Follow-up pipeline groove

A pipeline trough and follow-up technology, applied in the field of pipeline troughs, can solve the problems of long relocation period, poor versatility and high risk of drilling rigs, and achieve the effects of eliminating hoisting by cranes, facilitating pipeline maintenance and reducing operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

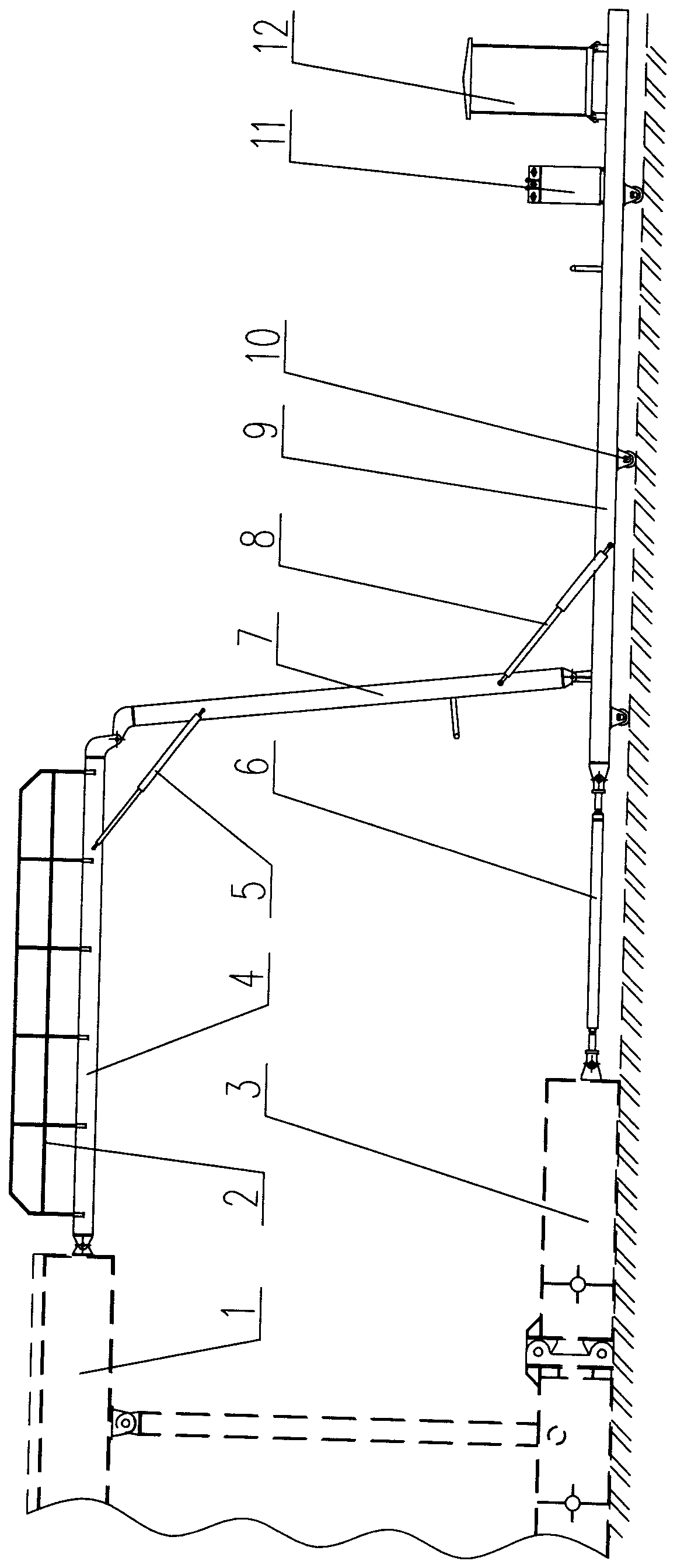

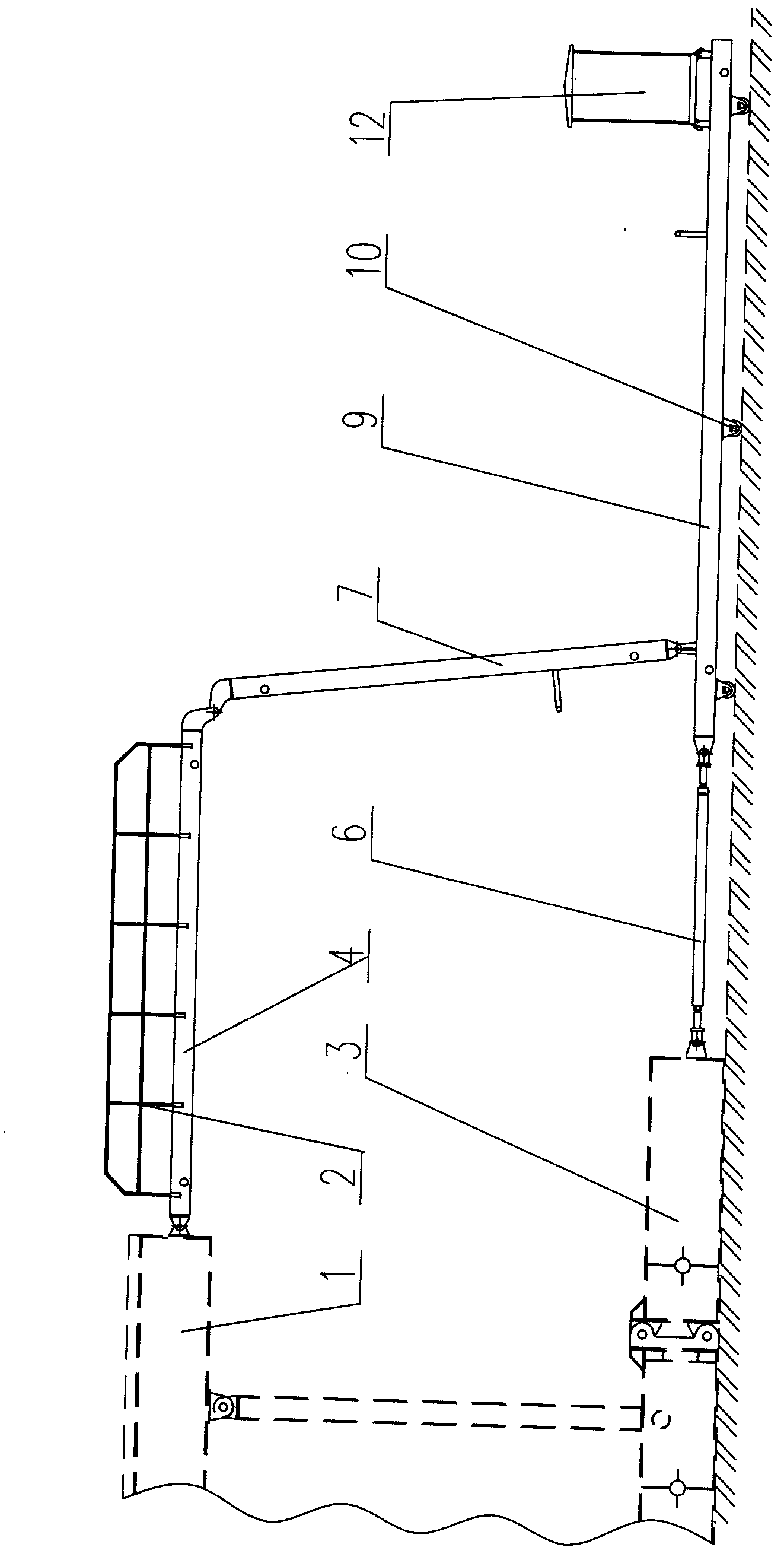

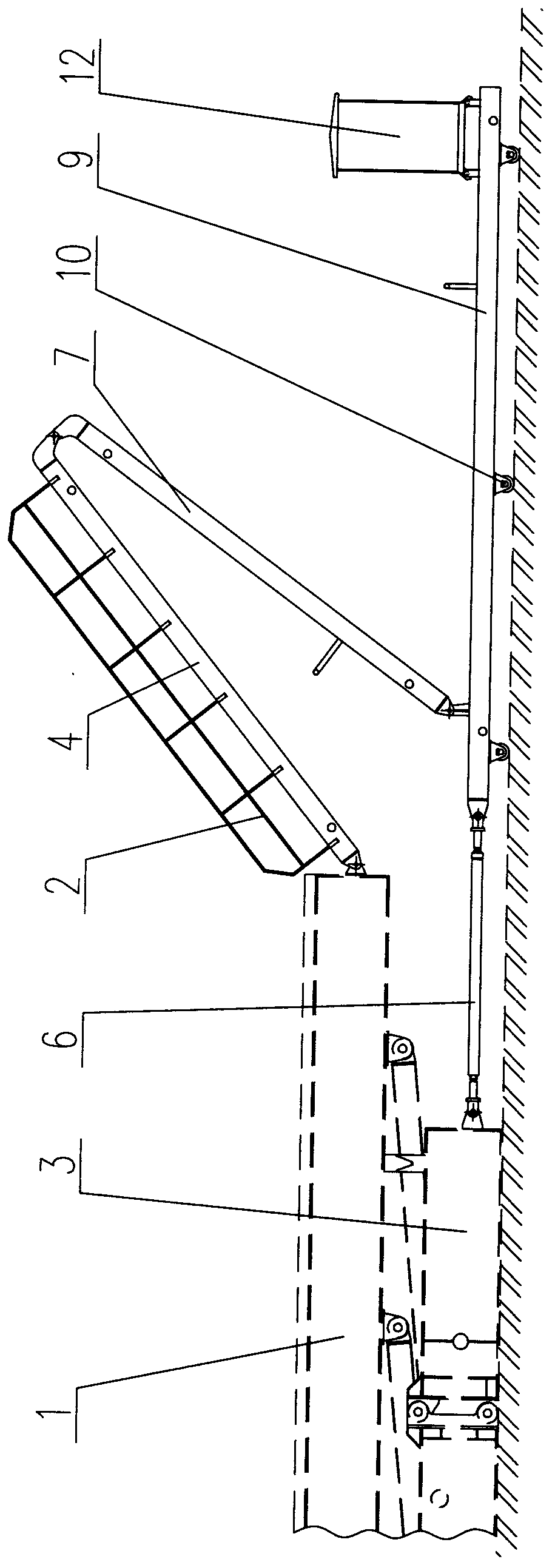

[0021] exist figure 2 , image 3 Among them, a follow-up pipeline trough is mainly composed of a high-level pipeline trough 4, a middle-level pipeline trough 7 and a low-level pipeline trough 9. The high-level pipeline trough 4 is provided with a guardrail 2, one end of which is hinged to the top floor 1 of the drill floor, and the other end Hinged with the middle pipeline trough 7, the front end of the low pipeline trough 9 is connected to the drill floor base 3 through an adjustable telescopic pull rod 6, and the other end of the middle pipeline trough 7 is hingedly connected to the low pipeline trough 9 near the telescopic pull rod 6 , the lower part of the low-level pipeline trough 9 is provided with a roller 10, and its end away from the telescopic pull rod 6 is provided with a transfer box 12.

[0022] When the drilling rig is at a low position, the high-level pipeline trough 4 and the top floor of the drill floor 1, the high-level pipeline trough 4 and the middle pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com