Hinge type installation method for ship body steel structure

An installation method and steel structure technology, which is applied to ship components, ship construction, ship design, etc., can solve the problems of increasing assembly difficulty and work cycle, less closing workload, and time-consuming, so as to reduce the difficulty of hoisting and positioning work , save docking resources and save docking period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

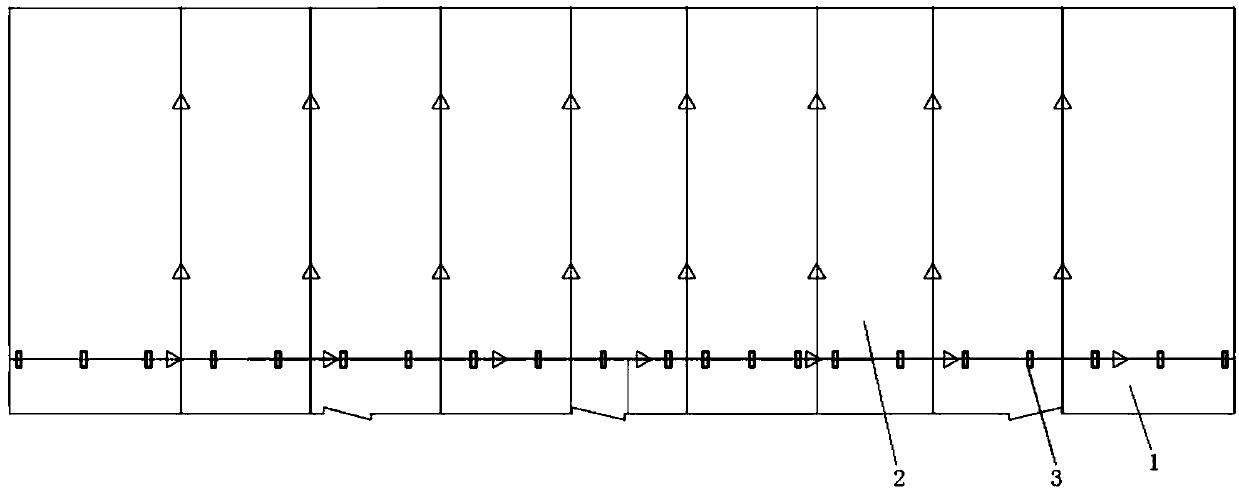

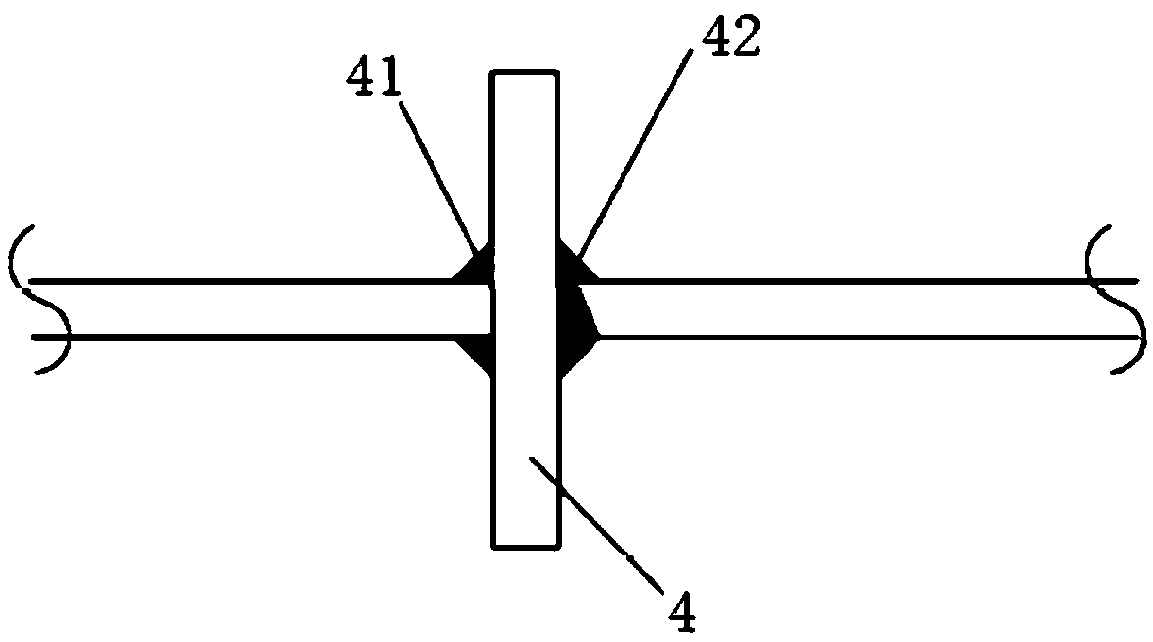

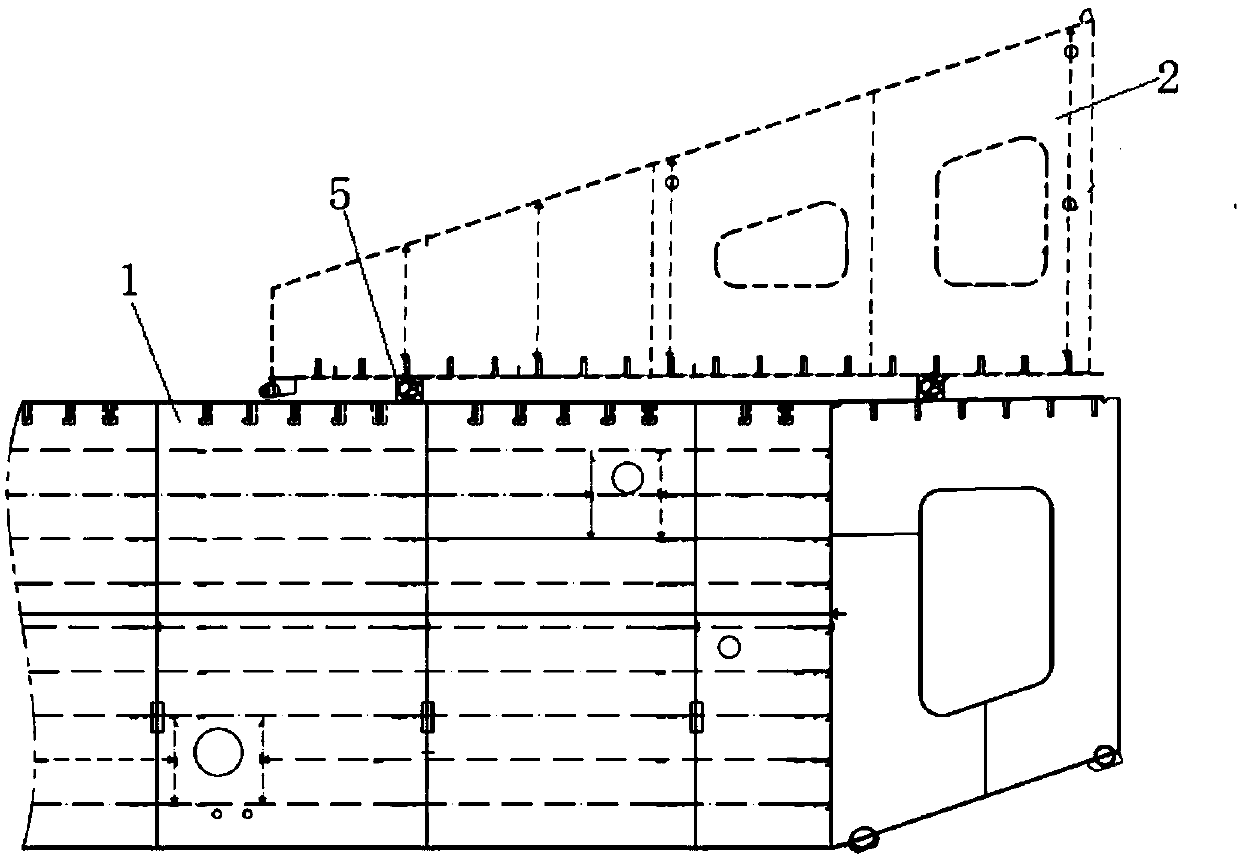

[0030] combine Figure 1 to Figure 7 As shown, a kind of hull steel structure hinge type installation method provided by the present invention, its specific implementation is as follows.

[0031] A hinged installation method for the hull steel structure solves the problem in the process of closing the main hull steel structure in the dock. The hinged assembly method is used to accurately assemble the steel structure segment 2 to the main hull 1 during the closing stage in the dock. After the assembly is qualified, it will be turned out of the theoretical installation position to save space in the dock. After the main hull 1 is fully undocked, the steel structure segments 2 are turned back to the theoretical position one by one by using the wharf portal crane. Under the guarantee of the reasonable design of the hinge 3 tooling at the installation position and its own strength, the steel structure fragments can be flipped in place at the wharf, that is, the independent assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com