Construction method for inserting steel column in bored pile

A technology of bored piles and construction methods, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of complex process steps, long construction time, low construction efficiency, etc., and achieve simple construction process steps and shorten construction Time and construction cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

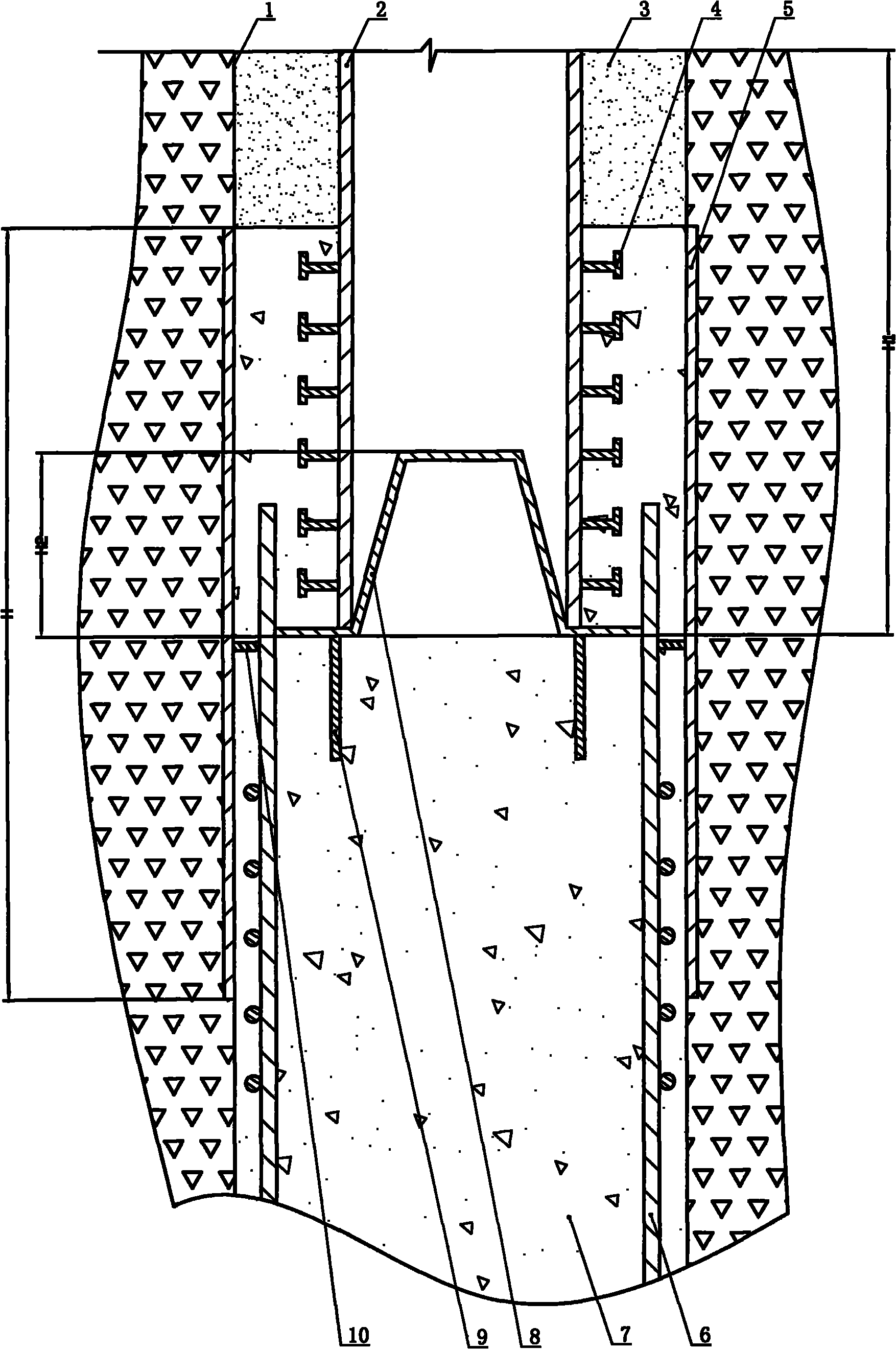

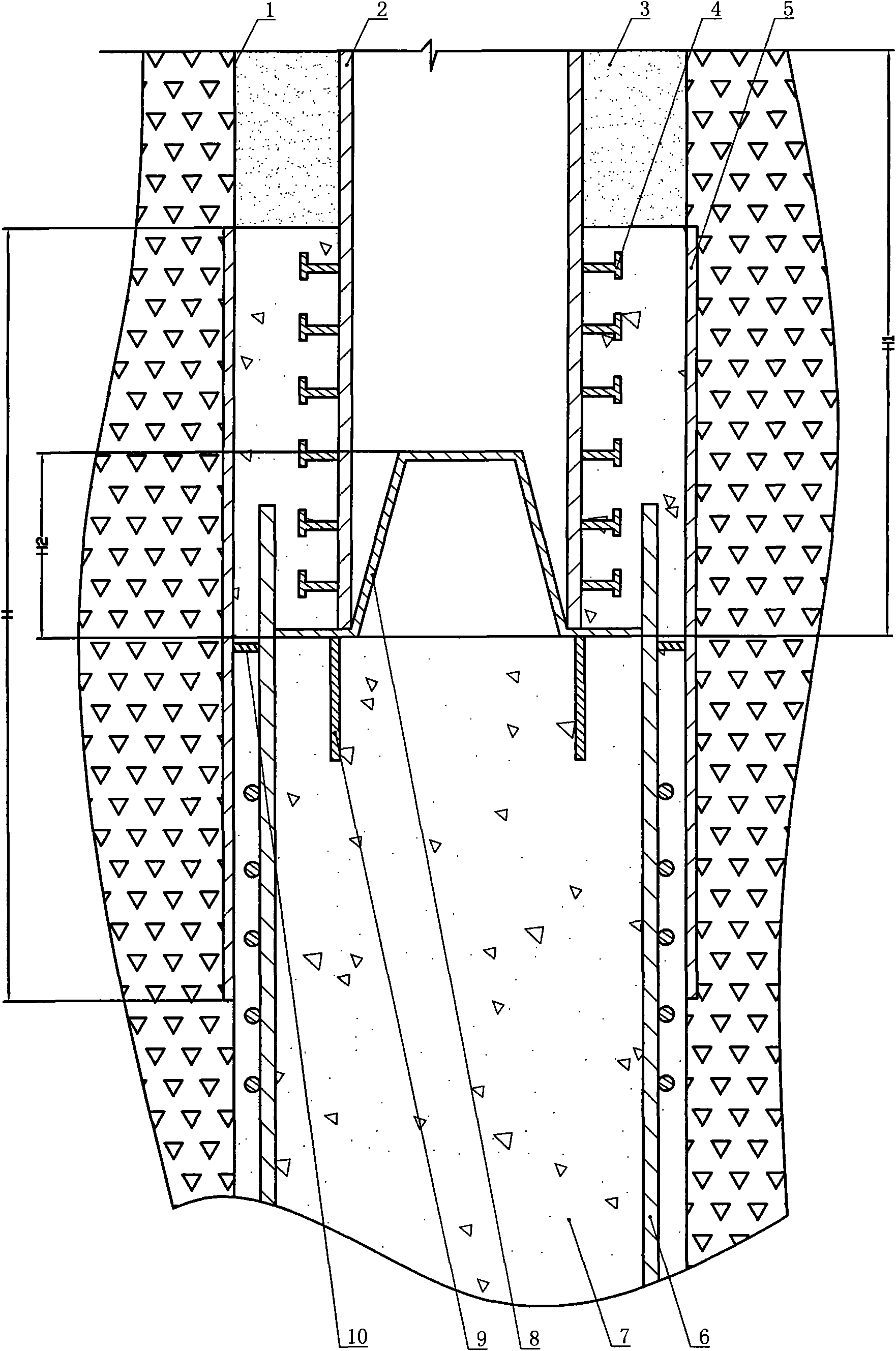

[0017] A construction method for inserting a steel column into a bored pile, comprising the following steps:

[0018] (1) Pile hole formation of cast-in-situ piles: do slope protection treatment to prevent the soil collapse at the upper end of the pile hole, and the pile driver will shape the pile hole and clean the pile hole;

[0019] (2) hoisting reinforcement cage 6;

[0020] (3) Pouring concrete 7;

[0021] (4) hoisting the steel protective pipe to protect the wall of the pile hole;

[0022] (5) Cleaning the pile holes: mainly to pump out the mud in the pile holes and the operator to enter the pile holes, clean up the pile head concrete and other sundries, and place the bottom fixer 8 of the steel column. The anchor bar 9 is welded und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com