A large offshore vertical axis wind turbine

A wind turbine, vertical axis technology, applied in wind turbine combinations, wind turbines, wind turbines at right angles to the wind direction, etc., can solve the problems of unsuitable structural type of large-scale wind turbines, high installation and maintenance costs, and achieves a solution to the problem. The upper limit of single machine capacity, efficiency improvement, and the effect of avoiding the danger of over-speed speeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

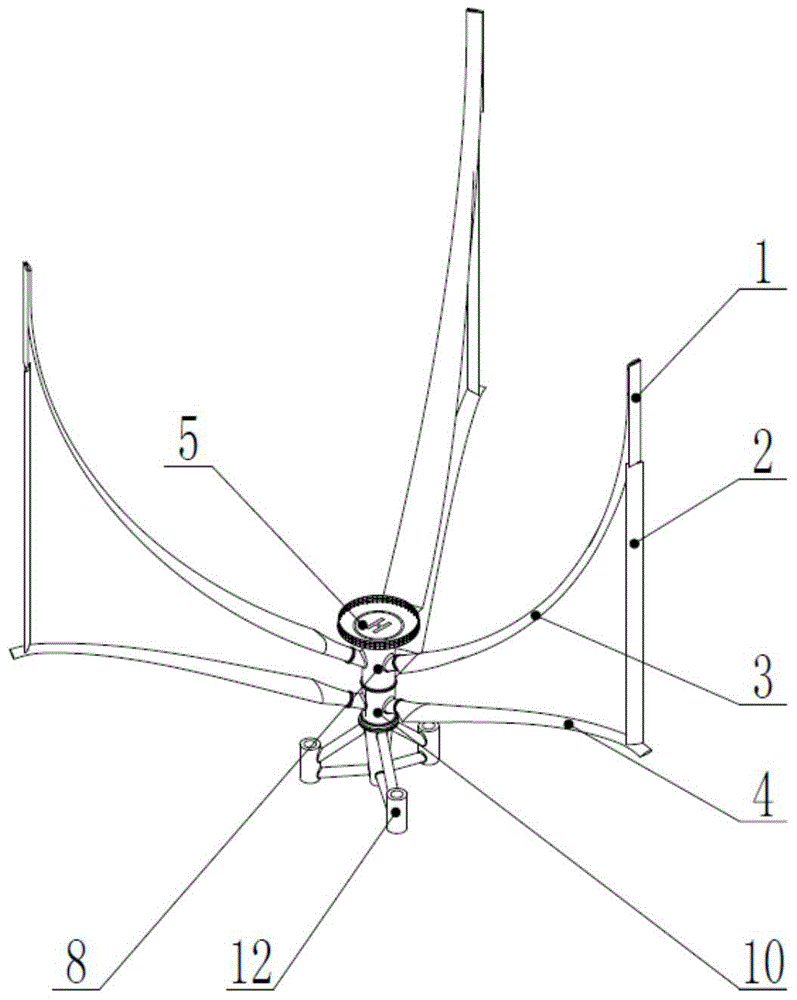

[0039] figure 1 As shown, it is a large-scale vertical axis wind turbine, which mainly includes the outer stationary blade 1, the outer variable pitch blade 2, the inner upper blade 3, the inner lower blade 4, the helicopter platform 5, the generator 6, the top bearing 7, The upper part of the moving shaft 8, the fixed shaft 9, the lower part of the moving shaft 10, the bottom bearing 11 and the offshore foundation 12;

[0040] Among them, one end of the outer static blade 1 is connected to the inner upper blade 3 by bolts, and the other end is connected to the outer pitch blade 2 by bolts;

[0041]One end of the outer pitch blade 2 is connected to the outer stationary blade 1, and the other end is connected to the inner lower blade 4 by bolts. The outer pitch blade 2 is a component that mainly captures wind energy, and it can be driven by an internal motor or hydraulic power equipment. , change the pitch angle of the blades, thereby changing the ability of the blades to capt...

Embodiment approach 2

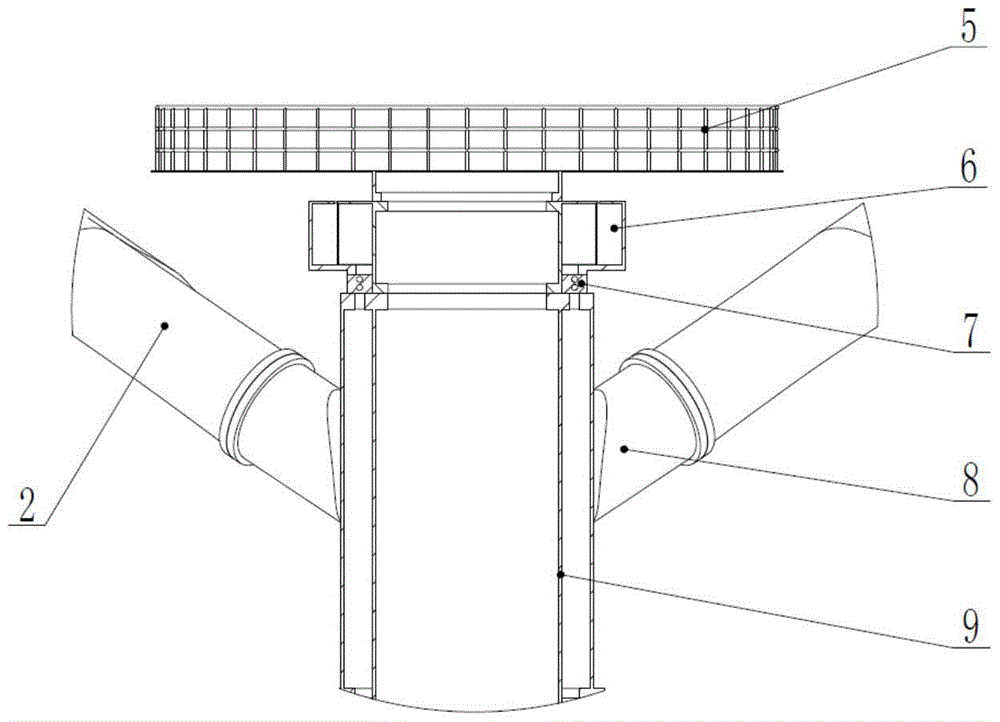

[0054] Figure 4 As shown, it is a large-scale vertical axis wind power generating set, which mainly includes a helicopter platform 5, a generator 6, a top bearing 7, a fixed shaft 9, a bottom bearing 11, an offshore foundation 12, blades 13 and a moving shaft 14;

[0055] Wherein, one end of the blade 13 is connected to the bolt and the moving shaft 14 through a flange;

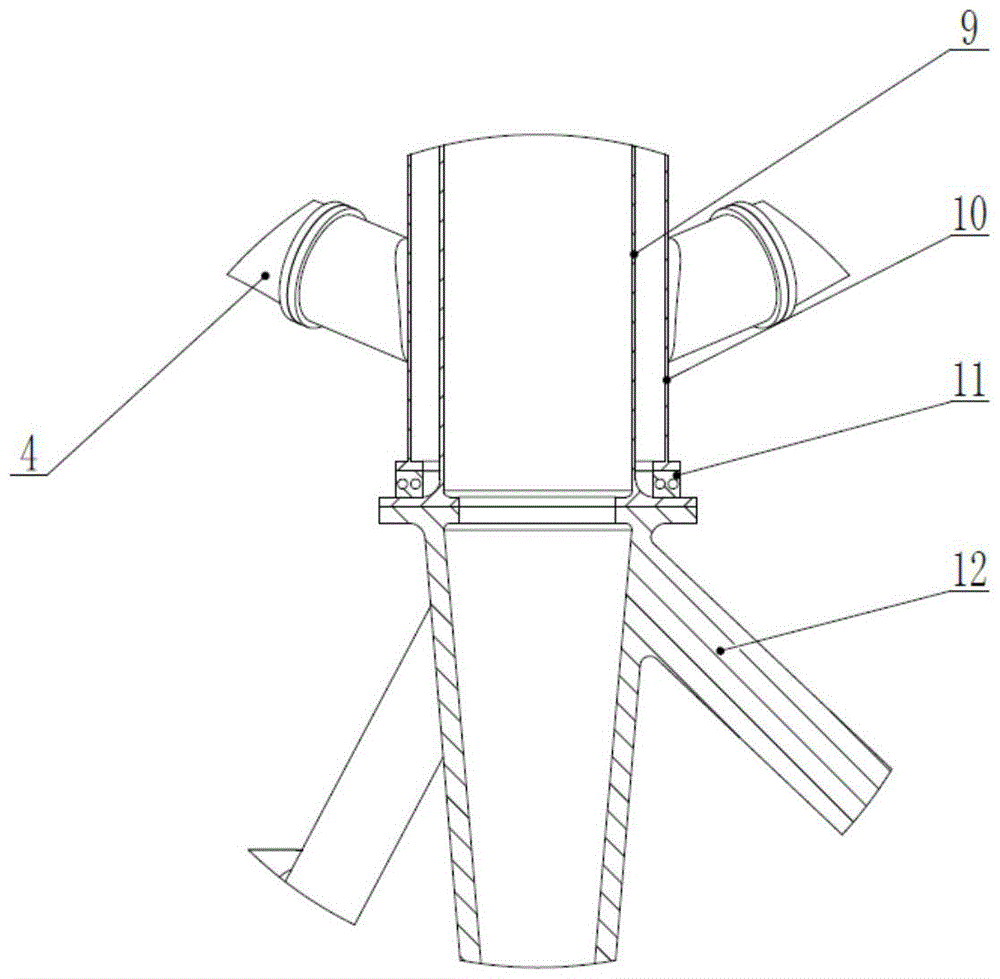

[0056] Figure 5 Shown is a partial cross-sectional view of the moving shaft at the bottom of the generator set;

[0057] The lower part of the helicopter platform 5 is connected with bolts and the stator of the generator 6 through flanges, and the main function of the helicopter platform 5 is to dock the helicopter and provide a landing place for the maintenance of the offshore wind power generating set;

[0058] The rotor of the generator 6 is connected with the outer ring of the top bearing 7 with bolts, one end of the stator part of the generator 6 is connected with the helicopter platform 5, and the o...

Embodiment approach 3

[0064] Figure 6 As shown, it is a large-scale vertical axis wind power generating set, which mainly includes the outer variable pitch blade 2, the inner upper blade 3, the inner lower blade 4, the helicopter platform 5, the generator 6, the top bearing 7, the upper part of the moving shaft 8, the fixed Shaft 9, lower part of moving shaft 10, bottom bearing 11 and offshore foundation 12;

[0065] Among them, one end of the outer pitch blade 2 is connected to the inner upper blade 3, and the other end is connected to the inner lower blade 4 by bolts. The outer pitch blade 2 is a component that mainly captures wind energy, and it can be powered by an internal motor or hydraulic power equipment. Drive to change the pitch angle of the blades, thereby changing the ability of the blades to capture wind energy, adjust the output power of the wind turbine, and prevent the wind turbine from flying under high wind conditions;

[0066] One end of the inner upper blade 3 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com