Patents

Literature

67results about How to "Reduce hoisting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

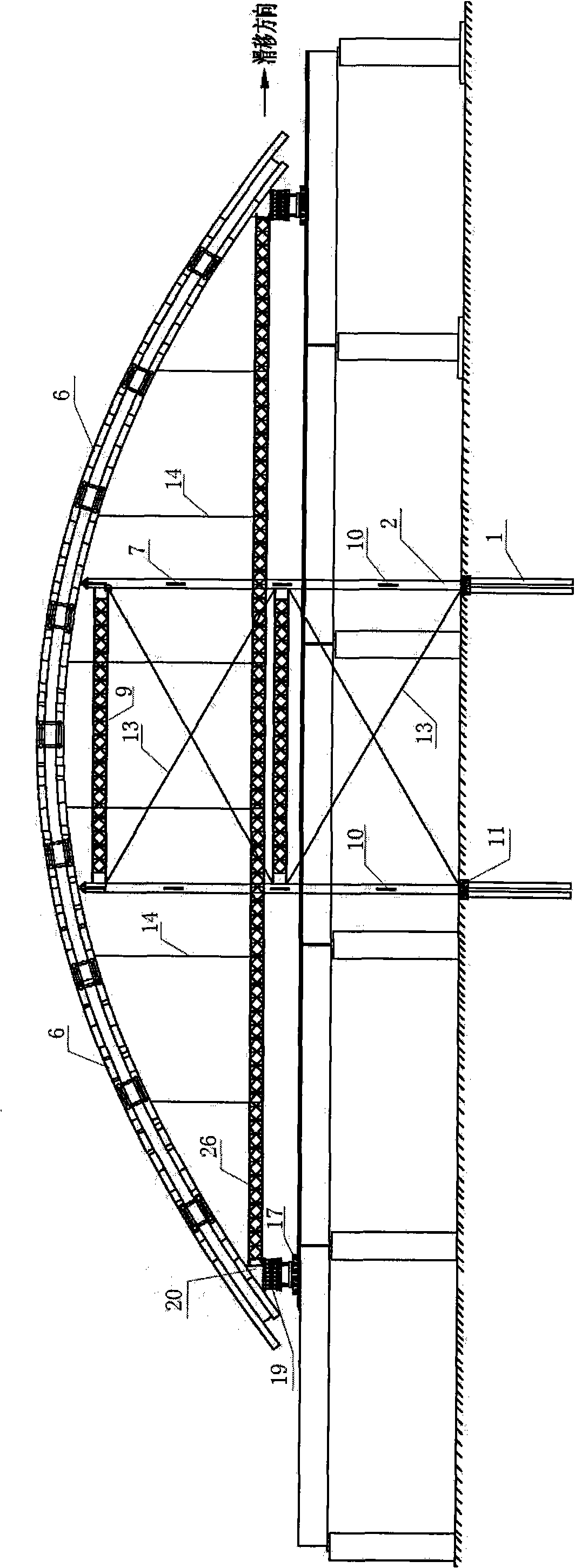

Construction method for integrally sliding large-span steel pipe arch of curved bridge

ActiveCN101935987AReduce occupancyReduce in quantityBridge erection/assemblyBridge engineeringConcrete beams

The invention relates to a construction method for integrally sliding a large-span steel pipe arch of a curved bridge, belonging to the field of bridge engineering construction. The method comprises the following steps: firstly, carrying out on-site splicing and welding on the manufacturing and installing sections of a steel pipe arch to form a large hoisting section; then installing a temporary arch-splicing support on a bridge-site longitudinal splicing site position, arranging arch ribs on the temporary arch-splicing support, and adopting an arch springing restraint device to preload arch springings after finishing splicing the steel pipe arch, thus enabling the steel pipe arch to form a stressed entirety; and finally, dismantling the temporary arch-splicing support, and adopting a pushing power system to realize integrally sliding the whole steel pipe arch into a proper position. The construction method of the invention has the advantages of small site occupation, integral hoisting of large sections, less hoisting subsection and less arch-splicing support amount, thus the construction cost is economical, the high-altitude welding quantity is less, the welding quality is ensured, the arch axis linetype control is easy, the steel pipe arch splicing and a concrete beam can be simultaneously constructed, arch splicing is carried out on an ectopic bridge site, the underbridge navigation is not influenced, the construction is safe and the construction progress can be quickened.

Owner:CHINA FIRST HIGHWAY ENG +1

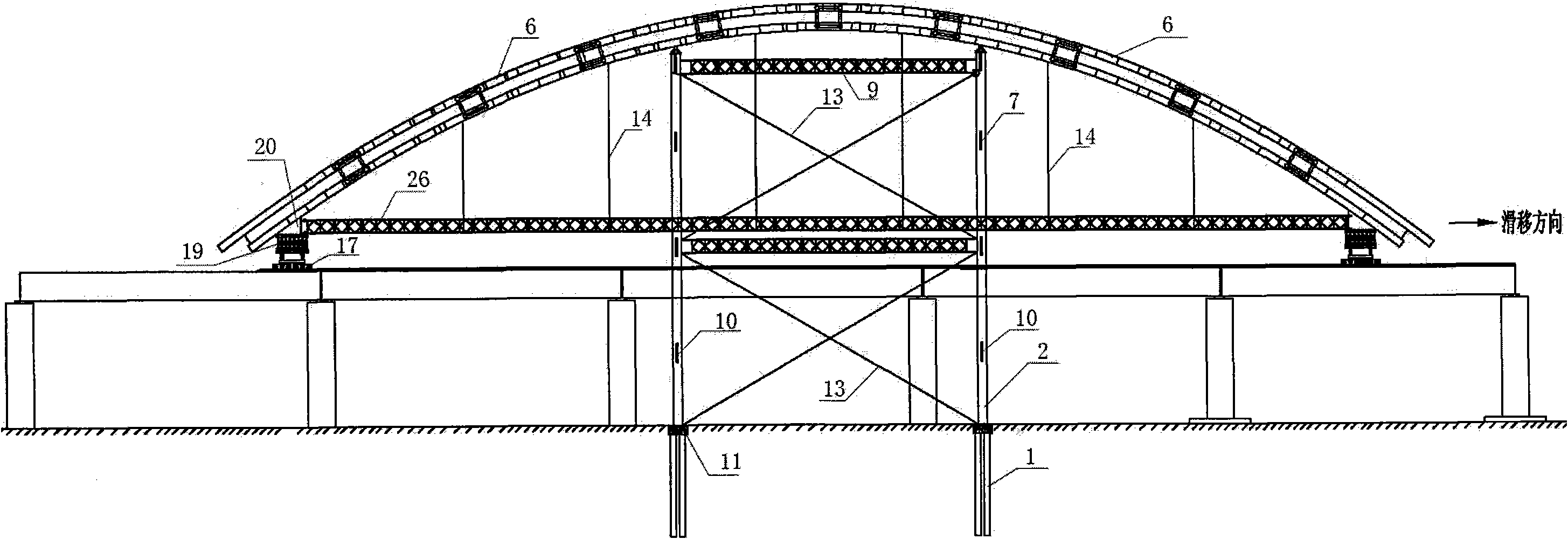

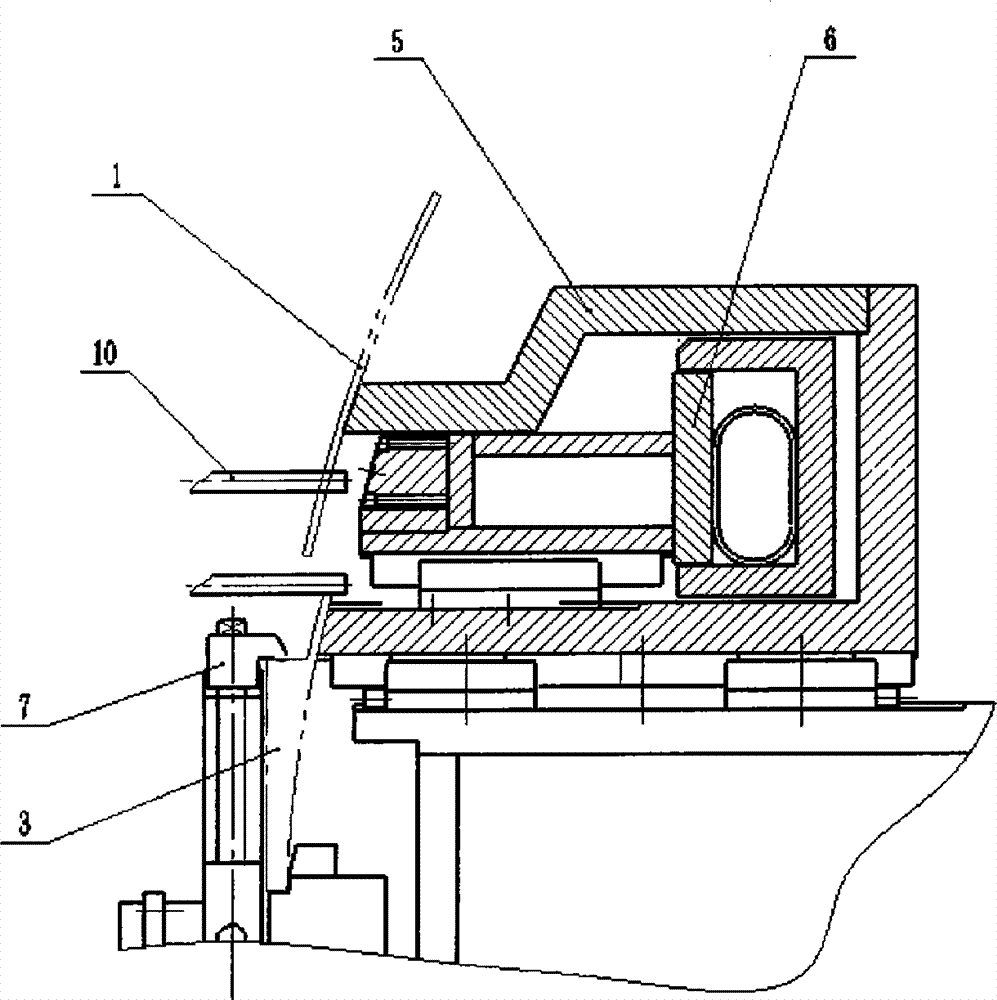

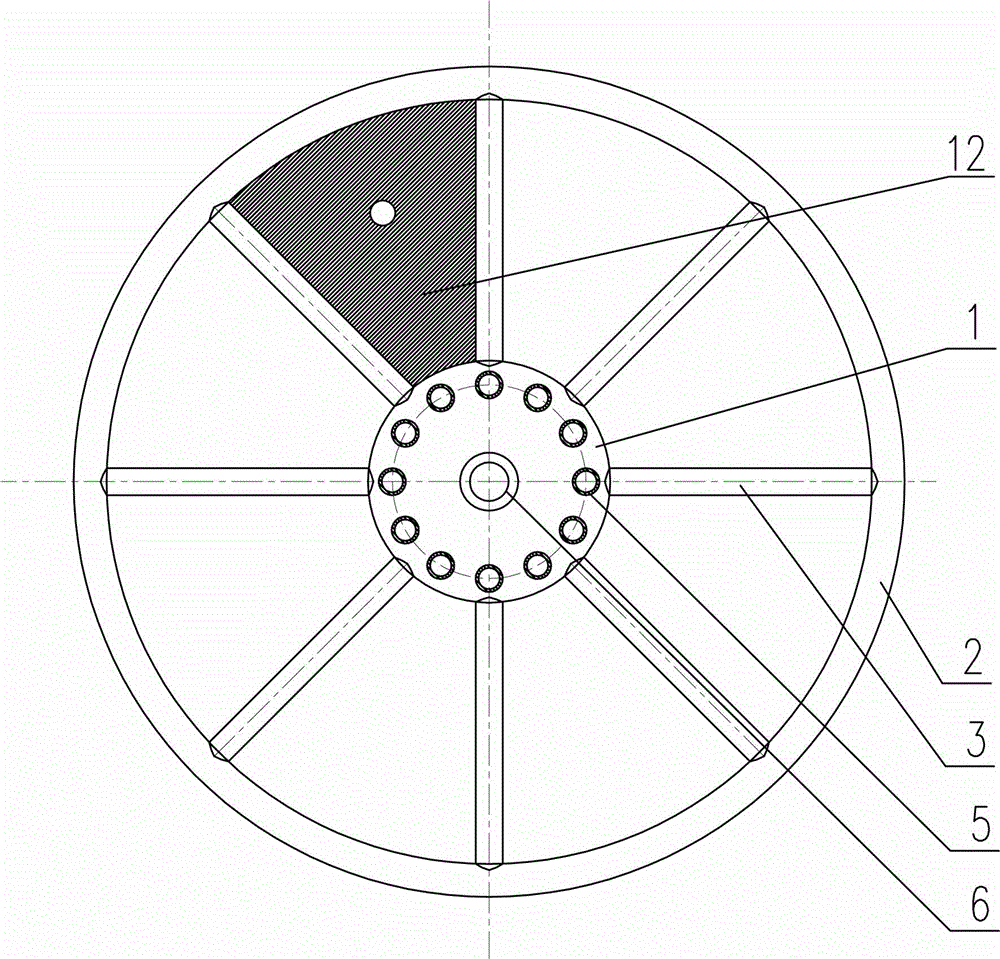

Milling and welding integrated device for upper and lower circular seams in bottom of storage box

ActiveCN104772626AReduce in quantityAvoid the trouble of shrinking and difficult to get out of the mold tireWelding/cutting auxillary devicesOther manufacturing equipments/toolsEngineeringWelding

The invention relates to a milling and welding integrated device for upper and lower circular seams in the bottom of a storage box. The device consists of a tool main body, an air cylinder inner supporting mechanism, an air bag inner supporting mechanism, a fork type ring lifting mechanism, a milling inner holder supporting mechanism, a welding back lining supporting mechanism and a circular seam outer pressing mechanism. The device disclosed by the invention has the advantages of guaranteeing accordant standards of milling, assembling and welding tools, preventing repeated assembly and location and effectively guaranteeing the product quality; by integrating milling, assembly and welding, the device has the advantages of reducing the steps of lifting, regulating, aligning, pressing and the like for replacing a work station, effectively shortening the production period, greatly improving the efficiency, also reducing the amount of tools and lowering the production cost. The air bag inner supporting mechanism has a telescopic function and can be used for preventing a trouble that a work piece is difficultly separated from a mold due to shrinkage after being welded.

Owner:AMET WELDING AUTOMATION TECH BEIJING

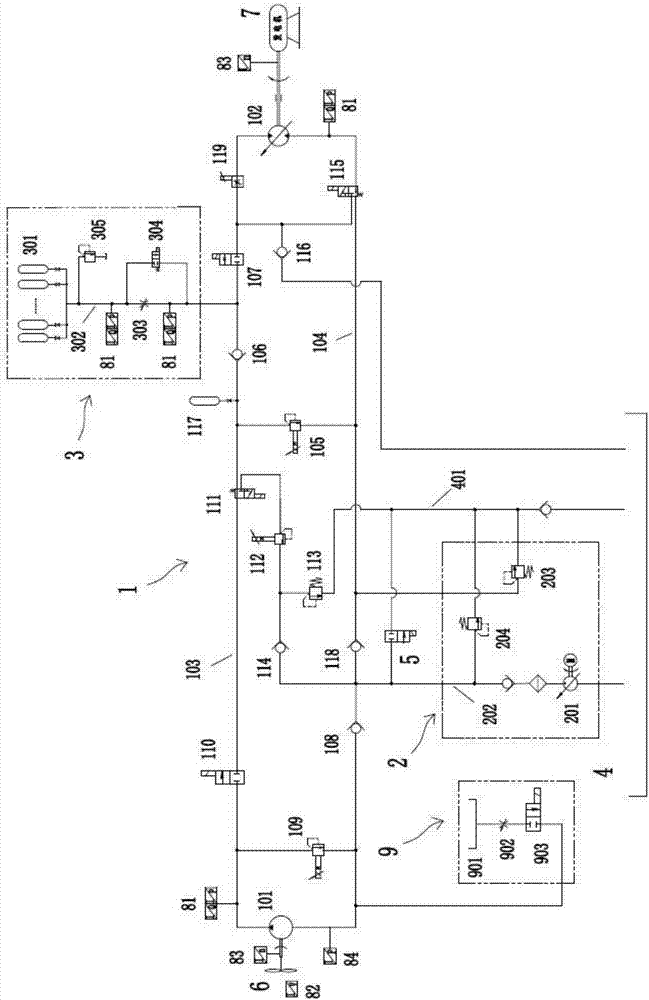

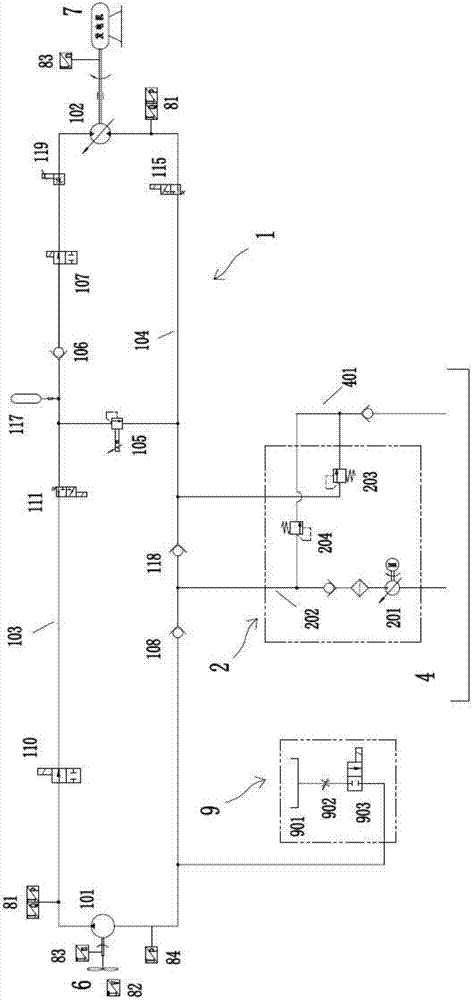

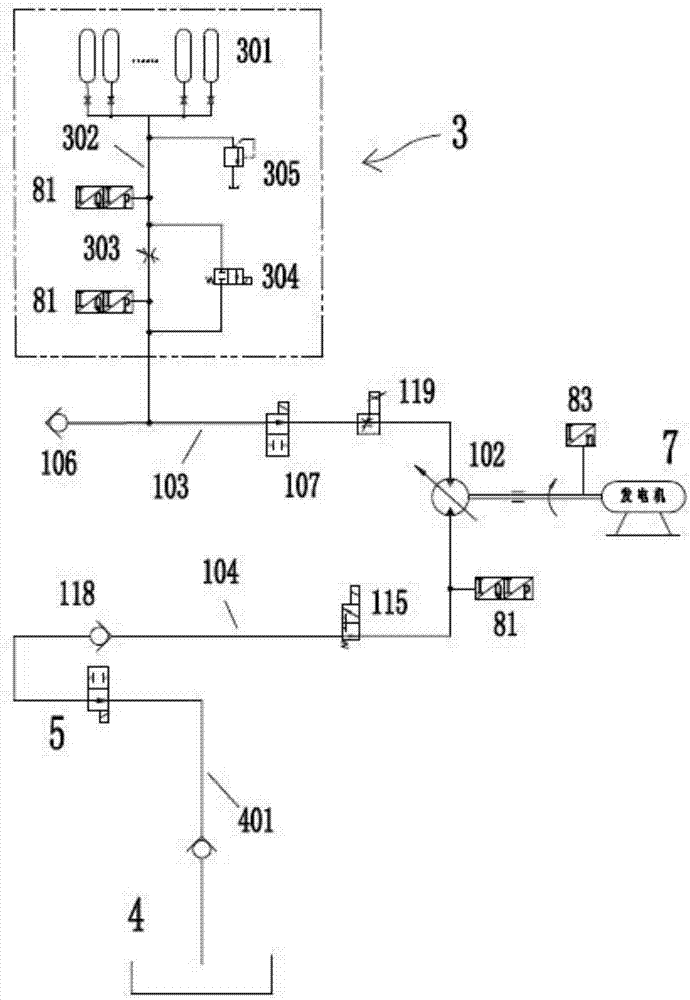

Static liquid energy storage hydraulic transmission type wind power generation set and control method

ActiveCN106870289AEasy to installEasy maintenanceWind motor controlEngine fuctionsFuel tankHydraulic pump

The invention belongs to the technical field of wind power generation control and discloses a static liquid energy storage hydraulic transmission type wind power generation set in order to solve the problems that in the actual operation process, existing wind power generation sets are unstable in power generation power due to unstable wind speed and are complicated in equipment structure during speed changing through a gear box structure. The wind power generation set comprises a main circulating system, a ground oil supplementing system, an energy storage system, a main oil tank, a first stop valve, a wind wheel and a generator, wherein the main circulating system comprises a hydraulic pump connected with the wind wheel, and a variable motor connected with the generator. According to the static liquid energy storage hydraulic transmission type wind power generation set, power fluctuation caused by wind speed change can be restrained; and in addition, the swing angle of the variable motor is adjusted according to the rotating speed of the wind wheel, thus, the output rotating speed of the variable motor is controlled, the rotating speed of the generator is stabilized, tends to the power frequency rotating speed and reaches the deviation range required by the grid-connected frequency, and grid-connected power generation is achieved more easily.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

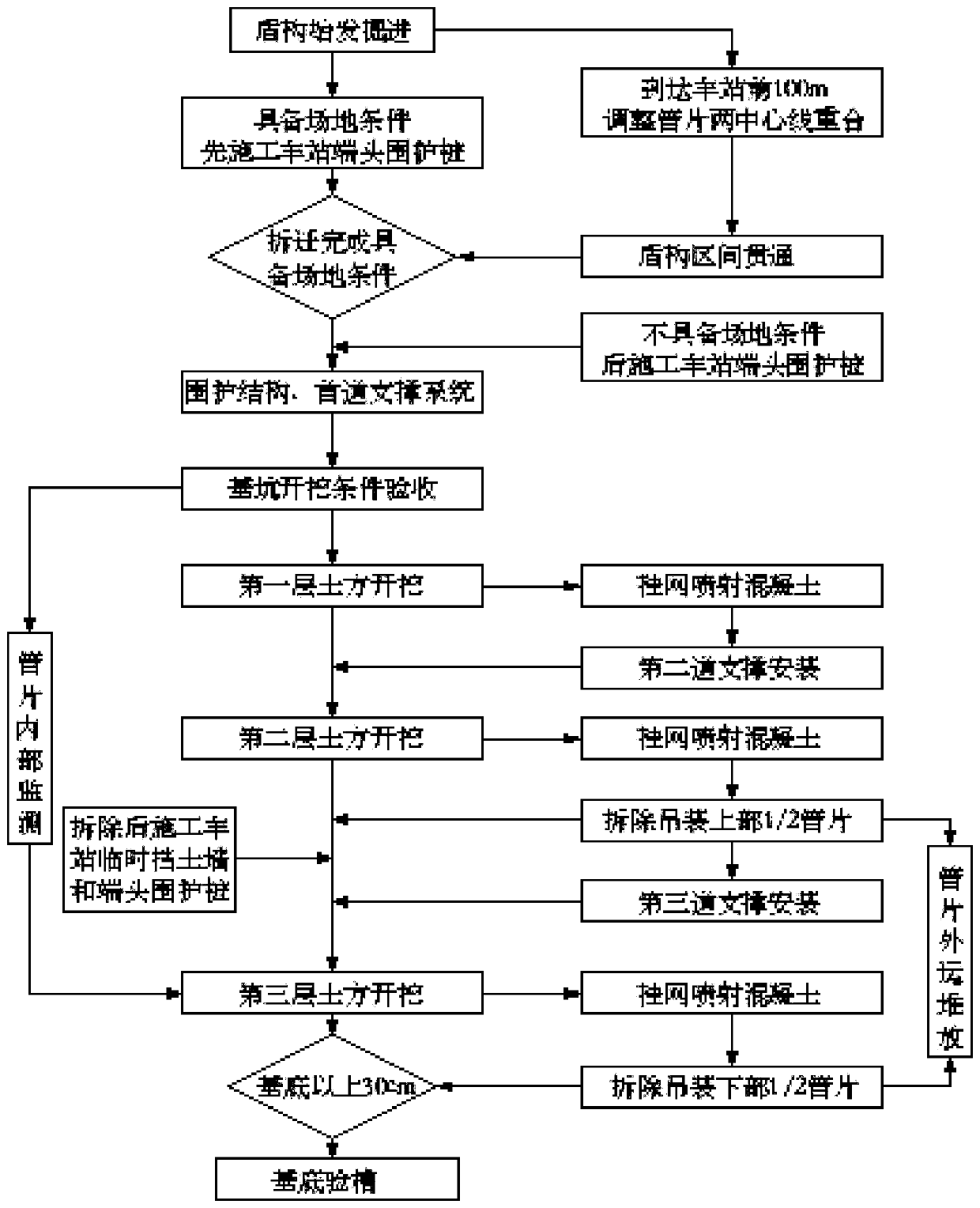

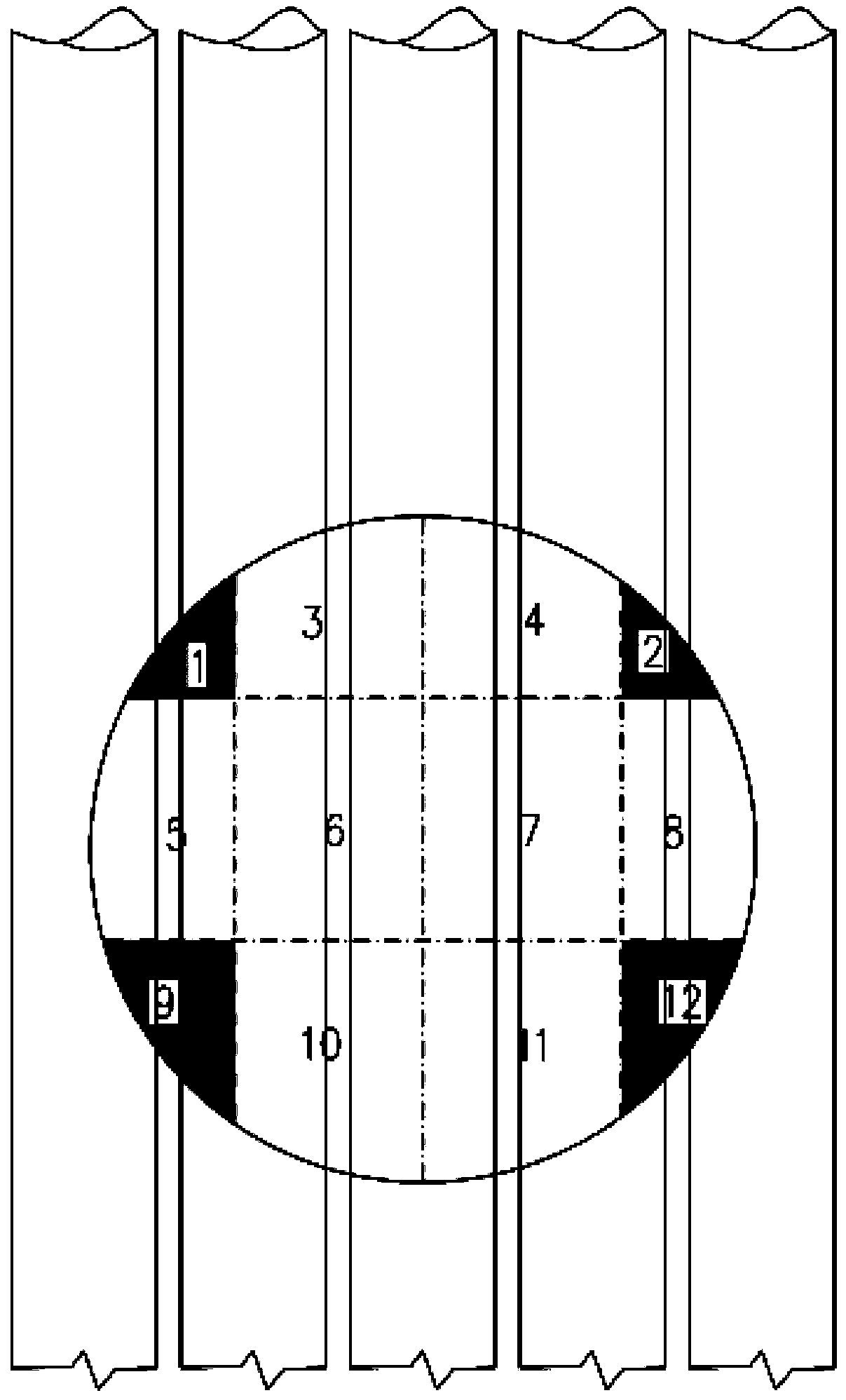

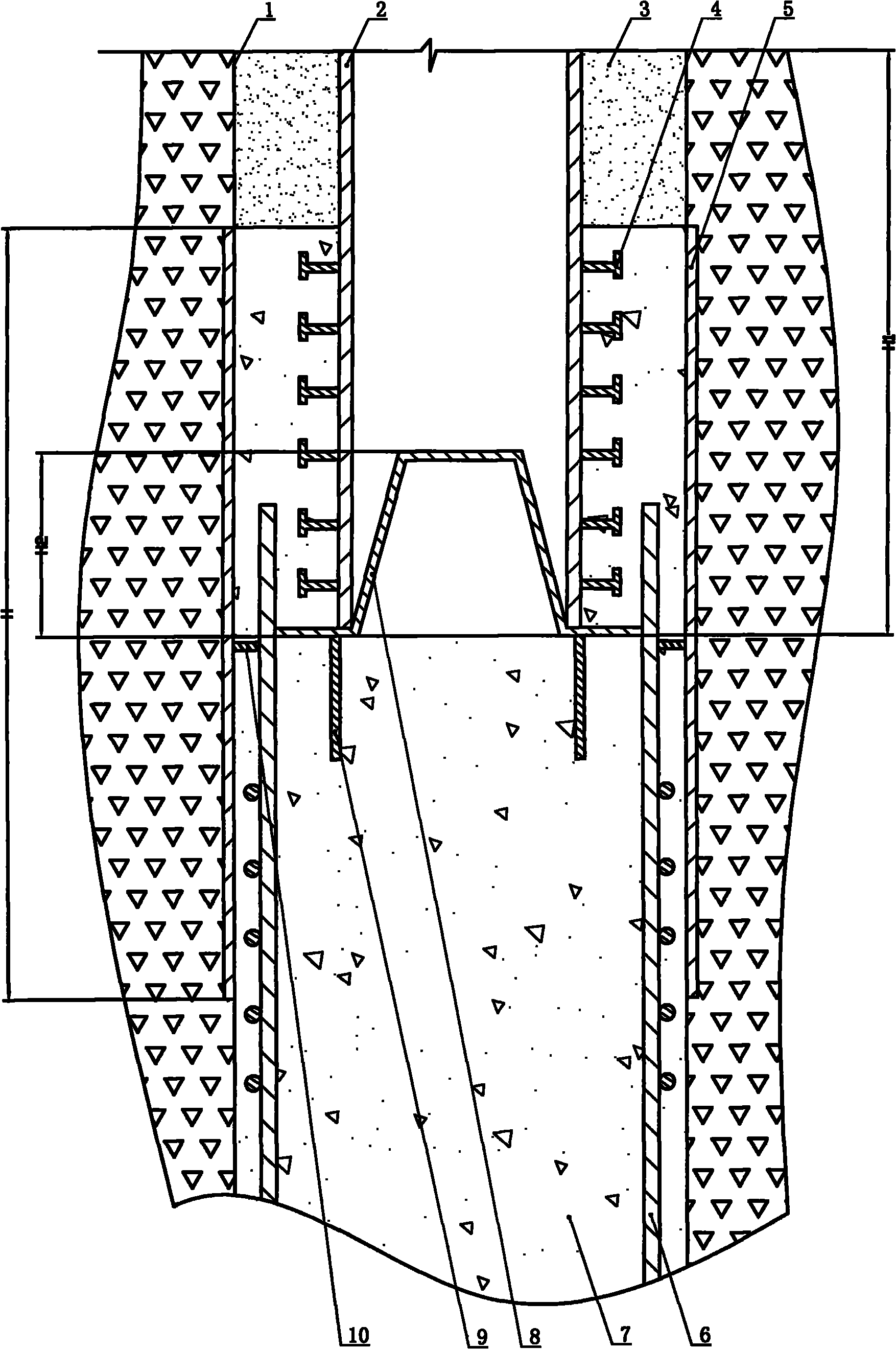

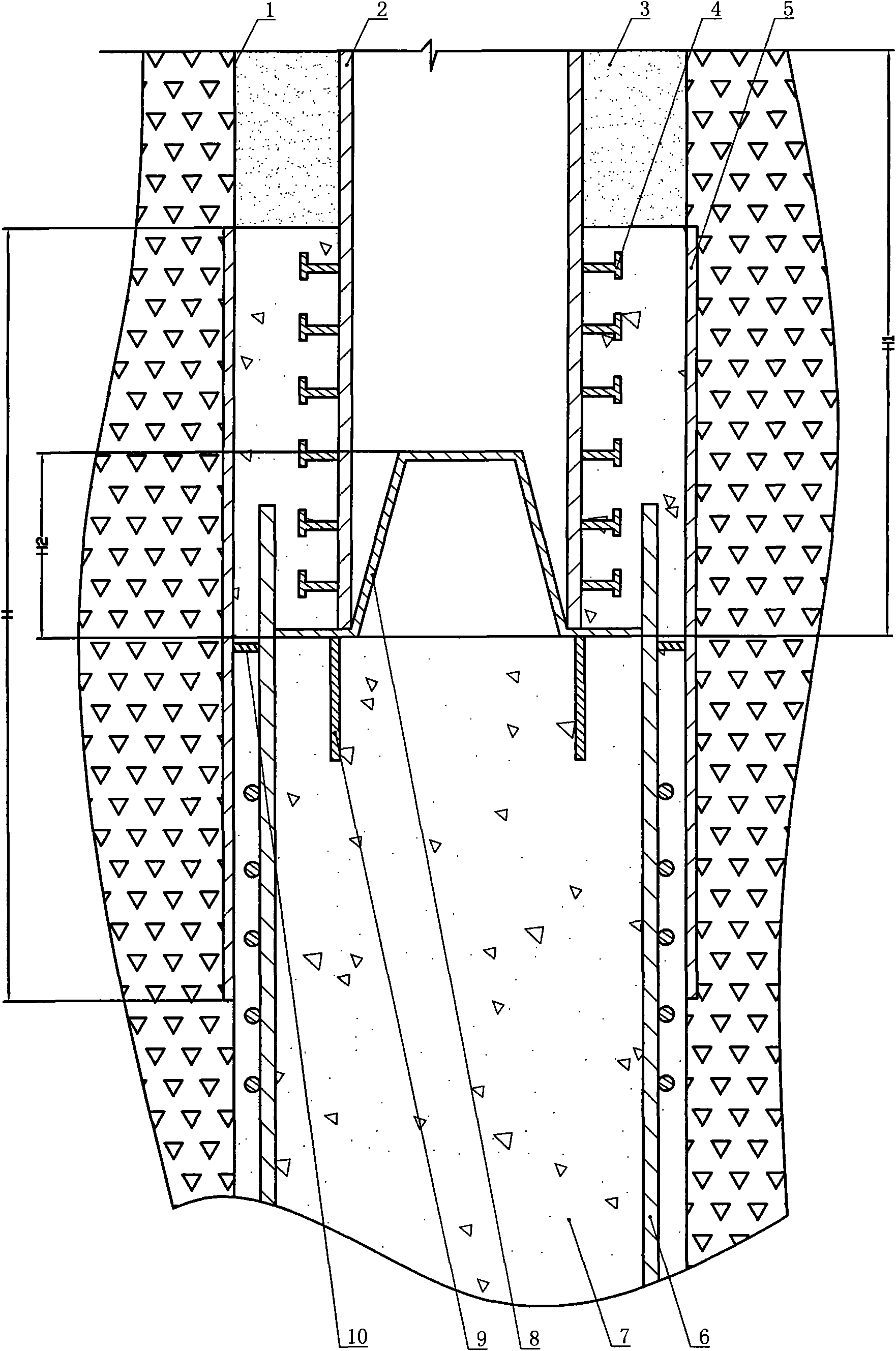

Tunnel-before-station open-cut station construction method

ActiveCN110424969ANot affected by land acquisition and demolitionControllable start timeArtificial islandsUnderground chambersArchitectural engineeringShield tunneling

The invention provides a tunnel-before-station open-cut station construction method. A shield tunneling machine carries out tunneling in advance to pass through the station range, and the problems that a station is influenced by land requisition and demolishing and does not have construction conditions, and starting and receiving conditions cannot be provided for the shield tunneling machine are solved; and the aim that the sections can be cut through firstly, and then the station is constructed is achieved.

Owner:中铁一局集团厦门建设工程有限公司 +1

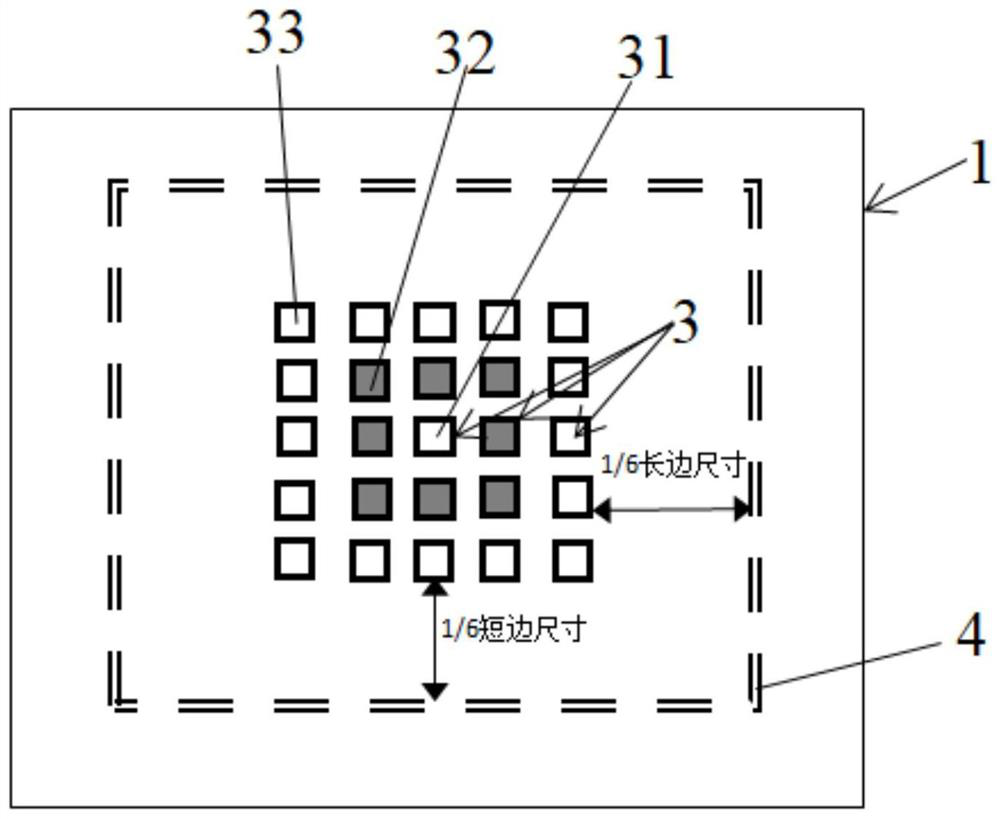

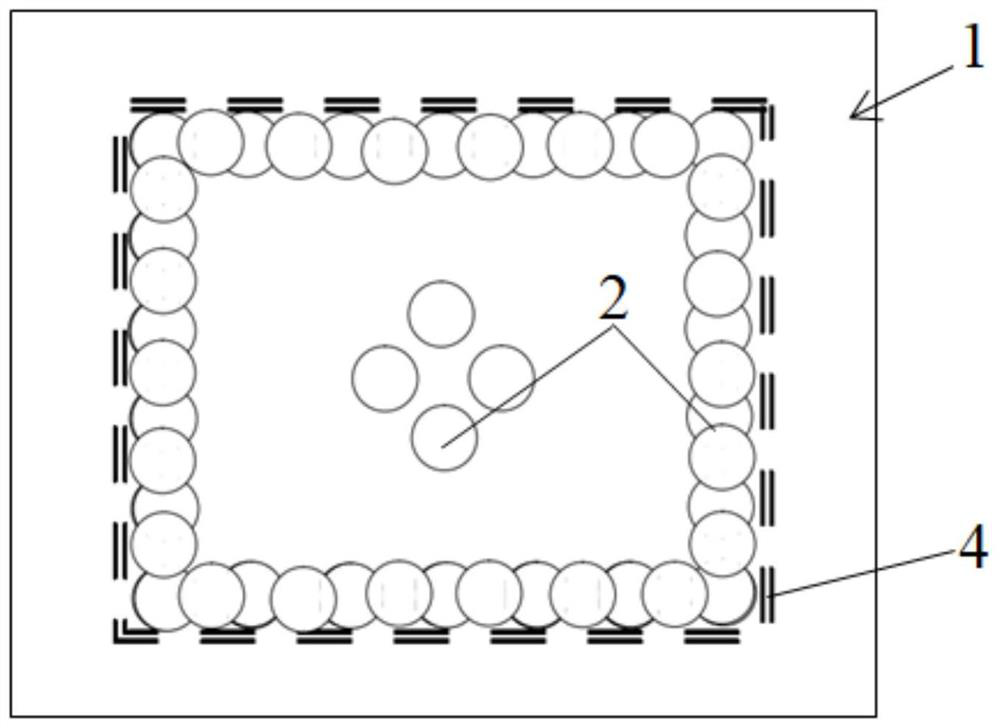

Composite positioning device and method for chassis foundation large-size component and FE end of multiple units

ActiveCN107350688APrecise positioningIngenious structural designWelding/cutting auxillary devicesAuxillary welding devicesEngineeringAssembly line

The invention provides a composite positioning device and method for a chassis foundation large-size component and an FE end of multiple units, and belongs to the field of assembly welding positioning auxiliary devices and application methods for chassis foundation large-size components and FE end components of multiple units. The composite positioning device comprises an FE end positioning tool, a chassis center line positioning tool and multiple boundary beam middle lateral tightening mechanisms, wherein the FE end positioning tool is used for clamping and positioning an FE end of a chassis, the chassis center line positioning tool is used for positioning a center line of the chassis in the length direction and the center of the chassis, and the boundary beam middle lateral tightening mechanisms are used for positioning the middles of boundary beams of the chassis. The FE end positioning tool of the composite positioning device can be modularly produced in batches, overhauling and maintenance are facilitated, production cost is reduced, the composite positioning device becomes a basis component of assembly line work, and a new subsequent process method of integrated machining after chassis assembly welding can become possible. The subsequent new method can effectively guarantee chassis geometric sizes and is beneficial to improving the product manufacturing precision and forming quality.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

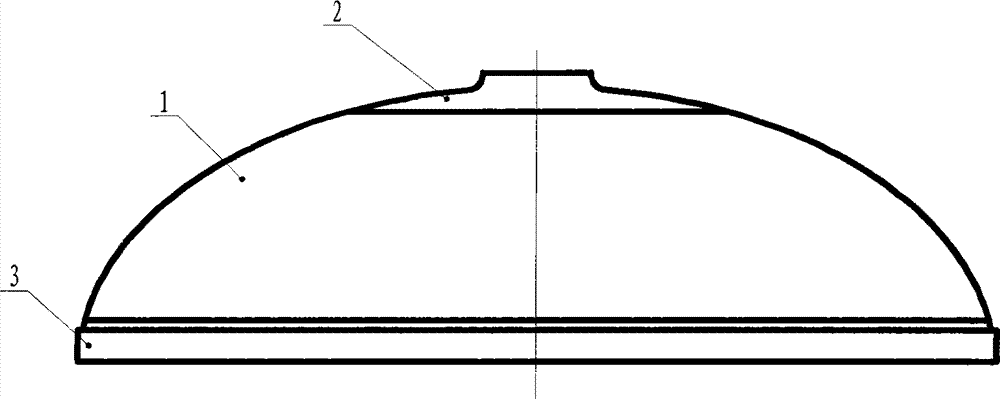

Assembly method of large-scale thin-wall steel containment vessel and auxiliary hoisting pieces

InactiveCN103241644AImprove effective lifting capacityIncreased effective lifting capacityLoad-engaging elementsEngineeringDistributor

The invention discloses an assembly method of a large-scale thin-wall steel containment vessel and auxiliary hoisting pieces, and belongs to the technical field of hoisting and transportation articles. The assembly method comprises the following steps of: arranging the auxiliary hoisting pieces, particularly, uniformly providing a plurality of first lifting lugs on a construction member to be hoisted of the containment vessel, preparing the corresponding riggings, connecting one ends of the riggings with a distributor respectively and the other ends of the riggings with adjustable drawbars respectively, connecting the distributor with a crane, hoisting the distributor and the riggings above the construction member to be hoisted, regulating each adjustable drawbar to enable the adjustable drawbar to extend to a proper length, and connecting each adjustable drawbar to the first lifting lugs respectively. According to the invention, the effective hoisting capability of the crane can be improved, the load of a foundation can be lightened, and deformation of each constructional element of the containment vessel can be reduced.

Owner:CHINA NUCLEAR IND ZHONGYUAN CONSTR +1

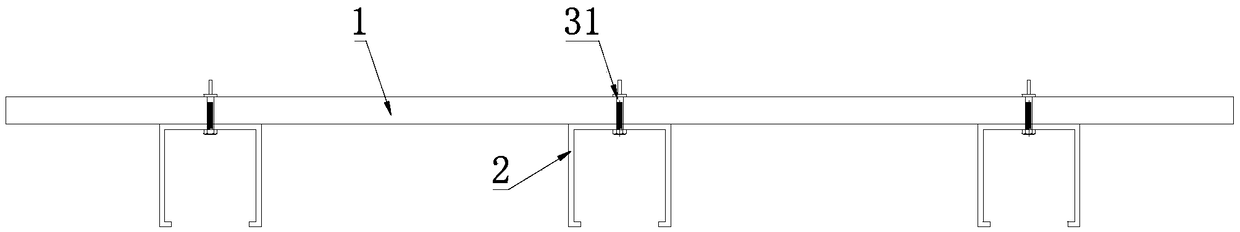

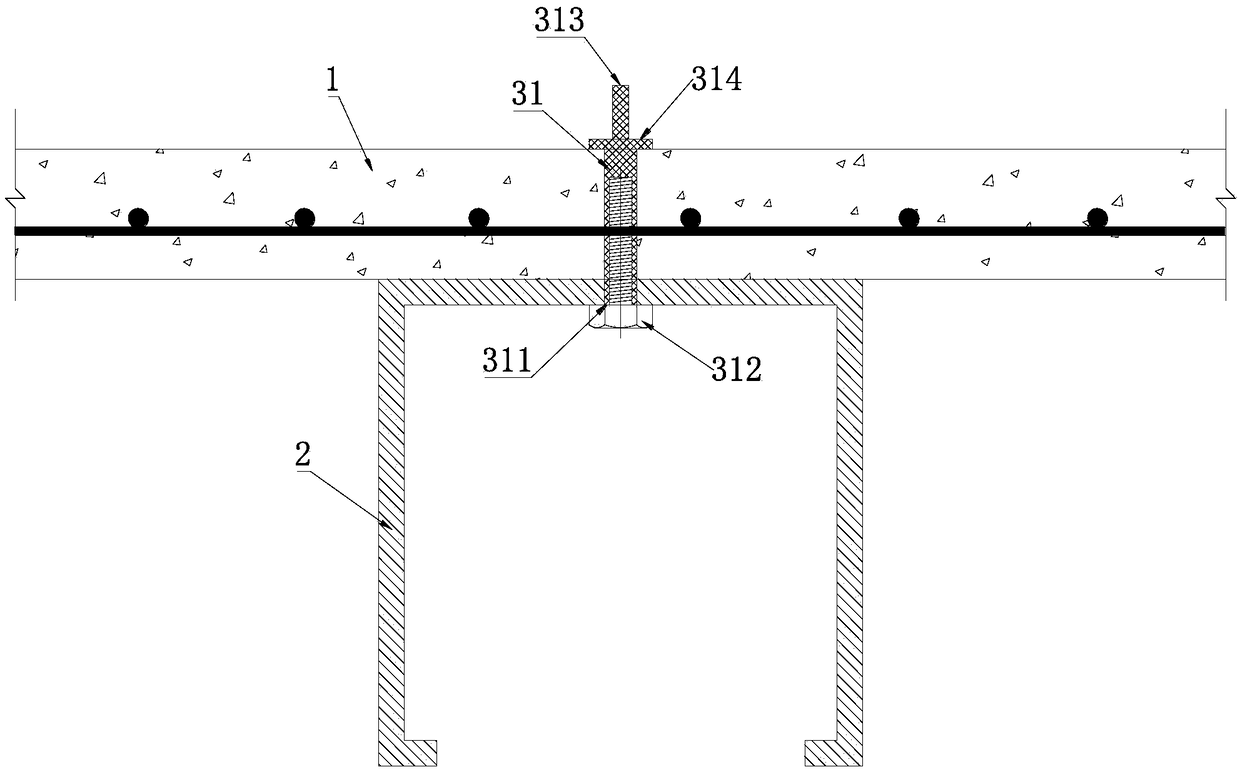

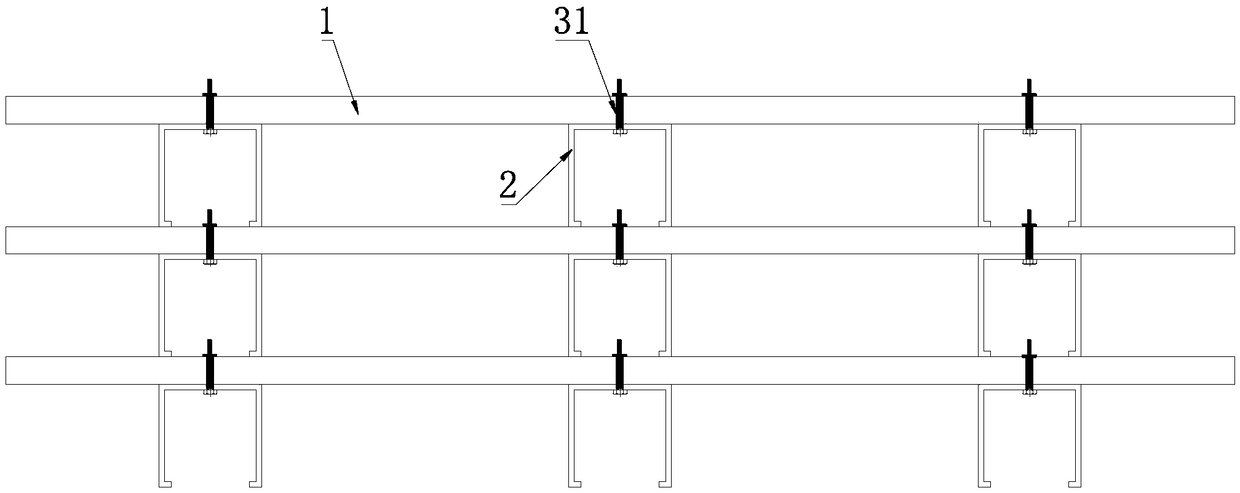

Combined prefabricated base board and composite floor slab structure and composite floor slab construction method

PendingCN109083320AFlexible adjustment of bending capacityIncreased shear capacityFloorsCrack resistanceFloor slab

The invention discloses a combined prefabricated base board and composite floor slab structure and a composite floor slab construction method and relates to the field of building structures. The problems are solved that the bending, shearing and cracking resistance capability of prefabricated base boards of existing composite floor slabs cannot be adjusted after forming; a variety of prefabricatedbase boards exist and are inconvenient to prefabricate, produce, transport and install; when spans are larger, the thickness is increased, the cost is high and hoisting is difficult. According to theadopted technical scheme, a combined prefabricated base board comprises a prefabricated base board body and a supporting part, a connector is embedded in the prefabricated base board body, the upperend of the connector penetrates out of the upper surface of the prefabricated base board, any one of the upper side and the lower side of the prefabricated base board body is connected with the supporting part, and the supporting part is detachably connected with the connector. The upper surface of the prefabricated base board body is poured with a later-poured concrete composite layer to form thecomposite floor slab structure. The prefabricated base board body is connected with the supporting part and can be made thinner, the bending resistance capability of the prefabricated base board bodyat a construction stage can also be adjusted, the types of combined prefabricated base boards are decreased, formwork-free construction is achieved, and development of prefabricated buildings is promoted.

Owner:邹胜斌

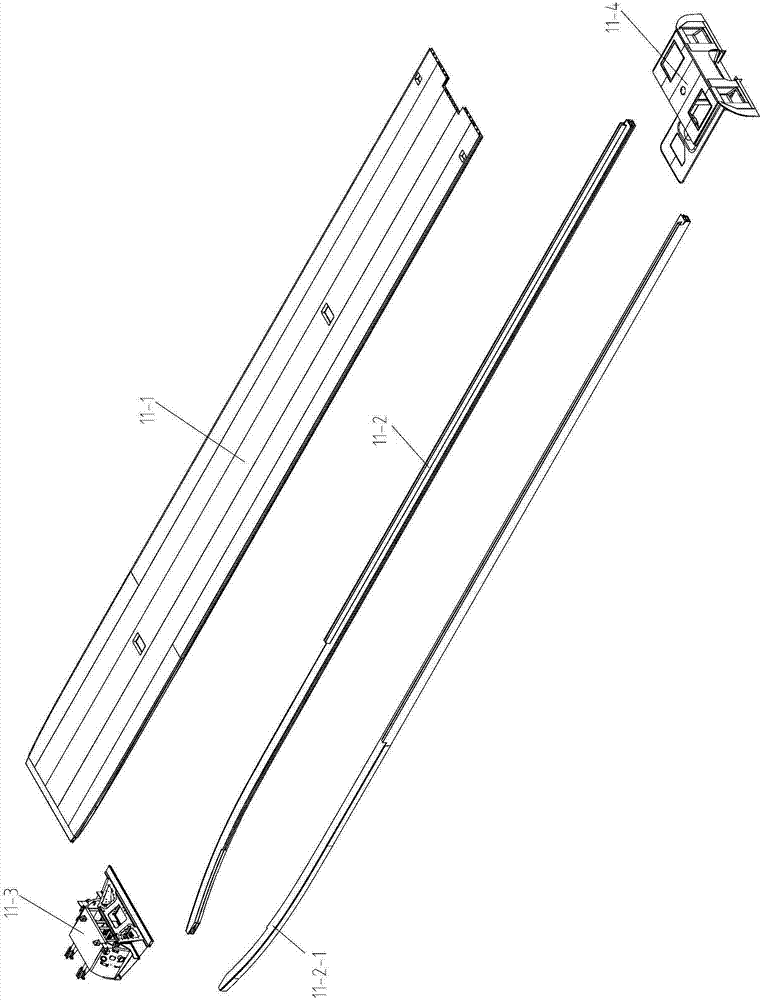

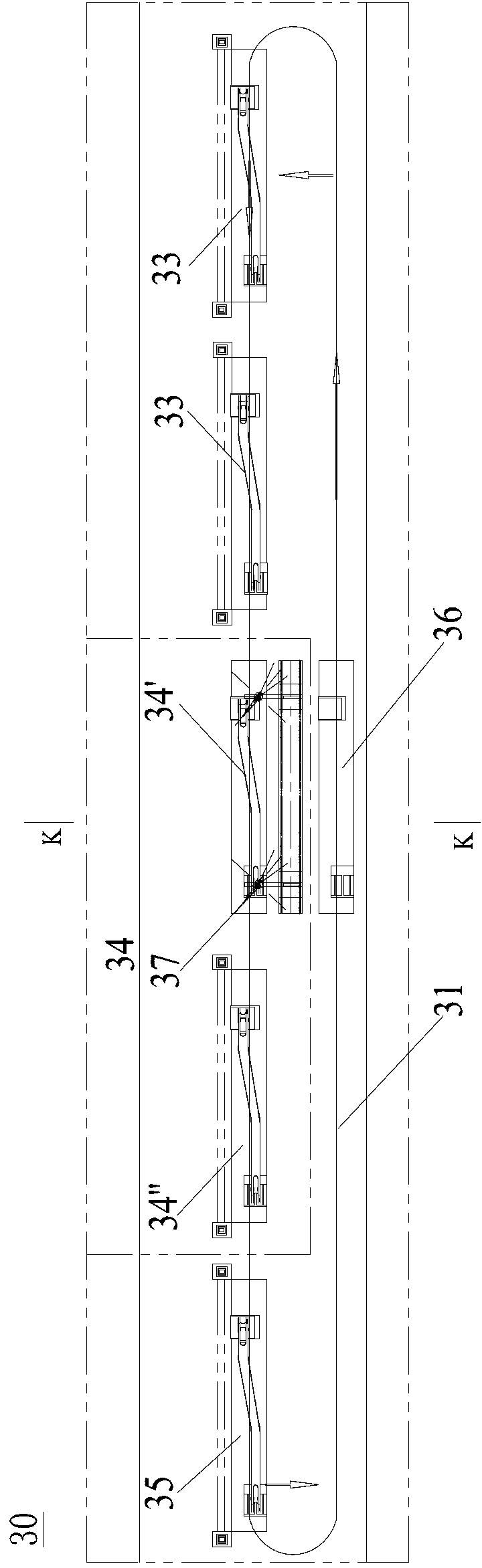

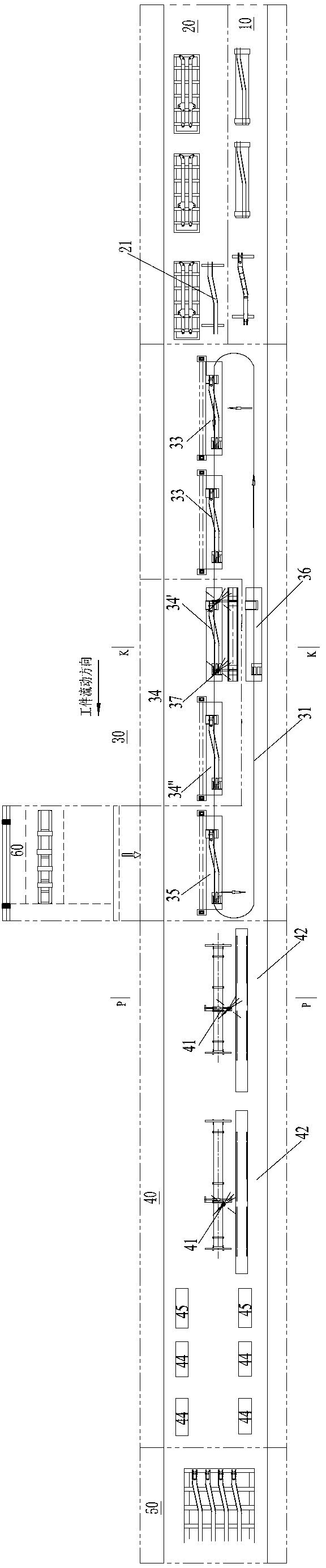

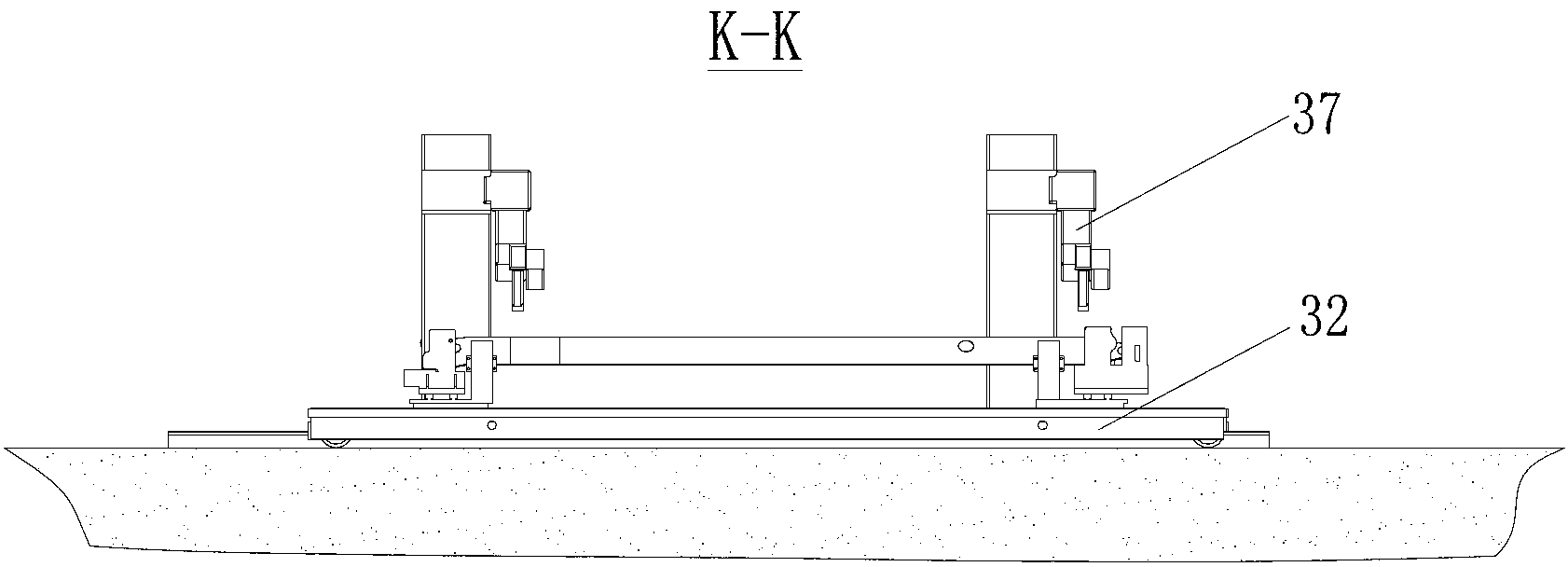

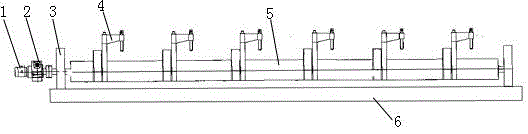

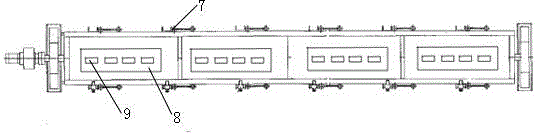

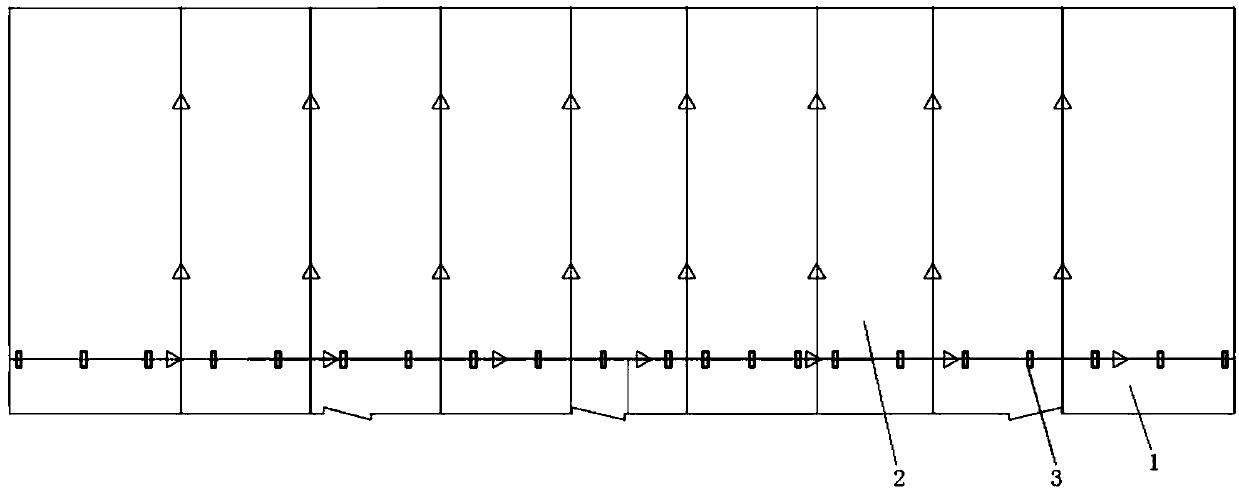

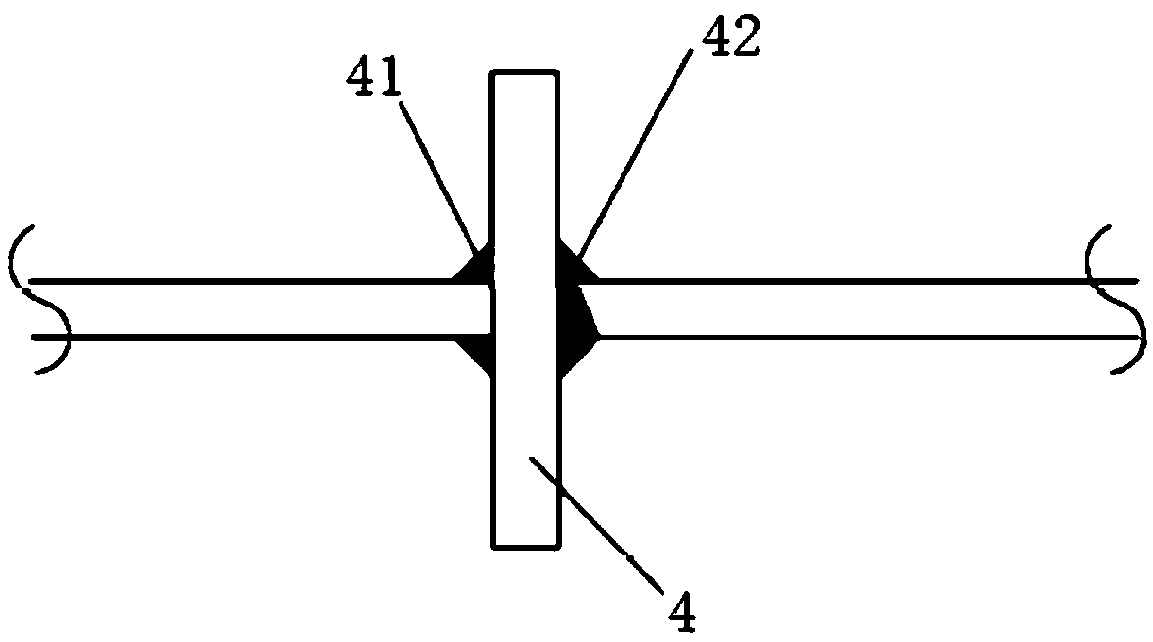

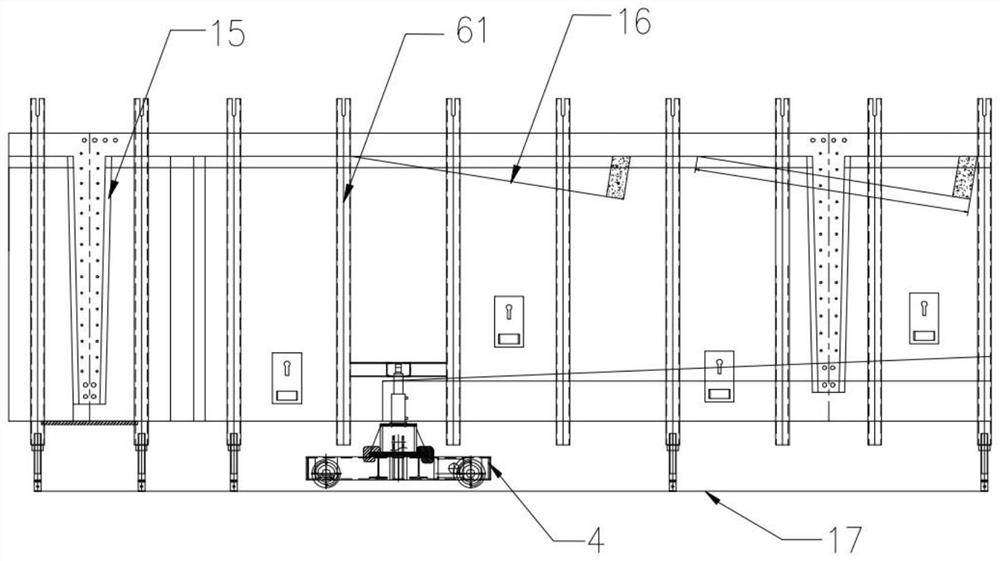

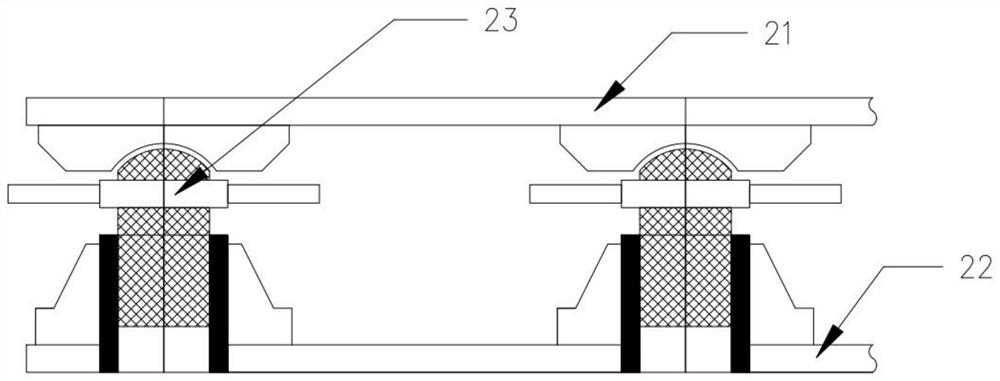

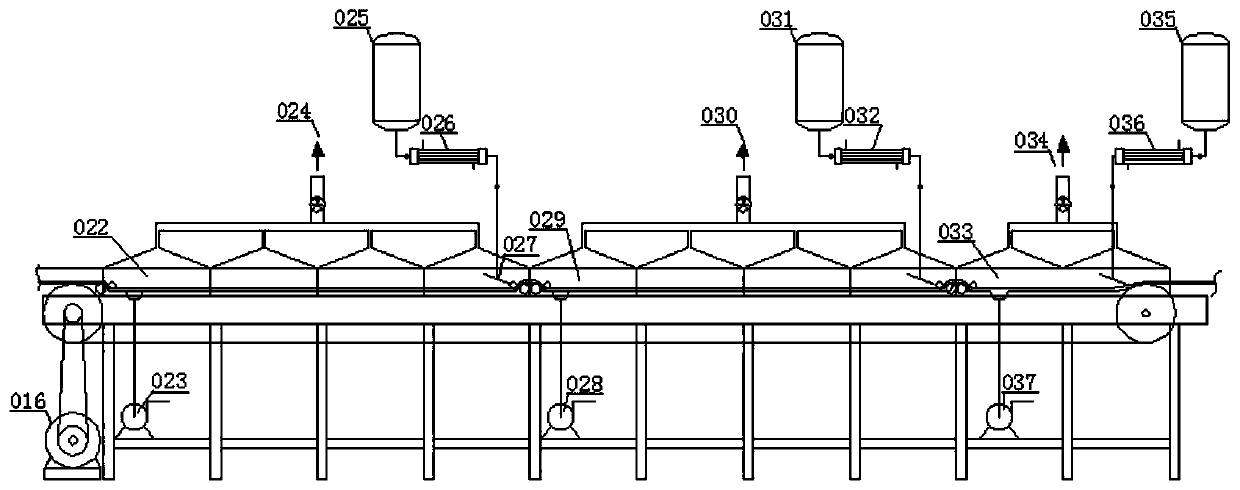

Box assembling production line, box assembling method, production system and production method for arm joint

ActiveCN103056665AReduce hoistingReduce handlingOther manufacturing equipments/toolsWelding apparatusProduction lineAutomated guided vehicle

The invention discloses a box assembling production line for an arm joint. The arm joint comprises an upper cover plate, a lower cover plate, a web and a partition plate. The box assembling production line comprises an annular track and an automatic guiding trolley arranged on the annular track movably. A web locating station, an inner welding station and an upper cover plate locating station are arranged on the annular track sequentially. The web locating station is used for locating the lower cover plate to be assembled and the web to be assembled, the inner welding station is used for welding the located lower cover plate and web together from the inside and welding the partition plate and the web from the inside, the upper cover plate locating station is used for assembling the upper cover plate to be assembled above the welded web and the partition plate and locating the upper cover plate to form a box structure. The invention further discloses a box assembling method, a production system and a production method for the arm joint. The box assembling production line enables box assembling operation of the arm joint to be automatic assembling line operation, is high in working efficiency and reduces labor.

Owner:ZOOMLION HEAVY IND CO LTD

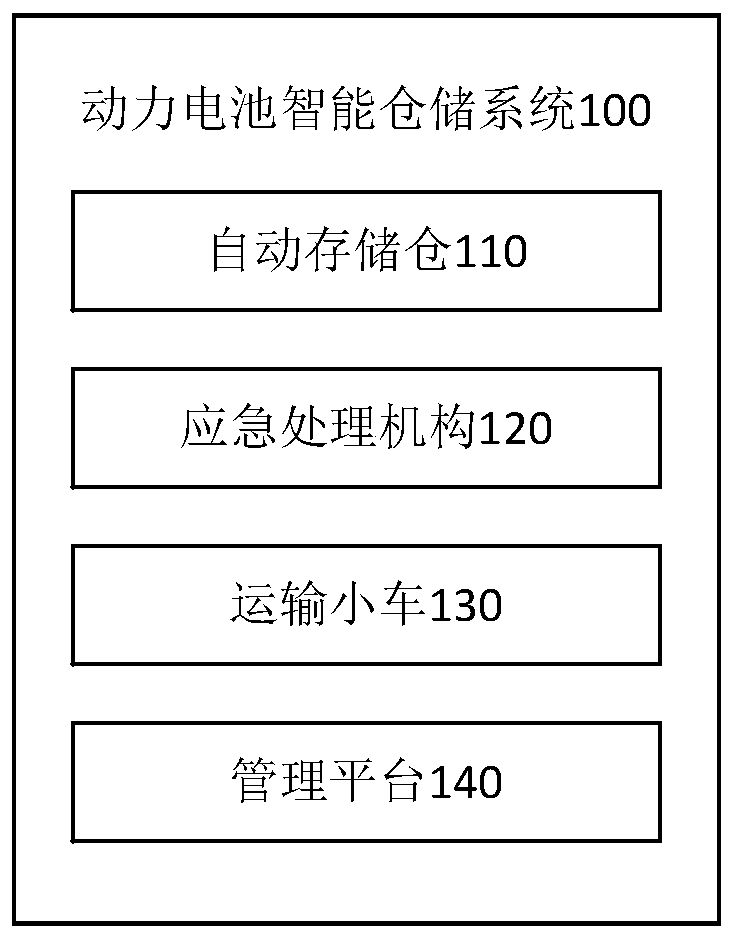

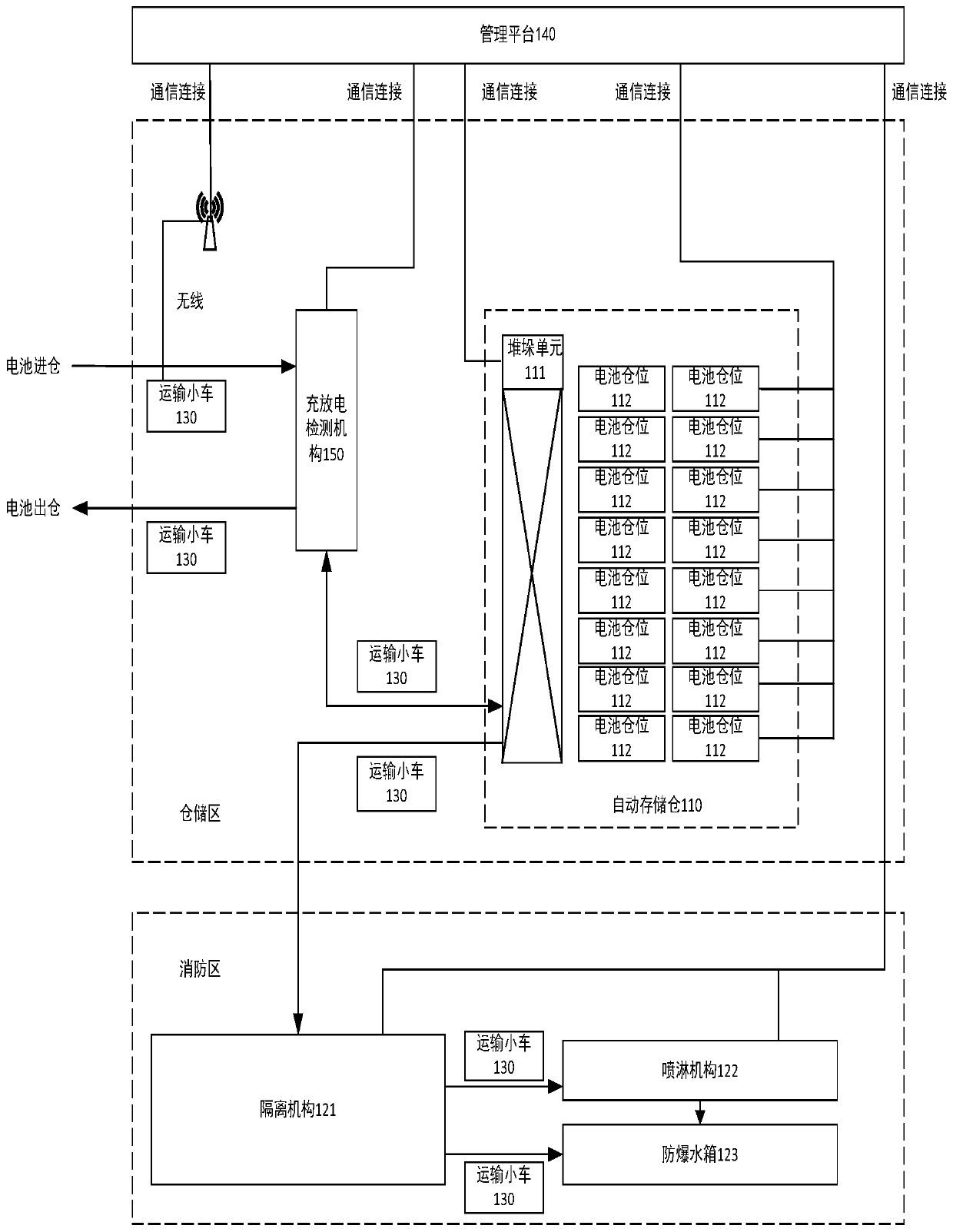

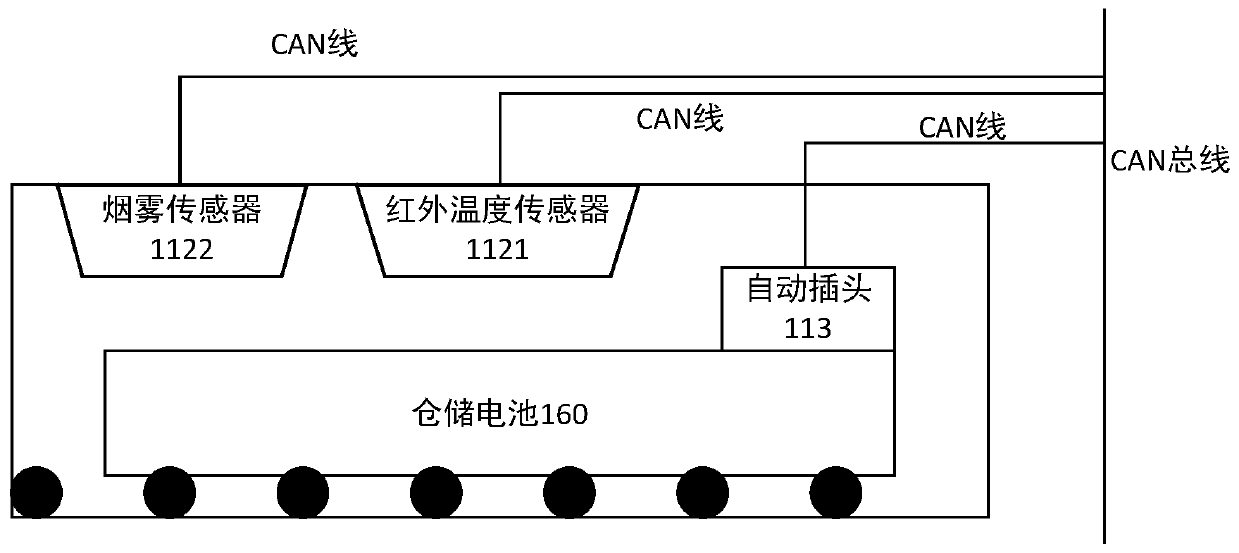

Power battery intelligent warehousing system and method

InactiveCN109733780AEnsure safetyFully automatedLogisticsStorage devicesPower batteryEmergency treatment

The invention relates to a power battery intelligent warehousing system and method. The power battery intelligent warehousing system comprises one or more automatic storage bins, one or more emergencytreatment mechanisms, one or more transport trolleys and a management platform. The automatic storage bins are used for storing batteries and arranged in the warehousing region of a warehouse. The emergency treatment mechanisms are used for conducting emergency treatment on abnormal batteries. The transport trolleys are used for transporting the batteries in the warehouse. The management platformis used for managing battery storage, battery ex-warehousing and battery safety. By means of the power battery intelligent warehousing system and method, automatic and intelligent power battery warehousing, monitoring and management are achieved, all the batteries in the warehouse can be managed in real time, the batteries with the safety risk can be timely found out, and emergency treatment is timely conducted.

Owner:NIO ANHUI HLDG CO LTD

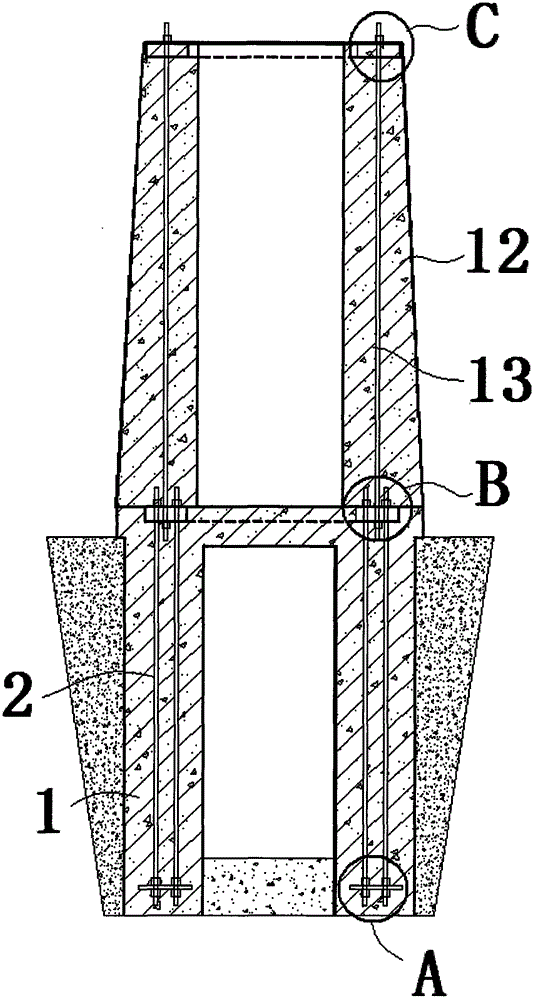

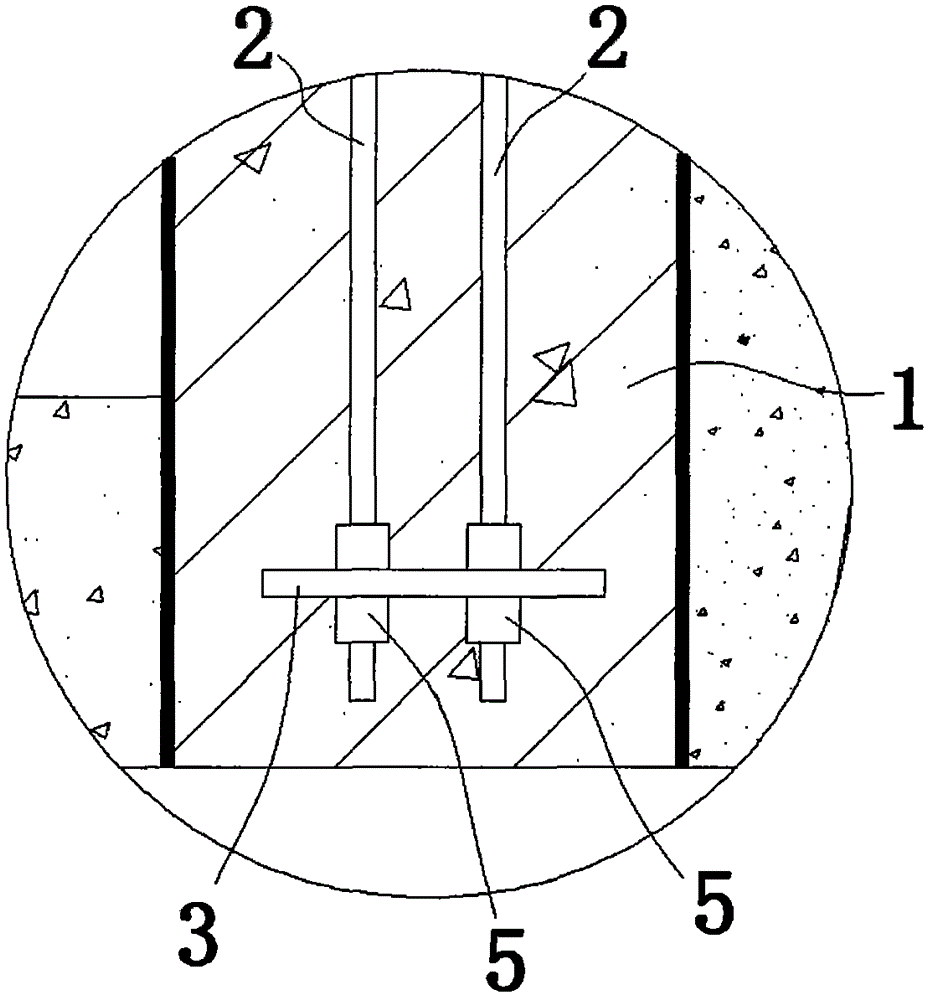

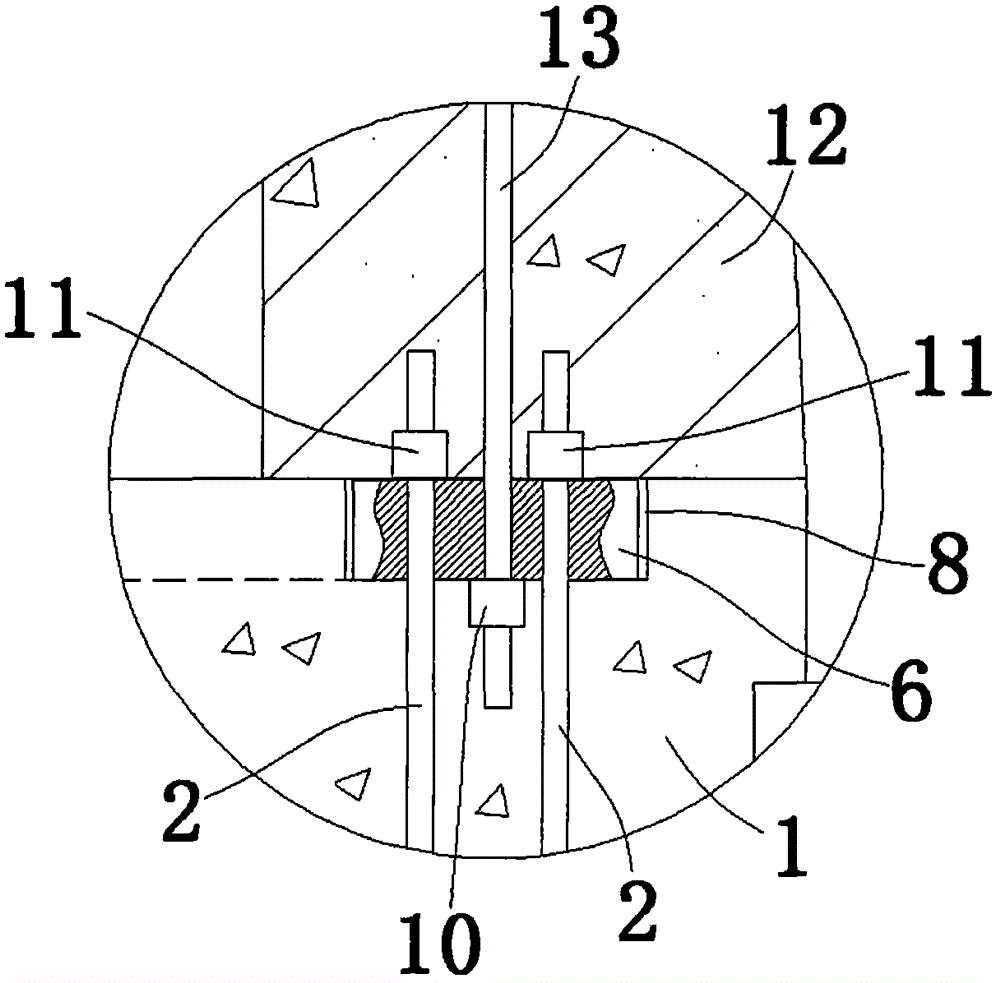

Construction method for inserting steel column in bored pile

InactiveCN102041806AReduce hoistingShorten construction timeBulkheads/pilesSteel columnsBuilding construction

The present invention relates to a construction method for inserting steel column in bored pile, comprising the following steps: (1) forming a pile hole of a bored pile; (2) hoisting a reinforcement cage; (3) pouring concretes; (4) hoisting a steel protection pipe; (5) cleaning the pile hole and placing a steel column bottom fixer; (6) hoisting a steel column, so as to complete the installation of the steel column; a top end of the hoisted reinforcement cage in the step (2) is coaxially and fixedly provided with a steel sleeve; the inner diameter of the steel sleeve is identical to the diameter of the pile hole; elevation at a top end of the steel sleeve is the same as the elevation at the top of the bored pile. The steps of construction technology of the present invention are simple; constructional time is shortened; working efficiency is improved; and constructional cost can be reduced effectively; and the present invention is a construction method for inserting steel column in bored pile with relatively high safety.

Owner:MCC TIANGONG GROUP

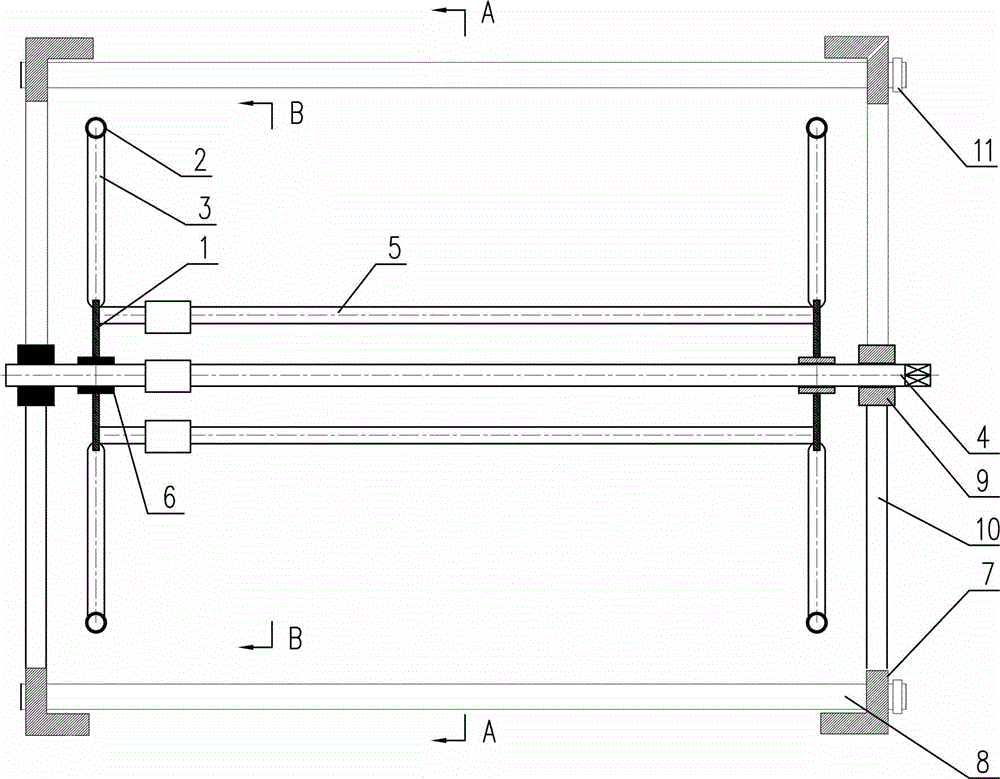

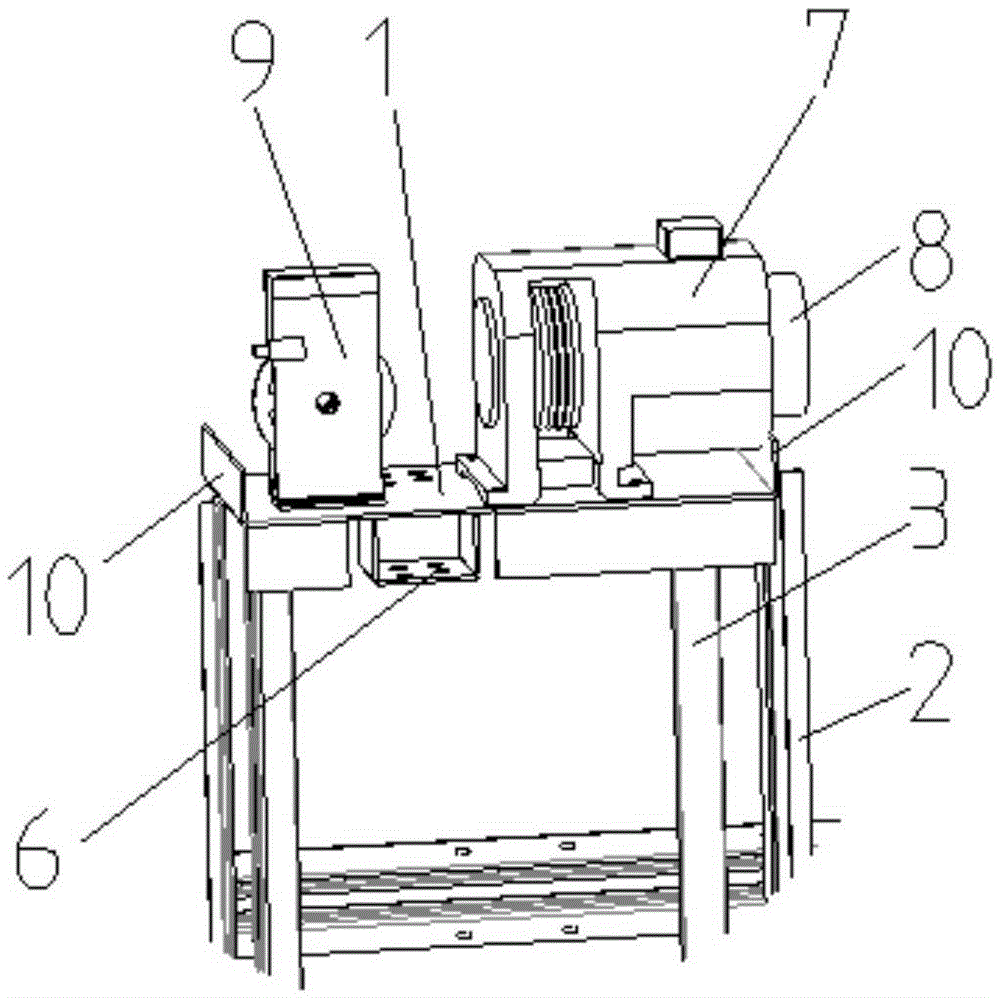

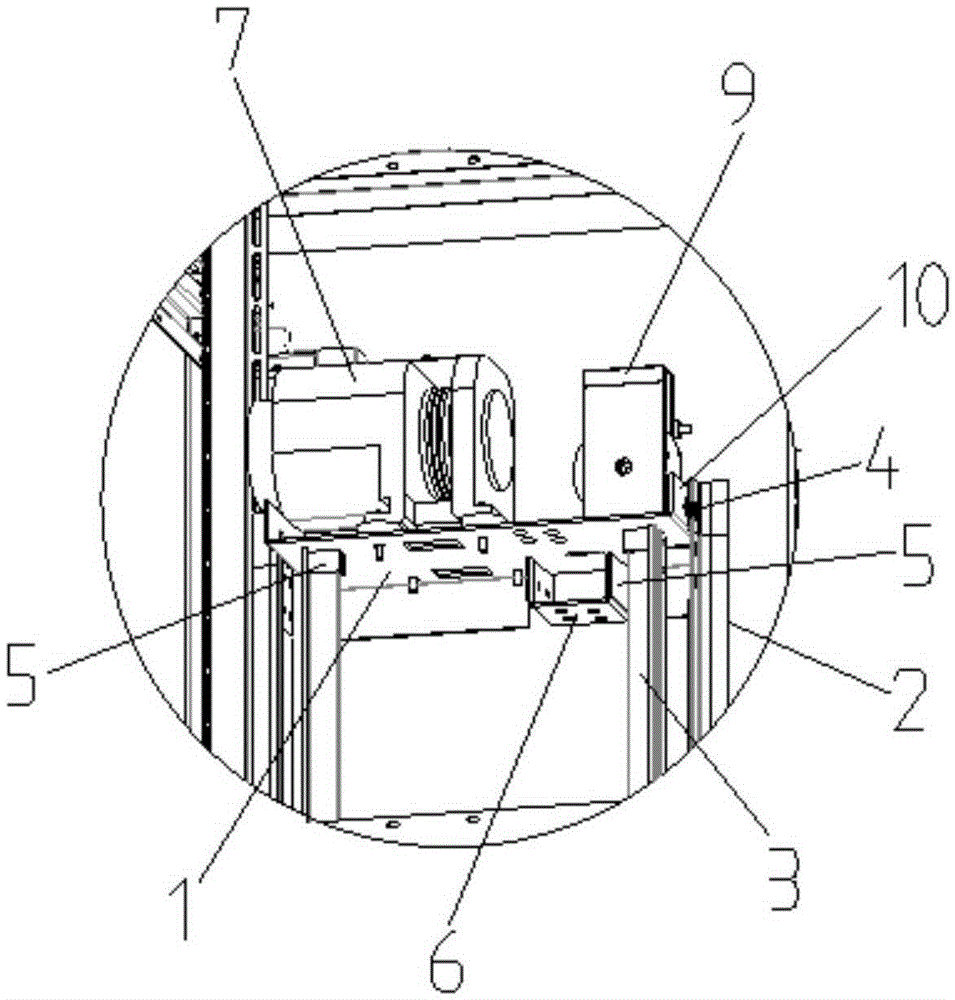

Work-piece welding turnover device

InactiveCN104400302AReduce hoistingSimple structureWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMachining

The invention relates to a work-piece welding turnover device and belongs to the technical field of machining devices. The device comprises a lifting platform, fixation seats are fixed on the lifting platform, a turnover platform is arranged on the fixation seats in a rotation fit mode, a group of first pneumatic compression mechanism and a group of second pneumatic compression mechanism are fixed on the two sides of the turnover platform, and air blowing mechanisms connected with air holes in the surface of the turnover platform are arranged in the middle of the turnover platform. According to the device, the structure is simple, the design is reasonable, work-pieces to be machined are lifted through the lifting platform, and accordingly, the hoisting of work-pieces is reduced, and welding is facilitated; work-pieces to be welded are turned over through the turnover table, so that the angles of the work-pieces to be welded can be adjusted arbitrarily, and the operation is facilitated; welding ash produced during welding can be removed through the air blowing mechanisms timely, so that the welding accuracy is improved.

Owner:新昌县成丰机械配件厂

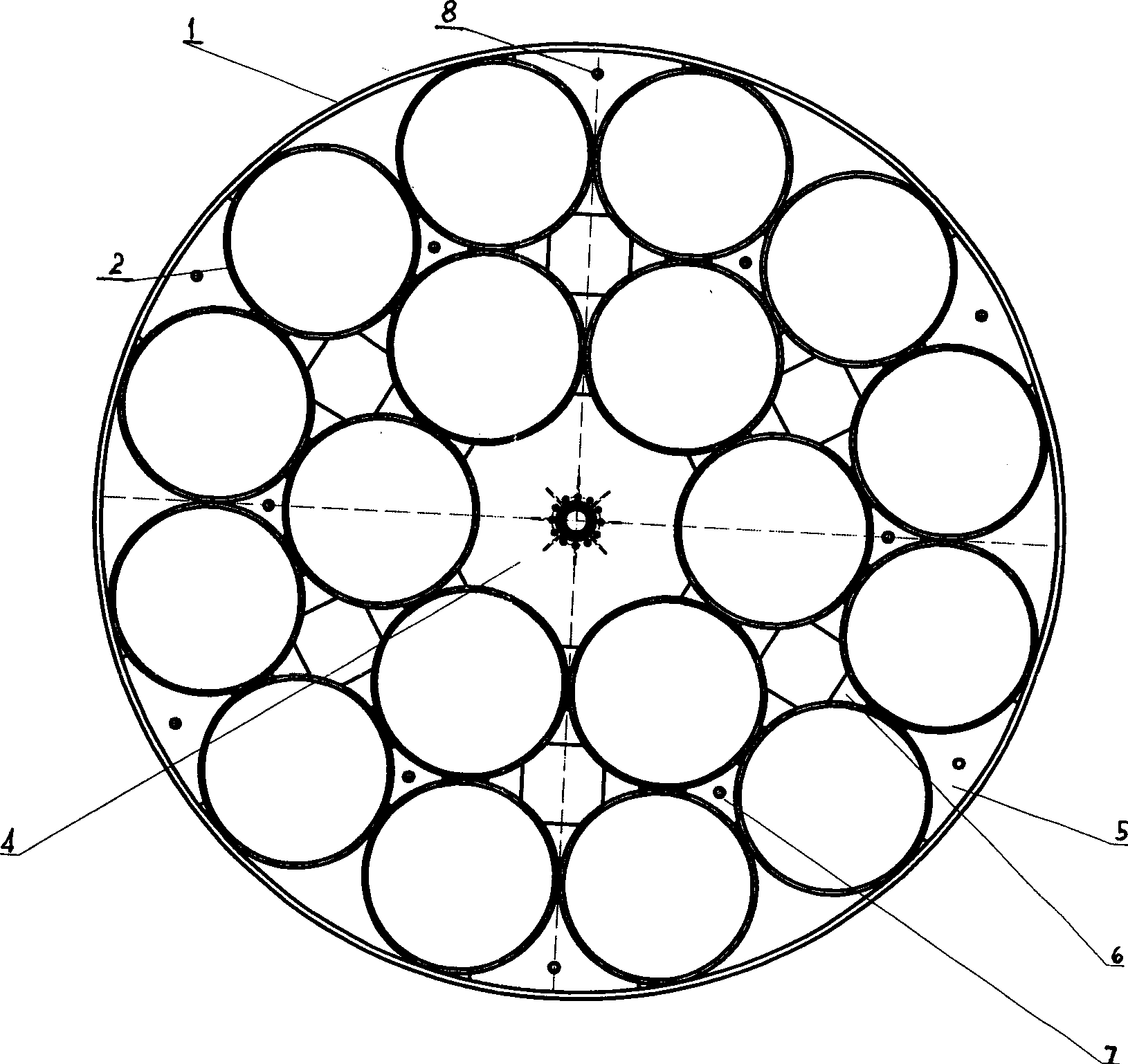

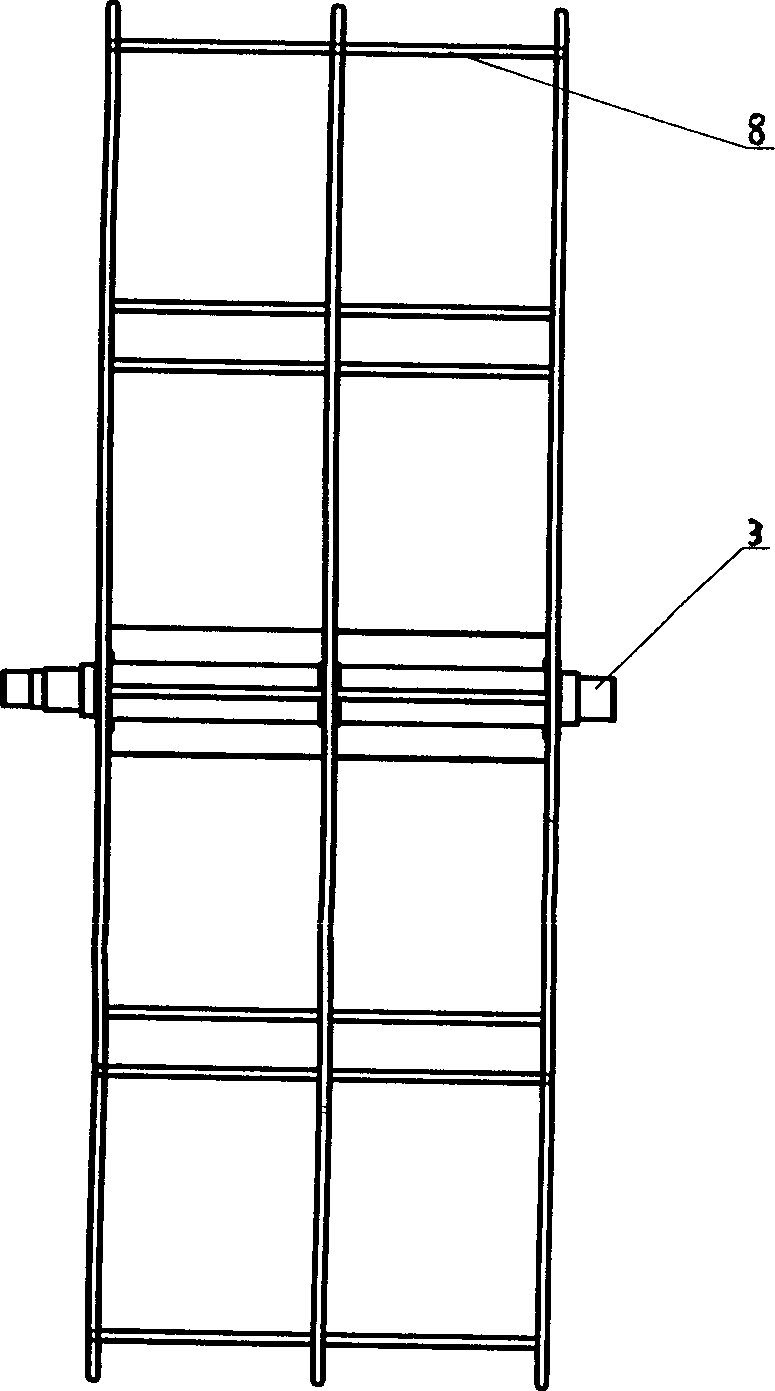

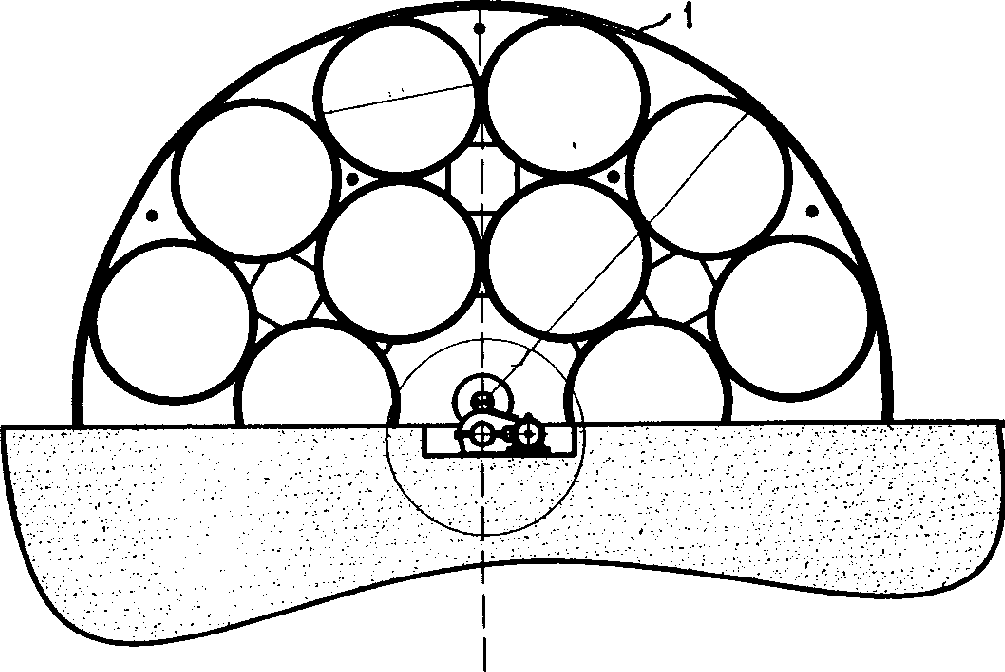

Rotation type multi-storey garage

The invention relates to rotating type stereo garage. It includes unit loading turn table, electric machine drive mechanism, and electric machine start-stop control device. The structure of the turn table is that three moment tube great circular rings are set at one axis with the same distance; each of the great circular rings is set many moment tube circular rings; adjoining circular rings are tangential; their gap is welded rib plate; the center of a circle ring is welded center rib plate; draw bar is set on the corresponding rib plate; the axis of the turning table is set on the center rib plate. The unit vehicle position is that the three moment tube circular rings are a flat car; the flat car is set caster; the caster is connected to the circular ring. Its advantages are little earth occupying, high utilization ratio, simple structure, and low cost.

Owner:唐西林 +1

Method for determining mass characteristic of spacecraft

InactiveCN107860513AAccurate correctionEasy CalibrationStatic/dynamic balance measurementSpecial data processing applicationsClassical mechanicsControl theory

The invention relates to a method for determining a mass characteristic of a spacecraft. The method comprises the following steps of establishing a three-dimensional model of a spacecraft cabin segment and equipment; calculating a mass characteristic initial value of the spacecraft cabin segment and the spacecraft after partial cargoes are loaded by means of the three-dimensional model; measuringthe actually measured mass characteristic of the spacecraft cabin segment and the spacecraft after partial cargoes are loaded by means of mass measuring equipment; comparing the mass characteristic measured in 1.3 with the mass characteristic initial value obtained in 1.2, and when a comparison result exceeds a preset range, correcting the three-dimensional model and returning to 1.2; and when thecomparison result is in the preset range, entering the step 1.5; and calculating the mass characteristic of the spacecraft in a full-load state by means of the three-dimensional model which is obtained in 1.4. According to the method of the invention, the mass characteristic of a large or an ultra-large spacecraft or satellite can be accurately determined by means of the three-dimensional model and partial actual measurement.

Owner:BEIJING SPACE TECH RES & TEST CENT

Hinge type installation method for ship body steel structure

ActiveCN109533196ASave dock resourcesReduce purchasesVessel designingManufacturing technologyMaterials science

The invention discloses a hinged installation method of a hull steel structure, relating to the technical field of ship manufacturing, and solving the technical problem that some steel structures occupy more dry dock positions in the construction process, including steps: A. the hull steel structure is produced in segments; B. mapping a steel structure segmentation line on the ship main body; C. installing steel structure segment supporting tools on the ship main body; D. hoisting and fitting the steel structure segments, and positioning and moving the steel structure segments; E. hinges are arranged between the steel structure segments and the ship main body, and the installation position and the installation angle of the hinges ensure the turning route of the steel structure segments; and F, moving the main ship body to the outside of the dry dock, and hoisting andturningsteel structure segmentsforautomatic positioning and installation. According to the method, fitting and installation of the steel structure segments are completed in dock stage, and turning and fitting can be carried out by using small-tonnage hoisting equipment, automatic positioning of the steel structure segments is realized by using the hinges, therefore installation precision is improved, and dock construction period of a ship is shortened.

Owner:QINGDAO BEIHAI SHIPBUILDING HEAVY IND CO LTD

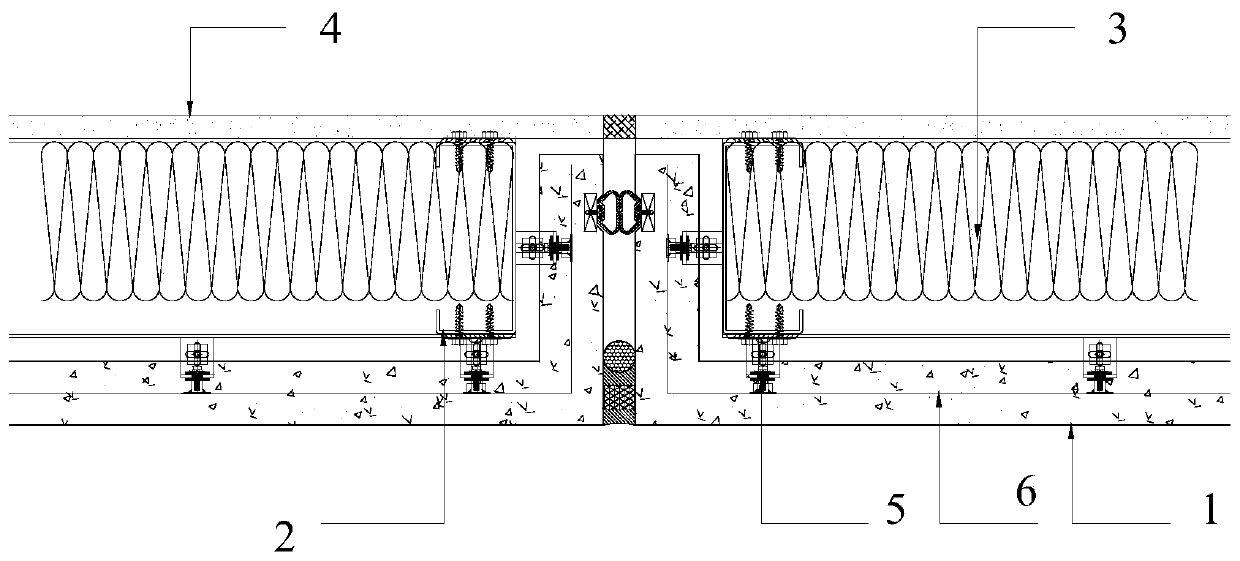

Integrated structure of concrete tower drum and foundation of fan

ActiveCN104612455AReduce hoistingLow costFinal product manufactureFoundation engineeringReinforced concrete columnRebar

The invention relates to an integrated structure of a concrete tower drum and a foundation of a fan. The integrated structure comprises a reinforced concrete column body, wherein the reinforced concrete tower drum is arranged at the top of the reinforced concrete column body; first high-strength bolts distributed along the circumference are buried in the reinforced concrete column body; bottom flanges are fixed at the lower ends of the first high-strength bolts; middle flanges are fixedly connected to the upper ends of the first high-strength bolts; second high-strength bolts distributed along the circumference are buried in the reinforced concrete tower drum; the lower ends of the second high-strength bolts are fixedly connected with the middle flanges; the upper ends of the second high-strength bolts are fixedly connected with top flanges. Compared with a conventional combination of a steel fan tower drum and a fan foundation, the integrated structure disclosed by the invention has the advantages that the manufacturing cost is reduced; furthermore, a foundation ring for connecting the fan foundation with the tower drum in the conventional technology is eliminated, so that the manufacturing cost is reduced; the concrete tower drum selects on-site pouring or factory production and transportation according to conditions of a construction site and a transportation road, so that transportation is facilitated. Compared with a conventional fan, the integrated structure disclosed by the invention further has the advantages that hoisting of the tower drum is avoided, and the working period is shortened.

Owner:健安诚(内蒙古)新能源科技有限公司

Fiberglass mesh ultra-high performance concrete thermal insulation and decoration integrated fabricated external wallboard

InactiveCN110056097AAnti-shedding effectLow structural costWallsHeat proofingGlass fiberFiberglass mesh

The invention discloses a fiberglass mesh ultra-high performance concrete thermal insulation and decoration integrated fabricated external wallboard, which comprises a fiberglass mesh ultra-high performance concrete surface layer, a pre-embedded stainless steel sleeve bolt assembly, a light steel keel, a thermal insulation layer and a high-strength internal hinge board. The concrete surface layeris poured by fiberglass mesh ultra-high performance concrete, and the surface layer is connected with the light steel keel through the pre-embedded stainless steel sleeve bolt assembly and an angle steel machining piece; and the thermal insulation layer is arranged between the concrete surface layer and the high-strength internal hinge board, and the high-strength internal hinge board is connectedwith the light steel keel through self-tapping and self-drilling nails. The cost is lowered while the weight is reduced; a fiberglass mesh achieves the effect of high-strength tensile reinforcing ribs, and even if a concrete board is cracked, the falling-off-preventing effect can also be achieved; and it is guaranteed that performance meets requirements, the high strength is achieved, and meanwhile the economical efficiency is relatively considerable.

Owner:上海君道住宅工业有限公司

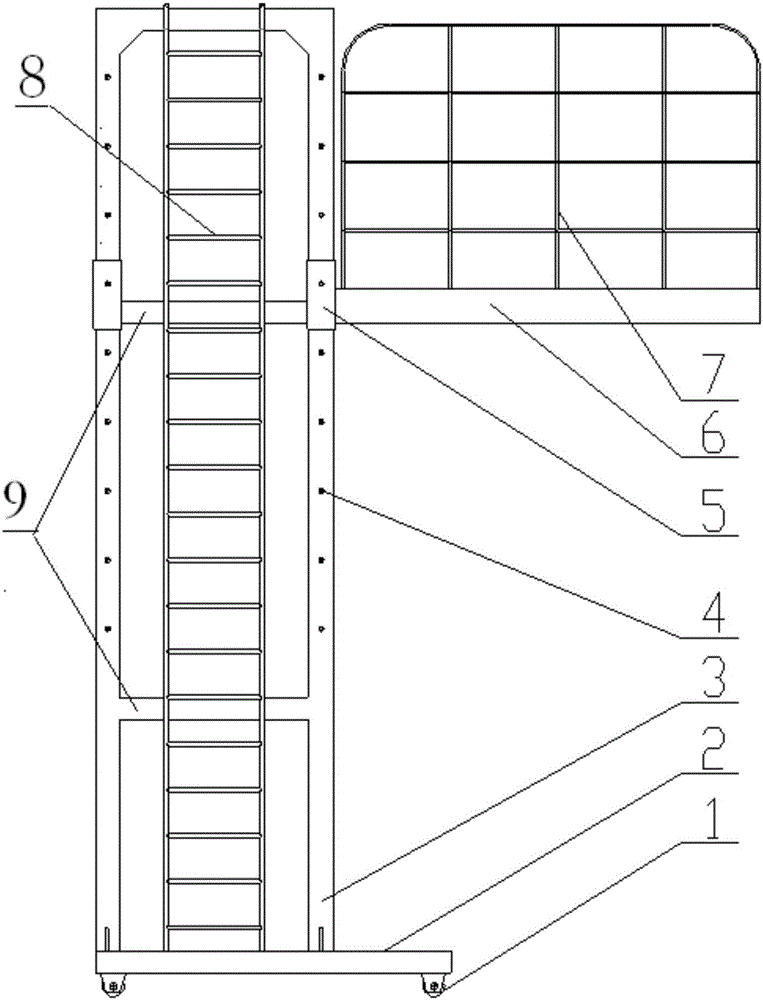

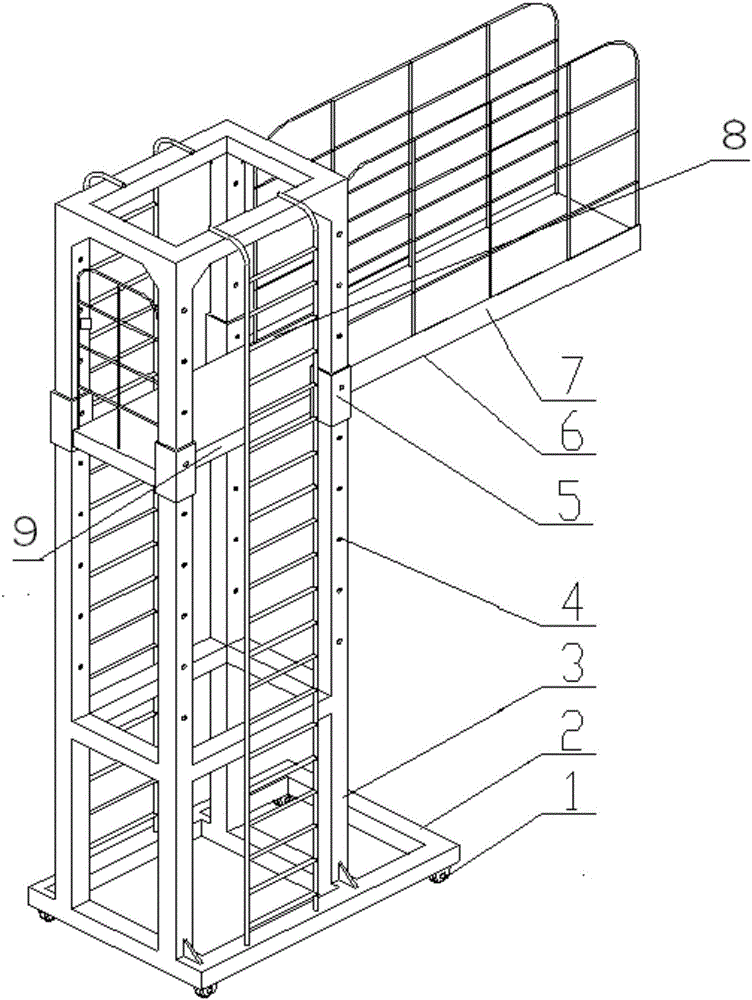

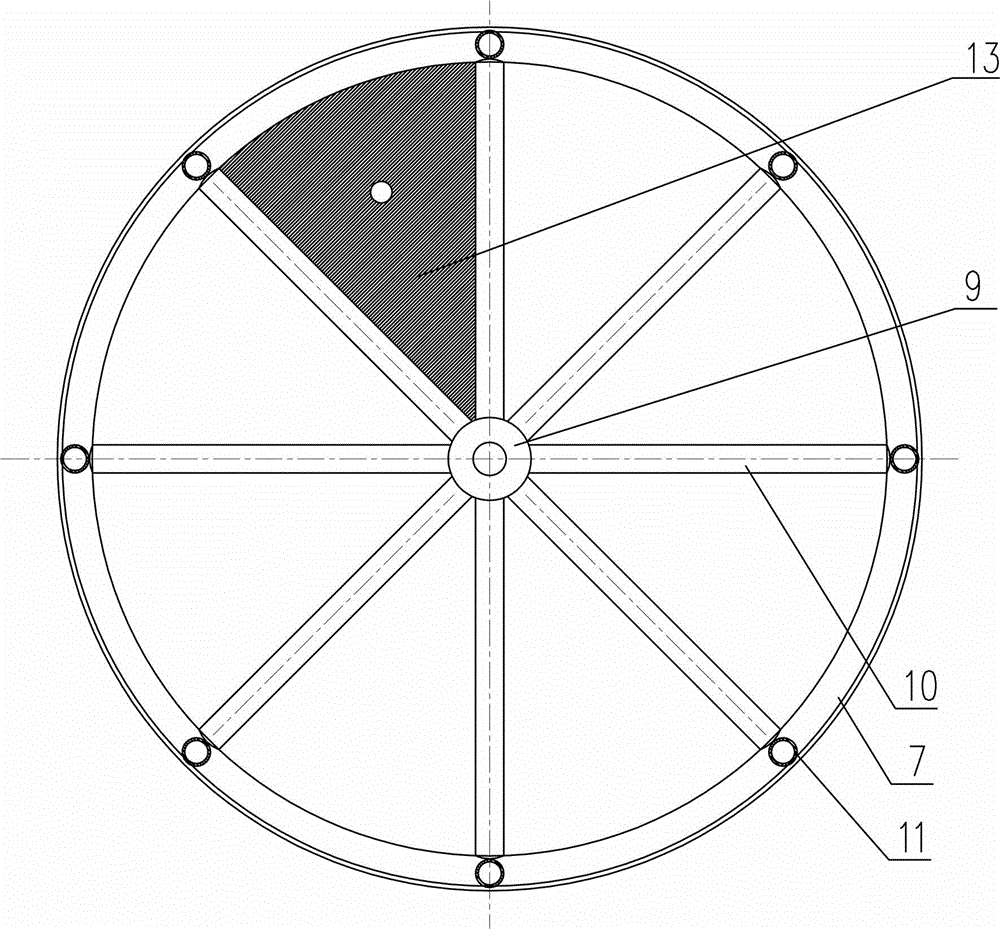

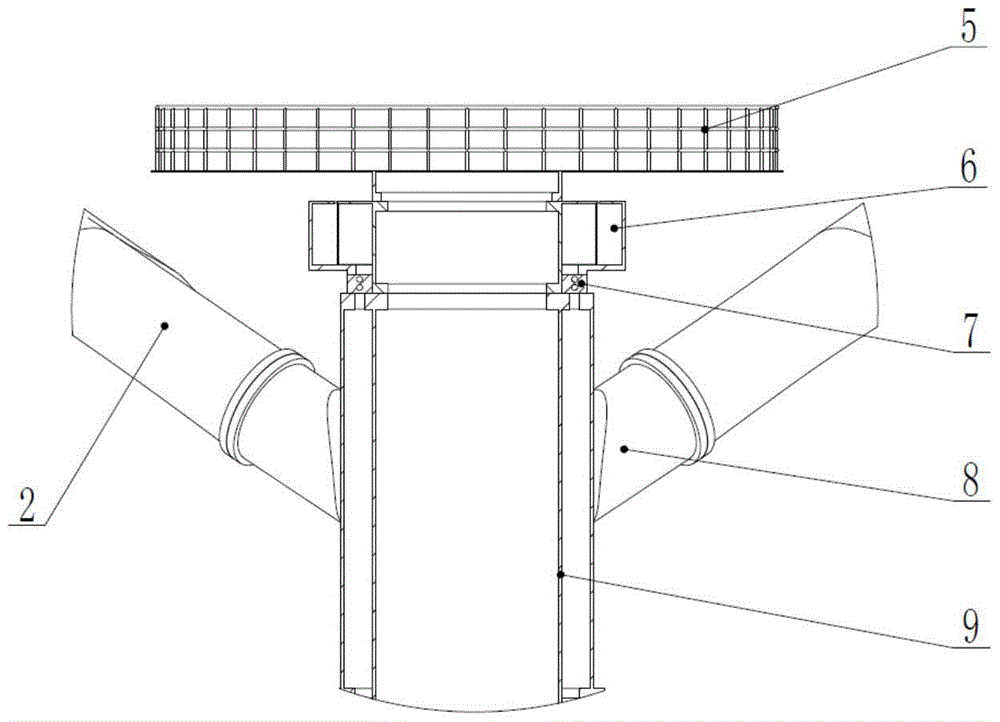

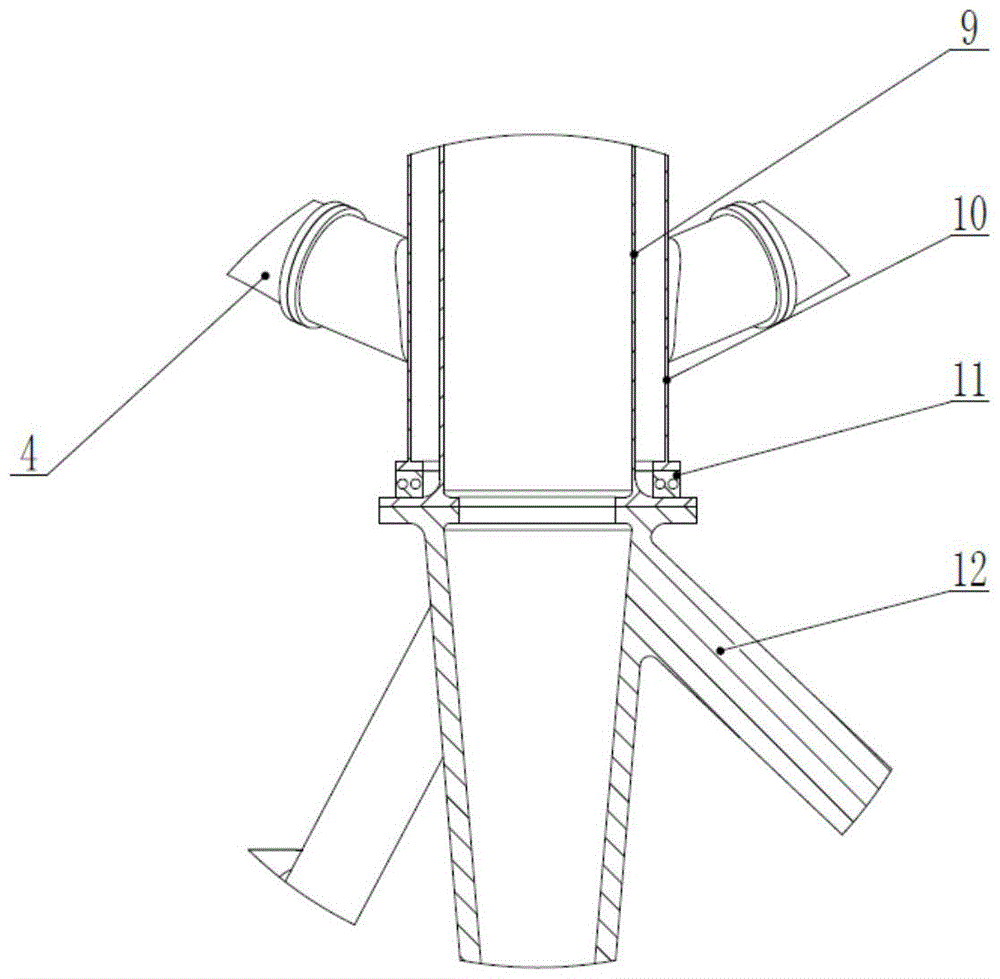

Jig frame used for cylindrical pile leg barrel submerged-arc welding

InactiveCN105127628AReduce hoistingAvoid bumpingWelding/cutting auxillary devicesAuxillary welding devicesSubmerged arc weldingEngineering

The invention relates to the field of ship engineering welding, in particular to a jig frame used for cylindrical pile leg barrel submerged-arc welding. The jig frame comprises base universal wheels, a base, a height-adjustable support, an operation platform, height adjustment holes, locking sleeves, a crawling ladder and a platform guardrail. The base is arranged on the base universal wheels. The base is fixedly connected with the height-adjustable support. The height-adjustable support is fixedly connected with the operation platform through the height adjustment holes and the locking sleeves. The height-adjustable support and the operation platform are welded and fixed. By means of the jig frame, hoisting of welding devices can be effectively reduced while the welding quality is ensured, and collision of the welding devices is avoided; a submerged-arc welding machine is placed on the operation platform with the guardrail, and safety of welding personnel and the welding devices is ensured.

Owner:TIANJIN HOIDI OFFSHORE ENG

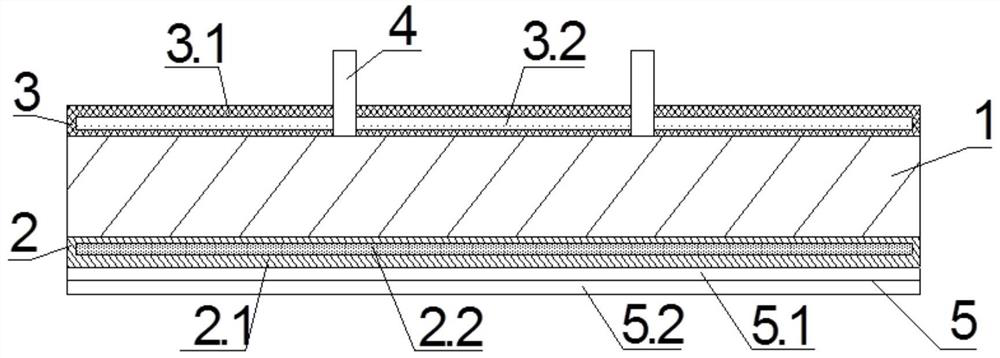

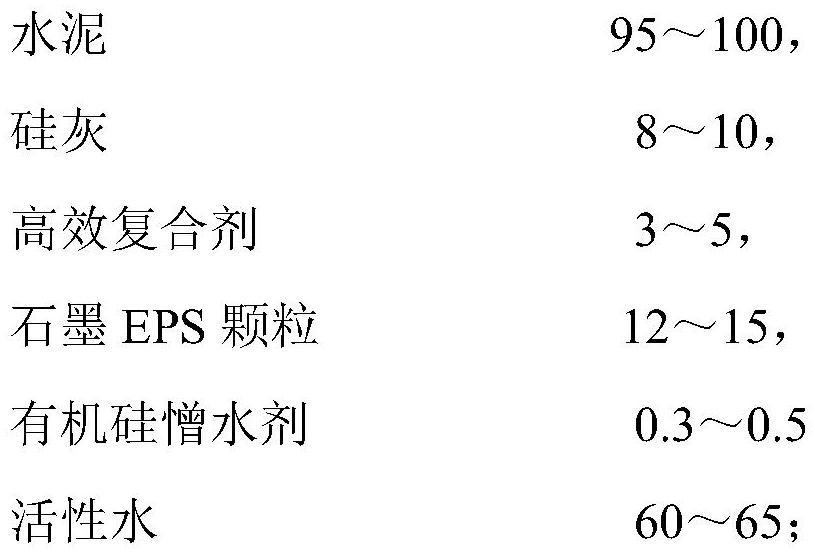

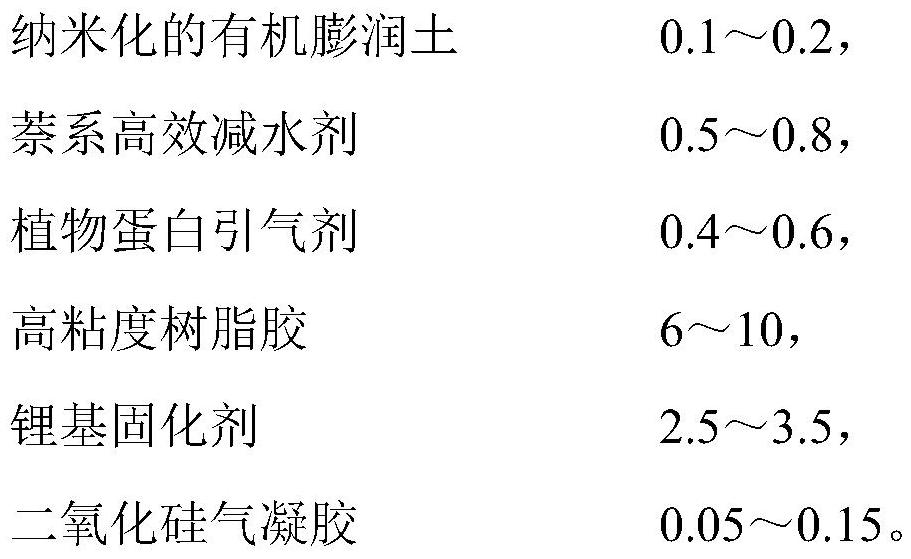

Double-sided composite reinforced thermal insulation and decoration integrated external wall panel

InactiveCN112196214AAnti-shedding effectLow thermal conductivityCovering/liningsFilling pastesAdhesive cementThermal insulation

The invention discloses a double-sided composite reinforced thermal insulation and decoration integrated external wall panel. The double-sided composite reinforced thermal insulation and decoration integrated external wall panel comprises a graphite homogeneous fireproof thermal insulation core material; the graphite homogeneous fireproof thermal insulation core material is prepared from cement, silica fume, an efficient complexing agent, an organosilicon water repellent, graphite EPS particles and active water; the front surface of the graphite homogeneous fireproof thermal insulation core material is provided with a rendering coat mortar composite reinforced net layer; an adhesive composite common net layer is arranged on the back face of the graphite homogeneous fireproof heat preservation core material; one ends of a plurality of back bolt connecting pieces are connected to the back face of the graphite homogeneous fireproof heat preservation core material; and the other ends of the back bolt connecting pieces penetrate out of the adhesive composite common net layer. The invention further discloses a preparation method of the double-sided composite reinforced thermal insulationand decoration integrated external wall panel. The double-sided composite reinforced thermal insulation and decoration integrated external wall panel has the advantages that the double-sided composite reinforced thermal insulation and decoration integrated external wall panel is not prone to combustion and falling off, the connection performance is good, the strength is high and the cost is low.

Owner:安徽福源春生建筑工程股份有限公司

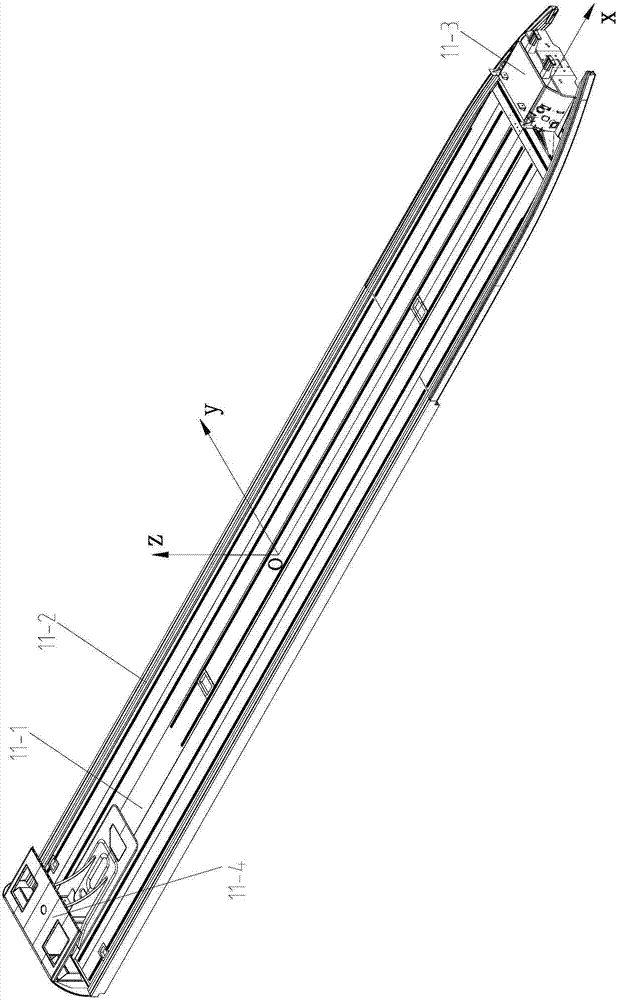

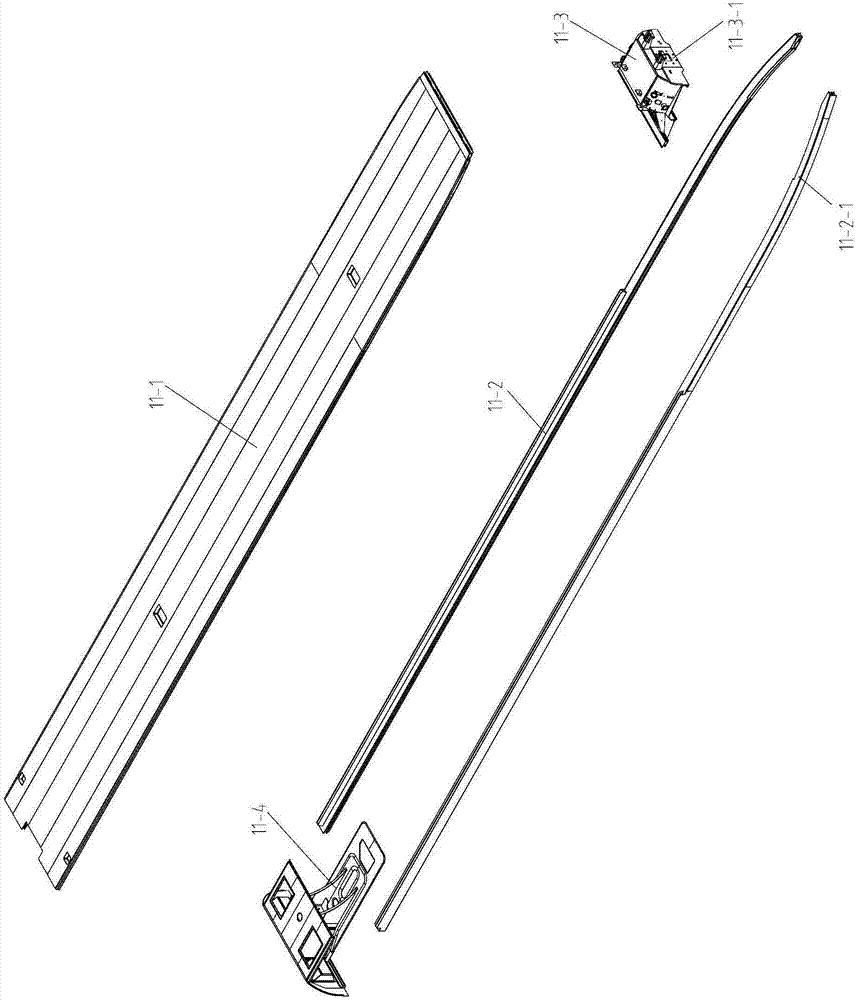

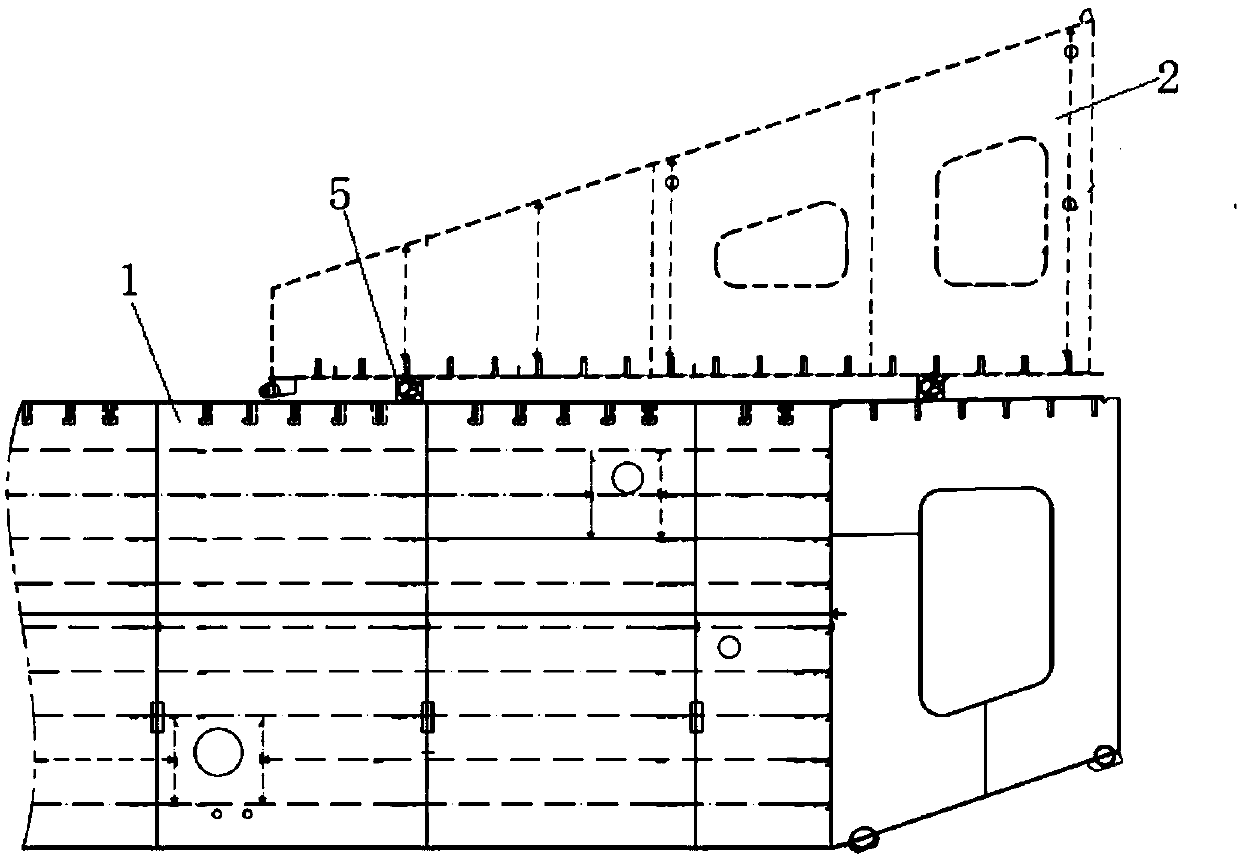

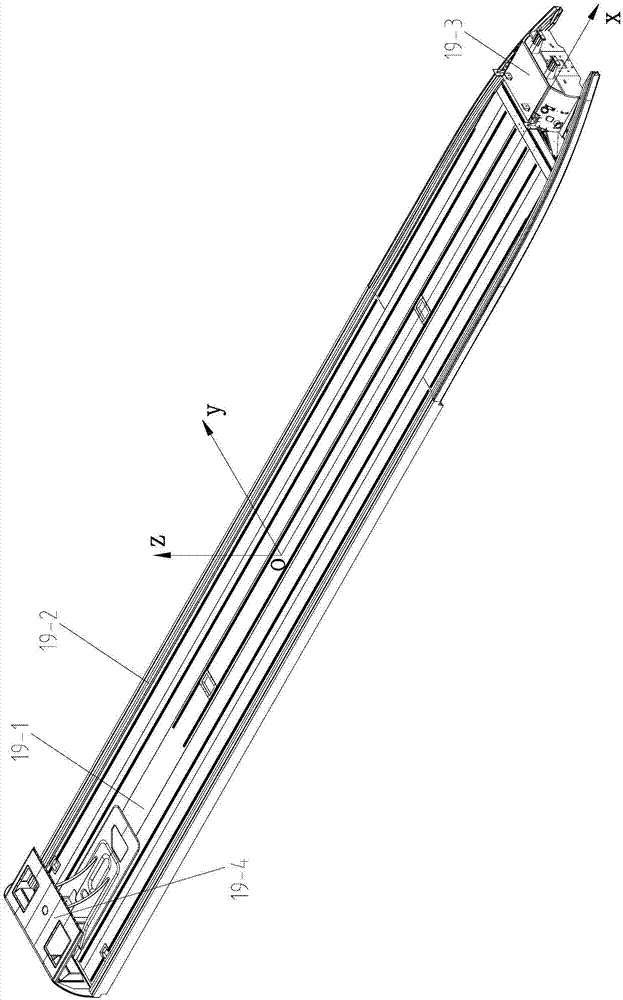

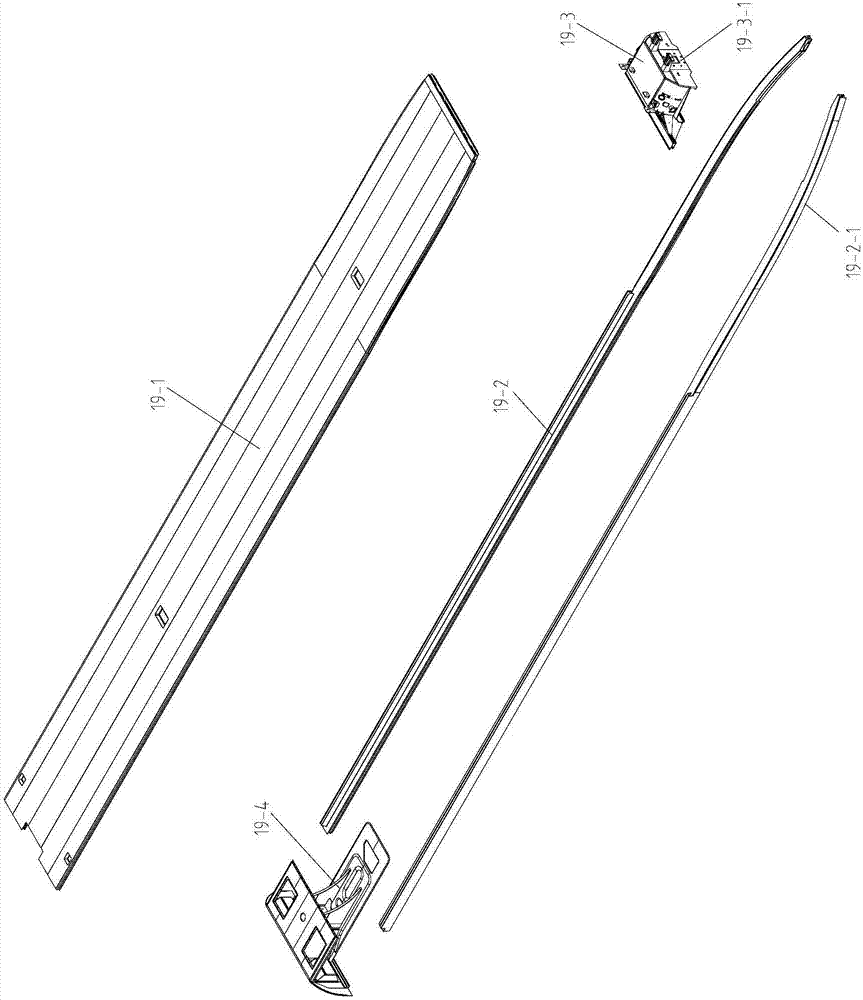

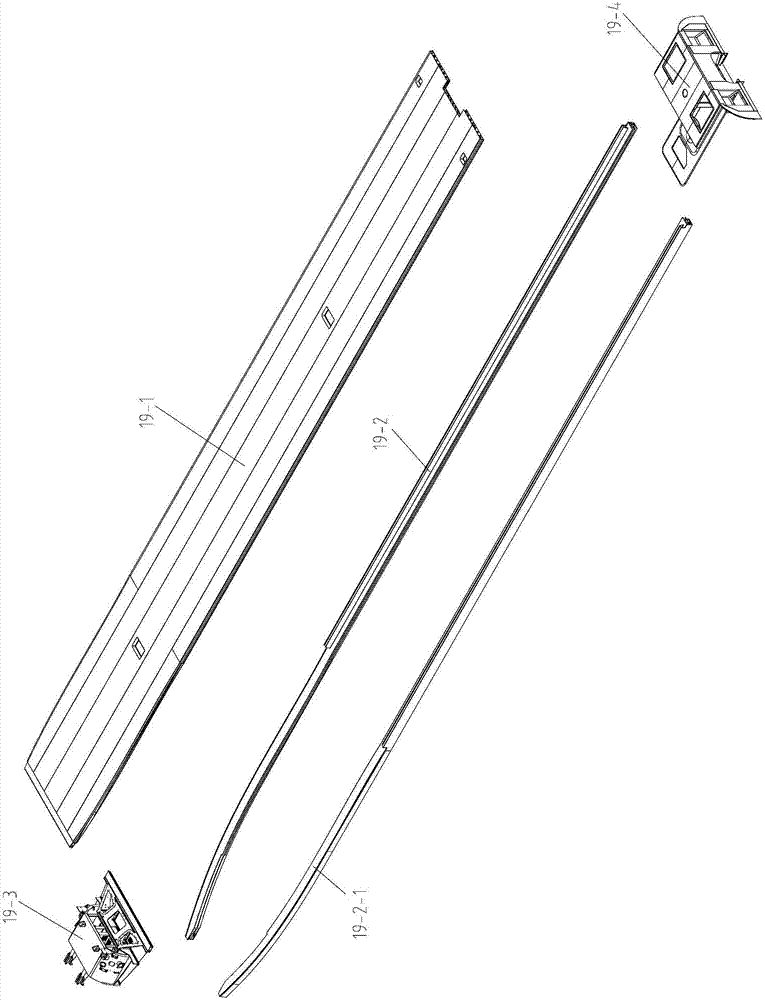

Standardized D-series high-speed train chassis combined positioning device and positioning method thereof

ActiveCN107498180ARapid positioningPrecise positioningLaser beam welding apparatusModularityEngineering

The invention discloses a standardized D-series high-speed train chassis combined positioning device and a positioning method thereof, and belongs to the field of standardized D-series high-speed train chassis large part whole installing and welding positioning auxiliary devices and using methods thereof. The positioning device comprises an FE end positioning tooling, an end chassis positioning tooling, a chassis center line positioning tooling and a plurality of side beam middle lateral jacking mechanisms. According to the combined positioning device, the parts such as the FE end positioning tooling and the end chassis positioning tooling can realize modular mass production, are convenient to overhaul and maintain, reduce the production cost, become base parts of assembly line work, and make a following process new method possible that a chassis is installed and welded and then machined overall; and the following whole machining method can effectively guarantee the geometrical size of the chassis, the position size of a floor doorway, the diagonal size of the chassis, the whole length of the chassis and the like, and is more advantageous to improve product manufacturing precision and forming quality.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

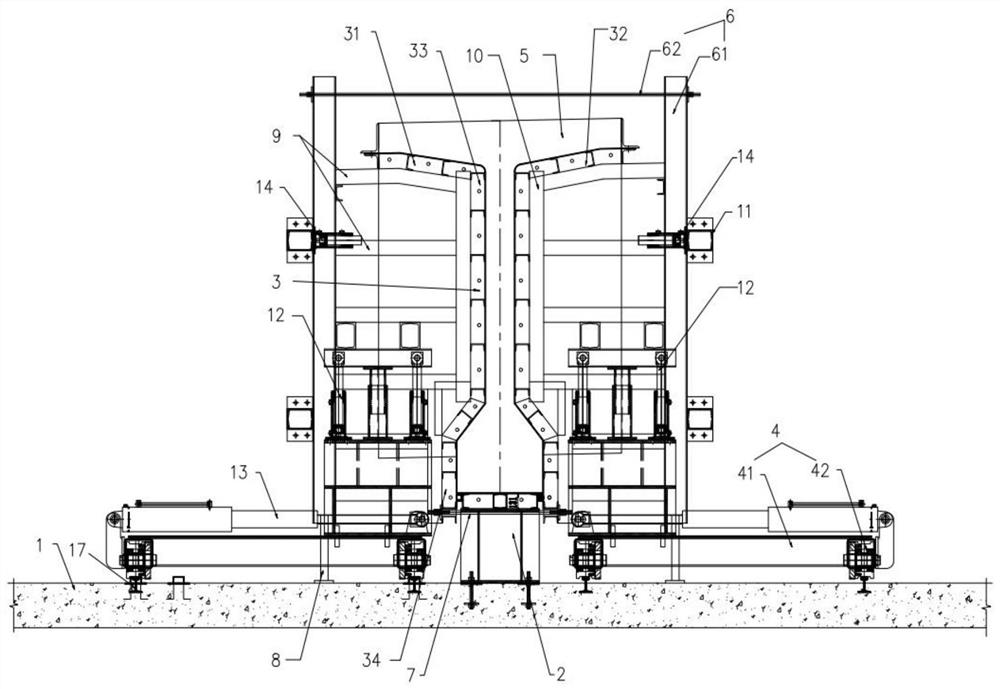

Self-propelled integral hydraulic template equipment for prefabricating T-shaped beam

PendingCN113103410AShorten the timeImprove work efficiencyMouldsShaped beamArchitectural engineering

The invention provides self-propelled integral hydraulic formwork equipment for prefabricating a T-shaped beam, and belongs to the technical field of road and bridge construction. The self-propelled integral hydraulic formwork equipment comprises a formwork assembly, supporting and reinforcing assemblies, a walking system, a steel pedestal structure and a hydraulic system, wherein the formwork assembly is mounted at the outer side of the T-shaped beam and used for limiting the shape of the T-shaped beam; the supporting and reinforcing assemblies are installed at the two sides and the bottom of the formwork assembly and used for bearing loads generated during concrete pouring of the prefabricated T-shaped beam and the gravity of the formwork assembly; the walking system is arranged below the formwork assembly and used for transferring the formwork assembly; the steel pedestal structure is fixed to a ground foundation, located below the formwork assembly and used for bearing the T-shaped beam and the formwork assembly; and the hydraulic system is used for providing power for mounting the formwork assembly and demolding. The formwork equipment is easy and convenient to disassemble and assemble, labor-saving and efficiency is high, the quality of the produced precast beam is high, and the repeated utilization rate of formworks is high.

Owner:CHINA RAILWAY FIRST GRP CO LTD

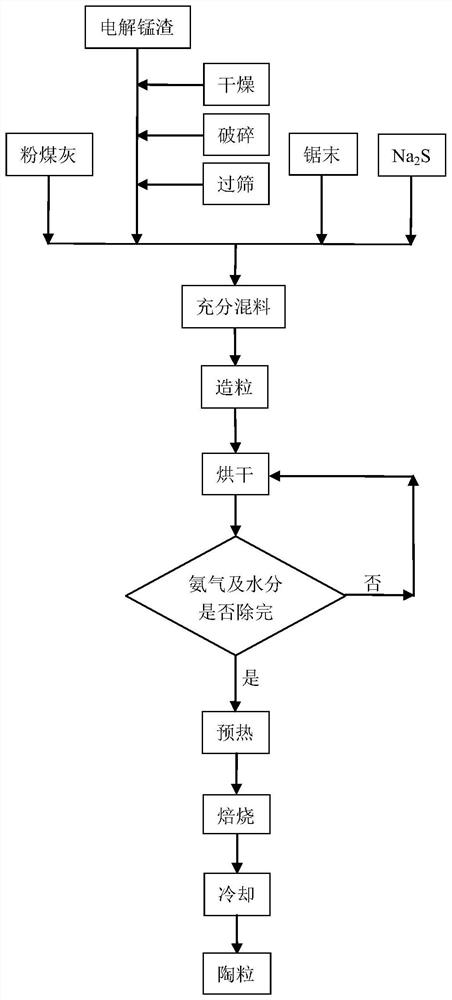

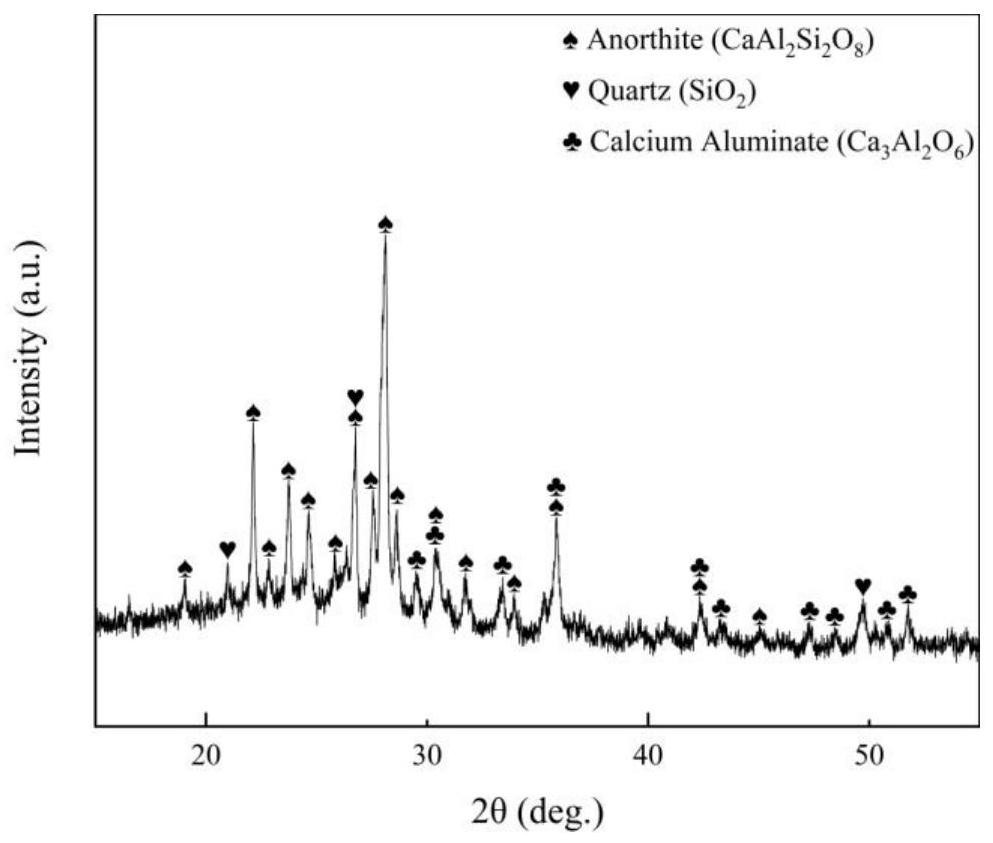

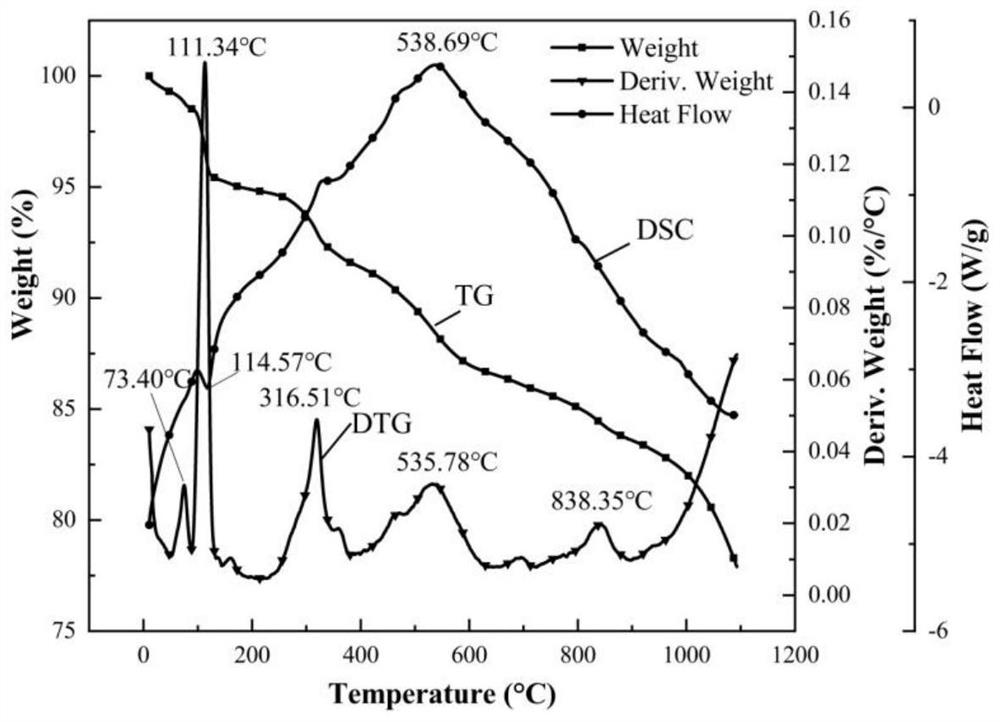

High-strength and high-porosity thermal-insulation ceramsite prepared by compounding electrolytic manganese residues with coal-series wastes and preparation method thereof

ActiveCN113233912ALow costSimple production processCeramic materials productionCeramicwareThermal insulationSaw dust

The invention discloses a high-strength and high-porosity thermal-insulation ceramsite prepared by compounding electrolytic manganese residues with coal-series wastes and a preparation method thereof. The ceramsite comprises the following raw materials in parts by mass: 100 parts of electrolytic manganese residues; 100 parts of fly ash; 5 parts of sawdust; and 1 part of Na2S. The production process is simple and environment-friendly, the used raw materials are low in cost and rich in source, and the obtained ceramsite has the advantages of high strength, high porosity, high thermal insulation performance and the like, can be widely applied to thermal insulation building walls, thermal insulation mortar, biological environment-friendly adsorption and the like, and has very wide prospects.

Owner:ANHUI UNIV OF SCI & TECH

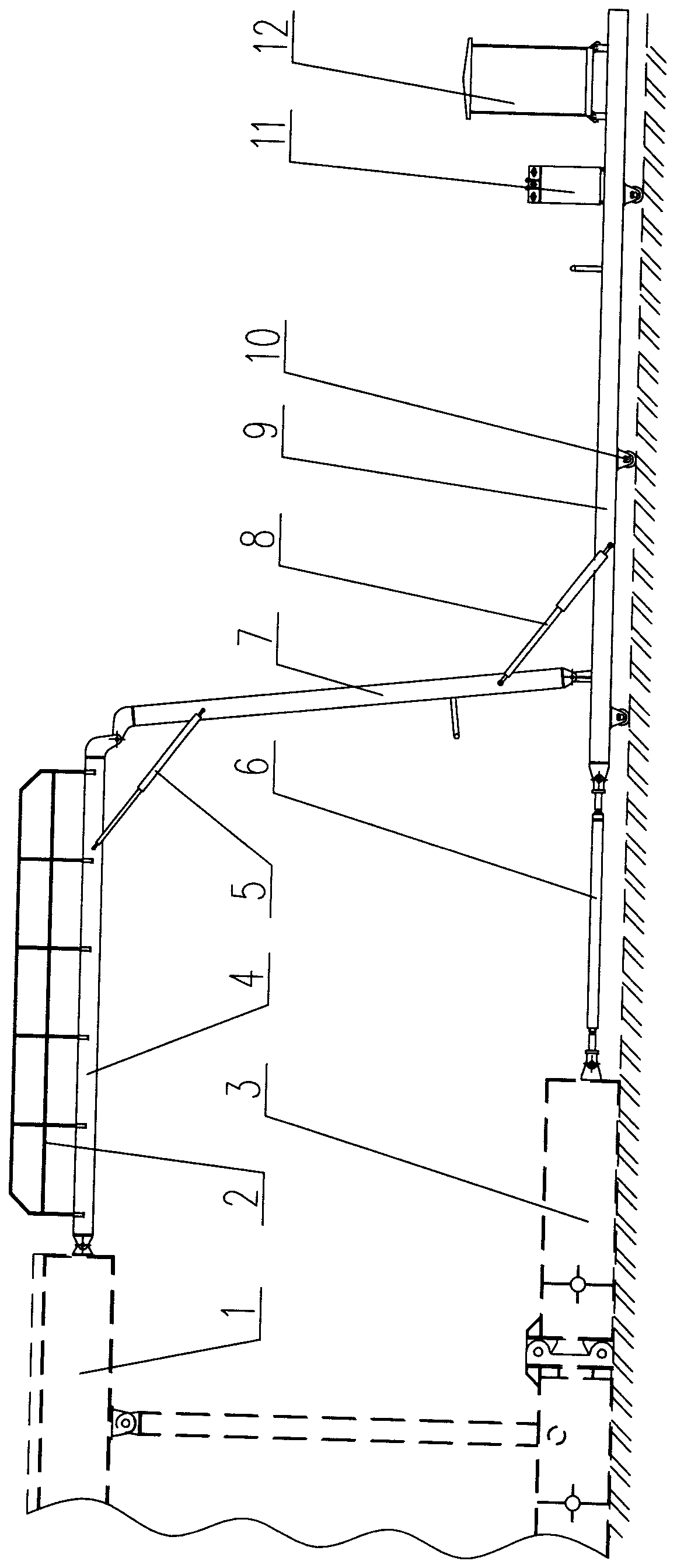

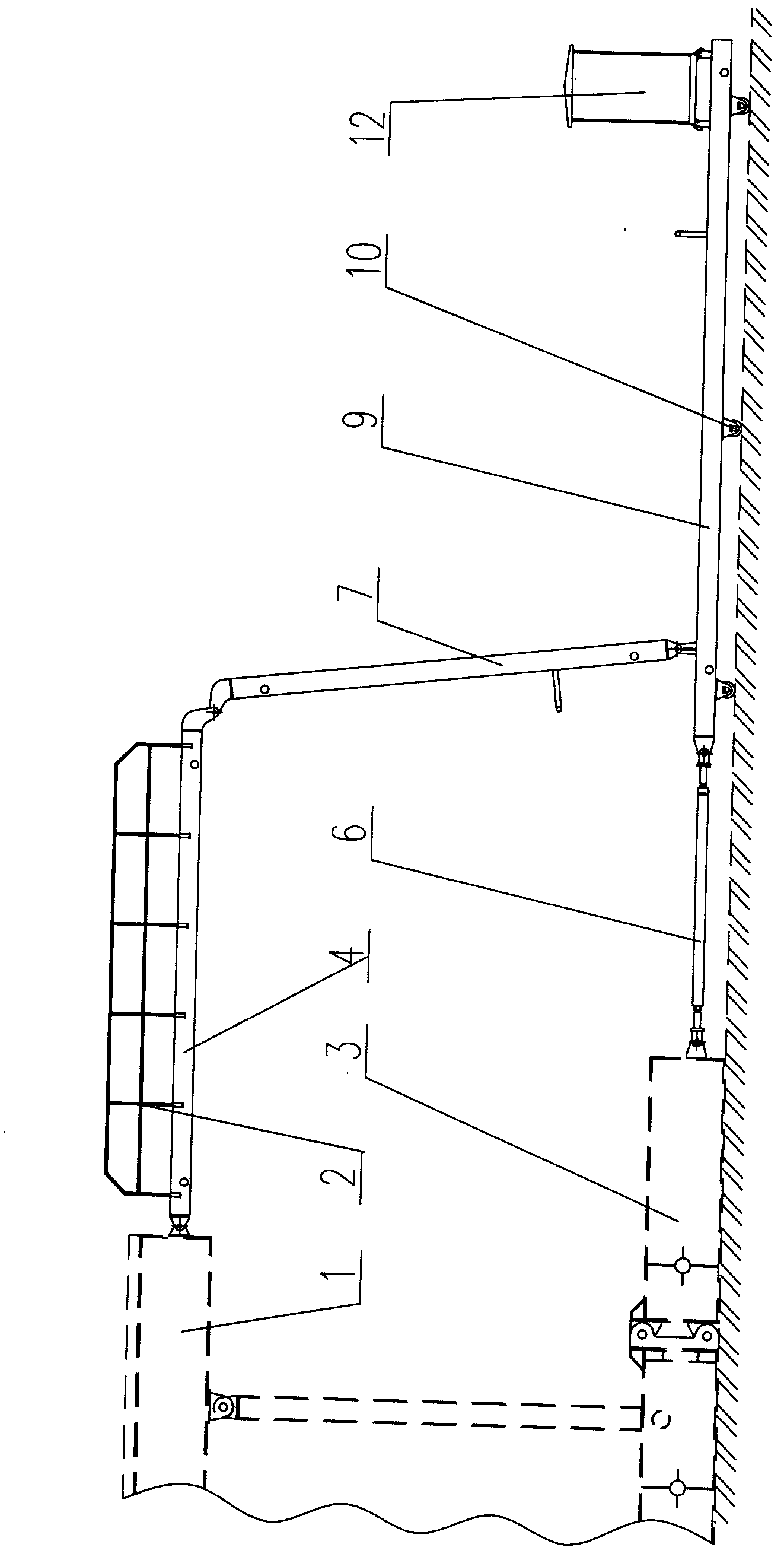

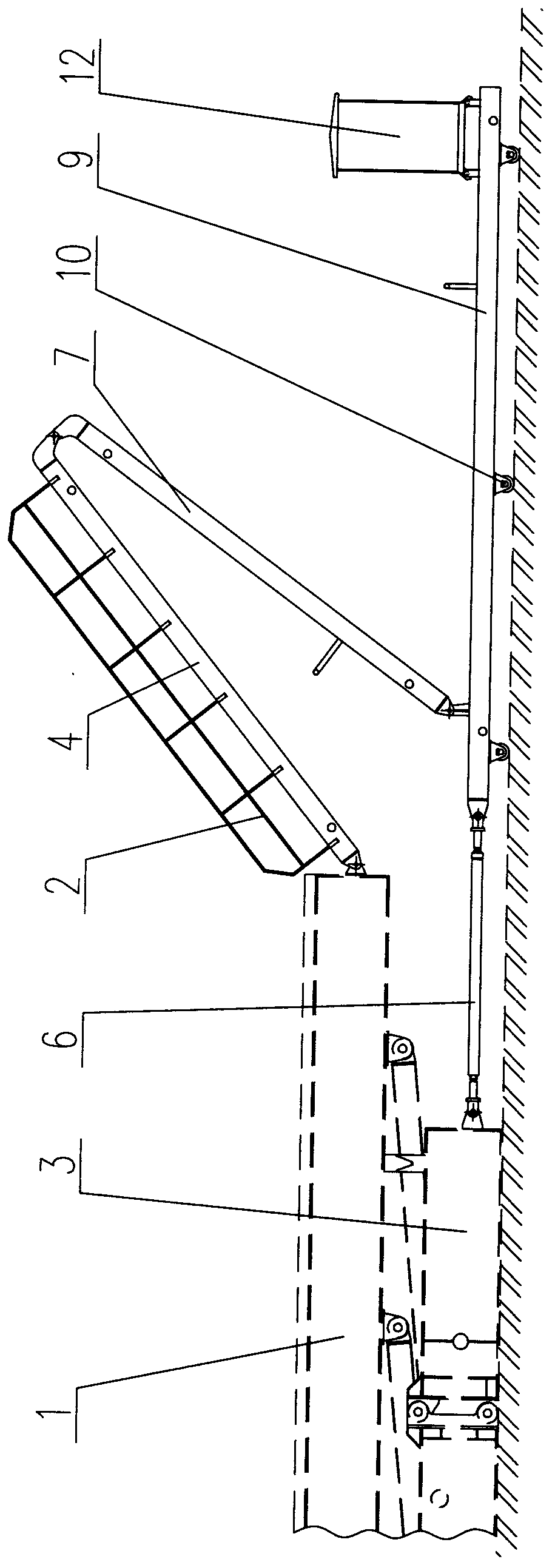

Follow-up pipeline groove

ActiveCN103912723AReduce hoistingReduce operating costsPipe supportsCable arrangements between relatively-moving partsTransfer caseAssistive device/technology

The invention provides a follow-up pipeline groove, and relates to the technical field of auxiliary equipment of drill rigs. The follow-up pipeline groove mainly comprises a high-position pipeline groove, a middle-position pipeline groove and a low-position pipeline groove. Guardrails are arranged on the high-position pipeline groove, one end of the high-position pipeline groove is hinged to a top layer of a drill floor, the other end of the high-position pipeline groove is hinged to the middle-position pipeline groove, the front end of the low-position pipeline groove is connected with a base of the drill floor by an adjustable telescopic draw bar, the other end of the middle-position pipeline groove is connected onto the low-position pipeline groove in a hinged manner and is close to the telescopic draw bar, rollers are arranged on the lower portion of the low-position pipeline groove, and a transfer case is arranged at the end, which is far away from the telescopic draw bar, of the low-position pipeline groove. The follow-up pipeline groove has the advantages that when the follow-up pipeline groove is mounted at a low position, the high-position pipeline groove is hinged to the top layer of the drill floor by the aid of an operation cylinder without being hoisted by a crane, and the length of the telescopic draw bar can be adjusted, so that a folding angle of the follow-up pipeline groove can be controlled, and the follow-up pipeline groove is applicable to different types of drill rigs provided with drill floors with different heights; the transfer case is mounted on the low-position pipeline groove, is convenient to operate and is safe and reliable, and the transfer case and the follow-up pipeline groove can form an integral transport unit.

Owner:ZYT GASOLINEEUM EQUIP

Multifunctional cable winding drum device

Owner:CHINA GEZHOUBA GROUP MACHINERY & SHIP

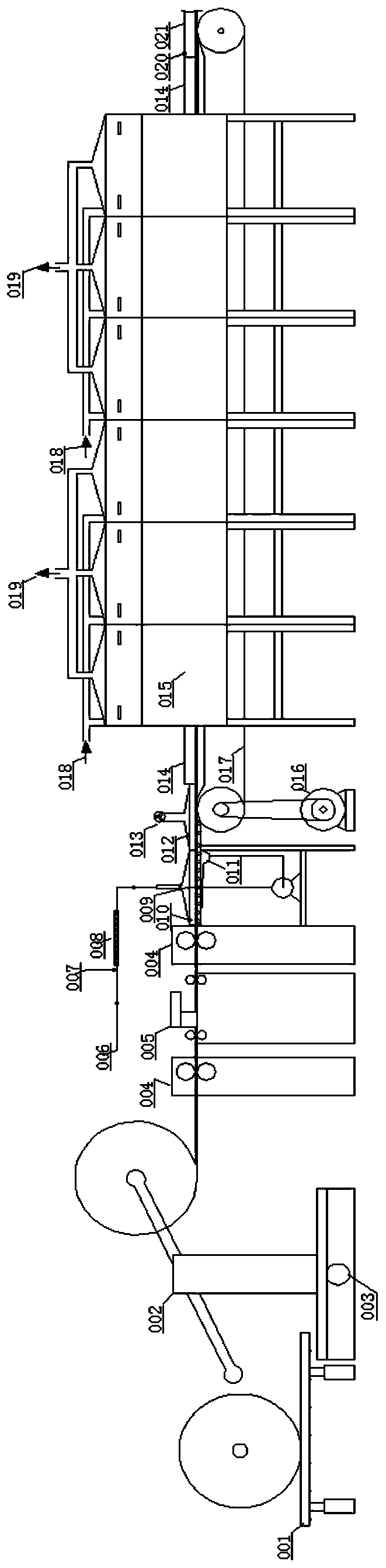

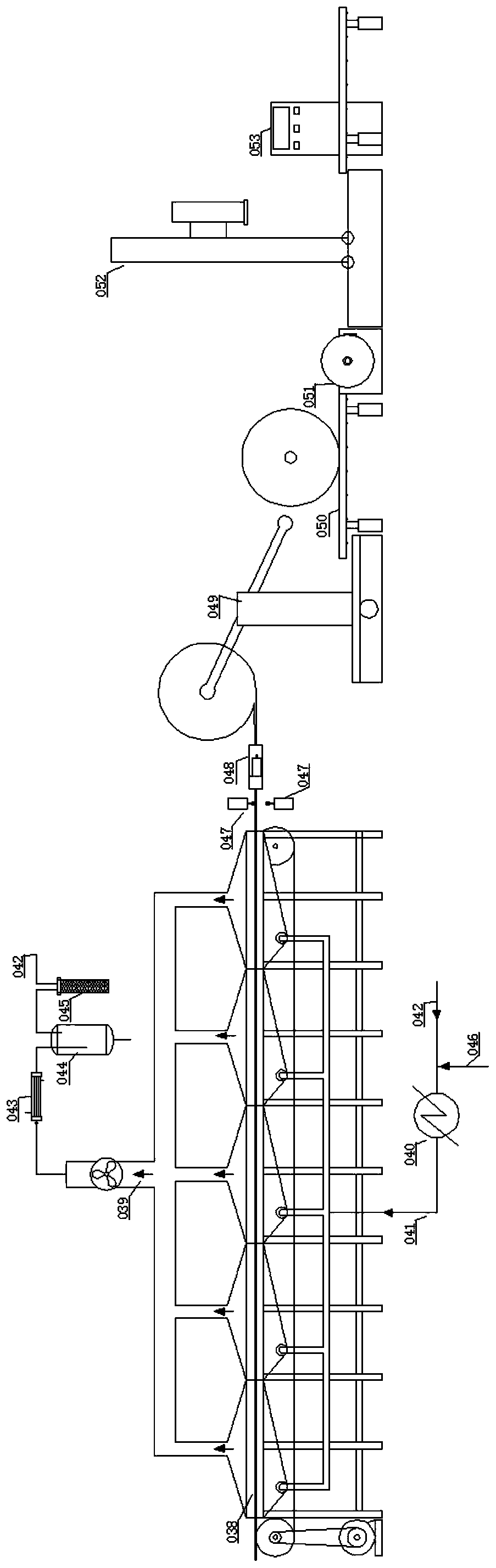

Device and industrial method for continuously producing aerogel felts

PendingCN111152383AImprove efficiencyReduce volatilityWrappingBinding material applicationProcess engineeringContinuous production

The invention discloses a device and industrial method for continuously producing aerogel felts, and relates to the technical field of aerogel production equipment. The device for continuously producing the aerogel felts comprises a first lifting platform, a double-station unwinding device, a fiber felt feeding device, a metal detection device, an impregnation device, a microwave curing device, ahydrophobic modification device, a hole structure protection device, a solvent cleaning device, a drying device, a winding device and a packaging device which are sequentially arranged from front to back. According to the device and industrial method for continuously producing the aerogel felts, the requirements of the equipment safety aspect, the solvent effective utilization aspect and the environmental protection aspect are simultaneously considered, and the continuous production of unwinding, forming, modification, winding and packaging is realized; and by means of the device, the raw materials can be directly produced into the aerogel felt products, and the packaging process can be completed.

Owner:中化学华陆新材料有限公司

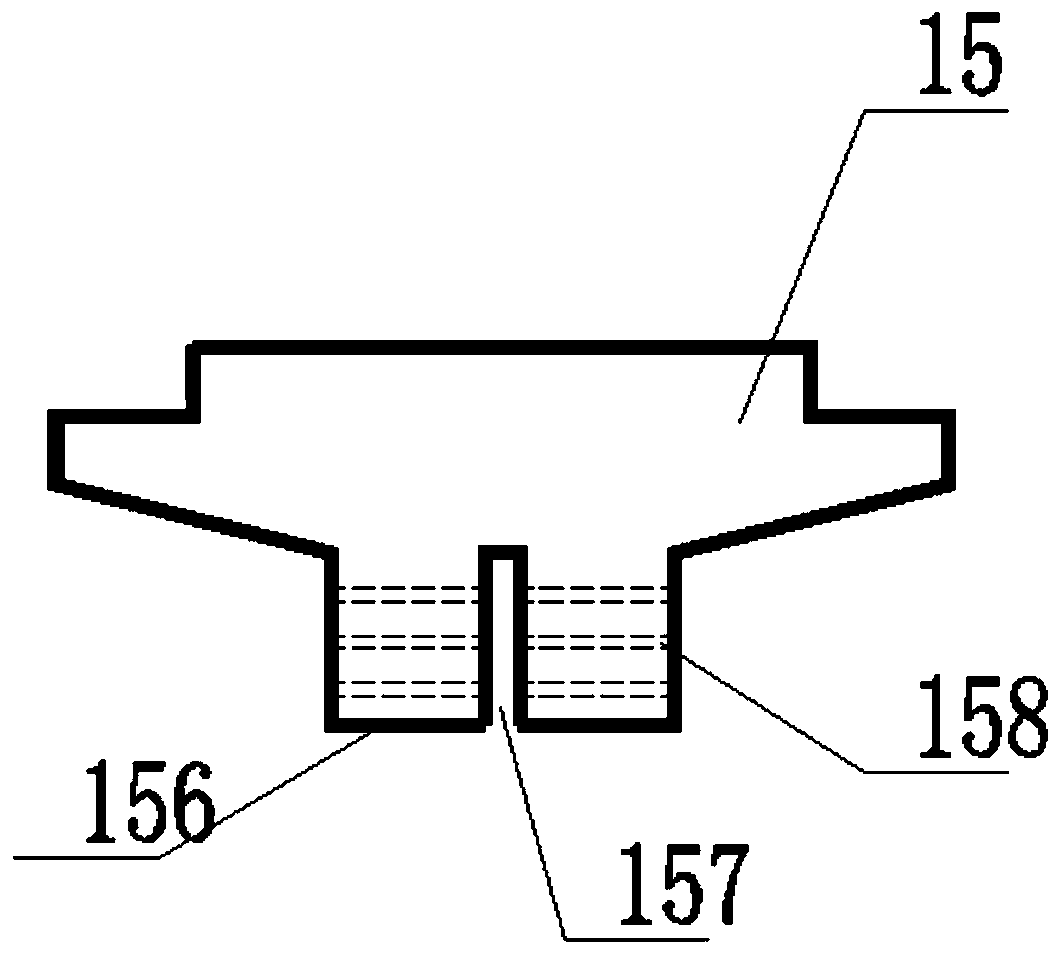

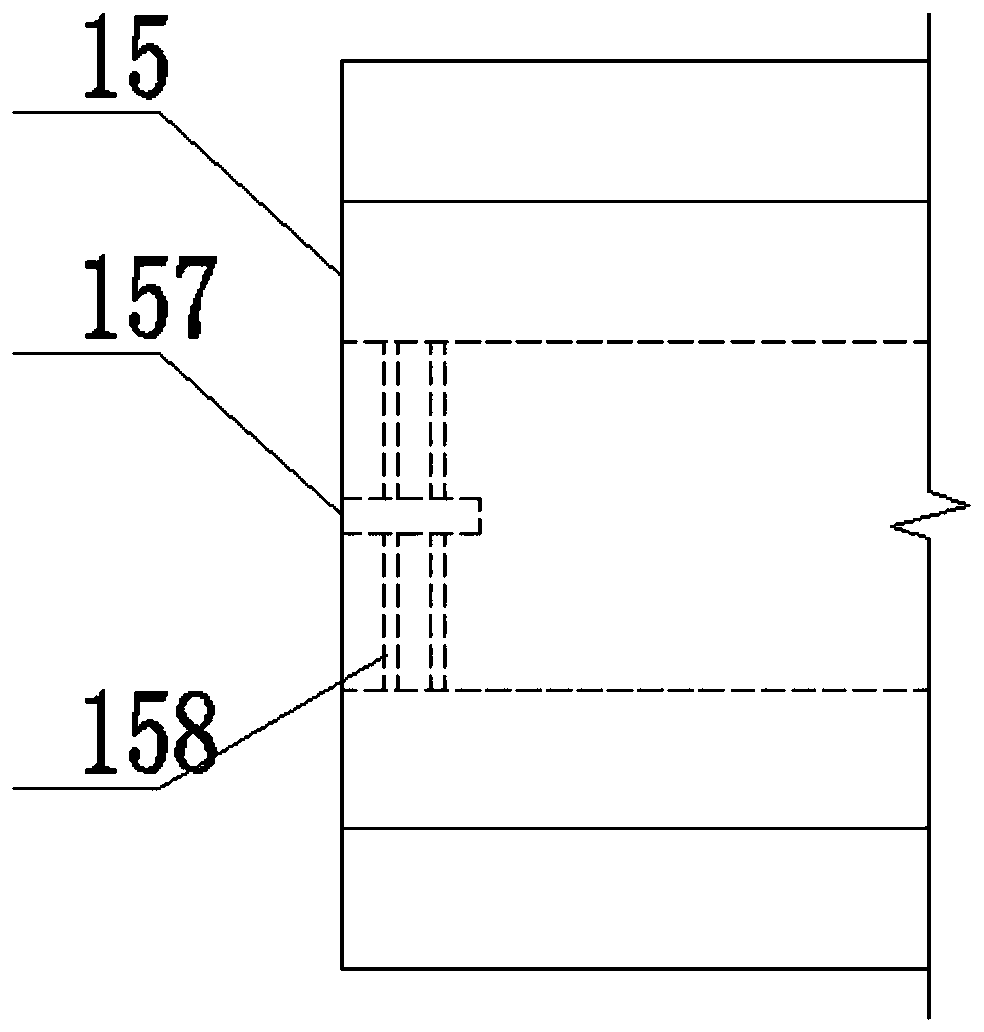

End joint and assembly method of composite assembly type subway station integrated prefabricated front lower frame

PendingCN110004979AImprove seismic performanceSimple structureArtificial islandsUnderwater structuresSubway stationEngineering

The invention discloses a composite assembly type subway station integrated prefabricated front lower frame. The prefabricated front lower frame is arranged between steel stand columns of a compositeassembly type subway station or between steel stand columns and an underground wall; the prefabricated front lower frame is an integrated prefabricated piece, the cross section of the prefabricated front lower frame is integrally in a T shape, and protruding rabbets are reserved on the two transverse outer sides of a longitudinal beam of the upper end surface of the transverse part of the T shape;and vertical and inward concave beam clamping grooves are formed in local parts of the two ends of the longitudinal beam, of the middle of the lower end of the vertical part of the T shape, a beam bolt hole is transversely formed in the local beam clamping groove range of the two ends of the longitudinal beam, of the lower part of the vertical part of the T shape in a communicating mode, and thebeam clamping grooves and the beam bolt hole are used for clamping, locking and fixing a joint of the steel stand columns of the composite assembly type subway station. The joint transfers force clearly, the prefabricated front lower frame is simple to install, the prefabricated front lower frame is only need to be installed on steel clamping blocks above steel pipe column circular flanges on thetwo sides, high-strength bolts are tightened and assembly is completed, and the construction difficulty of a prefabricated structure is reduced.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

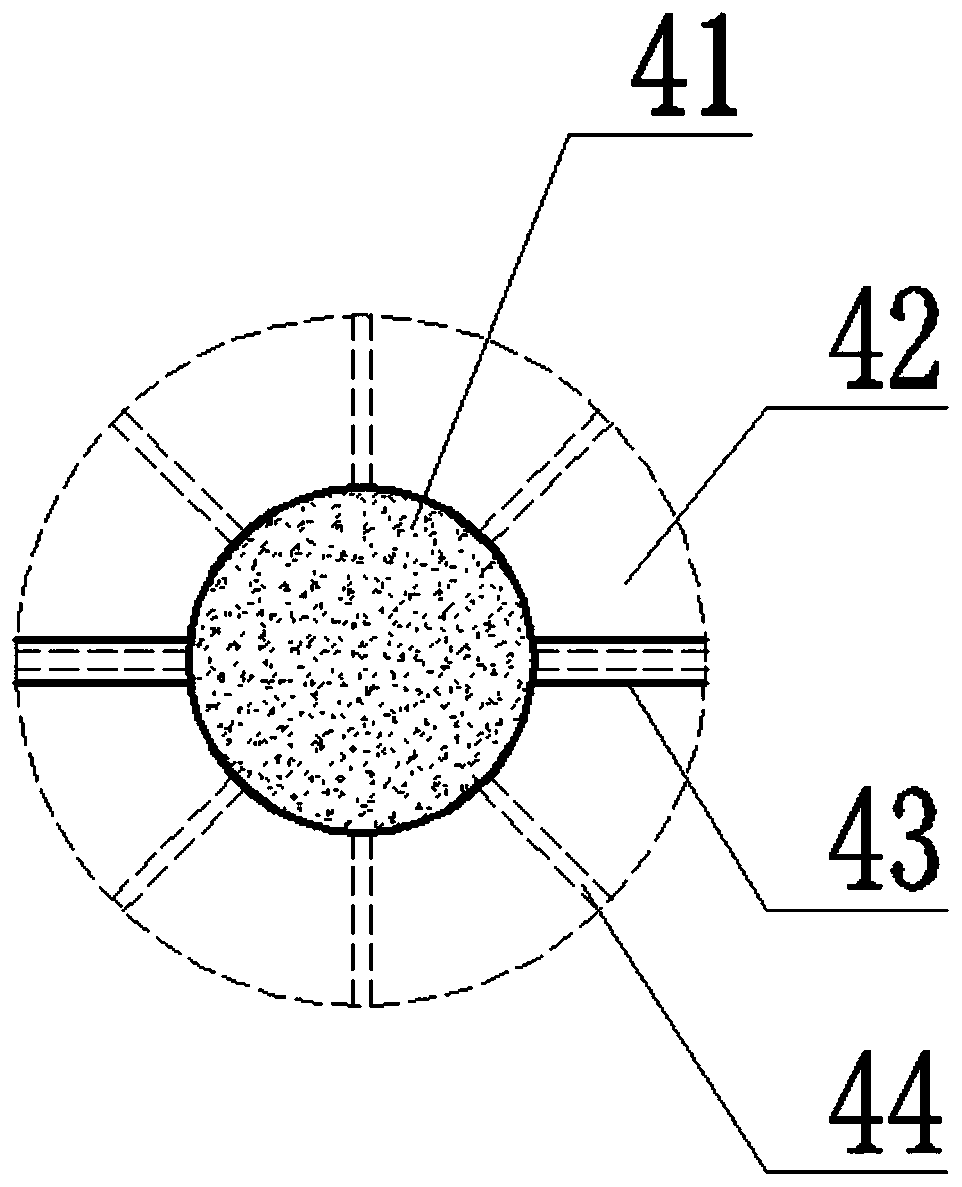

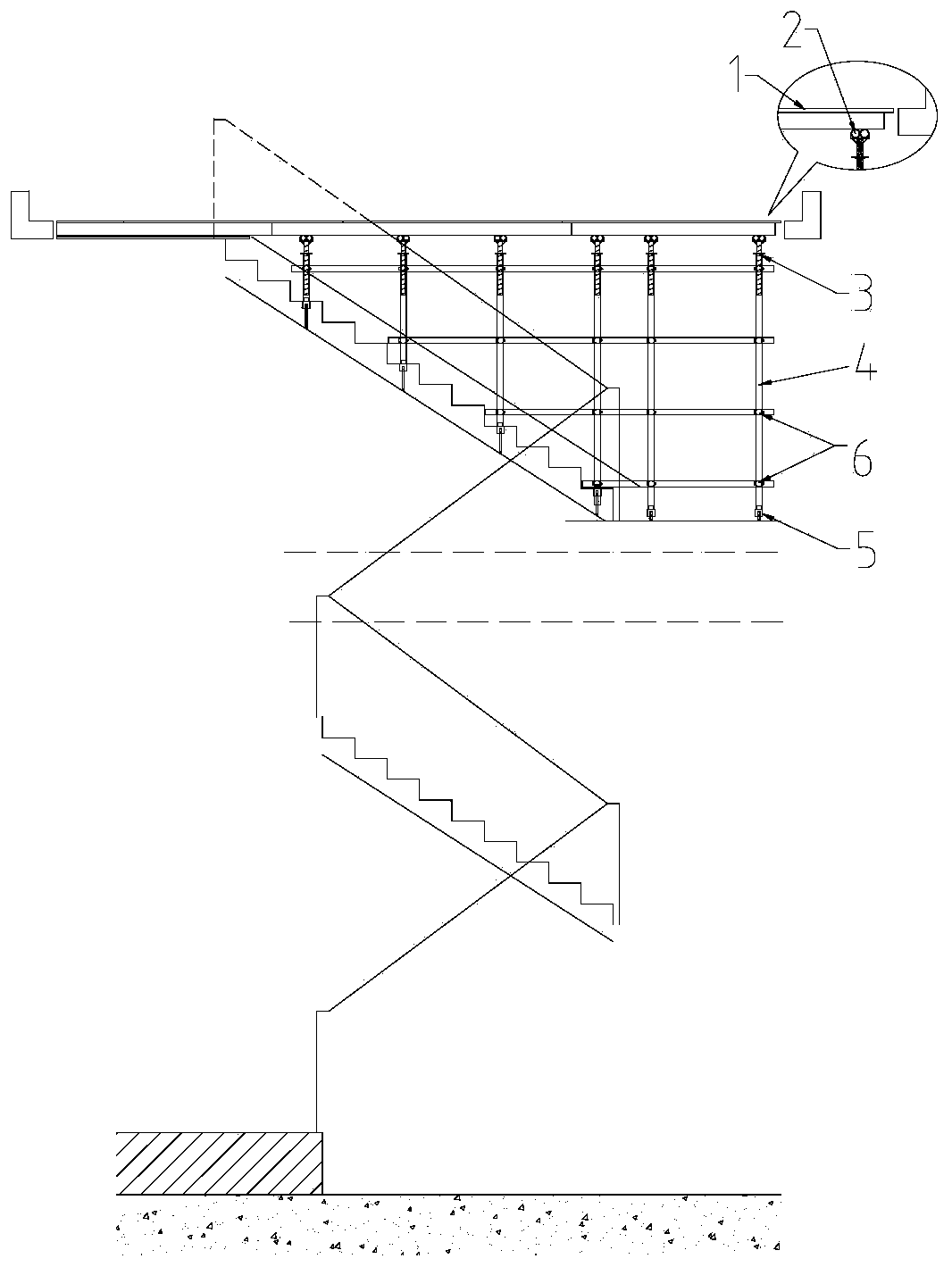

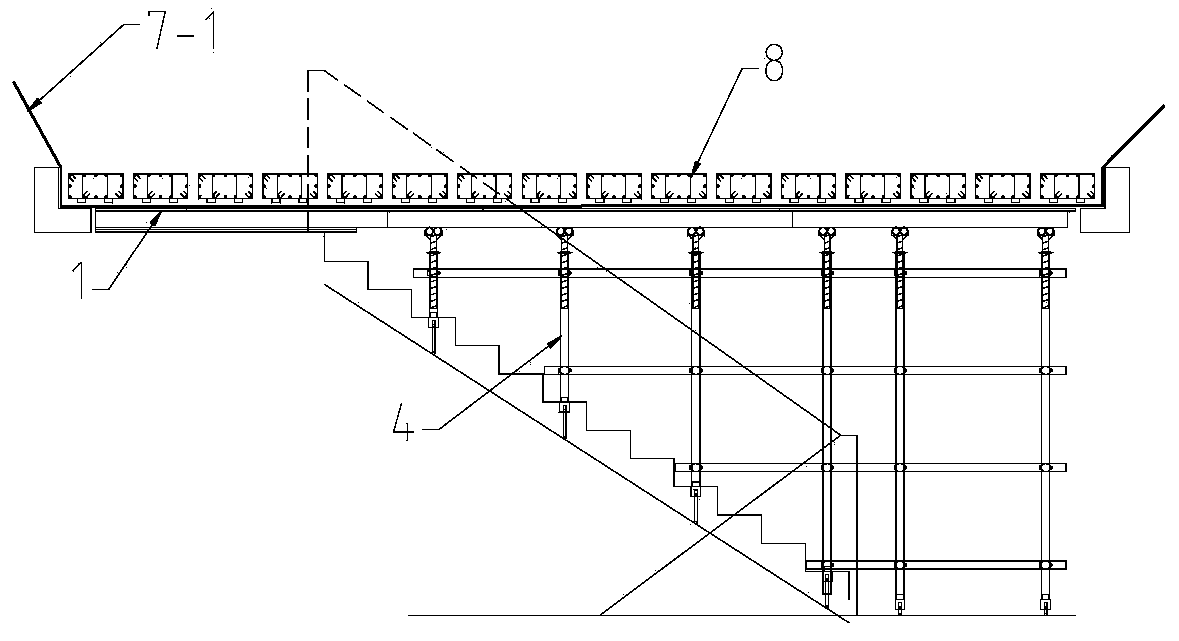

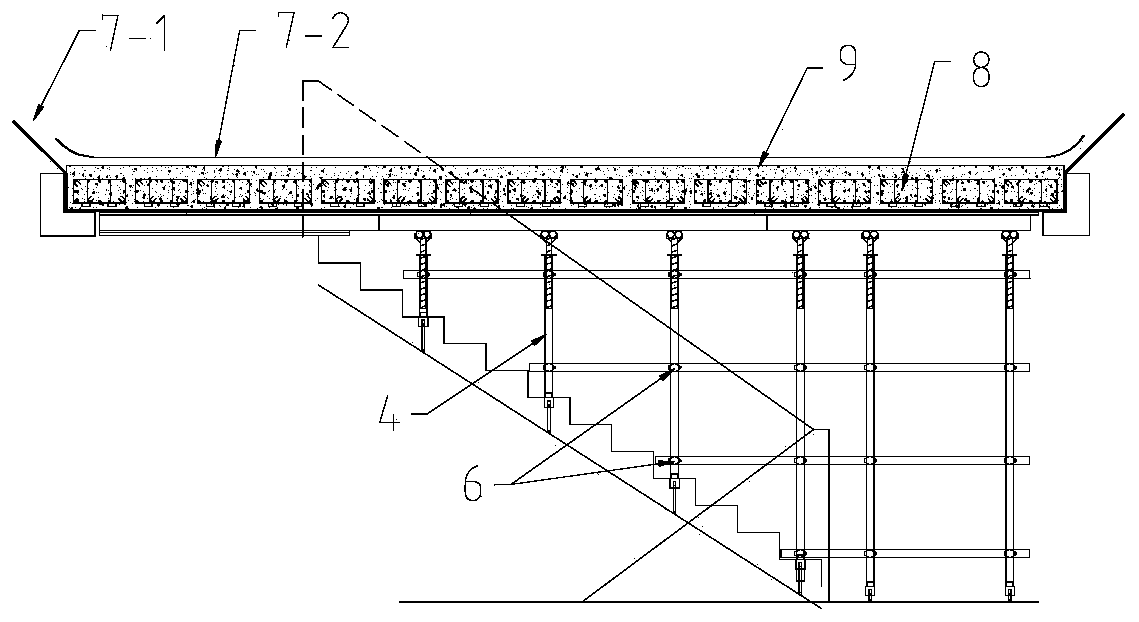

Construction method for cover plate of civil air defense stair

ActiveCN111287455ASave spaceReduce hoistingForms/shuttering/falseworksBuilding material handlingSupporting systemFloor slab

The invention provides a construction method for a cover plate of a civil air defense stair. The method comprises the steps that vertical steel pipe supporting assemblies are uniformly erected below acover plate hole when a floor formwork is erected, the vertical steel pipe supporting assemblies are fixedly tied through rod pieces and fasteners to form supporting planes, the equidistant supporting planes form a vertical supporting system, and the top bearing surface of the vertical supporting system is located on the plane where a key keel of a cover plate formwork is located; the key keel, asecondary keel and a formwork body of the cover plate formwork are arranged at the cover plate hole; a first separation membrane is laid on the upper surface of the formwork body, embedded steel barsare arranged for the cover plate, and all the embedded steel bars are parallel and independent of one another; cover-plate concrete is poured, and vibrating and surface finishing are conducted till the interior of the concrete is solid and the exterior of the concrete is smooth; a second separation membrane is laid on the surface of the cover plate concrete; and the second separation membrane iscut into the cover plate concrete with the surface initially set through a cutting plate, and the concrete within the range of a cover plate is cut into plate strips. According to the construction method, the concrete is partitioned on site, the occupied space of prefabricated parts is saved, and top plate sealing is facilitated.

Owner:CHINA 22MCC GROUP CORP

Reshaping device and flatness reshaping treatment process for heating stand

ActiveCN111975374AReduce peelingReduce grindingShaping toolsOther manufacturing equipments/toolsThermodynamicsSand blasting

The invention discloses a reshaping device for a heating stand. The reshaping device comprises a thermal reshaping furnace, balancing weights and mica sheets. An in-furnace platform of the thermal reshaping furnace is used for storing the heating stand. The mica sheets are arranged on the in-furnace platform. One side of each mica sheet is attached to the in-furnace platform, and the other side ofeach mica sheet is attached to the lower surface of the heating stand. The balancing weights are arranged on the upper surface of the heating stand in a laid manner. The contact area of the in-furnace platform and the heating stand is provided with a stainless steel product. The platform flatness of the in-furnace platform is less than or equal to 0.5 mm, and the surface of the in-furnace platform is in the pure flat state. The balancing weights are arranged in the center and at four edges of the to-be-reshaped heating stand in a laid manner. The balancing weights in the center are spread andlaid into a cross shape by one layer. The balancing weights at the four edges are laid by two layers in a staggered manner. The multiple mica sheets are laid in an area, needing to be covered, of theto-be-reshaped heating stand on the in-furnace platform. The invention further provides a flatness reshaping treatment process for the heating stand. The flatness reshaping treatment process comprises the steps of incoming material inspection, thermal reshaping, peeling, grinding, sand blasting and anodizing.

Owner:芜湖通潮精密机械股份有限公司

Villa lift bearing device

InactiveCN105366509AReduce hoistingReduce labor intensityBuilding liftsTractorArchitectural engineering

The invention provides a villa lift bearing device. The villa lift bearing device comprises a tractor bottom plate, two main guide rails and two subsidiary guide rails, wherein two opposite sides of the tractor bottom plate are both bent upwards to form lug plates; fixing holes are formed in the lug plates near the front side of the tractor bottom plate; the main guide rails are fixedly connected onto the lug plates through the fixing holes; the two subsidiary guide rails are fixedly arranged on the rear side of the lower end of the tractor bottom plate; a cross beam for fixing a tractor is arranged on the upper end surface of the tractor bottom plate; and a rope end support is arranged on the front side of the lower end surface of the tractor bottom plate. According to the villa lift bearing device, as the tractor bottom plate is very small, the lifting is convenient. The problems in the prior art that the tractor assembly work load is large; the civil engineering construction is difficult; the adjusting is difficult; and the like are solved. The labor intensity of assembly personnel is greatly lowered, and the assembly cost is reduced.

Owner:ARIS CO LTD

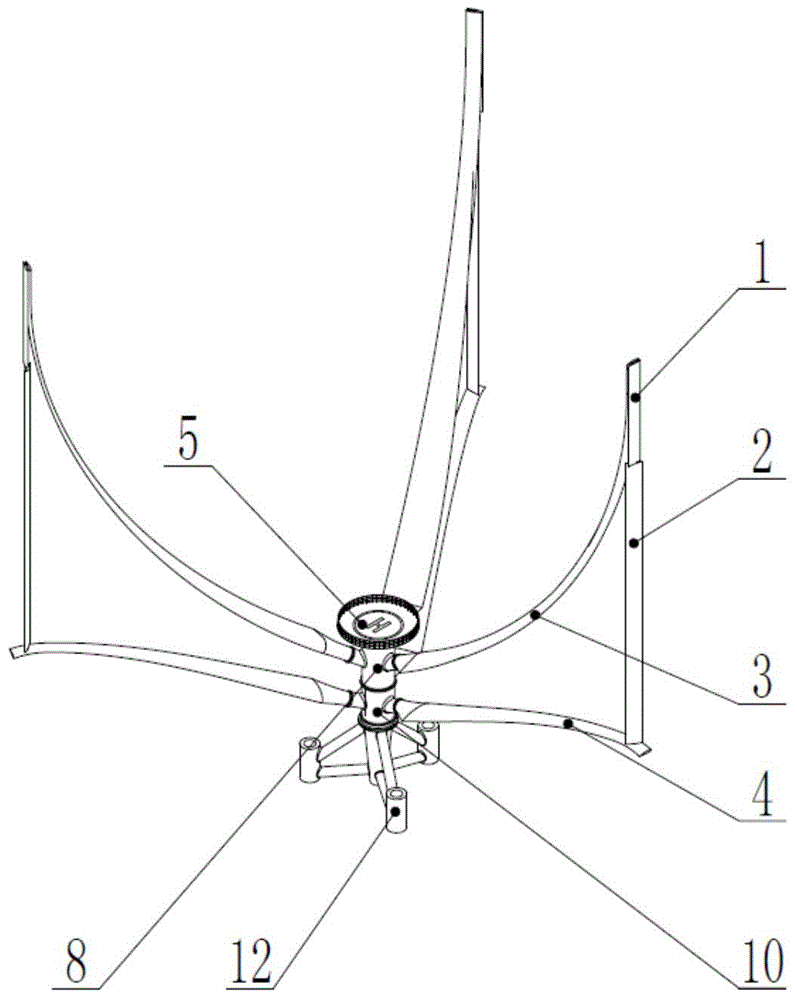

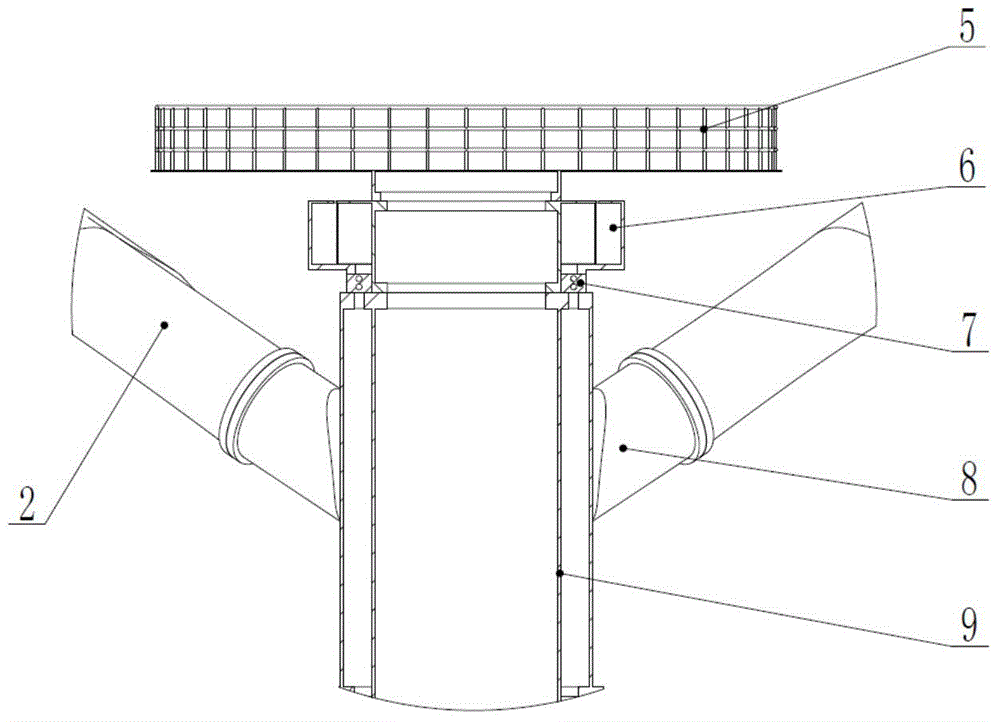

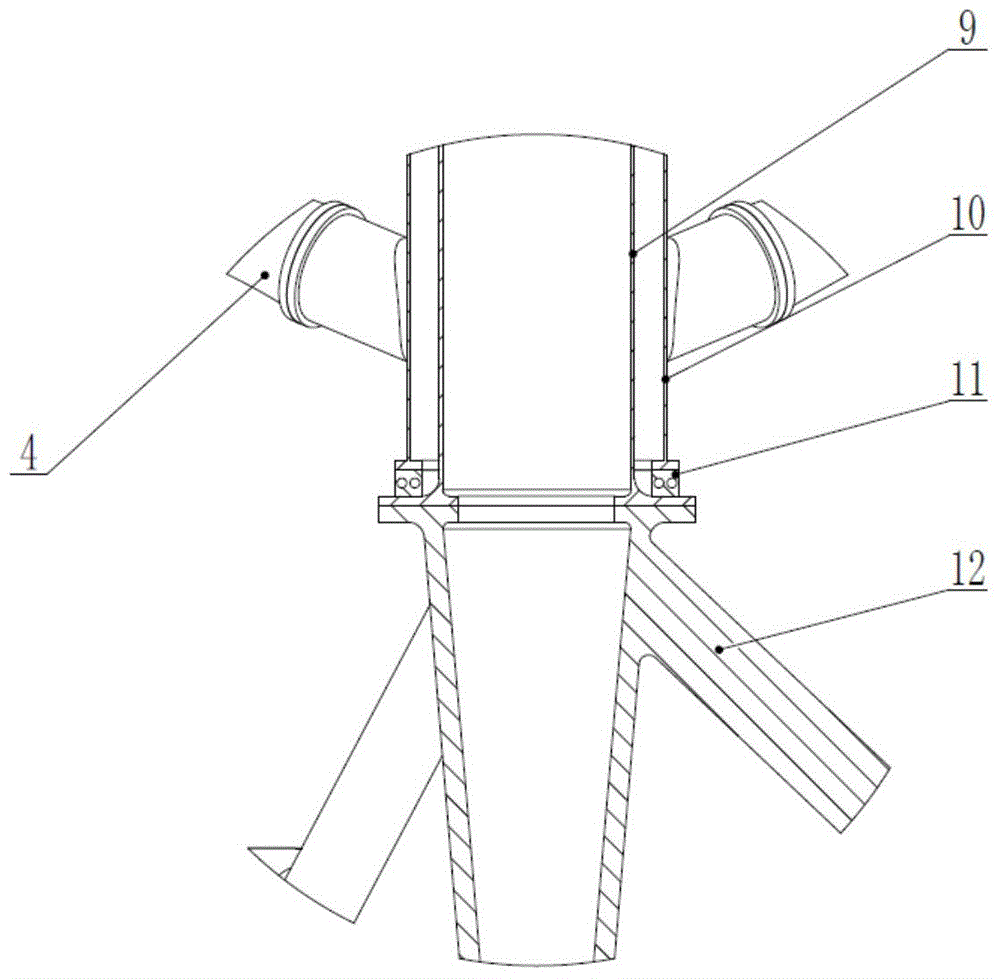

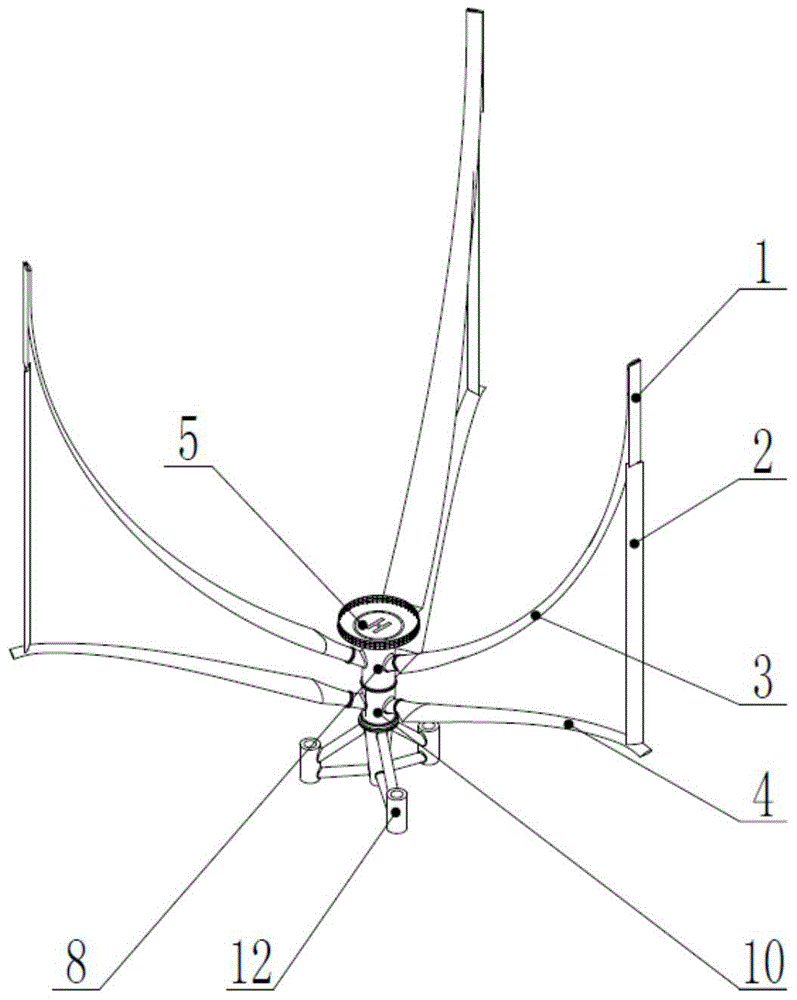

Large offshore perpendicular-axis wind power generator unit

InactiveCN104153944AImprove efficiencyAvoid over-speeding hazardsWind motor controlWind motor combinationsAutomotive engineeringWind force

The invention belongs to the technical field of motors and particularly relates to a large offshore perpendicular-axis wind power generator unit. The wind power generator unit adopts a unique V-shaped structure and comprises blades, a power generator, a helicopter platform, a dynamic and static shaft, a top bearing, a bottom bearing, an off-shore foundation and auxiliary devices. The blades are composed of outer-layer blades and inner-layer blades, a variable pitch system is adopted in the outer-layer blades to avoid galloping dangers caused by overhigh rotation speed due to strong wind or typhoon, and cross sections of the inner-layer supporting blades are of wing-shaped structures to improve the utilization rate of wind energy of the wind power generator unit. The power generator, a gearbox, a converter and other auxiliary devices are arranged at the bottom of the wind power generator unit, so that part replacement and maintenance cost of the wind power generator unit in the hanging process and the later period can be reduced. Compared with a horizontal-axis wind power generator unit, the large offshore perpendicular-axis wind power generator unit effectively solves the problem of the upper limit of power per unit of the horizontal-axis wind power generator unit, is more suitable for the designing scheme of large 10MW or higher than 10MW offshore perpendicular-axis wind power generator units, and has high market utilizing value.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

A large offshore vertical axis wind turbine

InactiveCN104153944BPlay the role of supporting the outer leavesIncreased efficiency in absorbing wind energyWind motor controlWind motor supports/mountsHorizontal axisVertical axis wind turbine

The invention belongs to the technical field of generators, and in particular relates to a large offshore vertical axis wind power generating set. The wind turbine adopts a unique V-shaped structure, including blades, generators, helicopter platforms, dynamic and static shafts, top bearings, bottom bearings, offshore foundations and auxiliary equipment. The blades are composed of outer and inner blades. The outer blades adopt a variable pitch system to avoid the risk of over-speeding caused by strong winds or typhoons; the cross-section of the inner supporting blades adopts an airfoil structure to improve the wind energy utilization rate of the wind turbine. All auxiliary equipment such as generators, gearboxes, and converters are installed at the bottom of the wind turbine, which reduces the cost of hoisting, replacement of components and maintenance of the wind turbine. Compared with the horizontal axis wind power generating set, the present invention effectively solves the upper limit problem of the single unit capacity of the horizontal axis wind power generating set, is more suitable for the design scheme of large offshore wind power generating sets of 10MW or above, and has wider market utilization value.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com