Tire assembly drum

A technology for tire building drums and tires, applied in the field of tire building drums, which can solve the problems of accelerating side edge wear, reducing drum roundness, and reducing drum forming efficiency, so as to improve forming efficiency and design efficiency, and suppress the reduction of roundness , the effect of preventing quality degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

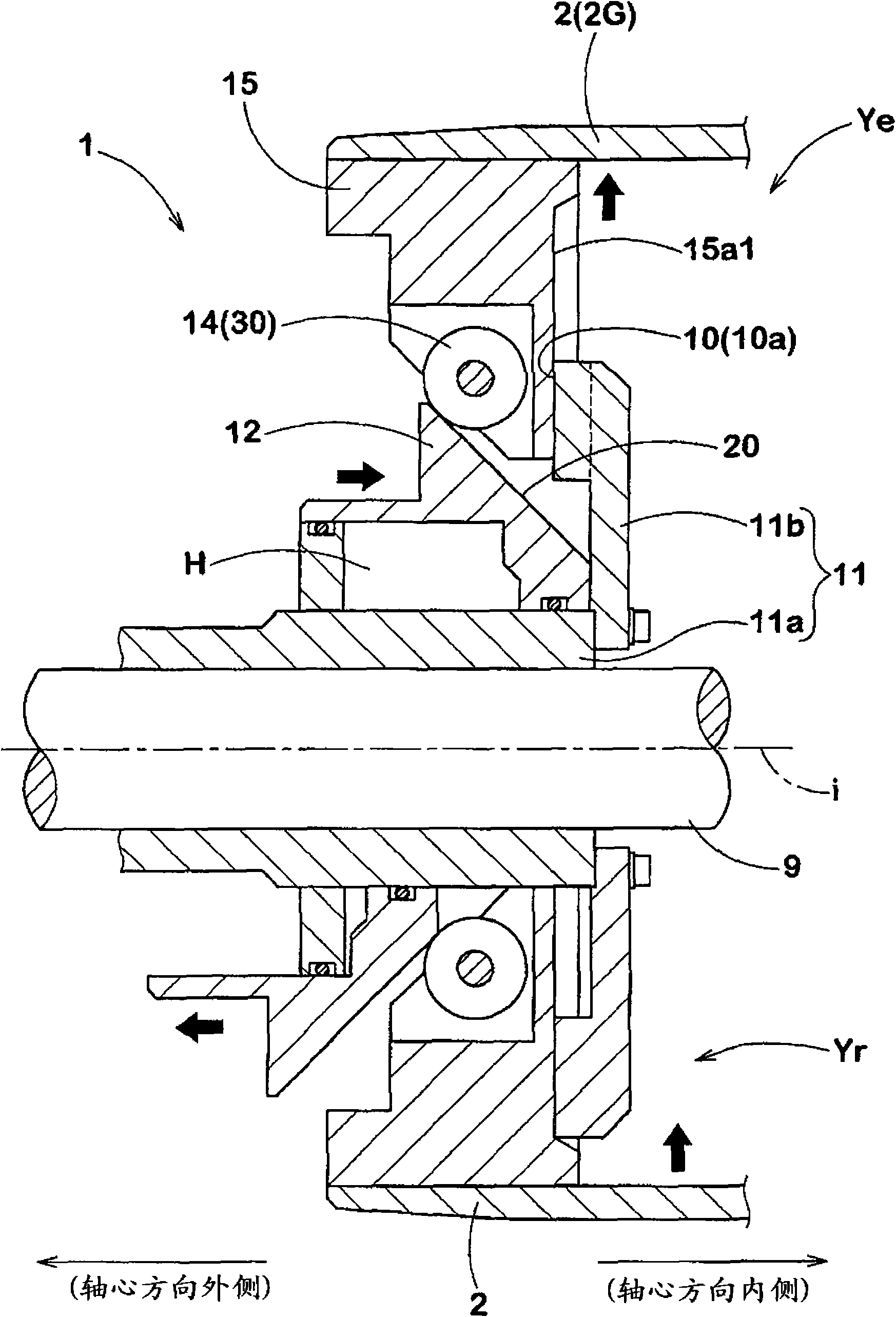

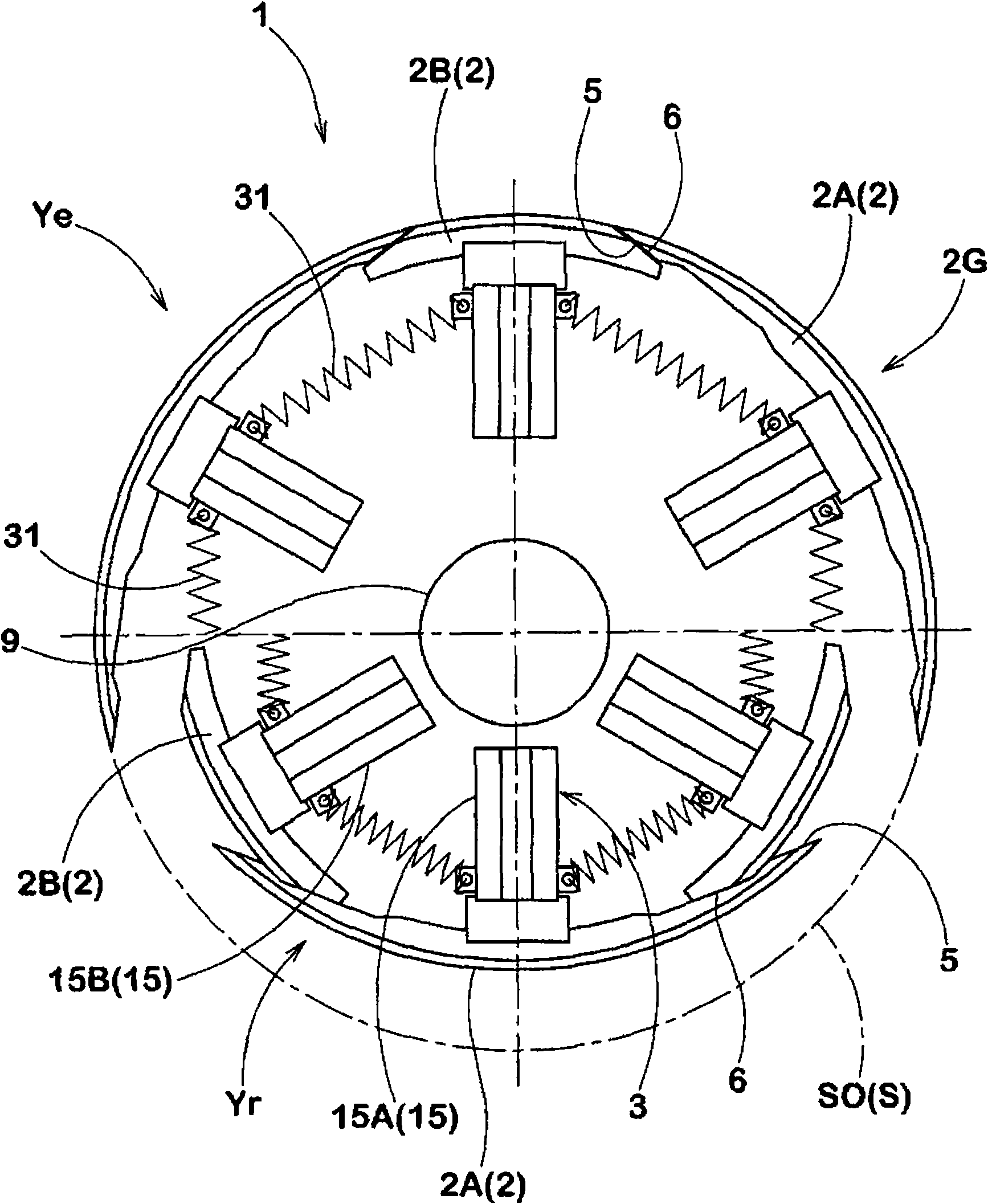

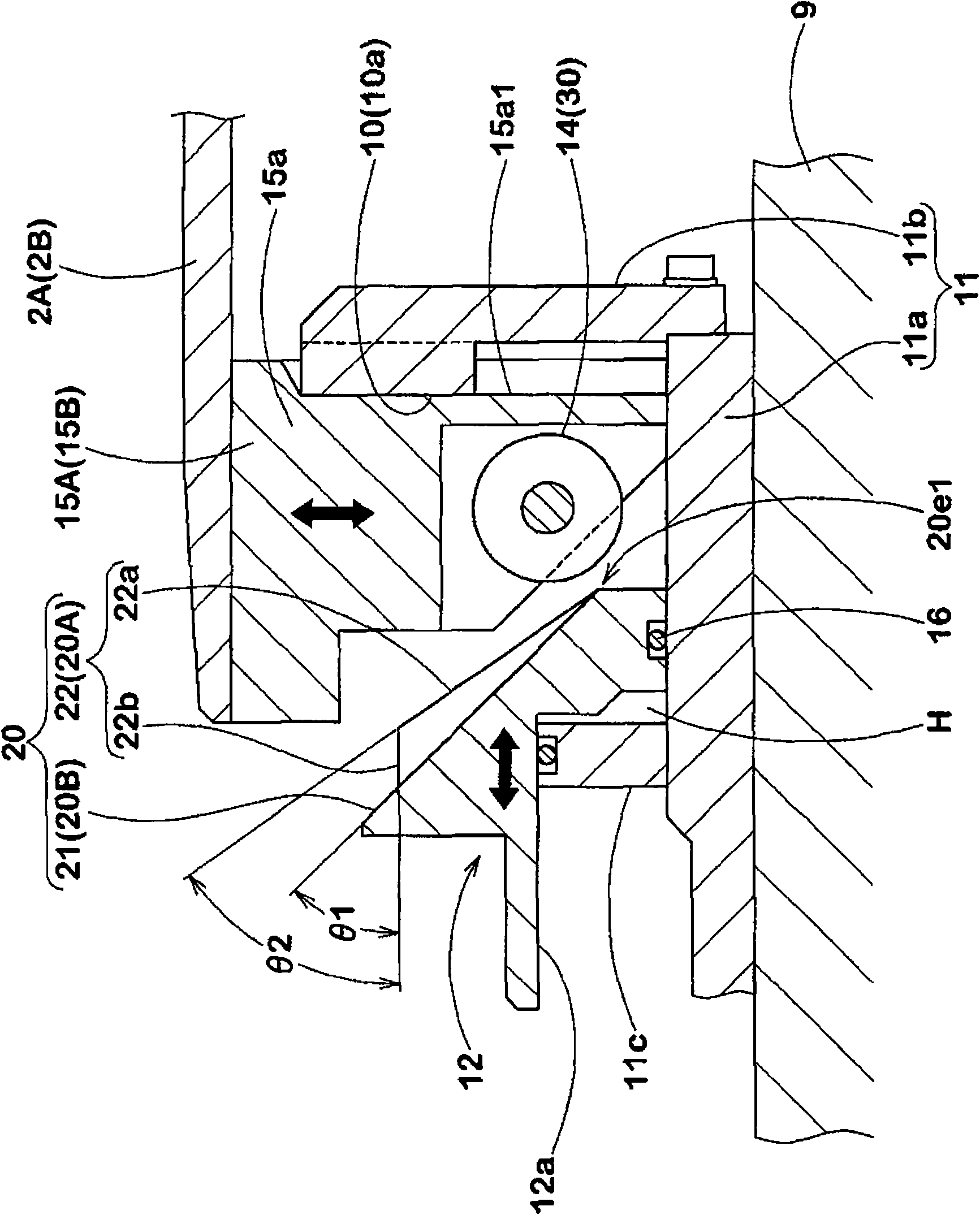

[0035] Next, embodiments of the present invention will be described in detail. figure 1 It is a sectional view showing the axial direction of the main part of the tire building drum of the present invention. Here for the sake of illustration, figure 1 The tire building drum 1 in the diameter-expanded state Ye is shown on the upper side of the axis i of the drum support shaft 9, and the tire building drum 1 in the reduced-diameter state Yr is shown on the lower side.

[0036] Such as figure 1 , 2 As shown, the tire building drum 1 of this embodiment has: a combined mold group 2G composed of a plurality of divided molds 2 divided in the circumferential direction, and an expansion and contraction unit 3 for moving each combined mold 2 radially inward and outward. In the expansion / contraction unit 3 , the split mold 2 moves between a diameter-shrinking state Yr in which the outer surface S shrinks in diameter and a diameter-expanding state Ye in which the outer surface S exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com