Combined prefabricated base board and composite floor slab structure and composite floor slab construction method

A technology for superimposing floors and bottom slabs, which is applied in the direction of floors, building components, building structures, etc. It can solve the problems of inability to adjust the bending resistance, shear resistance and crack resistance, inconvenient prefabricated production, transportation and installation, and many types of prefabricated bottom slabs. problems, to achieve the effect of simplifying prefabricated production, avoiding heavy lifting, and expanding the applicable span range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

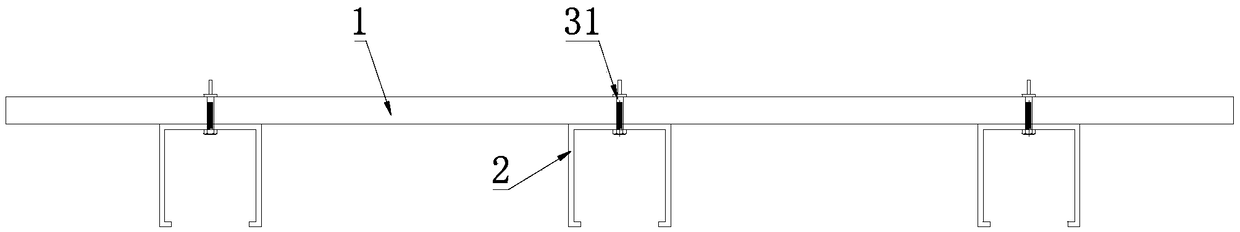

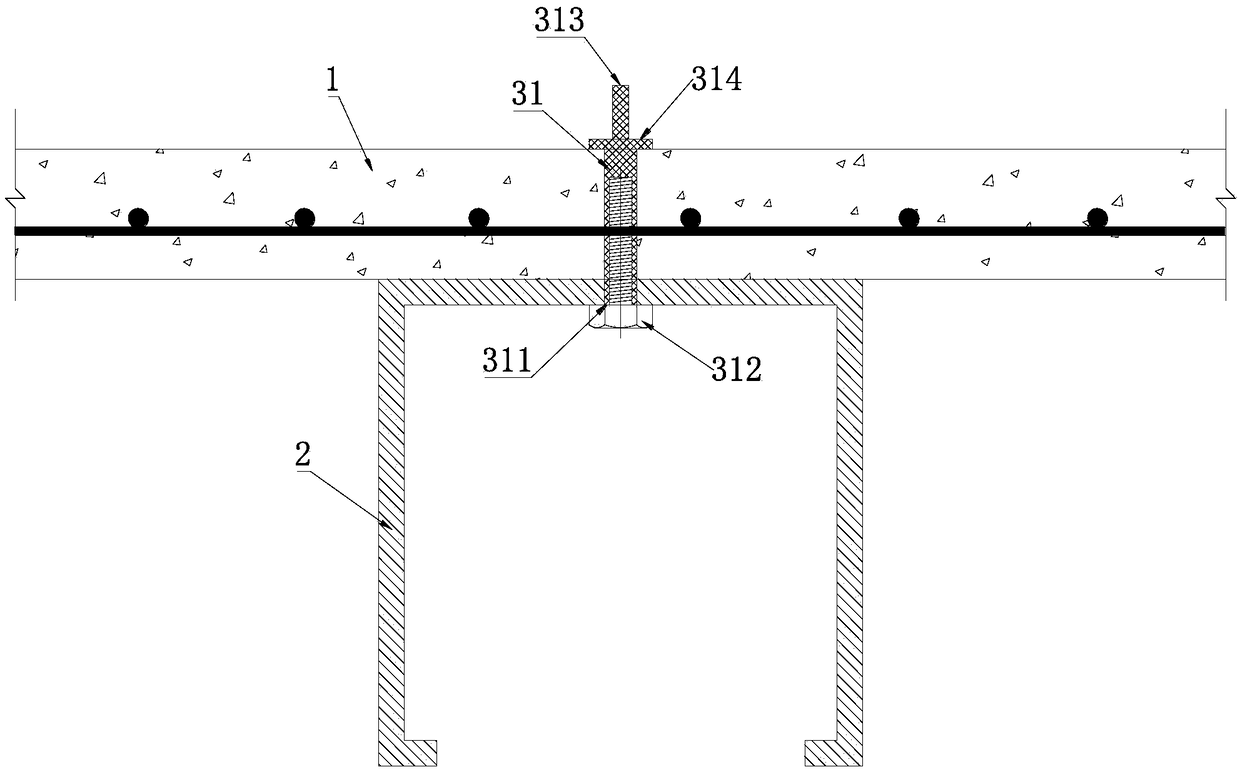

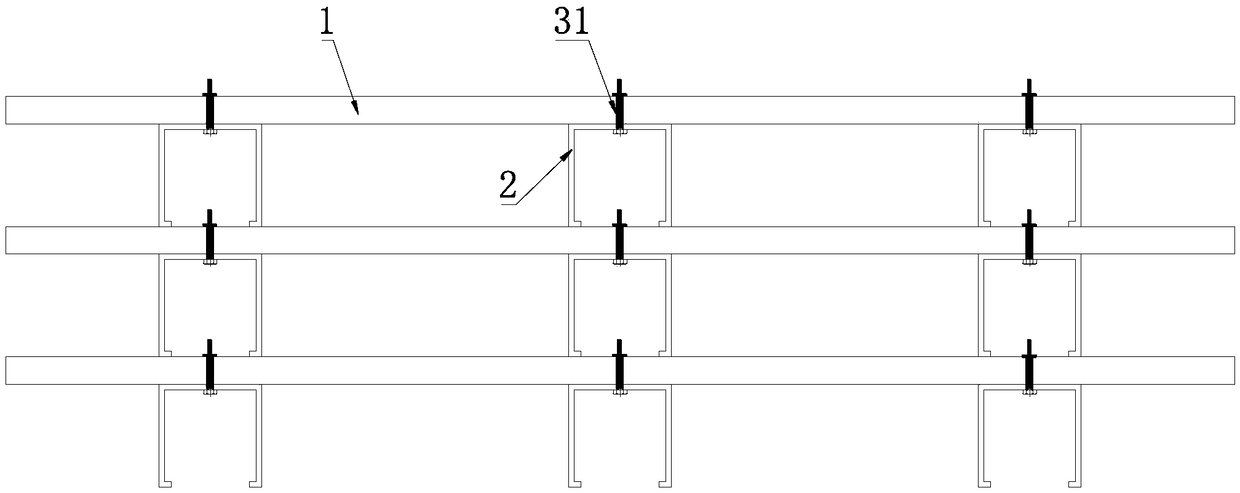

[0041] The present invention will be further described below in conjunction with accompanying drawing.

[0042] The combined prefabricated bottom plate of the present invention includes a prefabricated bottom plate 1 and a support member 2, and the prefabricated bottom plate 1 is equipped with reinforcement, that is, the prefabricated bottom plate 1 is provided with a reinforcement mesh. The prefabricated bottom slab 1 is a reinforced concrete slab or a prestressed reinforced concrete slab. Connectors are embedded in the prefabricated floor 1. The upper ends of the connectors pass through the upper surface of the prefabricated floor 1, and the parts that pass through the upper surface of the prefabricated floor 1 form shear studs. The new concrete on the surface, that is, the shear connection between the laminated layers of post-cast concrete. Specifically, such as Figure 1~5 As shown, the connector is a sleeve 31, and the part passing through the upper surface of the prefa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com