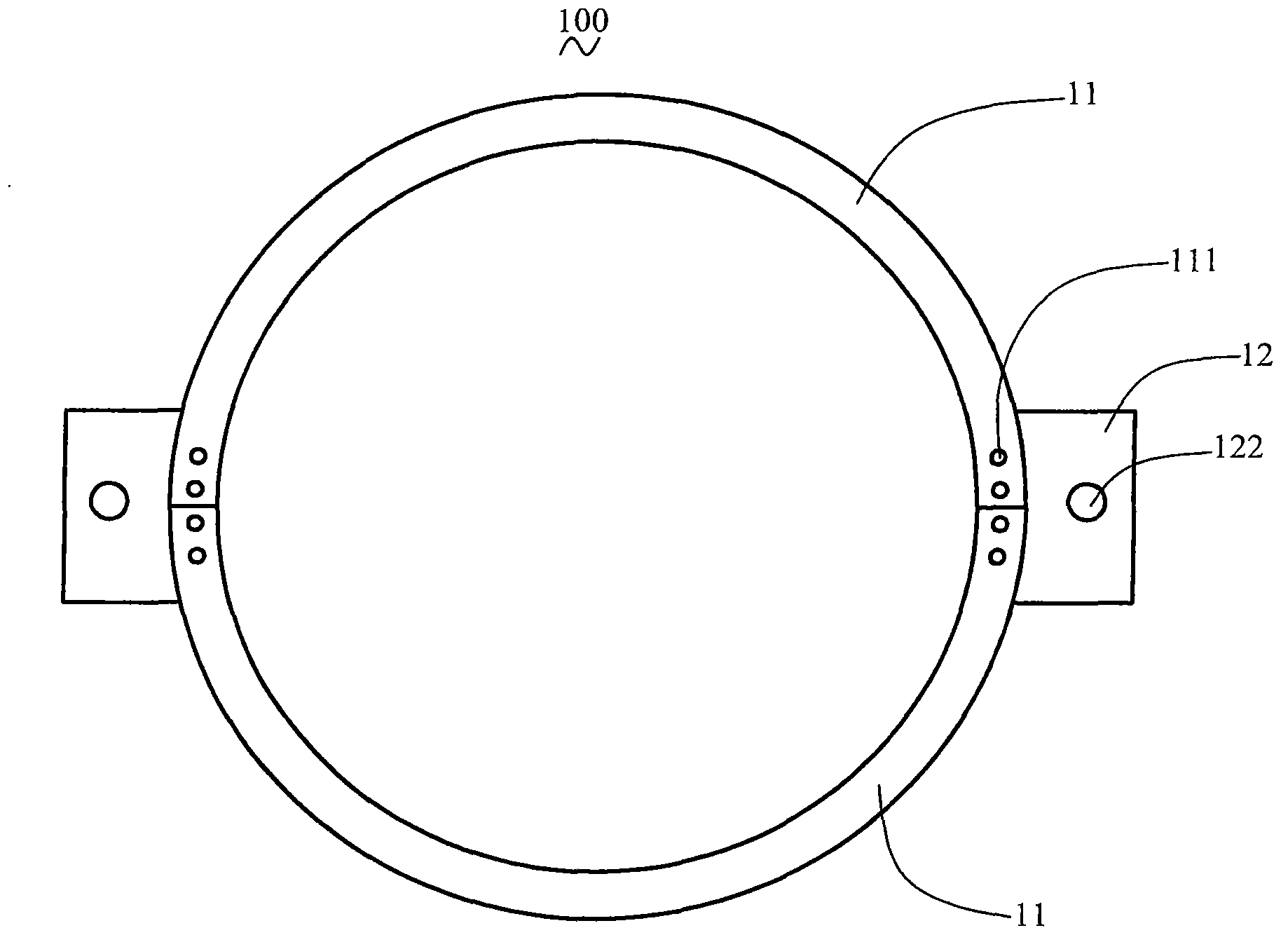

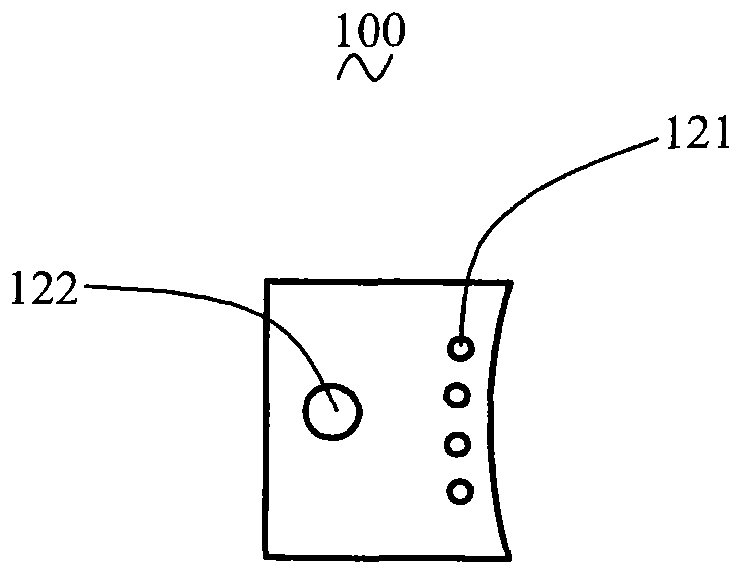

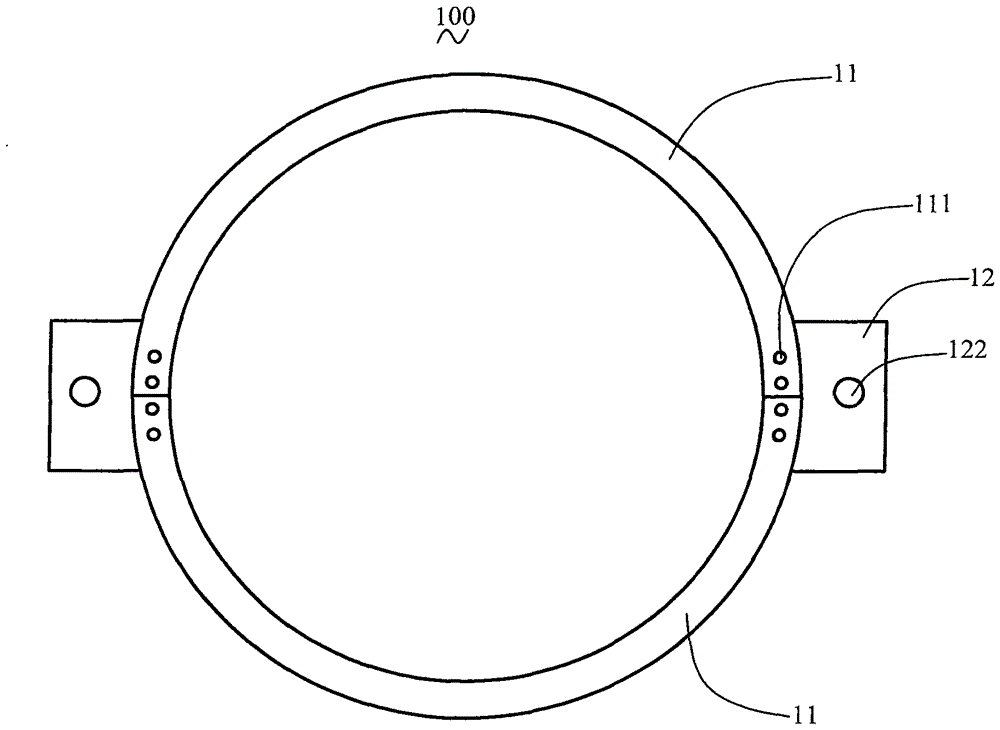

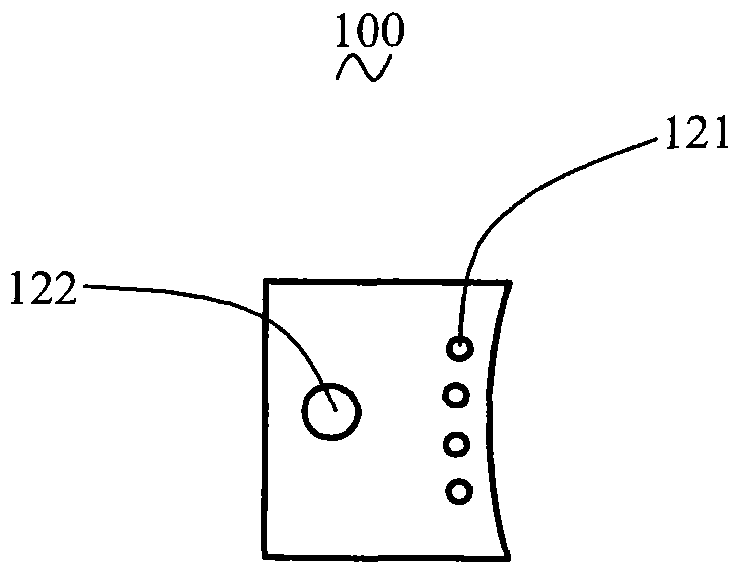

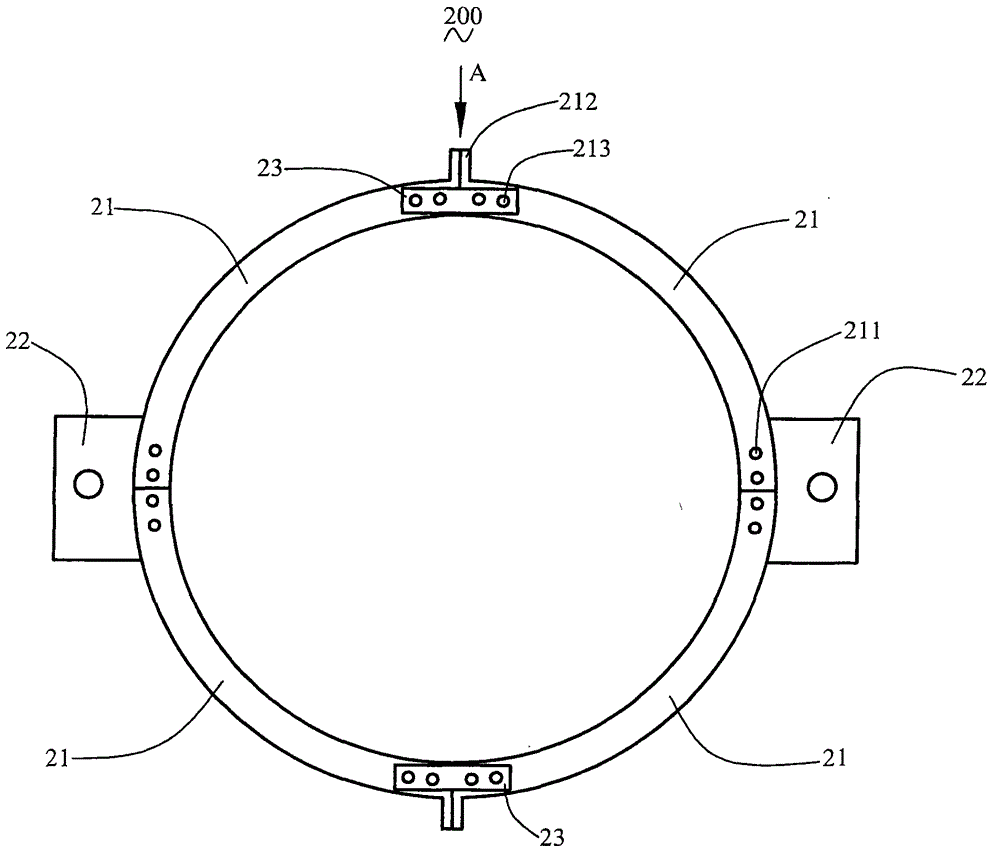

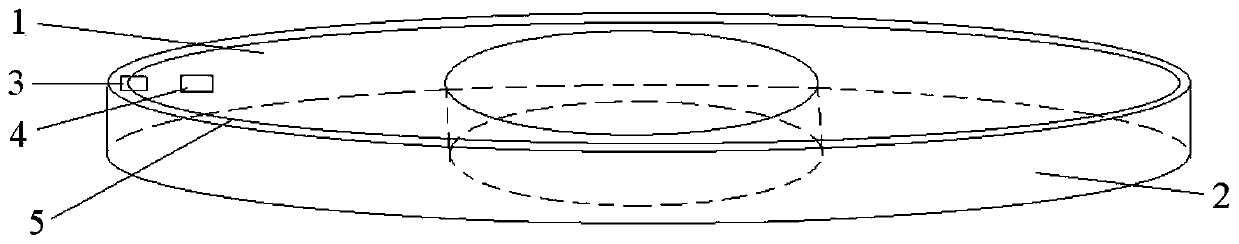

Large-diameter tube assembling and lifting tool

ActiveCN102982924AAvoid loss of roundnessLow roundnessInsulatorsLoad-engaging elementsRADIUSEngineering

Provided is a large-diameter tube assembling and lifting tool. The large-diameter tube assembling and lifting tool comprises two arc-shaped inclasping pieces and two lifting pieces used for connecting the at least two arc-shaped inclasping pieces. The arc radiuses of the arc-shaped inclasping pieces are equal to the radius of a tube. The two lifting pieces are arranged on the extension line of the diameter of the tube, and a lifting hole is formed in each lifting piece. The lifting holes are used for connecting a lifting rope in a penetrating mode. Due to the fact that a circular ring is used to lift the large-diameter tube, gravity stressed by the large-diameter tube assembling and lifting tool can be evenly distributed on the circular ring, and therefore pressure on each portion of the tube is roughly equal. Thus, the phenomenon that circular degrees of the tube are reduced caused by uneven stress in the process of lifting can be avoided.

Owner:JIANGSU SHENMA ELECTRIC CO LTD

A polylactic acid toughened material for 3D printing and its preparation method

ActiveCN104725806BImprove toughnessImprove shrinkageAdditive manufacturing apparatusPolymer scienceAntioxidant

The invention discloses a polylactic acid toughened material for 3D printing, which comprises polylactic acid and the following components in percentage by mass (on the basis of polylactic acid): 5-25% of toughener, 0.5-2.0% of lubricant, 0.5-2.0% of oxidized polyethylene wax, 0.3-1.0% of white oil, 5-25% of low-melting-point resin-coated inorganic powder and 0.3-0.9% of antioxidant. The material prepared by the technical scheme has the advantages of favorable toughness, high extrusion forming regularity and favorable line roundness. The printing proves that the product has the advantages of low shrinkage, no edge lifting, no cracking, high cooling speed and favorable appearance and has wide printing application range.

Owner:SHENZHEN ESUN IND

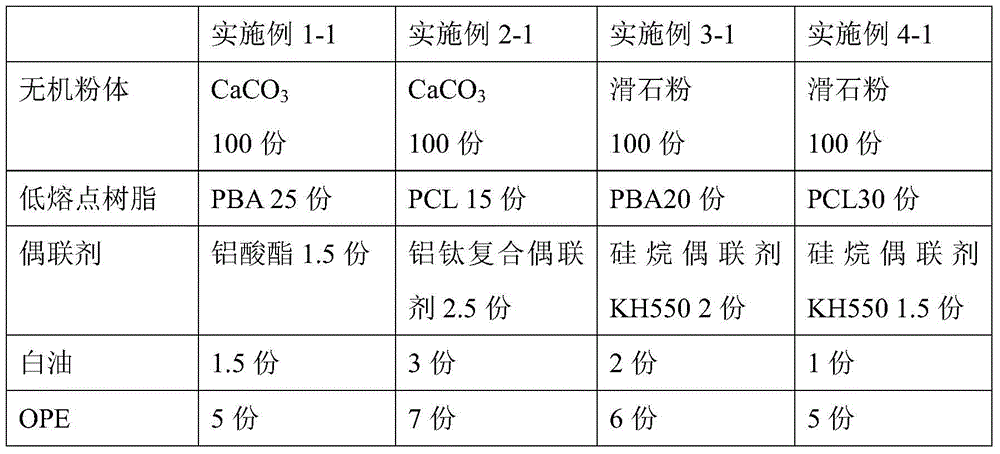

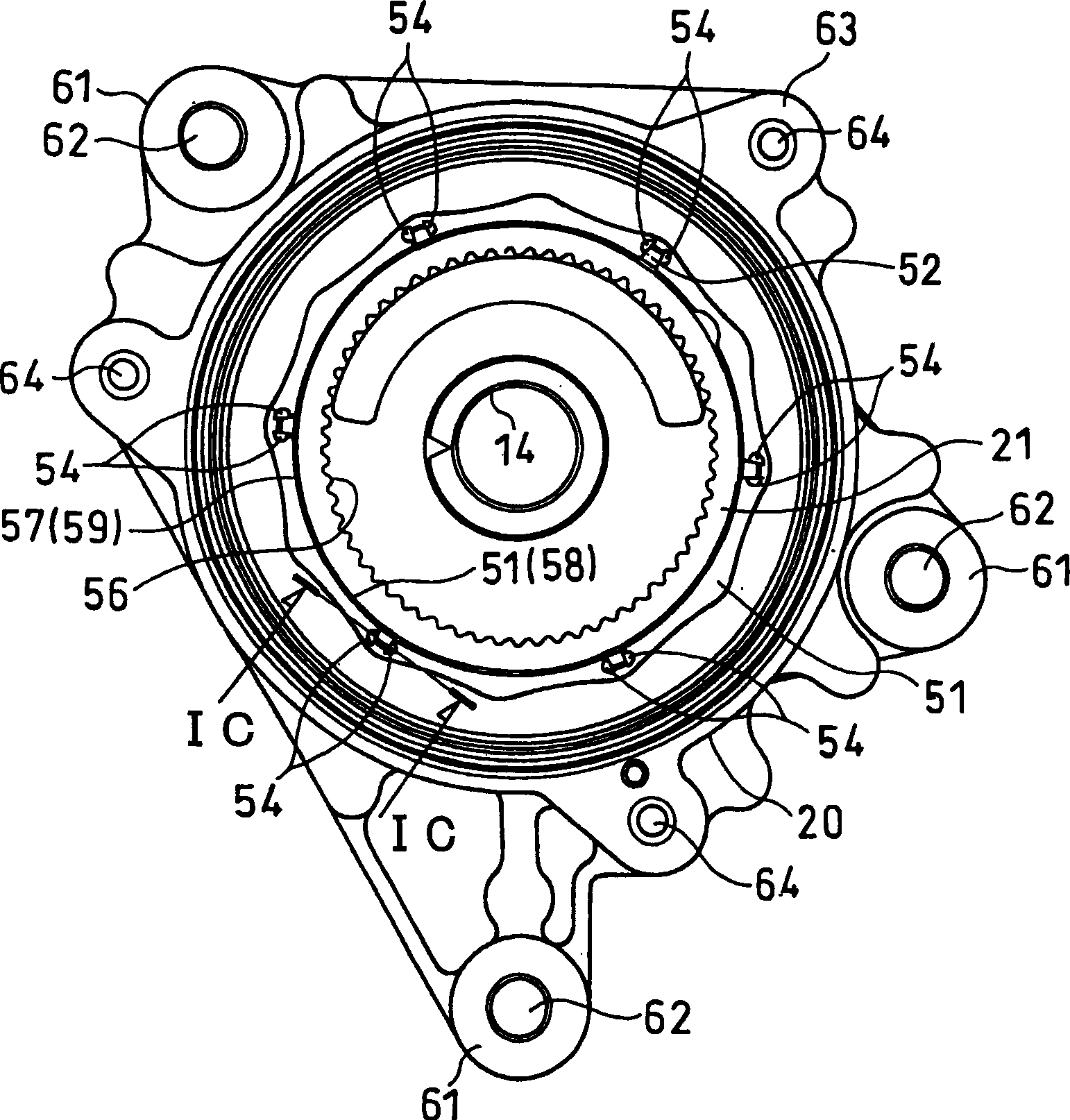

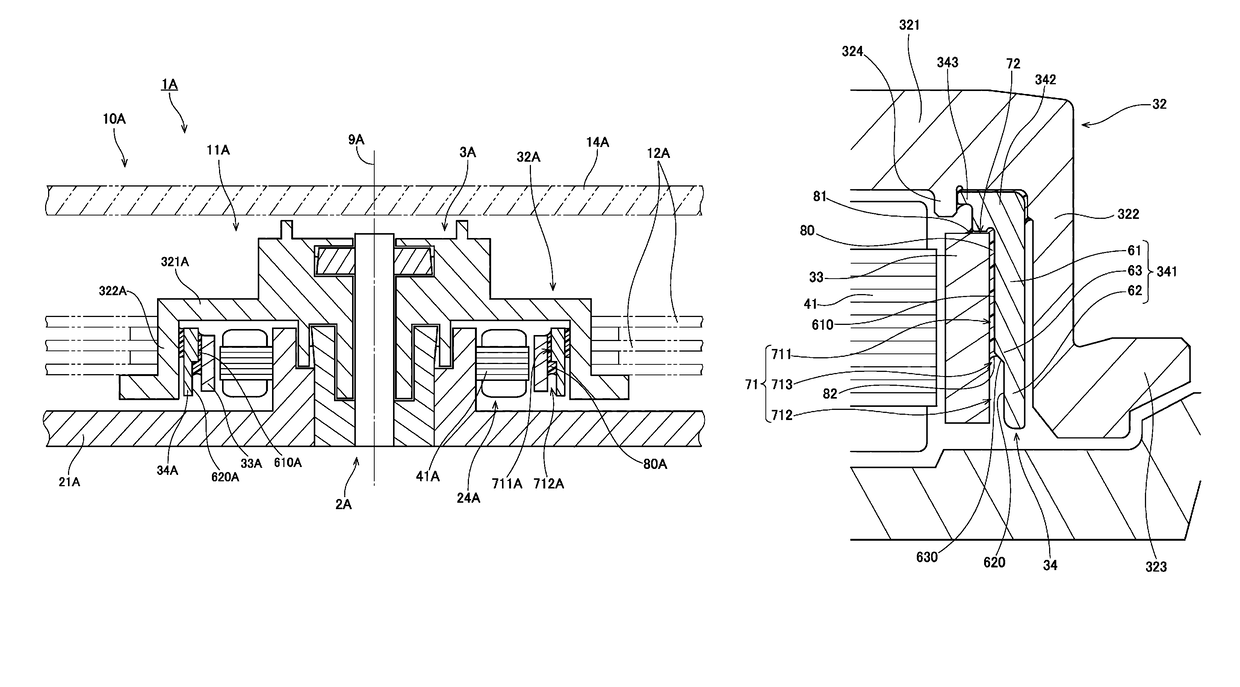

Gear device

ActiveCN1779298ALow roundnessReduce concentricityToothed gearingsPortable liftingGear wheelEngineering

The invention provides a toothed gearing, in which the peripheral part of internal gear circular part is press-inserted to the internal peripheral part of the front casing built-in wall. After a plurality of clamping catches are inserted in lots of clamping slots on the internal peripheral part of the front casing built-in wall, the two ends of clamping catches are applied the outside force to make them plastically deform, so as to form a plurality of riveted fixing part.

Owner:DENSO CORP +1

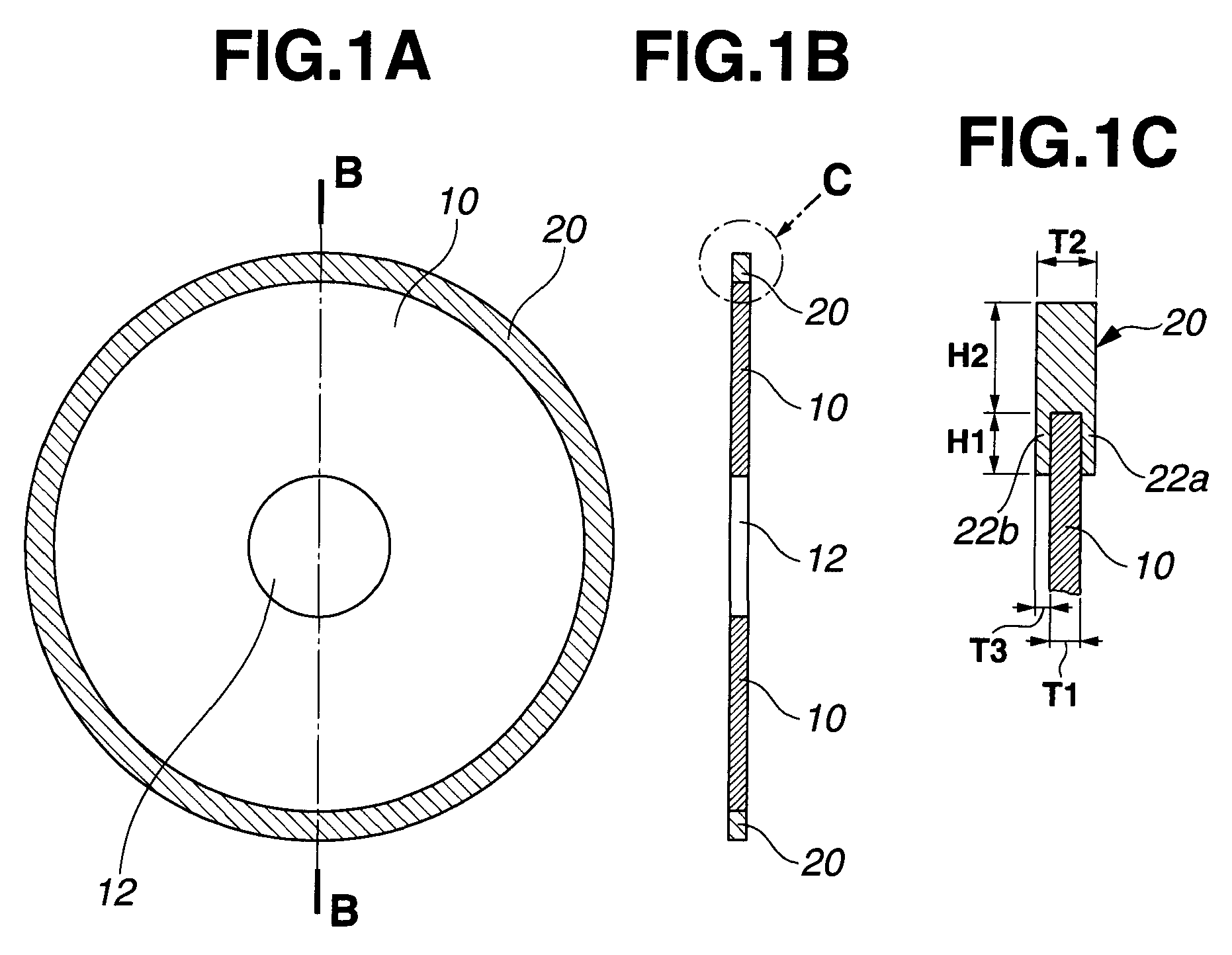

Cemented carbide base outer blade cutting wheel and making method

ActiveUS9016269B2High dimensional accuracyLow costPigmenting treatmentOther chemical processesAlloyCemented carbide

An outer blade cutting wheel comprising an annular thin disc base of cemented carbide and a blade section of metal or alloy-bonded abrasive grains on the outer periphery of the base is provided. The abrasive grains are diamond and / or cBN grains having an average grain size of 45-310 μm and a TI of at least 150. The blade section includes overlays having a thickness tolerance (T3max−T3min) of 0.001 mm to 0.1×T2 mm. The blade section has a roundness (ODmax / 2−ODmin / 2) of 0.001 mm to 0.01×ODmax mm.

Owner:SHIN ETSU CHEM IND CO LTD

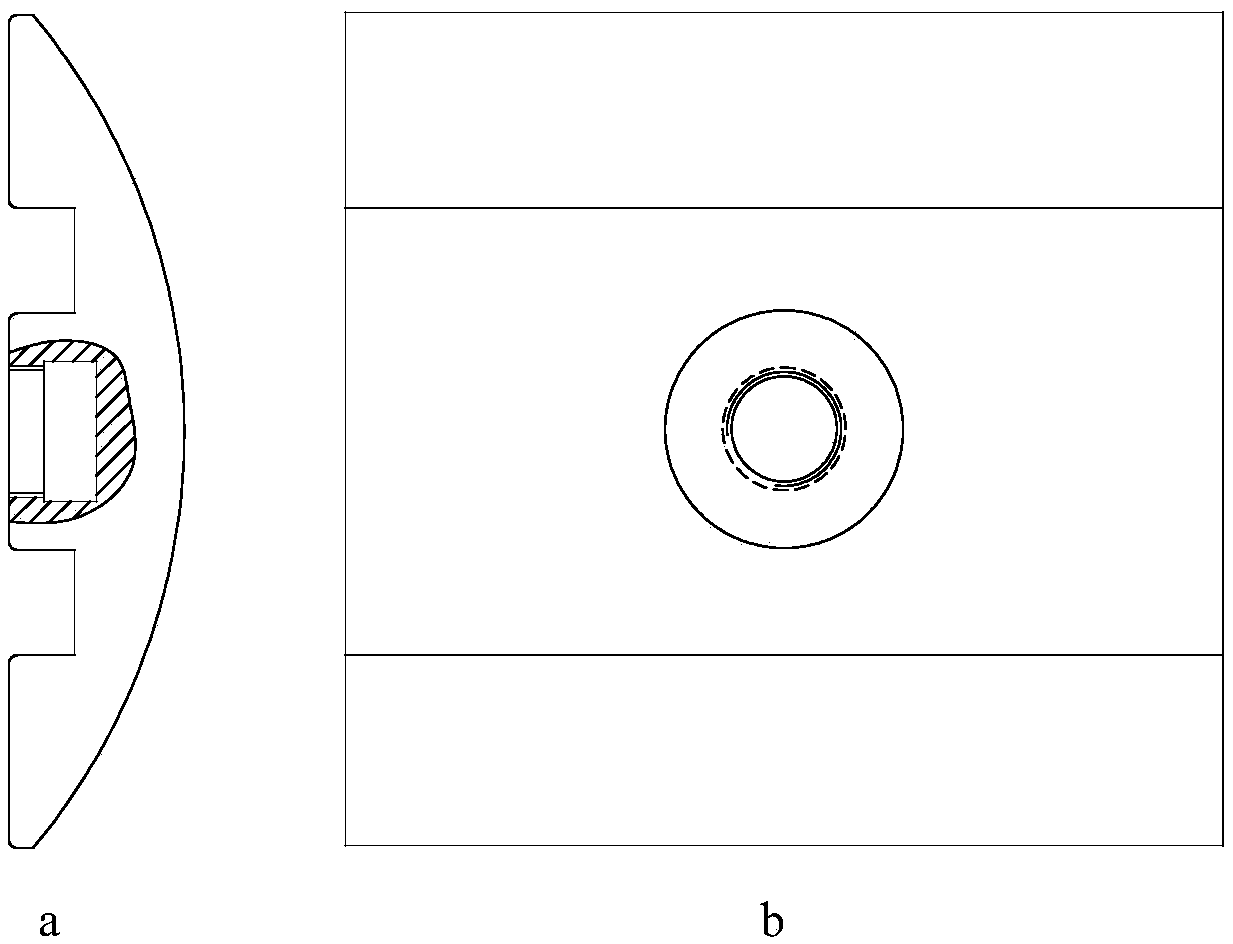

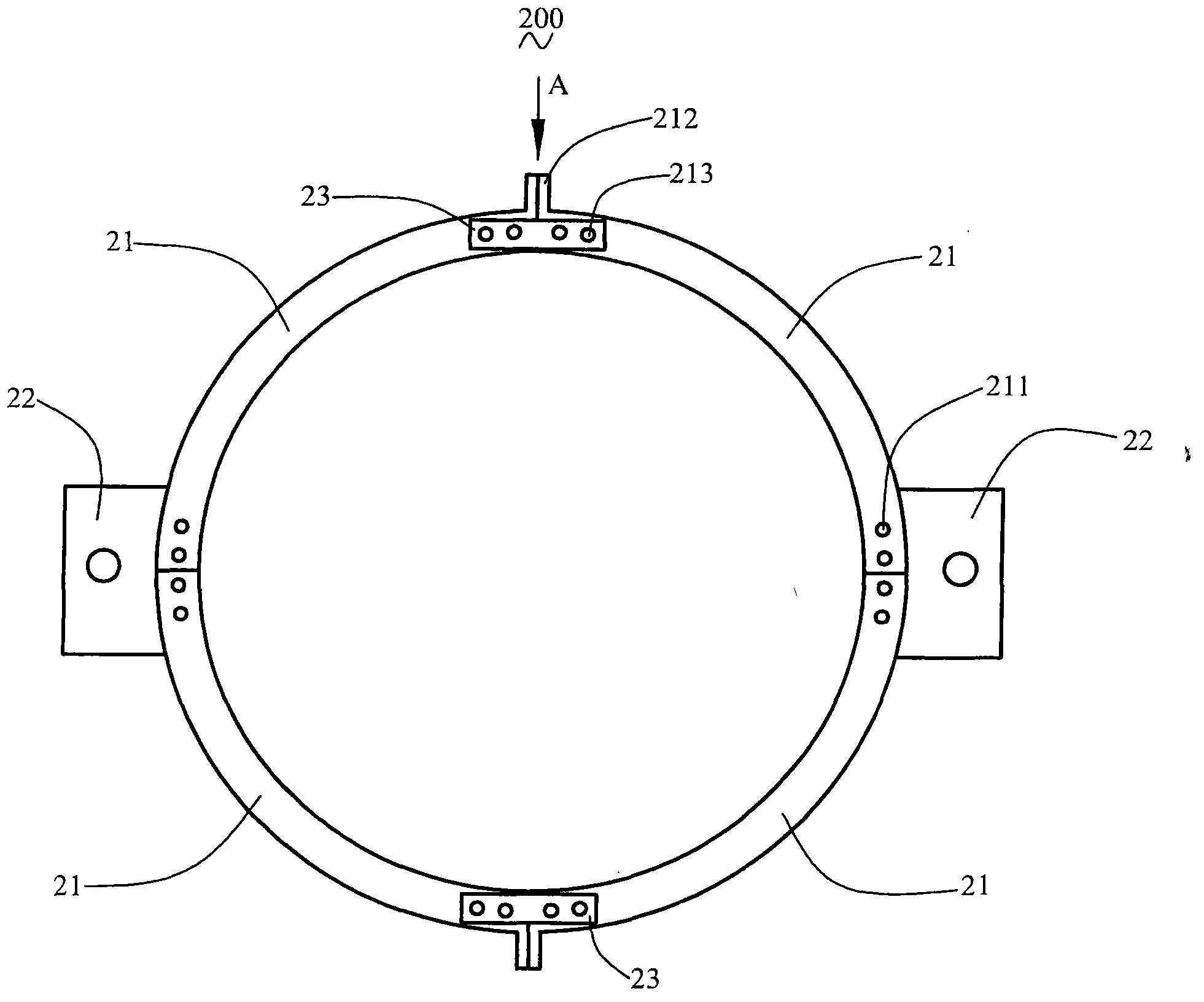

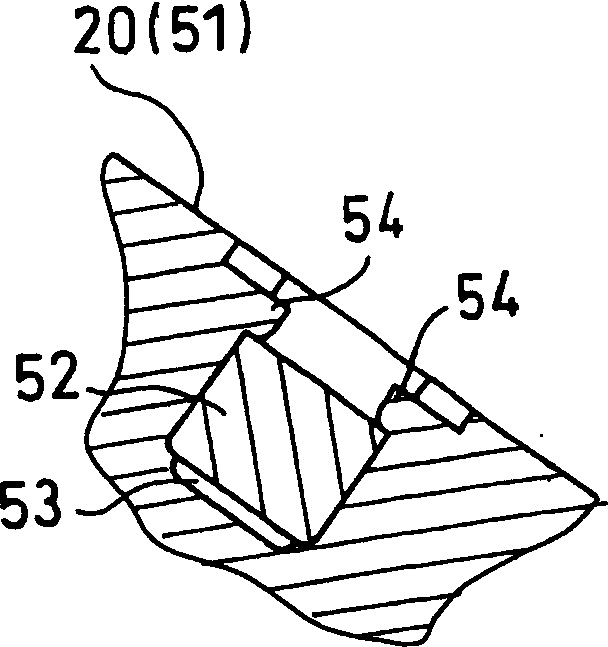

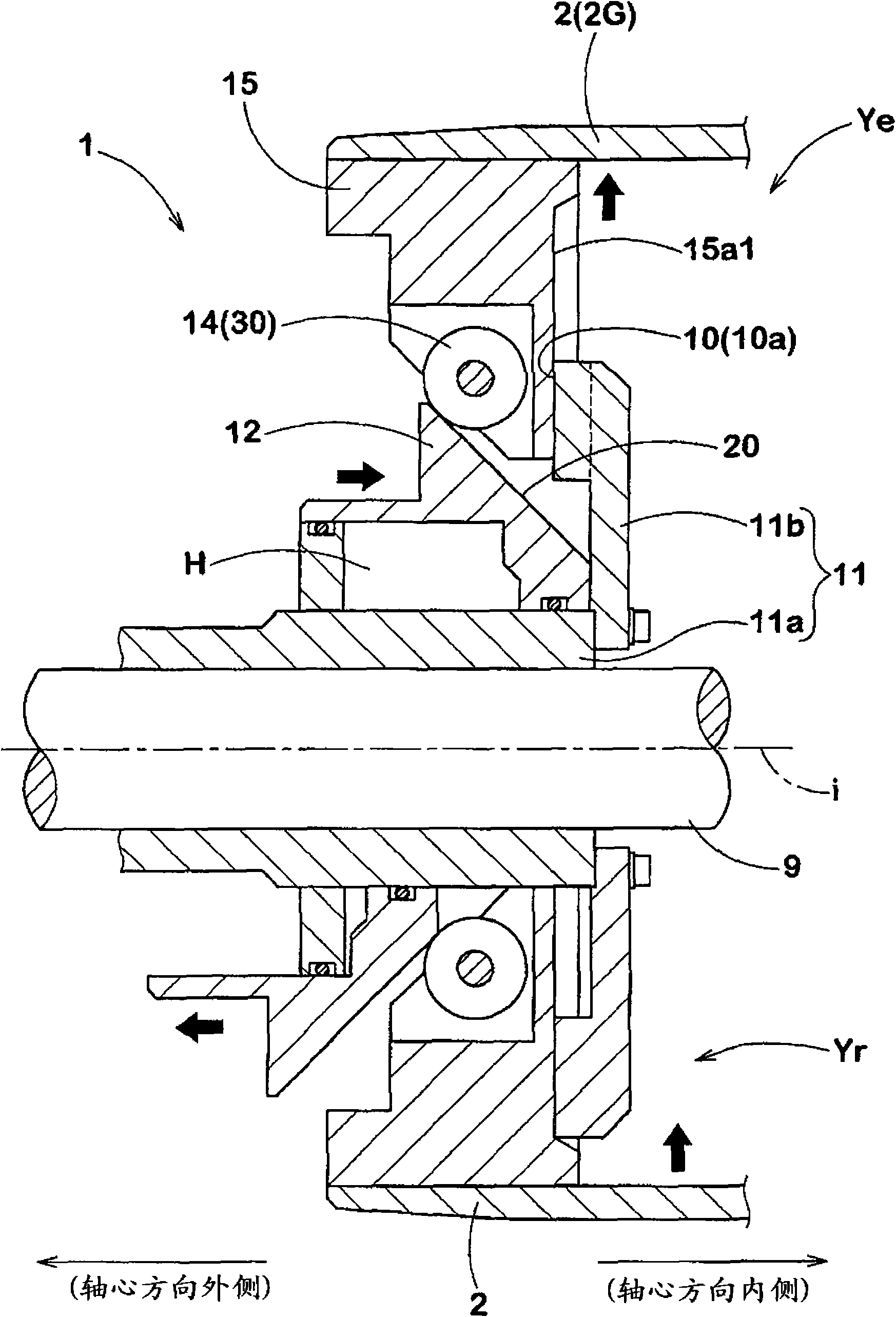

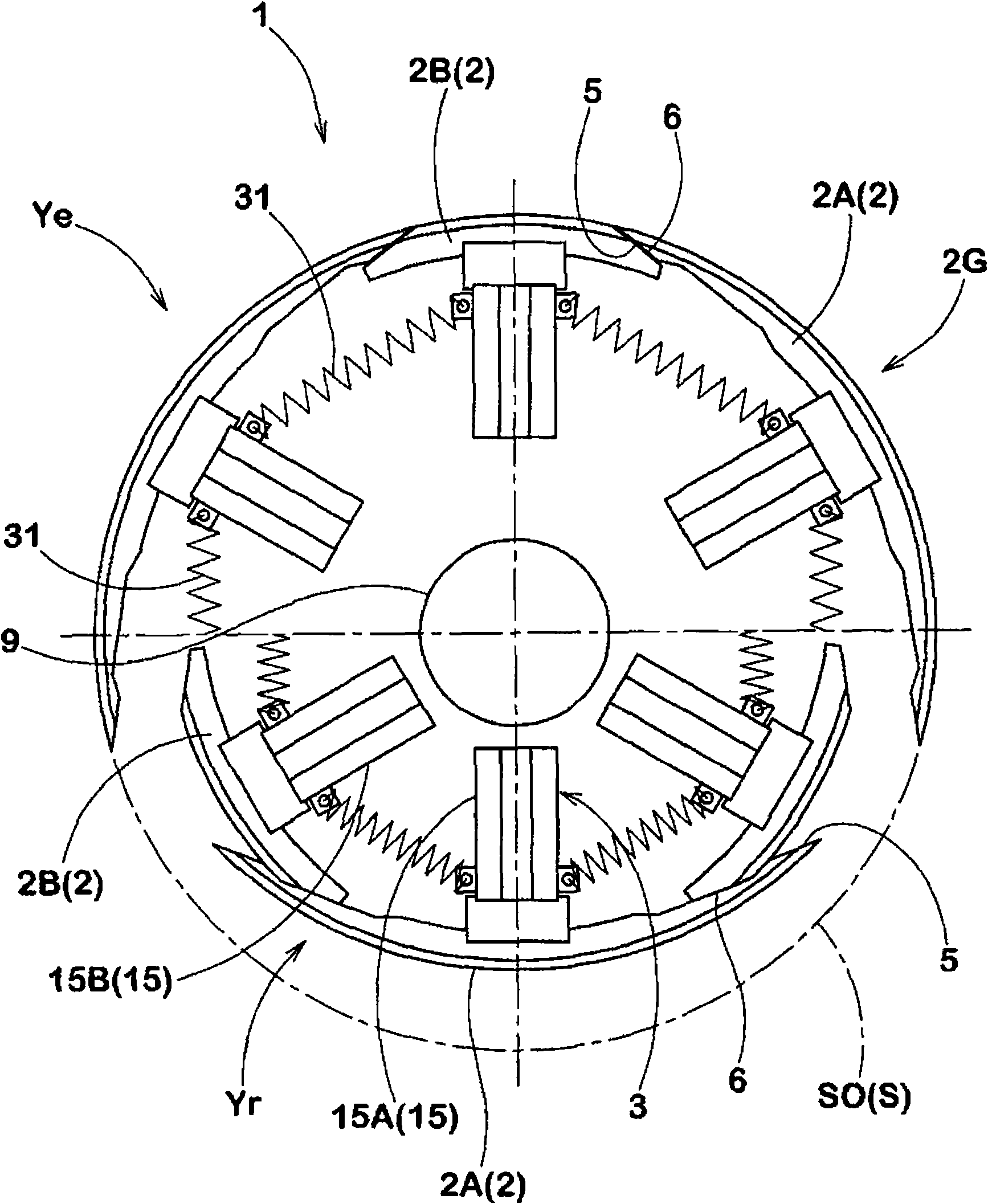

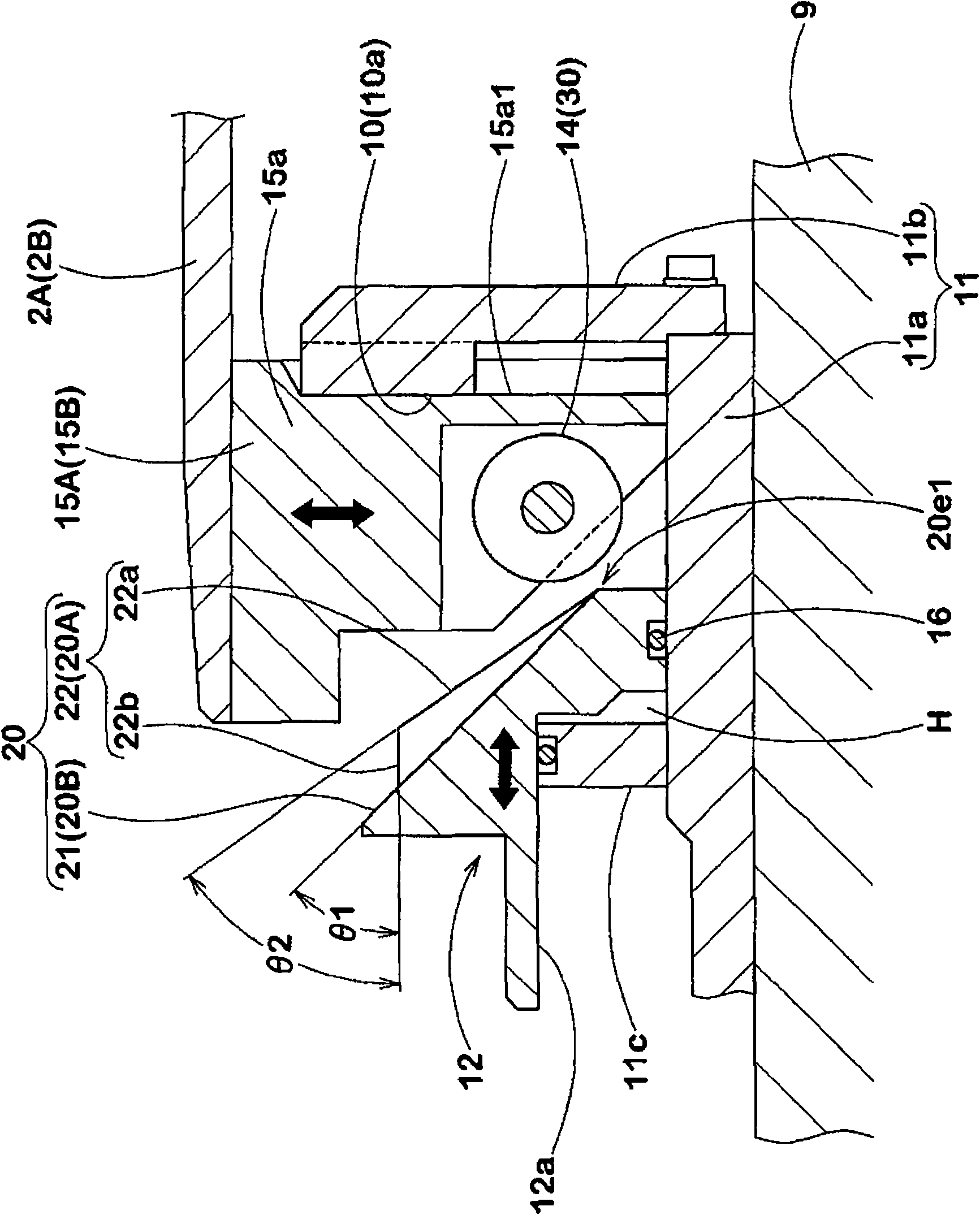

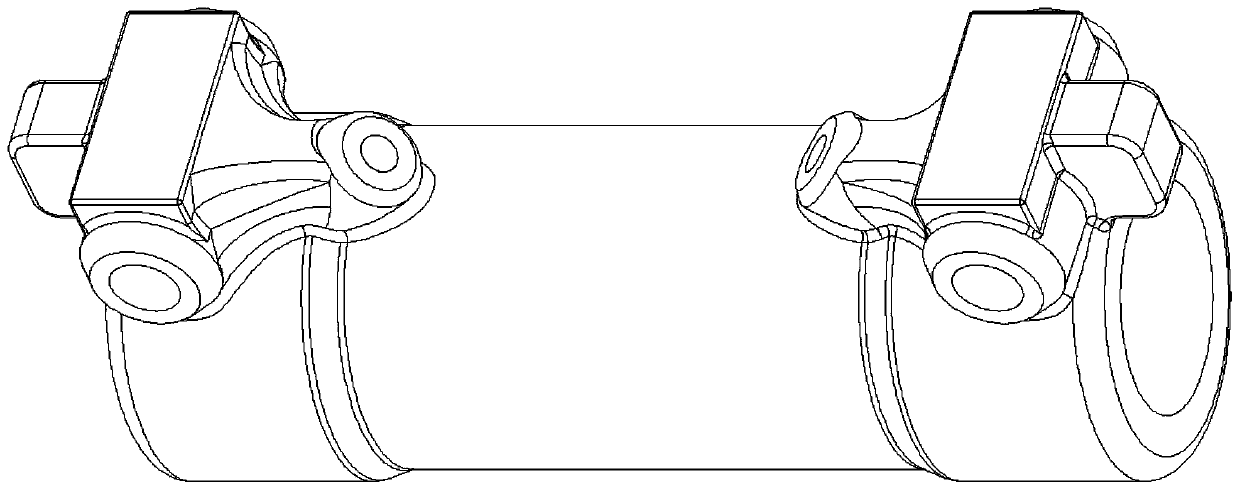

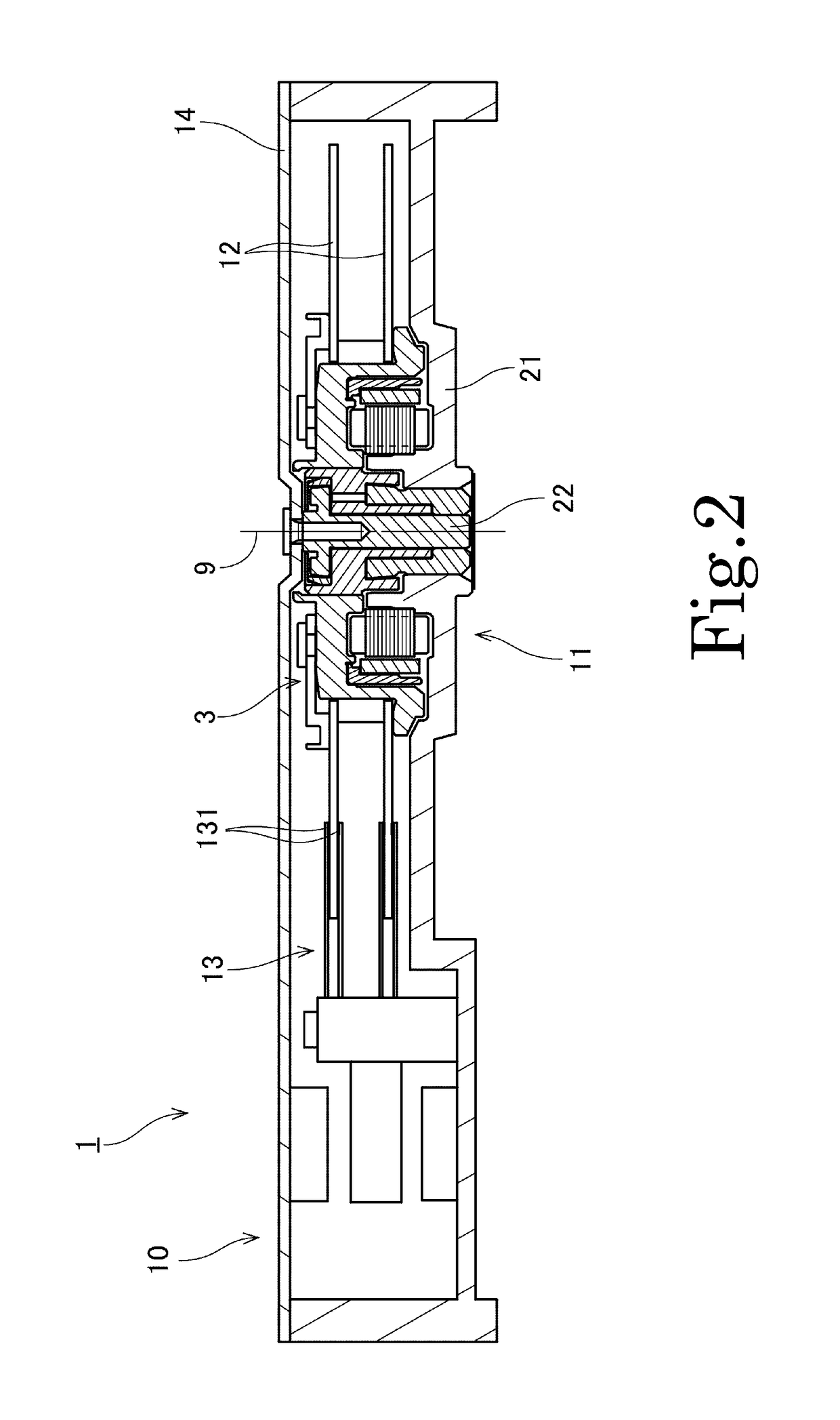

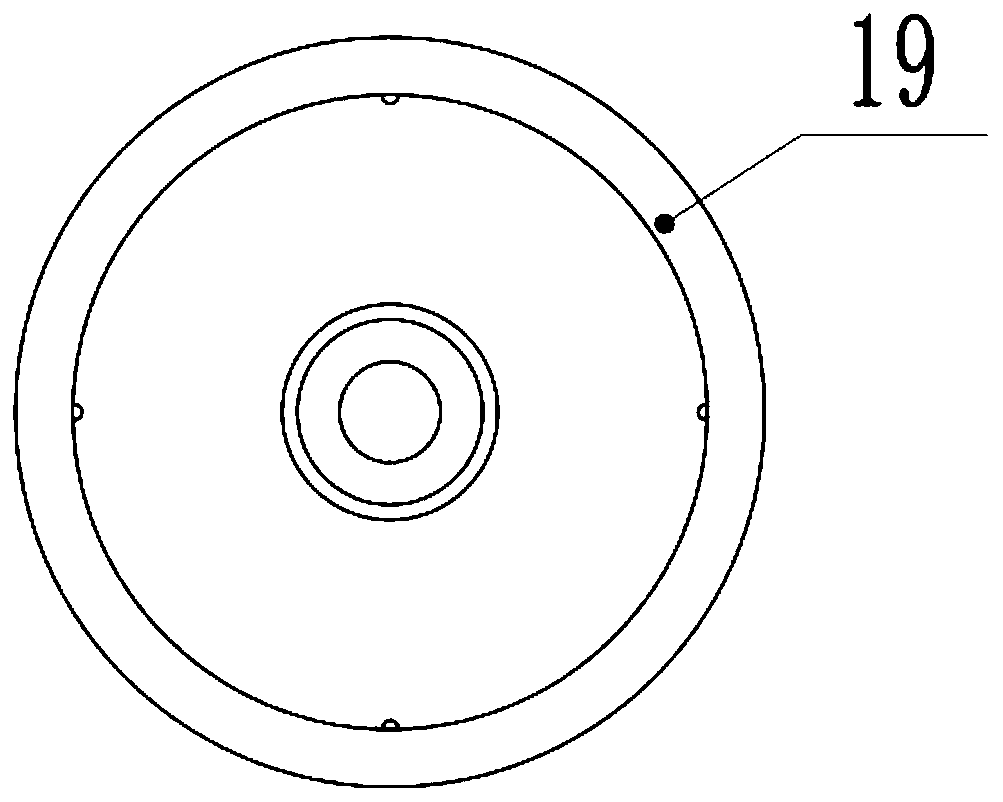

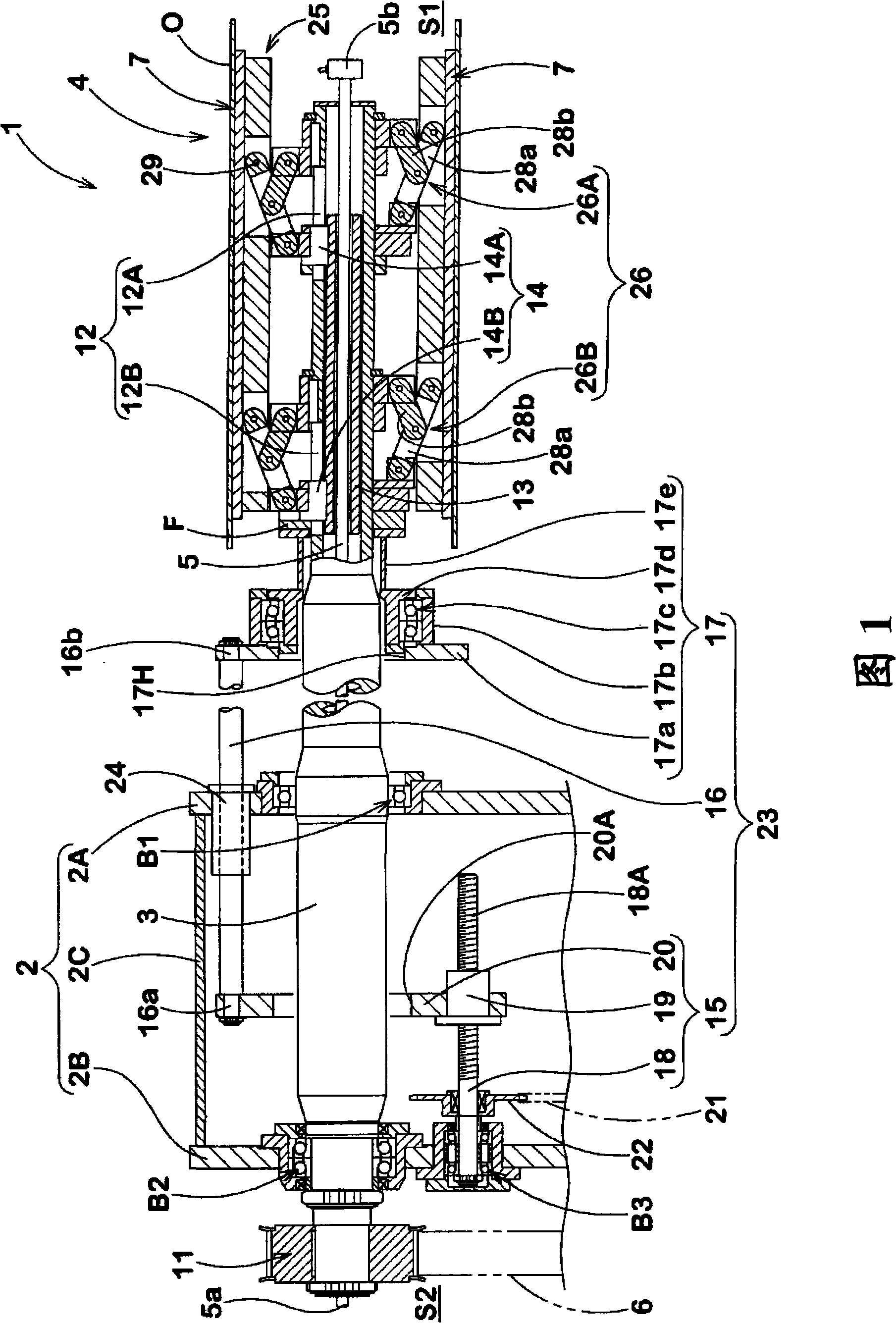

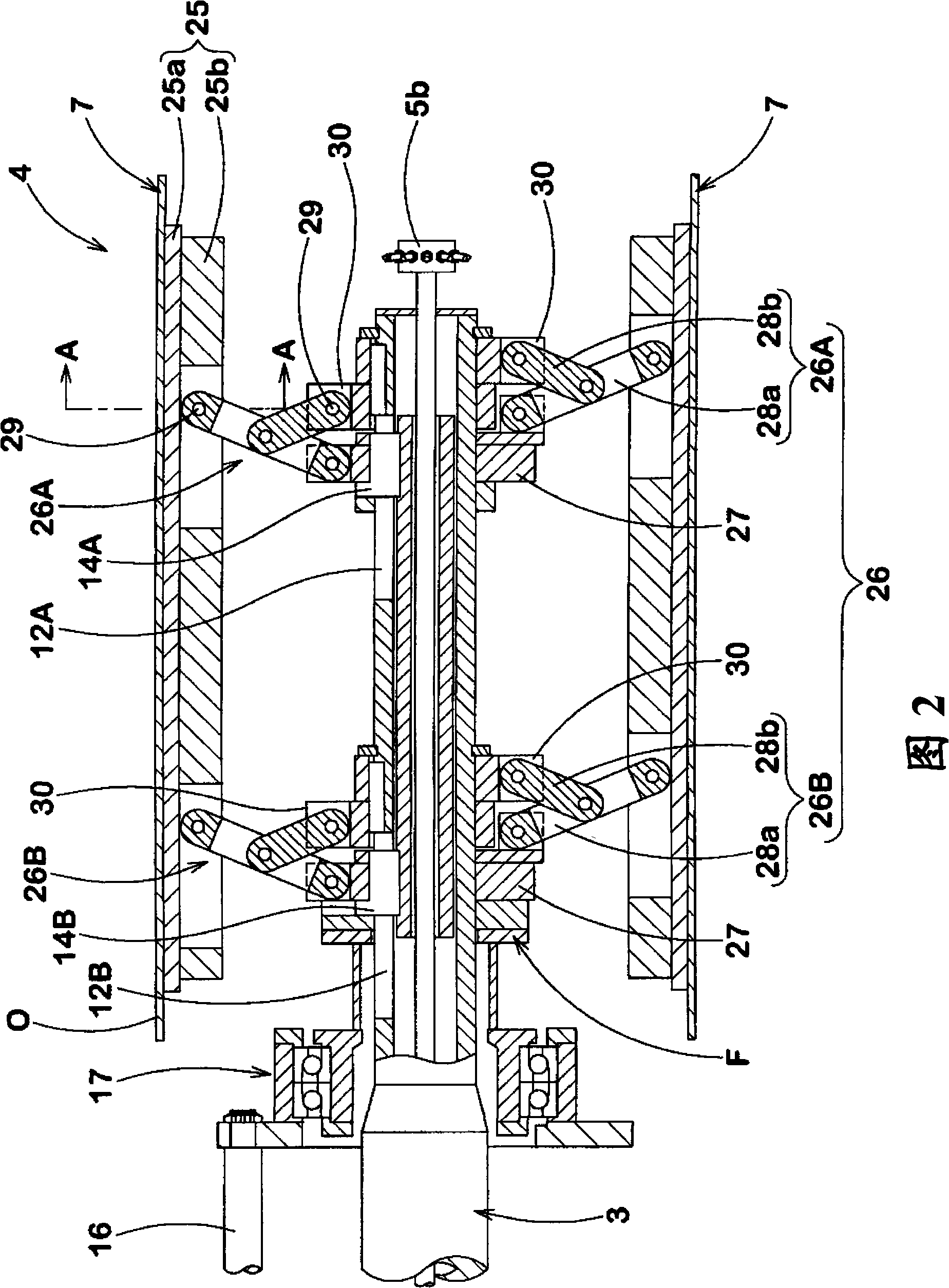

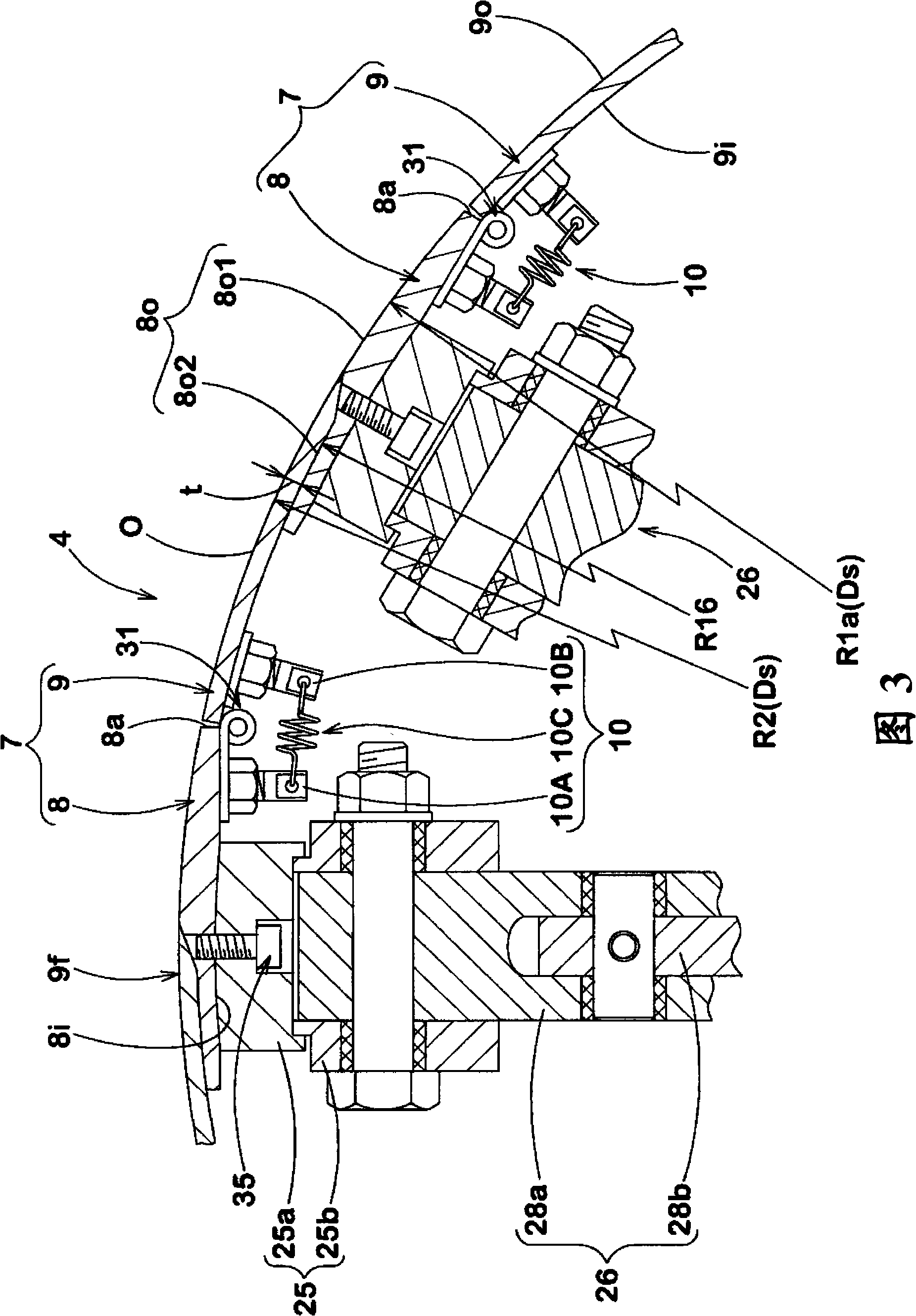

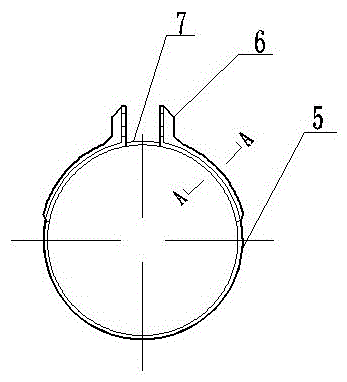

Tire assembly drum

The invention provides a tire assembly drum, capable of suppressing the abrasion between side ends of a combination die. The tire assembly drum comprises a first and a second combination die which are assembled alternately in a circumferential direction and can move between a shrinking state and an expanding state by aid of an expanding unit. The expanding unit comprises a cone-shaped sliding body which is capable of being guided to move in an axis direction and is provided with a guiding face at the inner end in the axis direction, a first and a second moving piece which are capable of being guided to move in and out in a radial direction and are provided with a first and a second combination die at the outer end in the radial direction. The guiding face consists of a first oblique face connected to a first moving piece in a snap-fit, a second oblique face which inclines differently from the first oblique face and is connected to a second moving piece in a snap-fit. At the time of expanding, the first combination die reaches to the expanding position earlier than the second combination die. At the time of shrinking, the first combination die moves from the expanding position towards the inner side in a radial direction later than the second combination die.

Owner:SUMITOMO RUBBER IND LTD

Titanium concentrate grinding aid

InactiveCN104650806AReduce surface tensionLower surface energyOther chemical processesGlycerolTitanium

The invention discloses a titanium concentrate grinding aid, which is characterized by comprising the following steps: adding 25-30% of glycerol by mass ratio in a reaction container, adding 50-60% triethanolamine by mass ratio, adding about 15% of mixture of neutralized formic acid and sodium dodecanesulphonate, then mixing and stirring, wherein the stirring speed is 400-500rotation / minute and the stirring time is 1.5-2 hours, and obtaining the titanium concentrate grinding aid. The mass ratio of glycerol to triethanolamine to neutralized formic acid to sodium dodecanesulphonate is 4: 8: 1: 1. Addition of the grinding aid can solve the problem of electrostatic interaction generated during the grinding process of titanium concentrate, so that good grinding effect is reached, and power consumption is saved.

Casting system and casting method of cylinder barrel

ActiveCN110315034ASpeed up coolingImprove machining accuracyFoundry mouldsFoundry coresCasting moldCasting defect

The invention discloses a casting system and casting method of a cylinder barrel. The casting system comprise a casting mold cavity and a pouring system, wherein the casting cavity comprises a cylinder barrel cavity body, a through hole is axially formed in the cylinder barrel cavity body, the cylinder barrel cavity body is composed of a cylinder barrel head part and a middle body part, the diameter of the cylinder barrel head part is larger than that of the middle body part, a radial protruding block is arranged on the cylinder barrel head part, and a supporting fixing hole and an oil passagehole are formed in the protruding block; the pouring system comprises a sprue, a transverse runner and an inner sprue, the sprue vertically communicates with the transverse runner, the two ends of the transverse runner communicate with the inner sprue through risers, and the inner sprue communicates with a convex block of the casting cavity; and the supporting fixing hole is filled with a first sand core, and an axial through hole of the cylinder barrel cavity body is filled with a second sand core. The casting system has the advantages that parts with the wall thickness of a casting are notprone to shrinkage and loosening defect generating, particularly, the casting defect is not easy to occur among the supporting fixing hole, the oil passage hole and the inner surface of the cylinder barrel, and a chill structure cannot be easily generated in parts with the thin wall thickness.

Owner:宁波拓铁机械有限公司

Feed for artificial culturing of leiocassis longirostris

InactiveCN107252009AImprove survival rateImprove economic efficiencyClimate change adaptationAnimal feeding stuffDandelionHerb

The invention discloses a feed for artificial culturing of leiocassis longirostris. Raw materials of the feed comprise, in parts by weight, 18-26 parts of millet, 5-10 parts of cicada pupa powder, 2-8 parts of kelp powder, 1-5 parts of mulberry leaf powder, 30-40 parts of an adhesive, 1-5 parts of baikal skullcap roots, 1-2 parts of dandelion herbs, 1-2 parts of immature flower of Japanese honeysuckle, 0.5-1.2 parts of coptis roots, 0.15-0.35 part of EM bacteria, 0.2-0.6 part of lecithin, 0.1-0.3 part of beta-carotene, and 0.5-1 part of a phagostimulant. The feed for artificial culturing of the leiocassis longirostris provided by the invention can obviously raise the surviving rate of the leiocassis longirostris, improve economic benefits of the artificial culturing, and significantly decrease the generation of bacterium infection and diseases such as fatty liver in a culturing process. The feed improves the quality of the leiocassis longirostris, and contains no antibiotic.

Owner:全椒县鮰鱼养殖专业合作社

High precision cotton spinning ring using low hardness steel material as base body and its manufacture method

InactiveCN101187095ASimple processReduce manufacturing costTextiles and paperManufacturing cost reductionWear resistant

The invention relates to a high precision cotton spinning ring which uses low hardness steels as a base and process for preparation, wherein the steels whose rockwell hardness is equal or lesser than 65 is minutely processed into the ring base according to a needed shape of a ring, a high hardness wear resistant layer is coated on the ring base, the thickness D of the high hardness wear resistant layer is equal or greater than 1micron and is equal or lesser than 30 micron. The process for preparation is that the steels are orderly processed into ring blank through blanking, then the ring blank is processed into the ring base whose spherical degree is lower than 40 micron and smoothness is lower than 10 micron through rough turning and finish turning, and then a product is obtained through the surface hardening wear-resistant treatment of the ring base. The invention overcomes technology bias, both is capable of observably improving the precision of the cotton spinning ring, and meets the requirements of high hardness wear resistance lubrication of the surface of the cotton spinning ring. The process for preparation not only has simple process and very easiest operation, but also observably reduces the manufacturing cost, and prolongs the service life of the cotton spinning ring.

Owner:李祥德

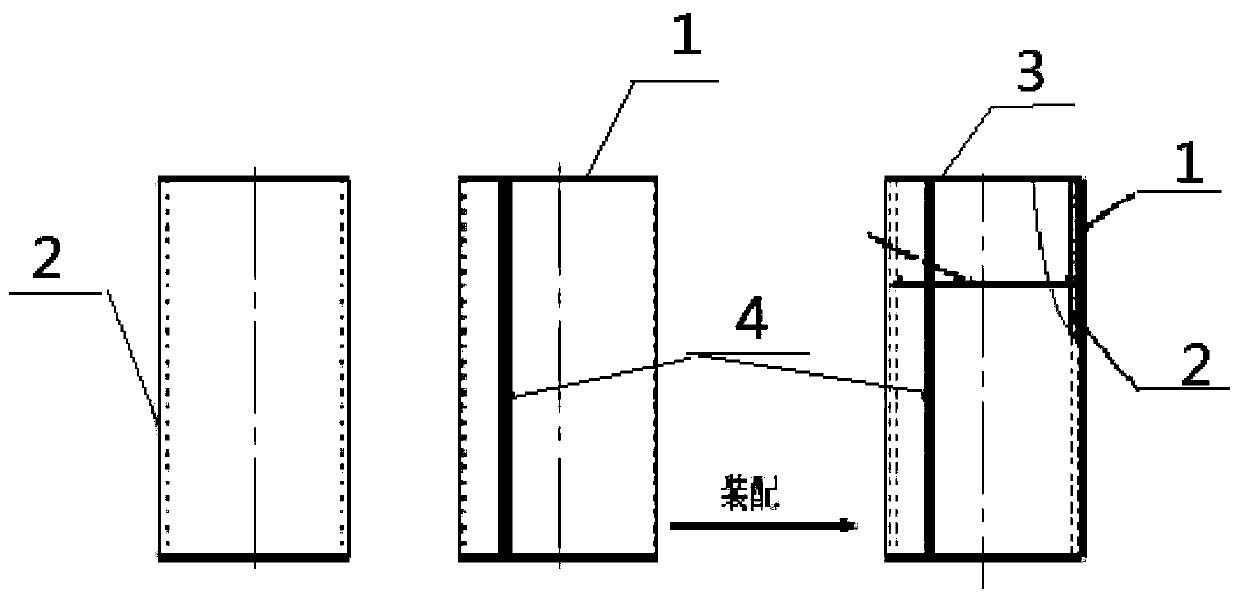

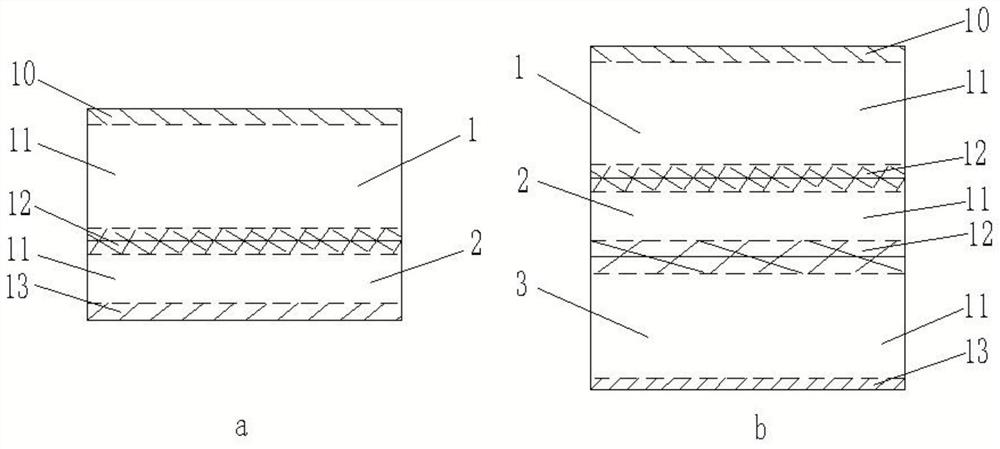

A kind of double-layer composite pipe and its preparation method

ActiveCN106903212BInhibition of deformation and thinningGood formabilityPipe fittingMachining process

The invention provides a double-layer composite pipe and a forming method thereof in order to solve the problem that in the prior art, as the contraction ratios of double-layer metal pipes are different and the machining process is complex, a complex-structure component can not be formed. The preparation method of the double-layer composite pipe includes the following steps that assembling is conducted, specifically, a hollow aluminum alloy pipe blank is arranged inside a hollow carbon steel pipe blank to form a double-layer composite pipe blank; forming is conducted, specifically, the double-layer composite pipe blank is arranged in an extrusion space, the extrusion space can be matched with the double-layer composite pipe blank, and a cavity in a target shape is formed; the hollow aluminum alloy pipe blank of the double-layer composite pipe blank is filled with medium particles; pressure is applied to the medium particles in the axial direction of the two ends of the double-layer composite pipe blank; and the double-layer composite pipe blank deforms to fill the cavity, and the double-layer composite pipe is formed. The double-layer composite pipe is easy to prepare, good in performance and capable of being used for manufacturing complex-structure pipe fittings.

Owner:YANSHAN UNIV

Method for reducing deformation residual stress of straight cylinder part in powerful spinning process

ActiveCN114406077ASmooth releaseRedistribute evenlyProcess efficiency improvementHollow articlesSpinningHardness

The invention belongs to the technical field of spinning forming, and relates to a method for reducing deformation residual stress of a straight cylinder part in a powerful spinning process, which comprises the following specific steps of: firstly selecting a blank material meeting processing requirements, then carving spiral dents at different intervals on the inner wall of the blank material by combining a spinning thinning rate and a pass ratio, and finally forming the spiral dents on the inner wall of the blank material. The straightness deviation of the spinning straight cylinder part is controlled within 0.2 mm, the roundness deviation is controlled within 0.03 mm, and the subsequent machining efficiency is improved by more than 50%; the hardness value of a spinning forming workpiece is reduced by about 15%, high-quality spinning can be achieved, meanwhile, the residual stress in the spinning forming workpiece is reduced, and the use performance is improved.

Owner:XIAN TAIJIN INDAL ELECTROCHEM TECH

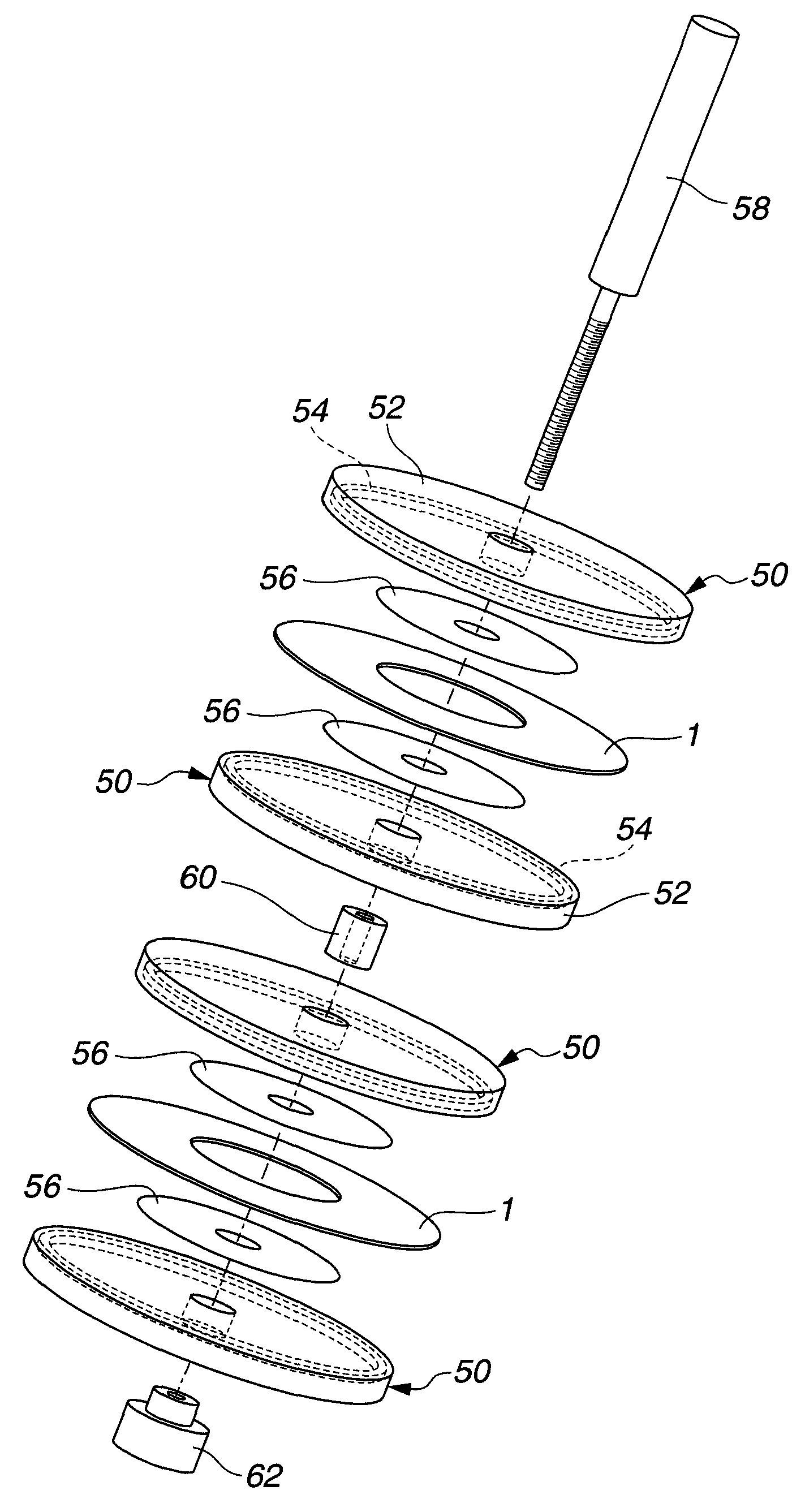

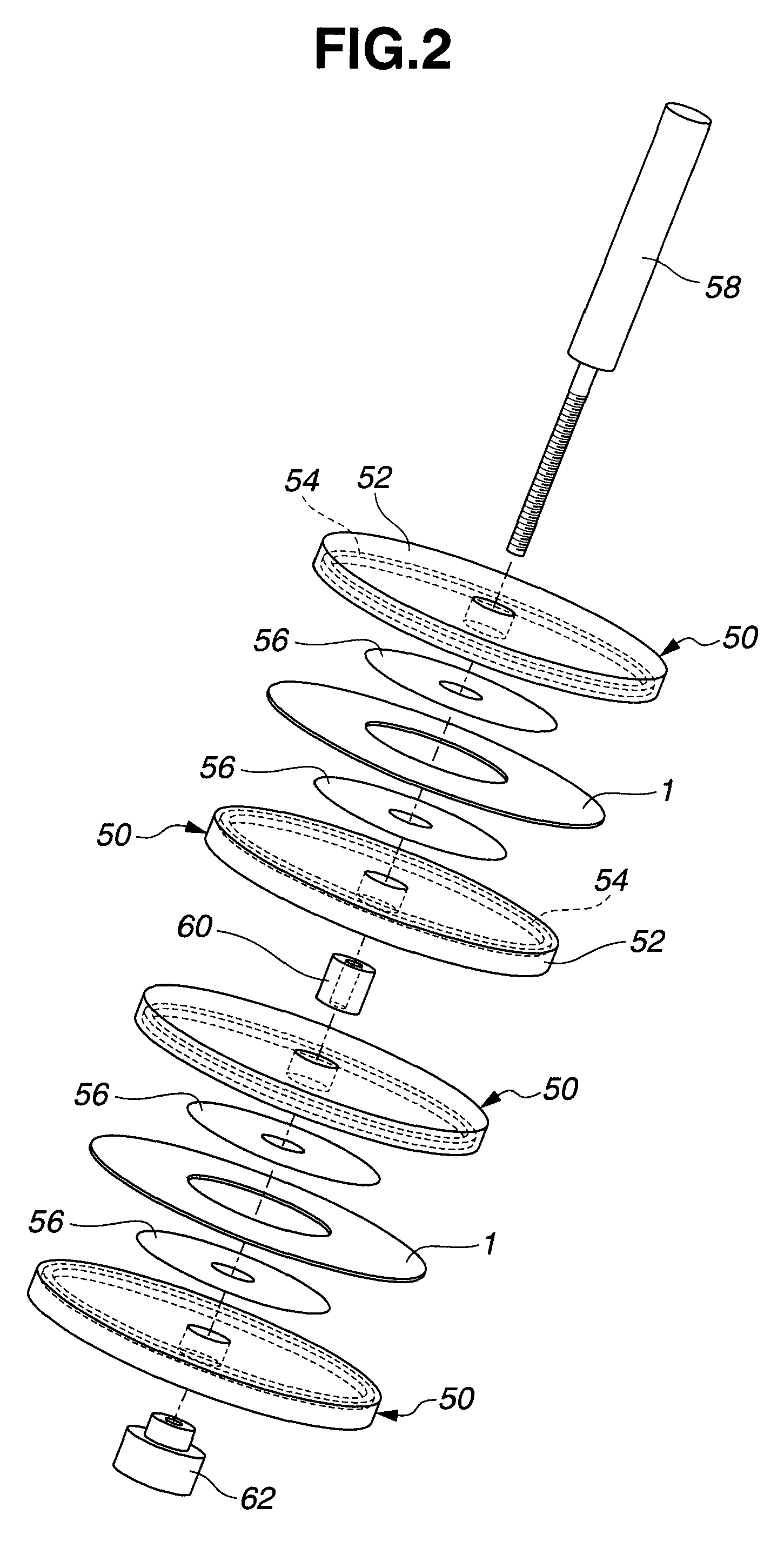

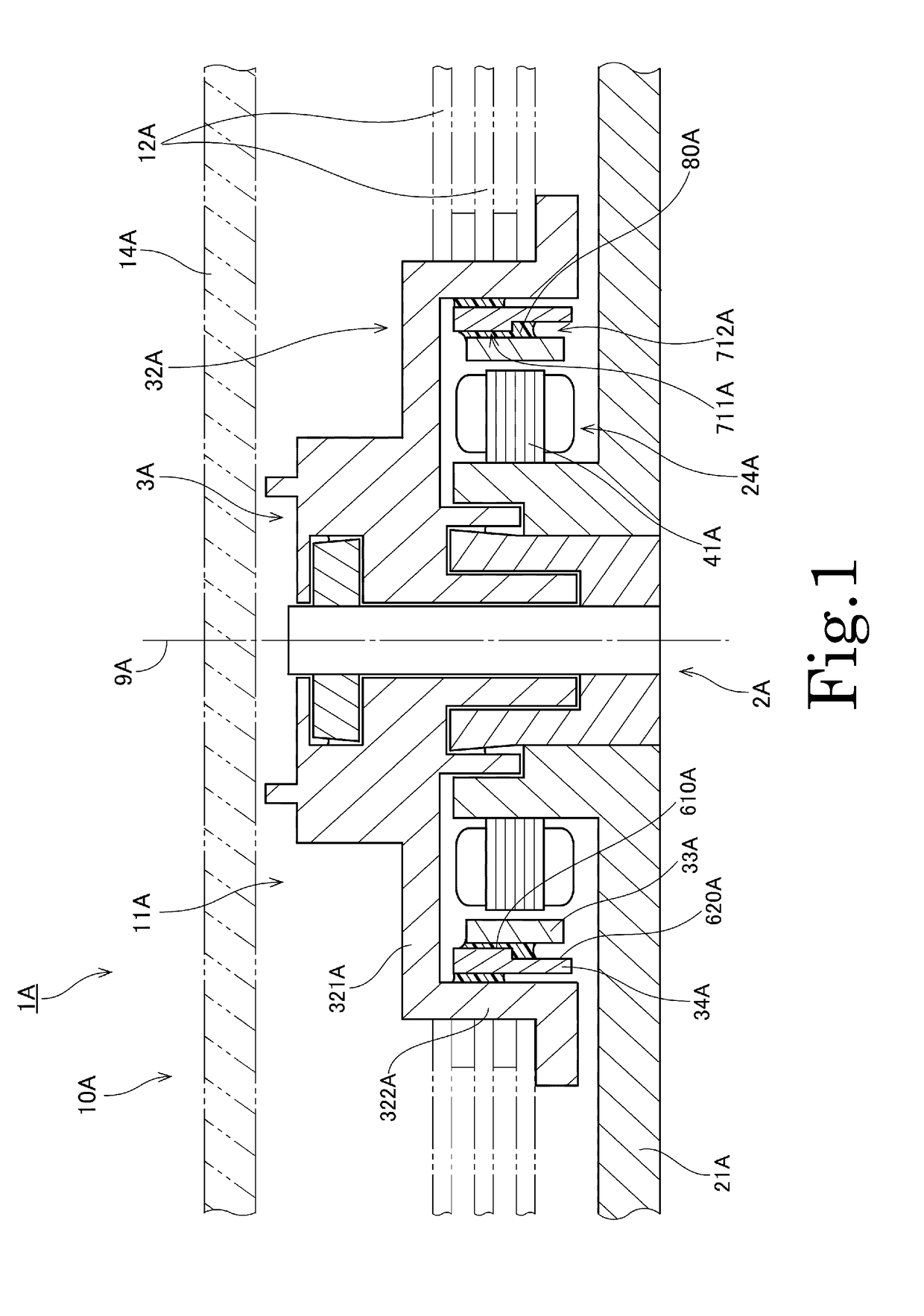

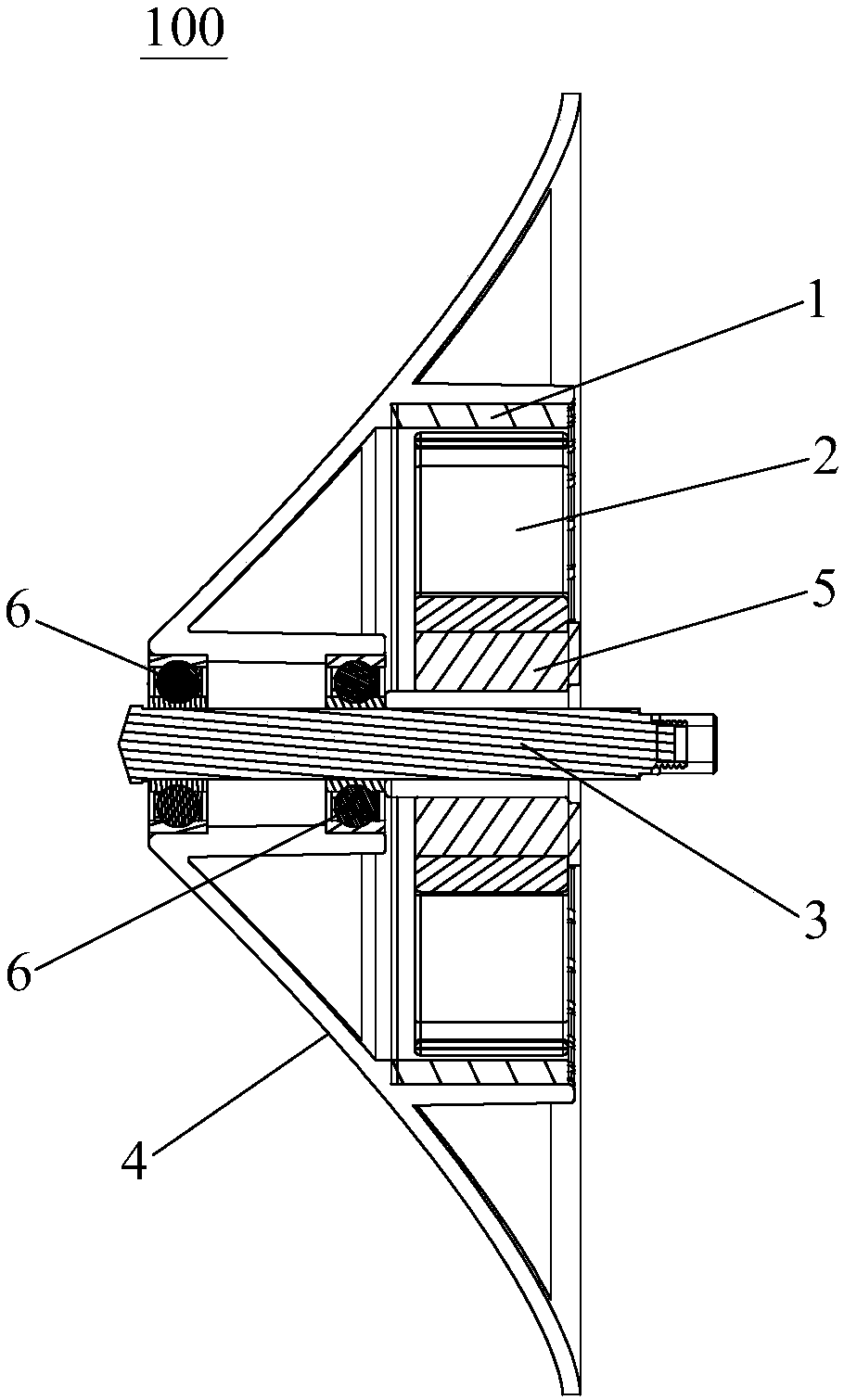

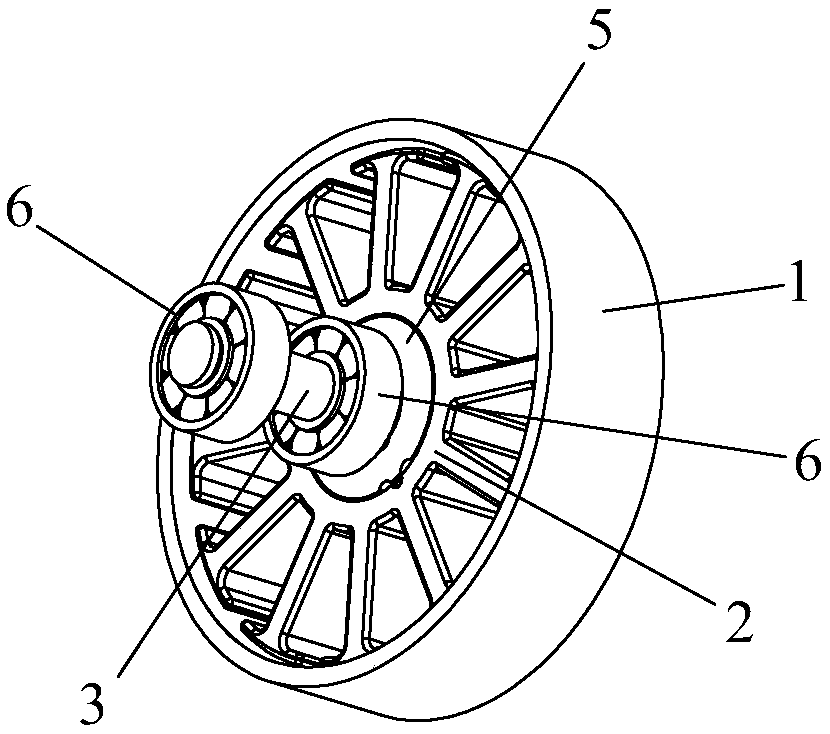

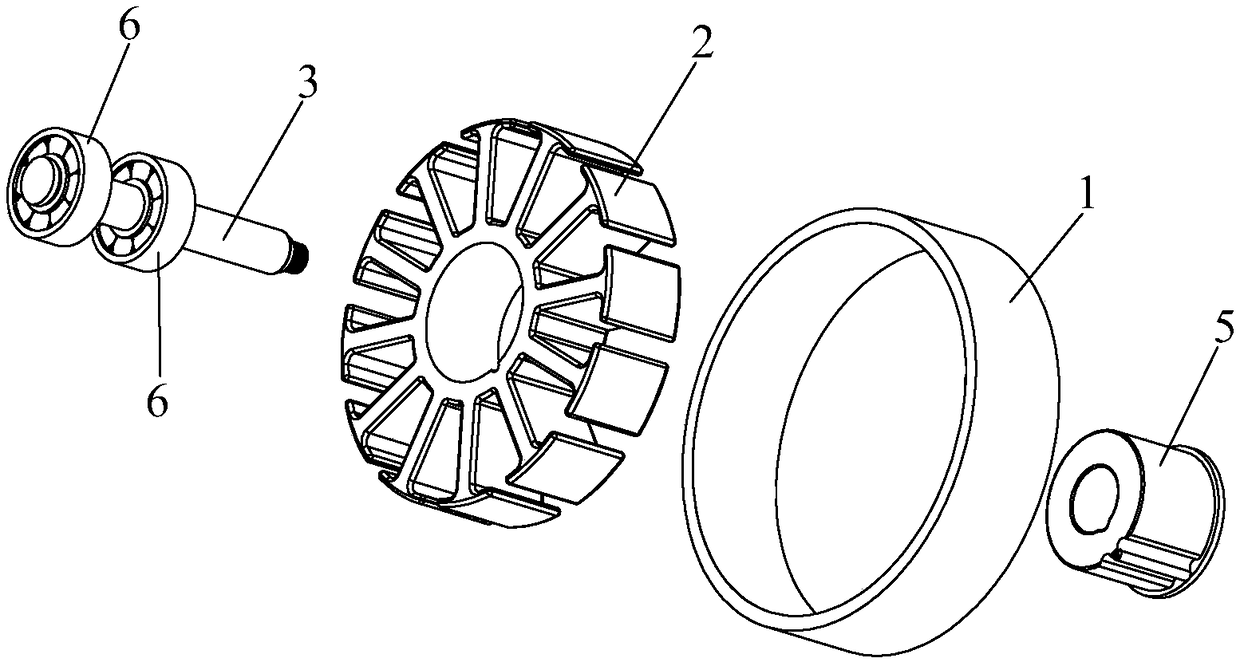

Motor and disk drive apparatus

ActiveUS9698637B2Low roundnessApparatus for flat record carriersMagnetic circuit rotating partsAdhesiveEngineering

Owner:NIDEC CORP

An adjustable galvanized sheet end cap grinding and removing device

ActiveCN108161653BImprove versatilityLower acquisition costsGrinding machinesGrinding work supportsInterference fitGear wheel

The invention discloses a grinding and removing device for a spigot of an adjustable galvanized plate end cover. The grinding and removing device comprises a base, clamping devices, an inner gear disc, a rotating motor and a grinding device, wherein the clamping devices are arranged on the left side and the right side of the inside of a lifting table, the inner gear disc is fixedly welded to the lower side of a sliding strip through a connecting rod, a connecting shaft is arranged at the center wheel core of a second gear in an interference fit mode, and a grinding device is arranged at the lower end of the connecting shaft. According to the grinding device, the end covers with different diameters can be clamped, so that the universality of the device is greatly improved, and the purchasing cost of equipment is saved; a grinding head on the grinding device is driven to carry out planetary rotation, and the spigot in the end cover is ground, so that compared with manual grinding, the grinding speed of the grinding and removing device is higher; the intensity of grinding each spigot can be the same, the degree of roundness of the end cover caused by different grinding strength is avoided, and the single-machine noise of a motor during final assembly is guaranteed.

Owner:NANTONG XINXIANG ZINC IND

A large-diameter pipe assembly lifting tool

Provided is a large-diameter tube assembling and lifting tool. The large-diameter tube assembling and lifting tool comprises two arc-shaped inclasping pieces and two lifting pieces used for connecting the at least two arc-shaped inclasping pieces. The arc radiuses of the arc-shaped inclasping pieces are equal to the radius of a tube. The two lifting pieces are arranged on the extension line of the diameter of the tube, and a lifting hole is formed in each lifting piece. The lifting holes are used for connecting a lifting rope in a penetrating mode. Due to the fact that a circular ring is used to lift the large-diameter tube, gravity stressed by the large-diameter tube assembling and lifting tool can be evenly distributed on the circular ring, and therefore pressure on each portion of the tube is roughly equal. Thus, the phenomenon that circular degrees of the tube are reduced caused by uneven stress in the process of lifting can be avoided.

Owner:JIANGSU SHENMA ELECTRIC CO LTD

Casting system and casting method for cylinder barrel

Owner:宁波拓铁机械有限公司

Fixed shaft type outer rotor brushless motor

InactiveCN108134496AReduce intensityLow roundnessMechanical energy handlingSynchronous machines with stationary armatures and rotating magnetsConductor CoilBrushless motors

The invention discloses a fixed shaft type outer rotor brushless motor, comprising a permanent magnet rotor, a winding stator, a fixed shaft and a shell. The fixed shaft is fixedly arranged. The winding stator is fixed to the fixed shaft. A bearing is arranged between the fixed shaft and the shell. The permanent magnet rotor is fixed to the inner wall of the shell, and surrounds the winding stator. The permanent magnet rotor drives the shell to rotate when rotating. By using the fixed shaft type outer rotor brushless motor, the requirement on the roundness, smoothness and concentricity of themotor output shaft can be reduced. Moreover, the fixed shaft type outer rotor brushless motor is of high reliability and lower cost.

Owner:东莞市卓奇电子科技有限公司

A method for planning the machining trajectory of a laminated material hole

ActiveCN111390253BAvoid processing defectsImprove processing qualityMilling equipment detailsStructural engineeringCutting force

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

A retractable inner support tooling

ActiveCN109366052BGuaranteed roundnessImplement rigid constraintsWelding/cutting auxillary devicesAuxillary welding devicesEngineeringStress relief

The invention discloses an extensible and retractable inner supporting tool. One end of a left-handed screw is installed in a screw installation hole in the plane geometric center of a supporting plate, and the left-handed screw is in rotating fit with the screw installation hole. A left-hand thread at the other end of the left-handed screw is installed in a threaded hole in the center at one endof a sleeve. One end of a right-handed screw is installed in a screw installation hole in the plane geometric center of the other supporting plate, and the right-handed screw is in rotating fit with the screw installation hole. A right-hand thread at the other end of the right-handed screw is loaded in a threaded hole in the center at the other end of the sleeve. The extensible and retractable inner supporting tool has extending and retracting functions; in a shortened state, the extensible and retractable inner supporting tool can be put into a shell and then extends to support a cylinder, rigid restraining to the cylinder is achieved, and the welding deformation is reduced; and by means of stress relief annealing heat treatment through the belt tool, deformation stress is eliminated, andtherefore the cylinder circular degree after welding is guaranteed, and the circular degree of the shell is reduced to 2.5 mm from 10 mm.

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

Tyre element assembly drum

The present invention provides a tyre element assembly drum capable of holding roundness even zooming radii of a segment mold. The drum forms the circular tyre element by winding tyre material on periphery surface of the drum. The drum comprises: a center shaft capable of being rotatably supported; a plurality of segment mold arranged surrounding the center shaft to form the periphery surface of the drum; a segment mold moving unit for moving the segment mold at drum neck in zoom manner. Each segment mold comprises a main segment mold slice moving in drum neck direction by using the segment mold moving unit; a bending segment mold slide capable of being fixed on a side edge on a side of main segment mold slide in circumferential direction in manner of cantilever and surrounding the axial line in the axial line of the drum. End of free end side of each bending segment mold slide is carried on outer surface of the main segment mold slide at other segment mold slide adjacent to the free end side, and is provided with a force applying unit for applying force on the bending segment mold slide to radial inner side of the drum.

Owner:SUMITOMO RUBBER IND LTD

Feed for improving leiocassis longirostris flavor

InactiveCN107183338AImprove survival rateImprove qualityClimate change adaptationAnimal feeding stuffOxygenase activityFood flavor

The invention discloses a feed for improving leiocassis longirostris flavor, which is prepared from, by weight, 4-8 parts of guar gum sodium carboxymethylcellulose composite, 40-50 parts of high gluten flour, 16-20 parts of maltose, 4-8 parts of bacteriostat system, 1-3 parts of hawthorn, 2-4 parts of Amomum tsao-ko, 30-50 parts of germinated brown rice powder, 16-22 parts of earthworm powder, 10-16 parts of seaweed meal, 4-8 parts of pine needle meal, and 3-3.6 parts of intestinal tract promoter. The feed has advantages of improving immunity and survival rate of leiocassis longirostris, obviously improving the survival rate, increasing economic benefit of artificial cultivation, effectively inhibiting lipoxidase activity, reducing generation of aldehydes material, and greatly decreasing stink odor of leiocassis longirostris; meanwhile, the leiocassis longirostris excrement is few and water body is not polluted.

Owner:全椒县鮰鱼养殖专业合作社

Composite cabin orthopedic tooling and orthopedic method

The invention relates to a tool and method for correcting the shape of a composite cabin section and belongs to the technical field of composite component curing deformation. In the method, the shape of the composite cabin section is corrected by using the tool at set temperature so as to reduce the problems that the deformation of a composite component causes product scrap, or too-concentrated stress on the following processing and assembly and the like.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Processing method of pipe clamp parts

ActiveCN102962375BSimple structureConsistent structureMetal-working apparatusGuide tubeBiomedical engineering

The invention discloses a processing method and tooling for a tube clamp part. The processing method and the tooling are used for processing a circular tube clamp part of which both ends are provided with small lugs. The circular tube clamp part also comprises a clamp ring and a tongue sheet. When the circular tube clamp part is formed by the processing method and the tooling, a closed die processing method is adopted. When the circular tube clamp part is bent, the die converges to the middle, and the circular tube clamp part is formed in a die cavity, so the outer circular size and the appearance quality of the circular tube clamp part are ensured, and the rebound is reduced. The tooling has the advantages that a half type upper and lower symmetrical structure is adopted, the structure is simple, the manufacture is easy, the shape is small, the manufacture cost is low, the shape of the die cavity of the tooling is the same as the shape of the circular tube clamp part, the circularity of the bent circular tube clamp part is good, the shape precision is high, and the production efficiency is high. The requirements on operation skills of operators are low, the assembly and disassembly are convenient, the production cost is low, and the circular tube clamp part has good size uniformity and stable quality.

Owner:GUIZHOU AEROSPACE PRECISION PRODS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com