Construction method for cover plate of civil air defense stair

A construction method and a technology of cover plates, which are applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the problems of high operating cost and long-term occupation of the construction site, and reduce hoisting and transshipment , reduce fragmented formwork, facilitate the effect of early closure and subsequent construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

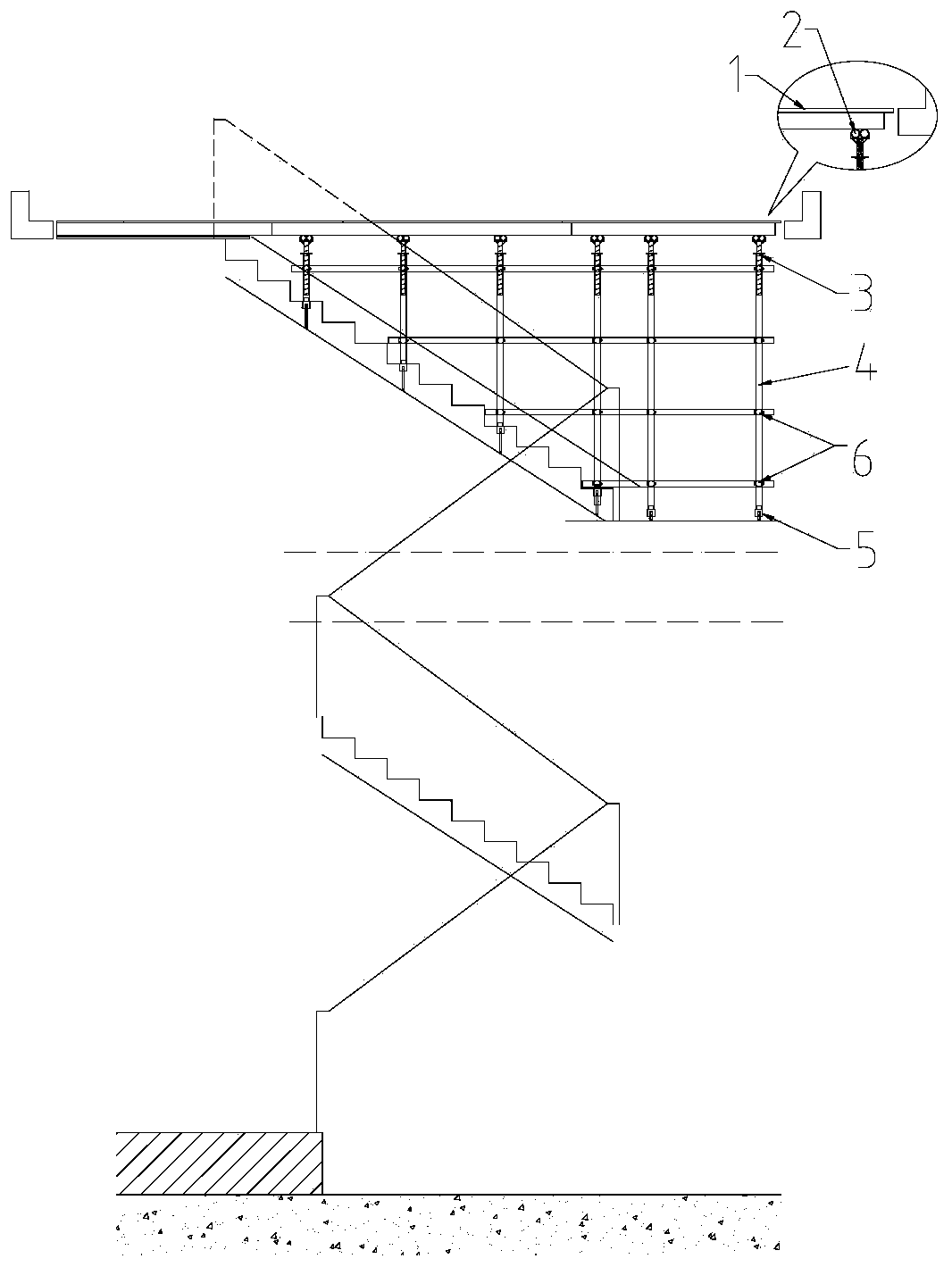

[0027] The construction of civil air defense cover in the prior art is to prefabricate many pieces of concrete slats according to the size of the stair opening, and the many pieces of concrete slats are transported to the site, and the assembly is pulled to be a cover slab just in time to close the opening. Concrete prefabricated parts are large in size and heavy in weight, which not only consumes engineering costs for component handling, but also requires a lot of manpower and material resources for on-site installation, and the construction safety is also low.

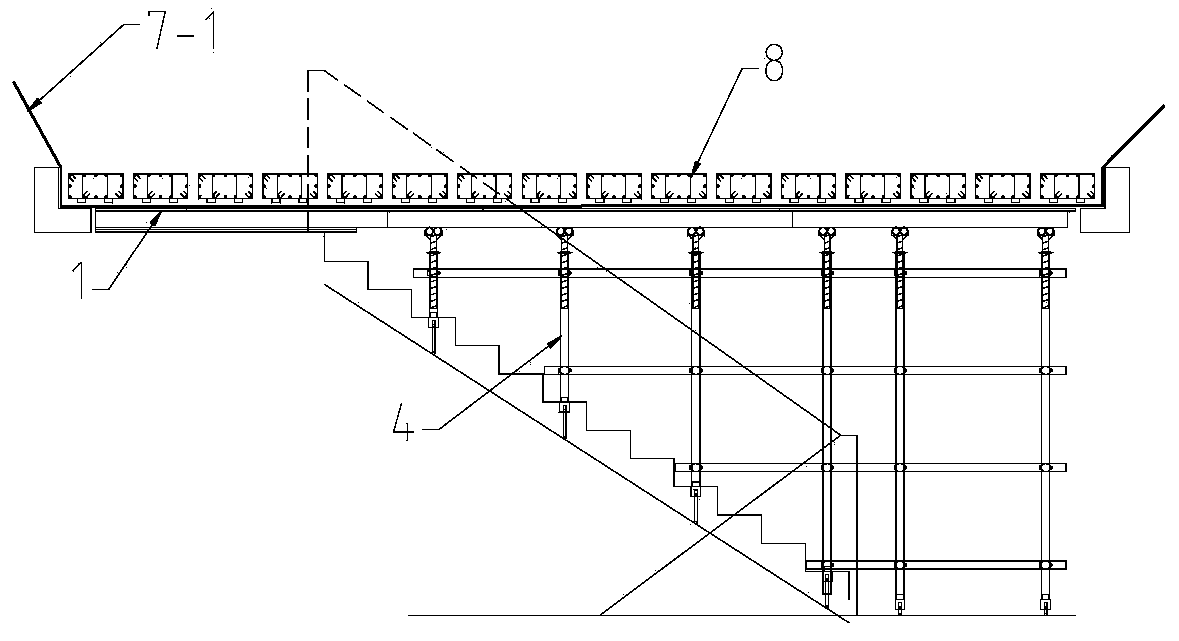

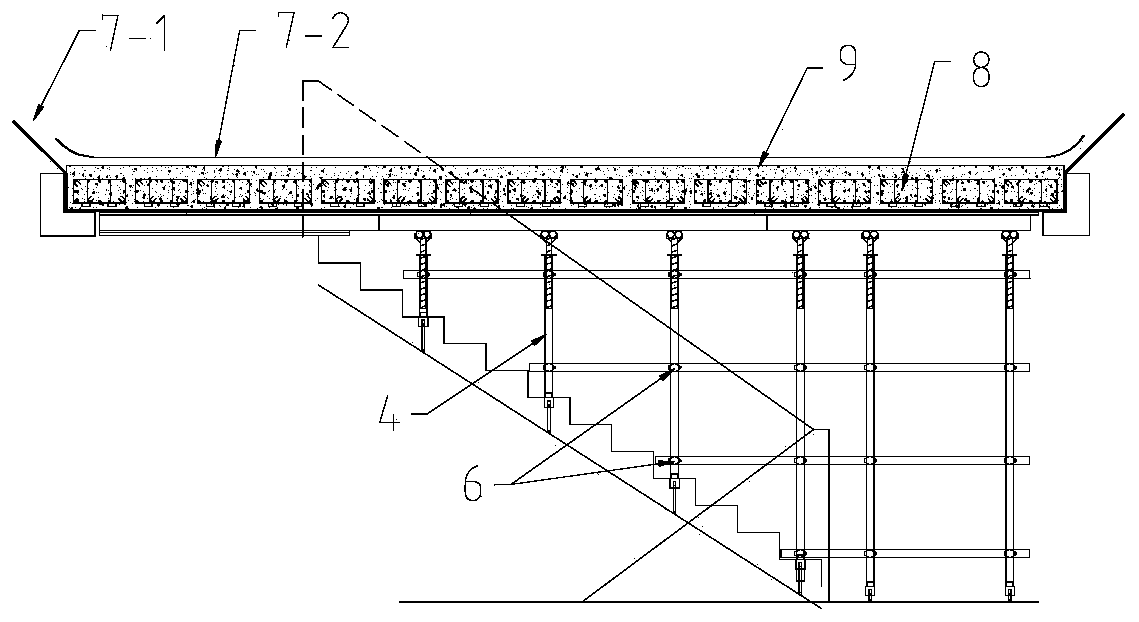

[0028] In order to solve the problem of large investment in transportation and installation of prefabricated concrete slats, the invention provides a cover slab cast-in-place construction method. The invention utilizes the concept of in-situ cast-in-place parts, adopts a formwork support system at the opening of the floor slab, and completes reinforcement binding and concrete pouring on the formwork surface, and uses ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com