Device and industrial method for continuously producing aerogel felts

An airgel blanket and equipment technology, applied in the field of continuous production of airgel blanket, can solve the problem of inability to achieve continuous production of supercritical dry airgel blanket, low heat transfer efficiency of heat transfer oil, high performance requirements of drying kettle, etc. problems, to avoid explosive mixed gas, avoid uneven drying, and reduce human misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

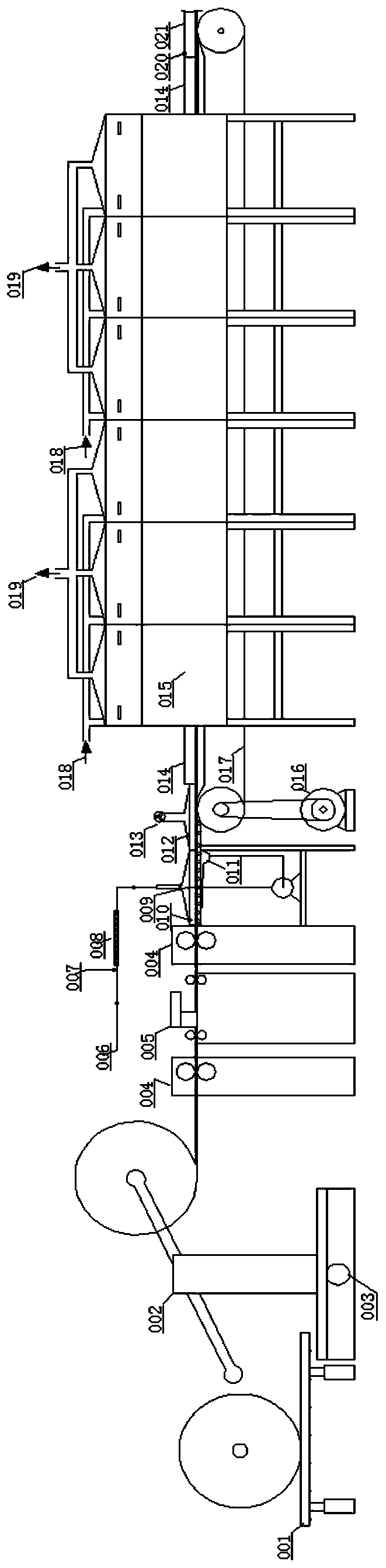

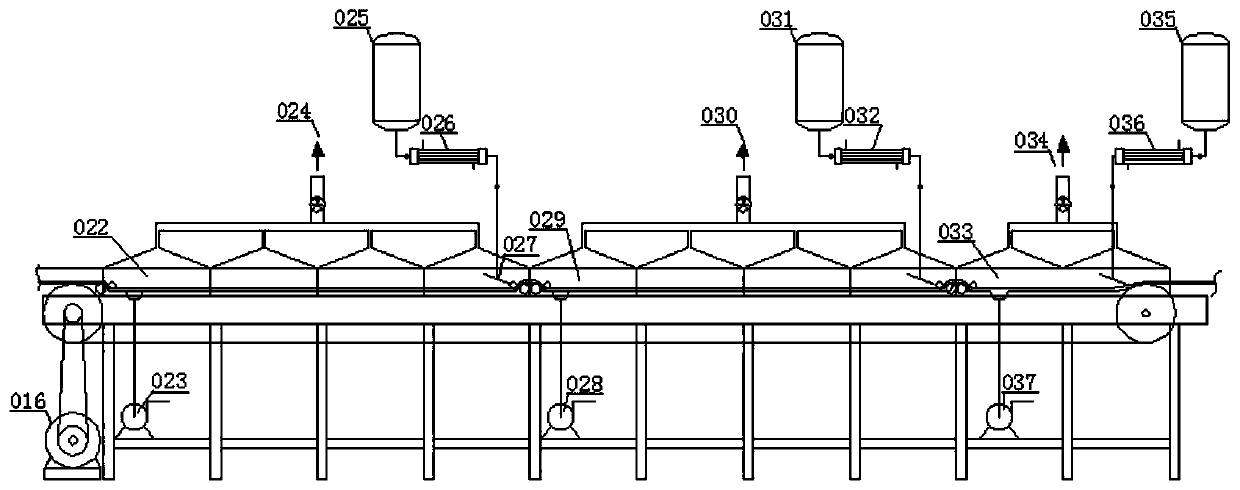

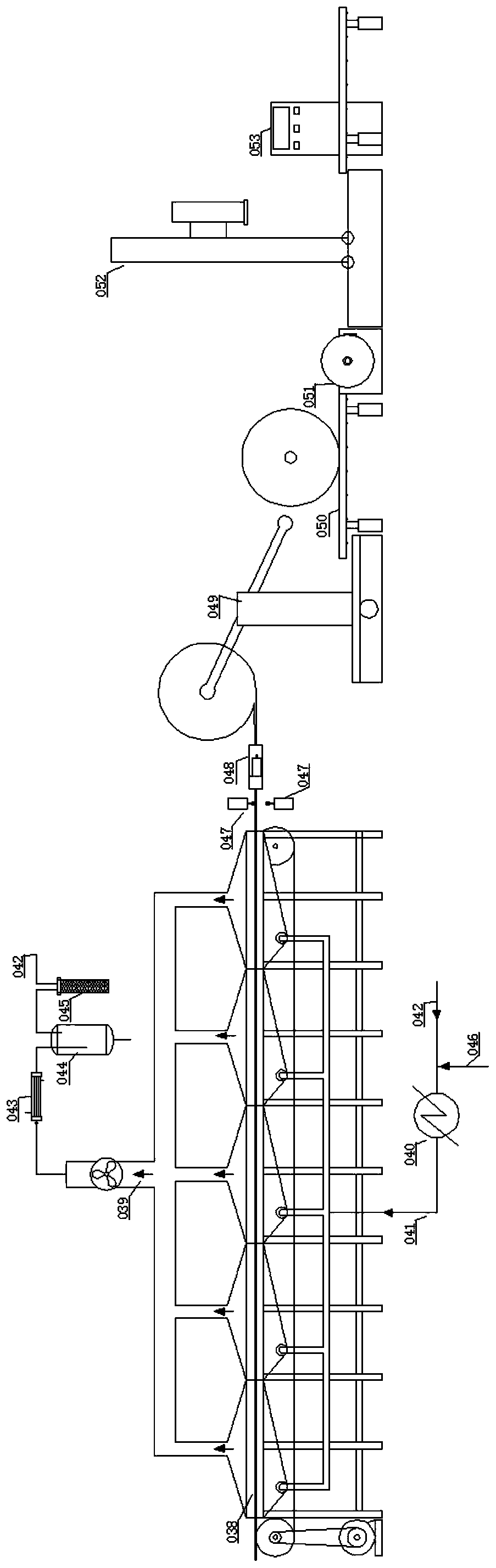

[0046] see figure 1 , figure 2 , image 3 and Figure 4 , the present invention provides a continuous production of airgel felt equipment, including a first lifting platform 001, a double-station unwinding device 002, a fiber felt feeding device 004, a metal detection device 005, a dipping device, microwave curing device, hydrophobic modification device, pore structure protection device, solvent cleaning device, drying device, winding device and packaging device;

[0047] The first lifting platform 001 is located at the front end of the whole set of equipment, and is used to lift the fiber mat to a certain height, so that the idle station of the double-station unwinding device 002 can tighten and clamp the fiber mat roll, and the double-station unwinding The bottom of the roll device 002 is equipped with a deviation correction motor 003, which is set next to the first lifting platform 001. There are two stations for alternately tightening and clamping fiber felt rolls, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com