Construction method for integrally sliding large-span steel pipe arch of curved bridge

A technology of integral sliding and construction methods, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., and can solve the problems of occupying a lot of space and long construction period of steel pipe arches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

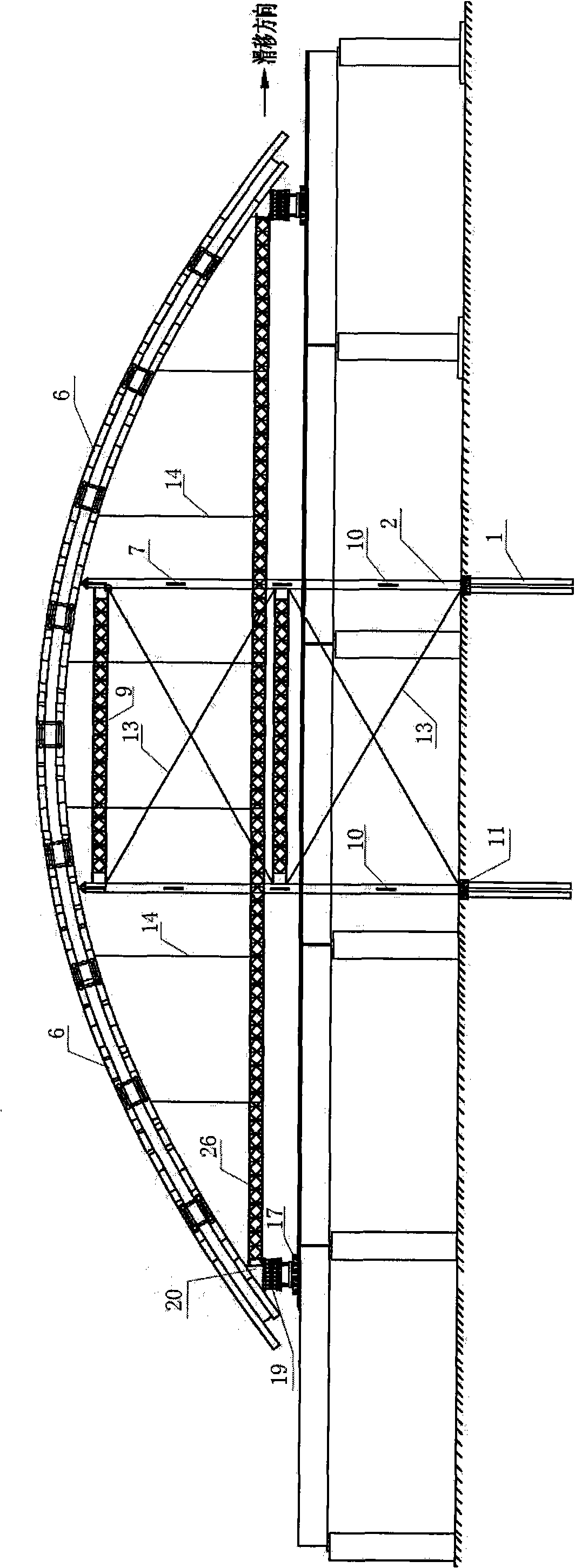

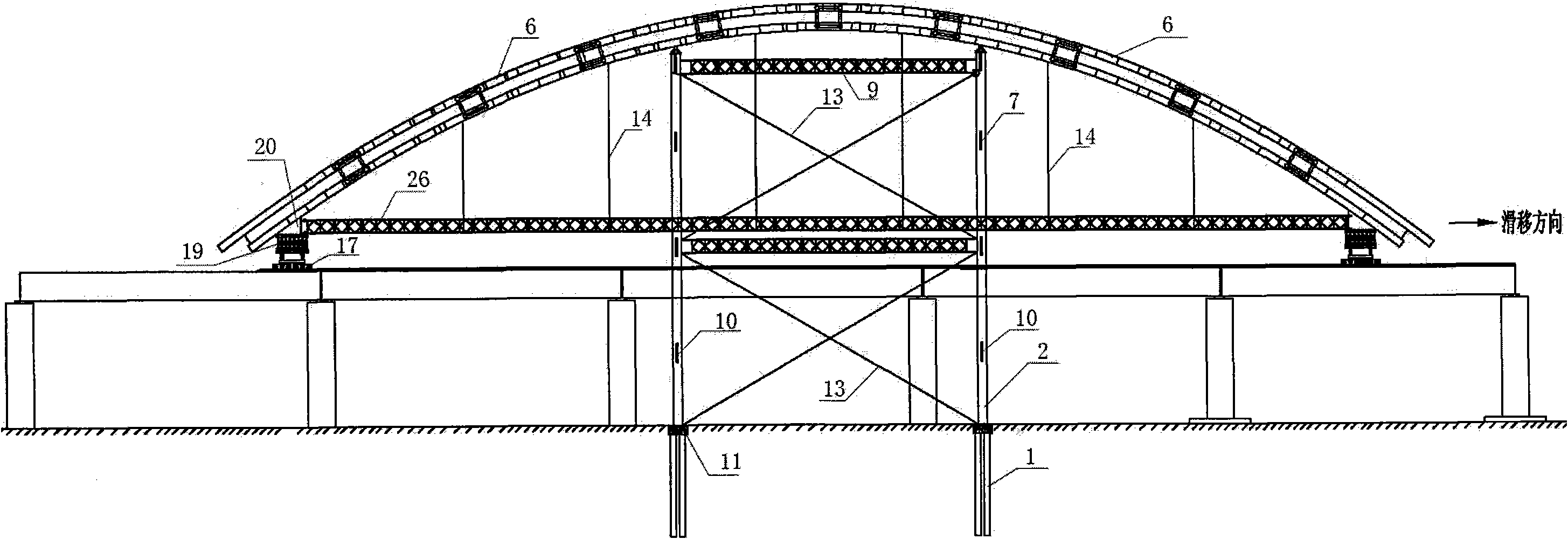

[0031] The following is combined with the specific figure 1 And embodiment the present invention is described further.

[0032] 1. Project overview

[0033] The superstructure of piers 715#~718# of the (70+136+70)m continuous beam arch bridge across the Loujiang River on the Beijing-Shanghai high-speed railway is a composite structure of (70+136+70)m prestressed concrete continuous beam and steel tube concrete arch. The two ends of the bridge are 30m simply supported box girders. The calculated span of the steel pipe arch is 136m, the rise-span ratio is 1 / 5, the rise height is 27.2m, the arch axis is a quadratic parabola (the design arch axis equation Y=-1 / 170X2+0.8X), and the maximum pre-camber of arch rib 6 is set to 0.15 m, and the construction elevation is 27.35m (construction arch axis equation Y=-0.005915X2+0.804412X). During the construction, it is manufactured and assembled according to the axis of the construction arch, and the arch rib chord is arched with a 2m lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com