Patents

Literature

40results about How to "Avoid quality fluctuations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

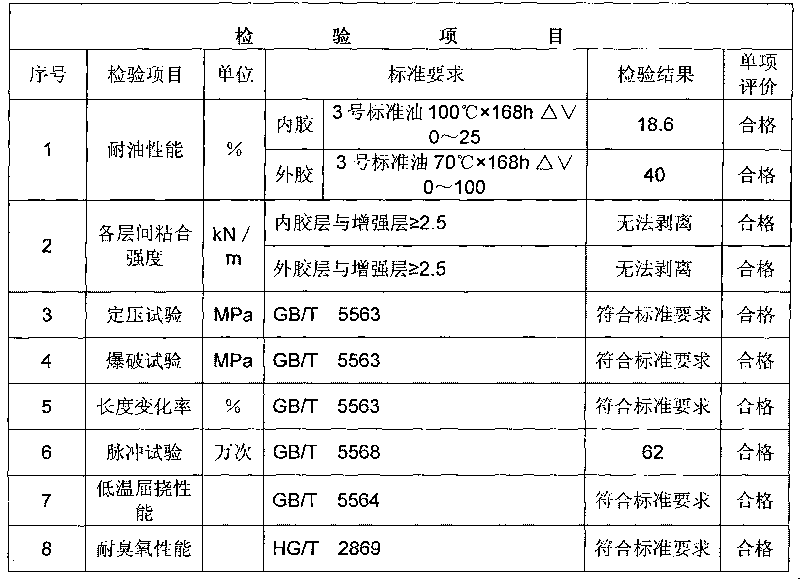

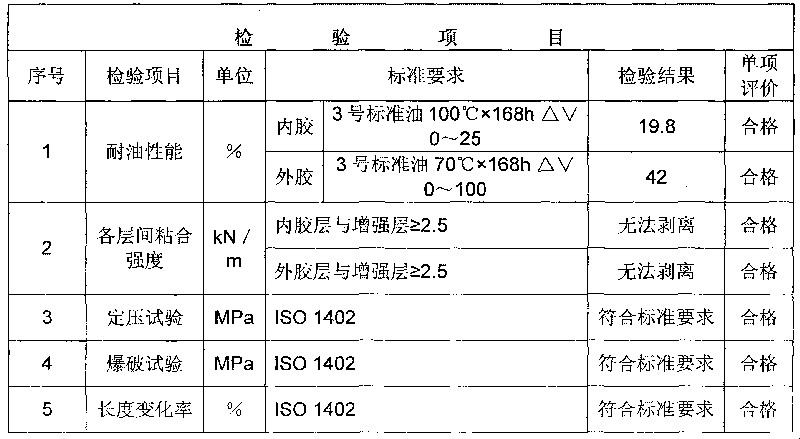

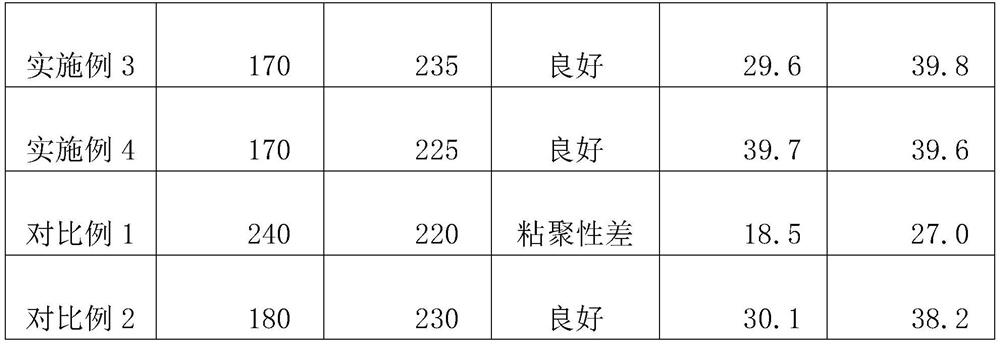

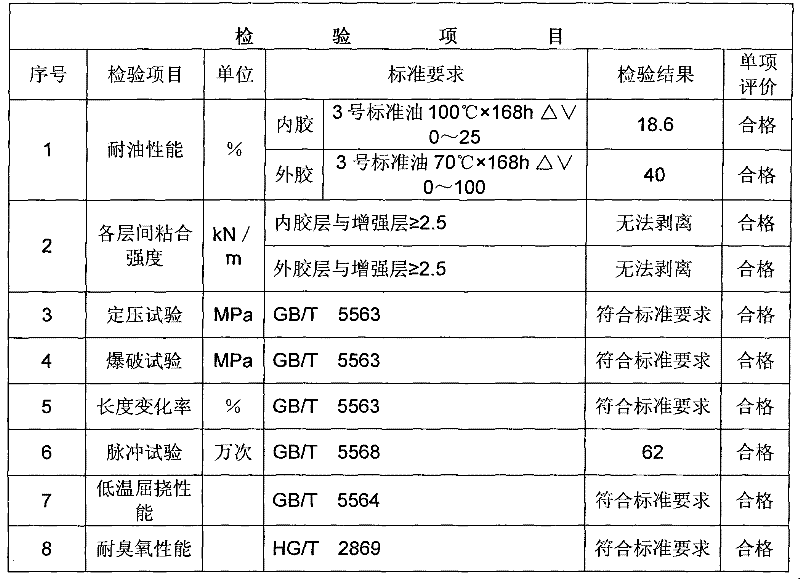

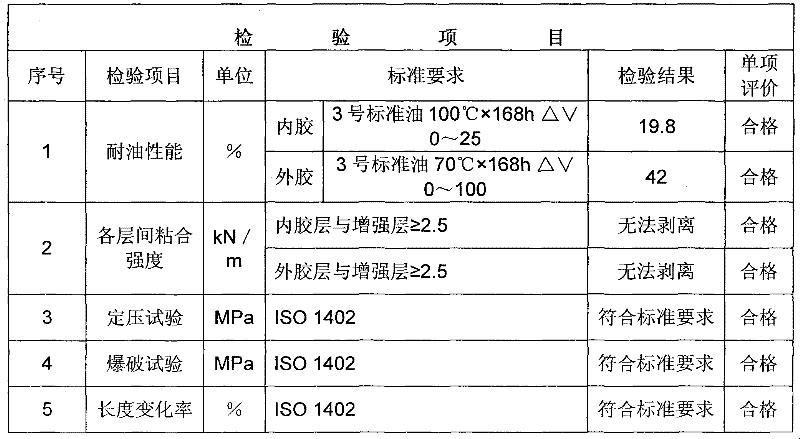

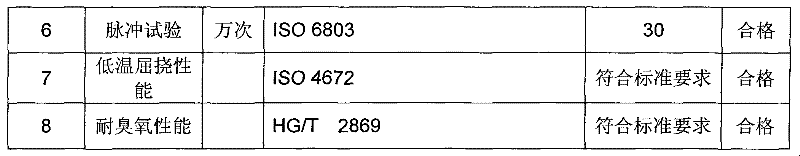

Lignin reinforcing filled butadiene-acrylonitrile rubber hose

The invention discloses a lignin reinforcing filled butadiene-acrylonitrile rubber hose which mainly comprises a lignin reinforcing filled butadiene-acrylonitrile rubber blended elastomer, sulfur, zinc oxide, stearic acid, a accelerant, an anti-aging agent and the like. The lignin reinforcing filled butadiene-acrylonitrile rubber hose has the advantages of high mechanical strength, favorable oil resistance, high adhesion strength with framework materials, such as steel wires and the like; and the finished product has the characteristics of light weight, high pulse resisting capacity and long service life, and can reduce the material cost and the environmental pollution.

Owner:张仲伦

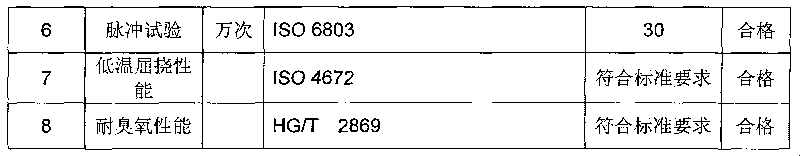

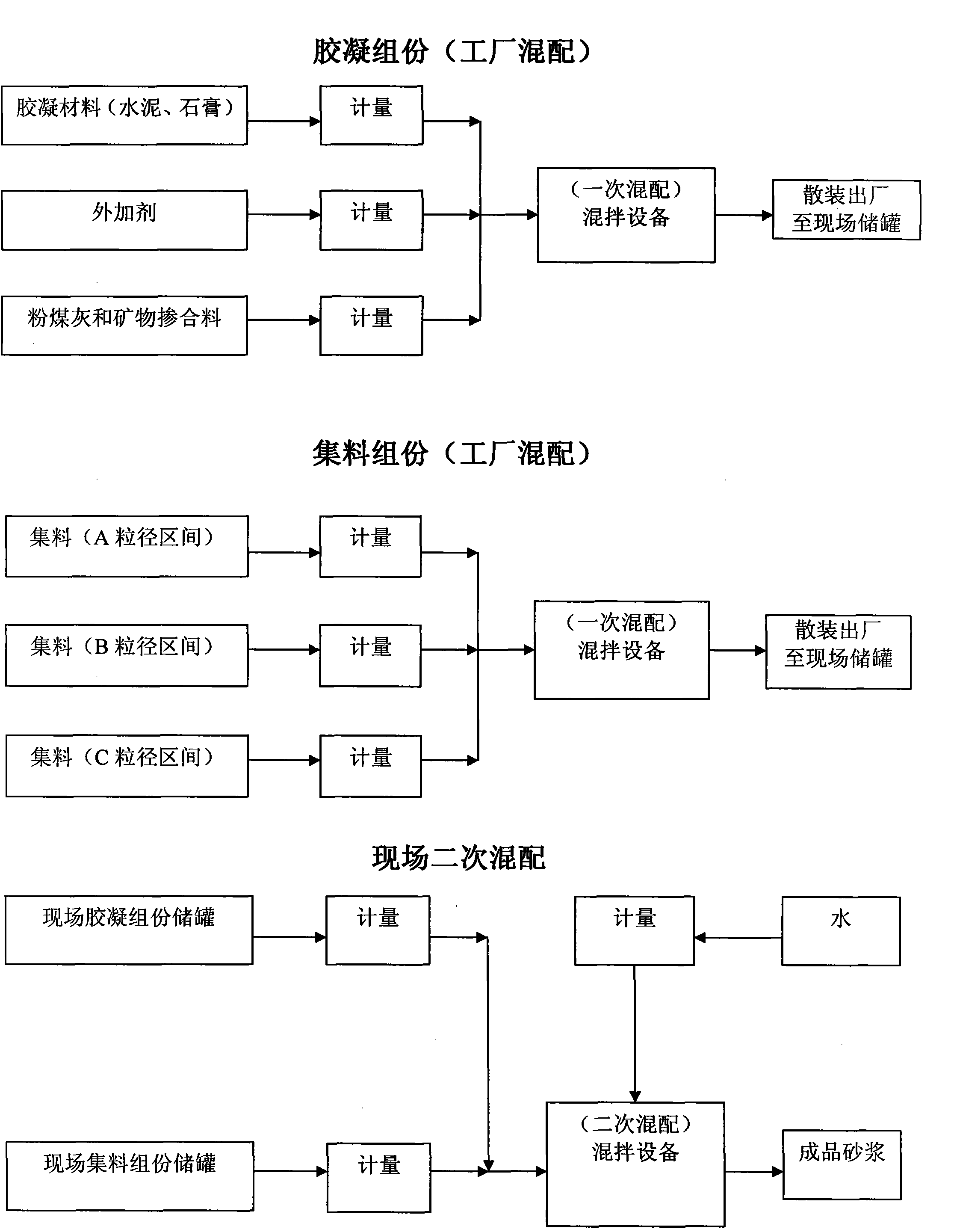

Method for preparing two-component pre-mixed mortar by mixing twice

InactiveCN102030504AGive full play to application advantagesAvoid quality fluctuationsSolid waste managementFly ashMaterials science

The invention provides a method for preparing two-component pre-mixed mortar by mixing twice, which comprises the following steps of: 1. weighing a cementing material, an additive, fly ash, silica ash and a mineral admixture in a certain proportion and mixing to obtain a cementing component; 2. Weighing weighing aggregates distributed by different grain sizes in a certain proportion and mixing to obtain an aggregate component; 3. Respectively respectively transporting the cementing component and the aggregate component in bulk or in bags to a construction site; performing secondary mixing in a sealed condition to mixing the cementing component and the aggregate component together to obtain the two-component pre-mixed mortar prepared by mixing twice, wherein the cementing material accounts for 15%-35%, the aggregate component accounts for 65%-85%, and water addition is determined by the type of the mortar. By the invention, quantity fluctuation of the mortar caused by the segregation and layering of the mortar in the processes of production, transportation, storage and use can be avoided, mismatching between consumption and transport loadage and between construction period and mortar coagulation time in the use process of the mortar can be solved thoroughly, and bulk utilization rate can be improved greatly.

Owner:张斌

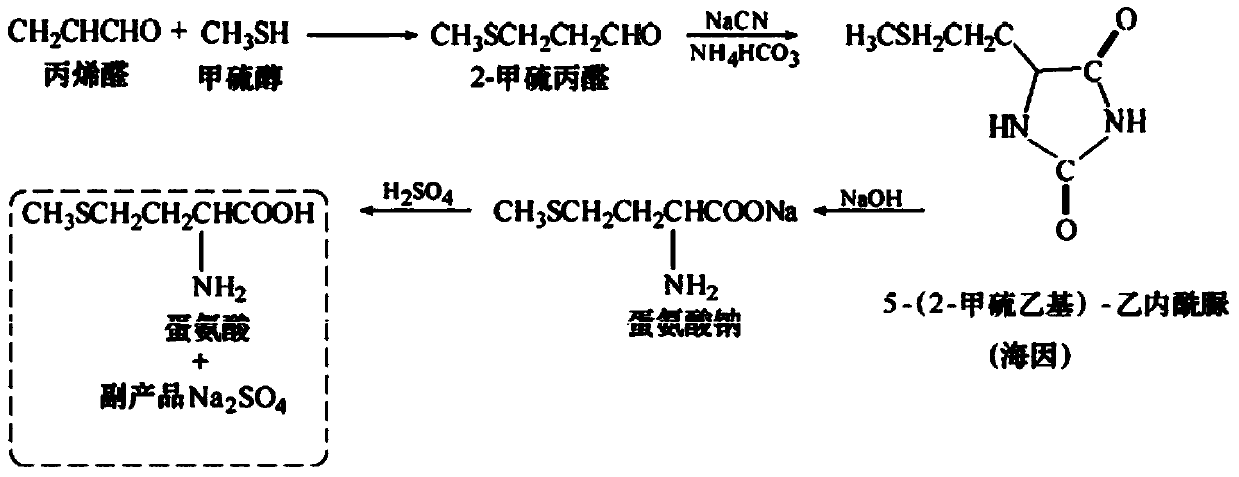

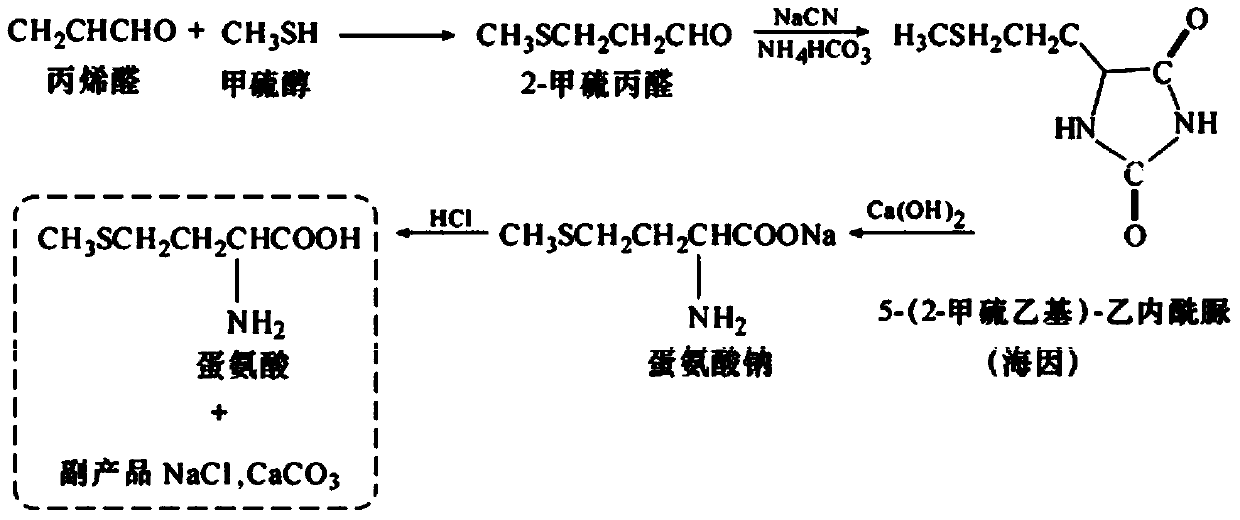

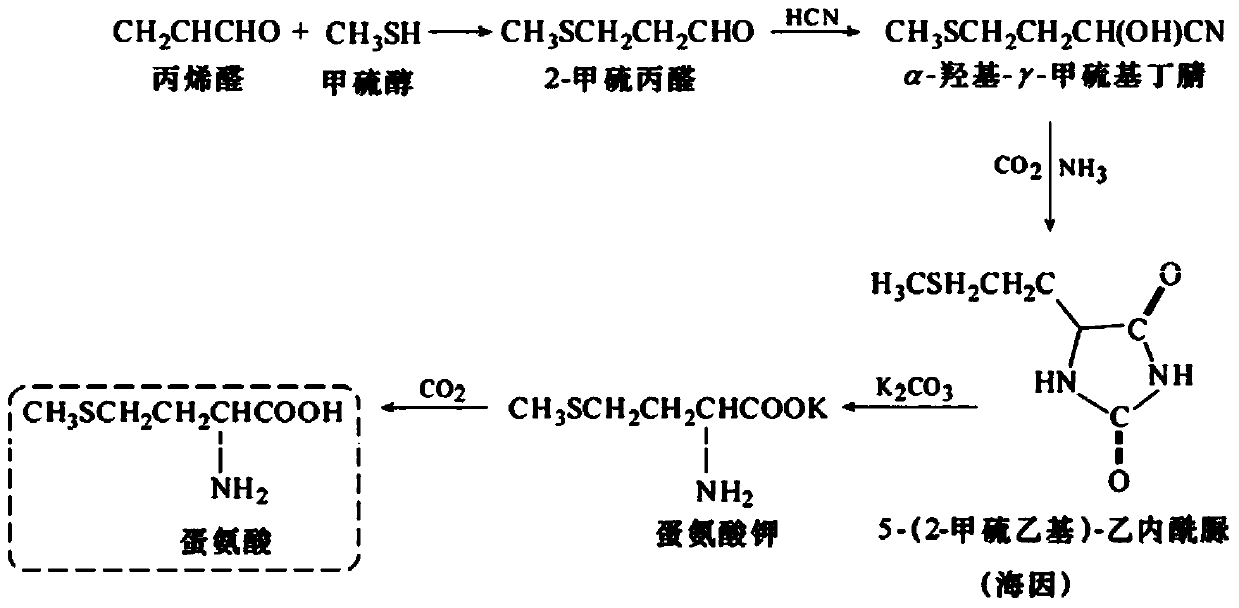

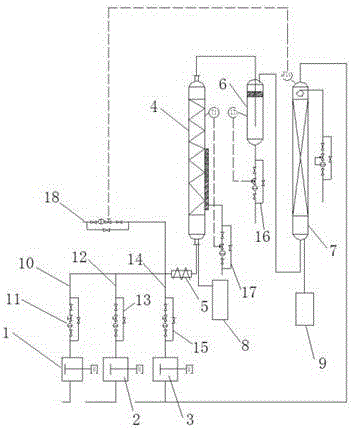

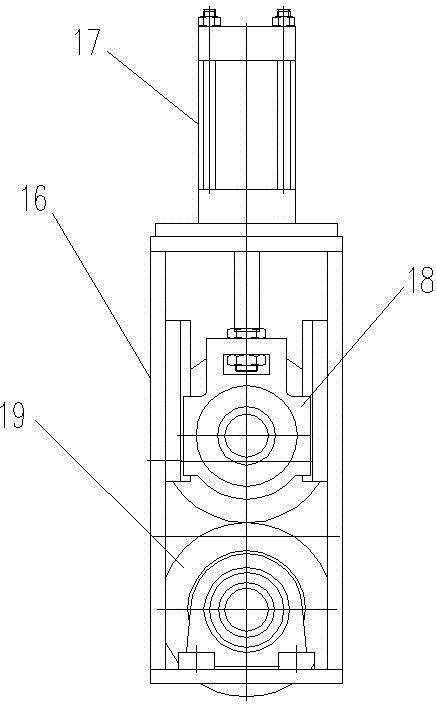

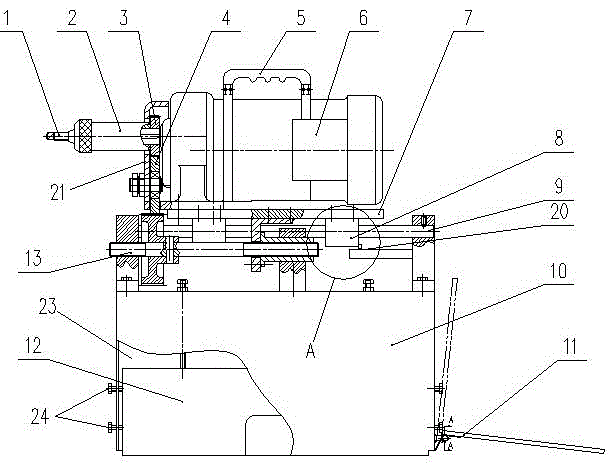

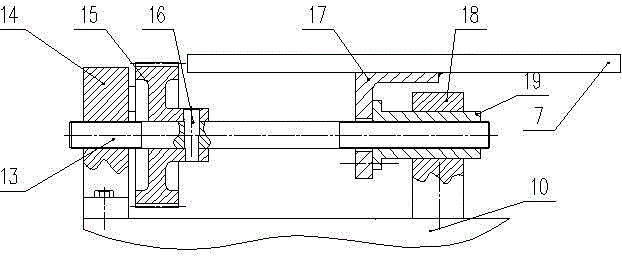

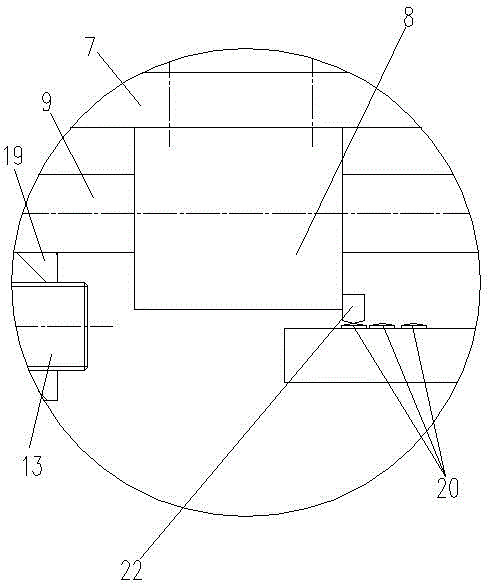

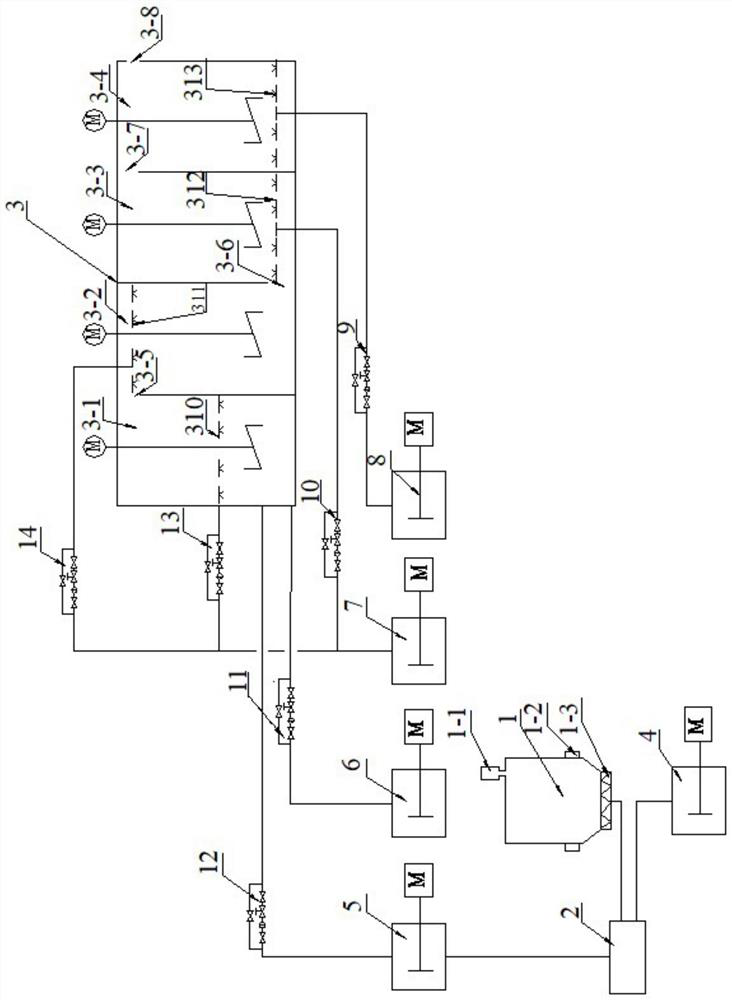

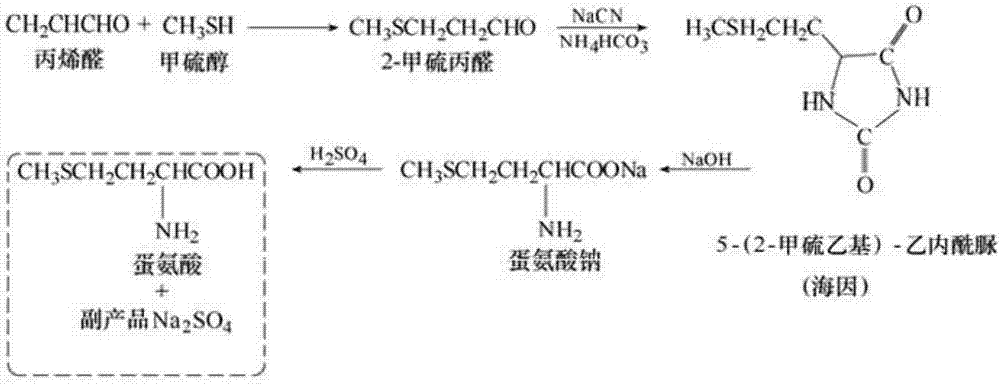

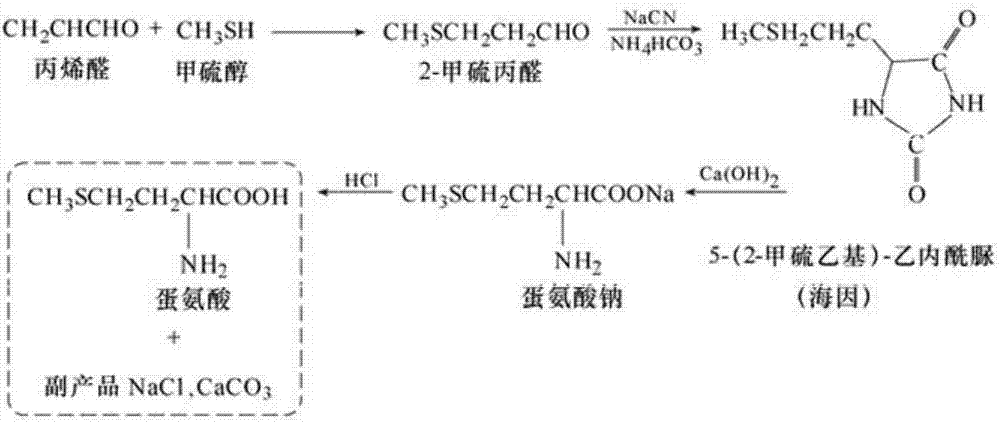

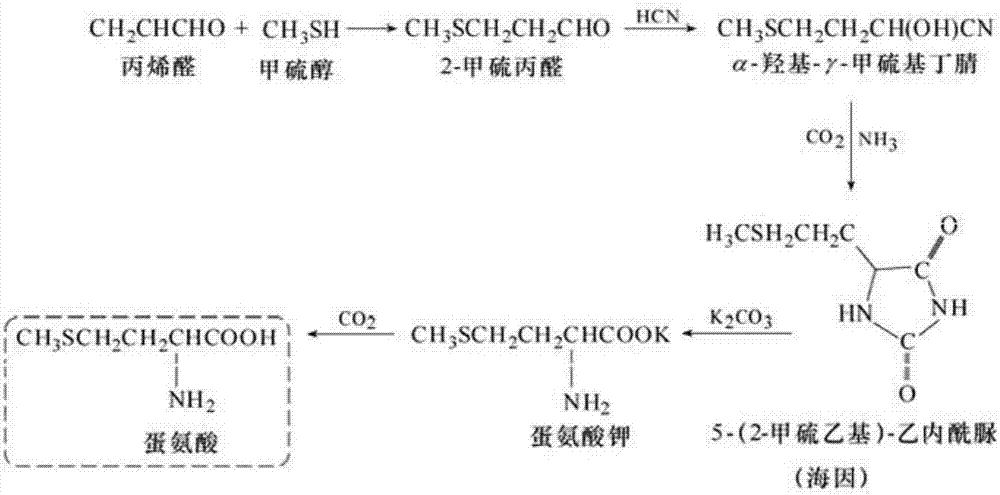

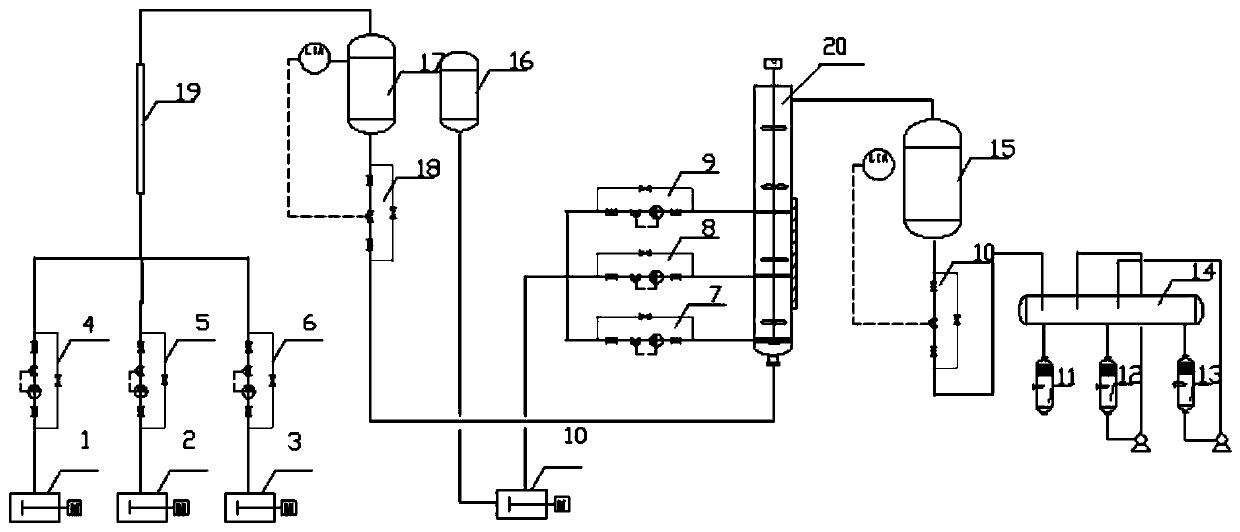

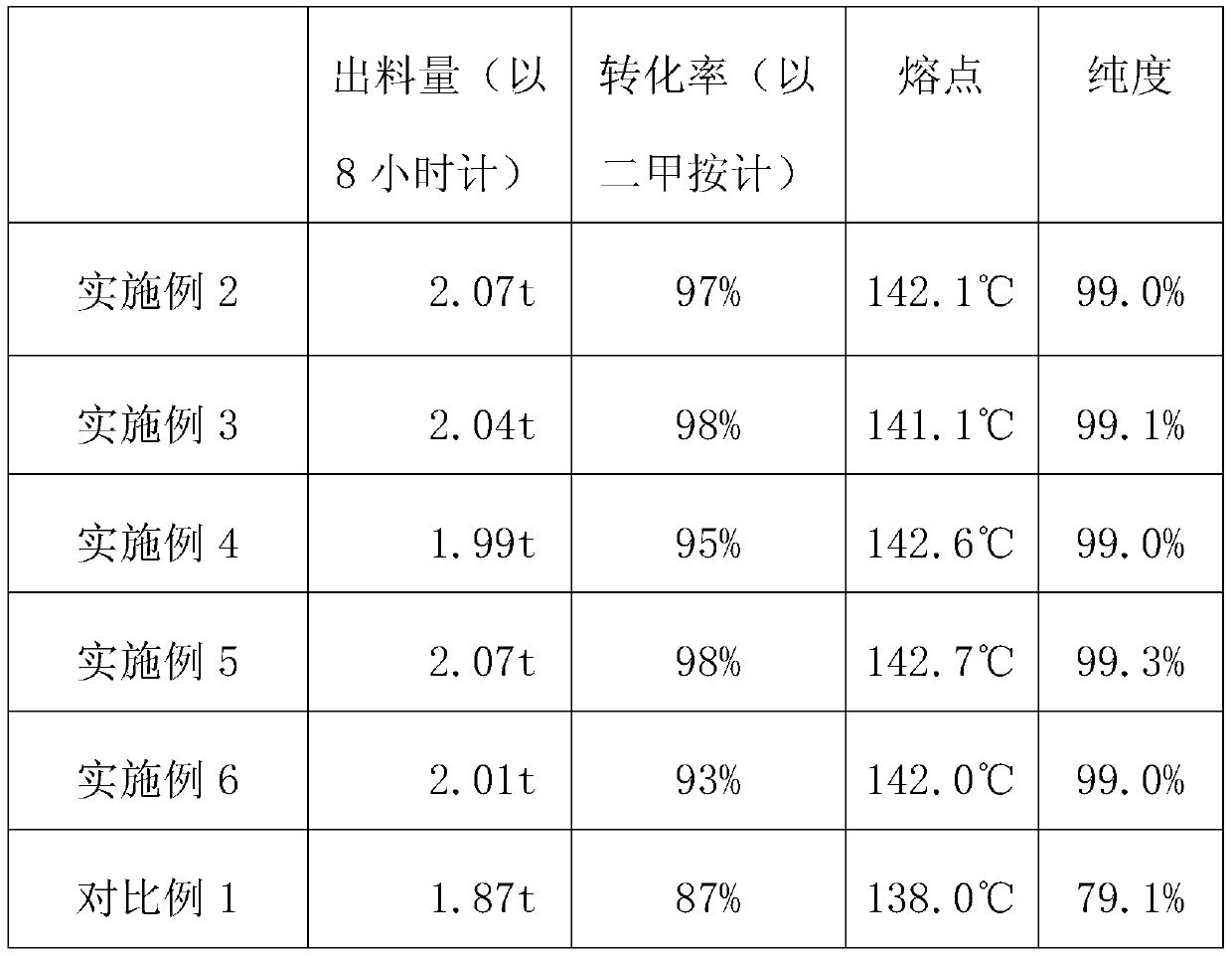

Method and special equipment for preparing methionine employing ion-exchange acidification methionine salt

InactiveCN103772246AImprove exchange efficiencyHigh yieldOrganic compound preparationSolid sorbent liquid separationMethionine biosynthesisIon exchange

The invention discloses a method for preparing methionine by adopting a weakly acidic cation exchange resin acidification methionine salt solution. The reaction temperature in acidification reaction is 30-90 DEG C, and the reaction pressure is 0.02-0.4MPa. The invention discloses equipment for preparing methionine from an acidification methionine salt. The equipment comprises a raw material buffer tank, a detergent buffer tank, a regenerant buffer tank, an adsorption column and a circulating pump, wherein the raw material buffer tank, the detergent buffer tank and the regenerant buffer tank are respectively communicated with the adsorption column through pipelines; a valve capable of independently controlling the communication relationship among the raw material buffer tank, the detergent buffer tank and the regenerant buffer tank is arranged on each pipeline; and a reactant outlet is formed on the adsorption column. Cationic resin in the method disclosed by the invention can be repeatedly utilized, high reaction efficiency can be achieved by controlling a reaction parameter, and the steps of adsorption column acidification, cleaning and cationic resin regeneration can be achieved just by controlling the switch in the overall working process of the equipment disclosed by the invention.

Owner:NINGXIA UNISPLENDOUR TIANHUA METHIONINE CO LTD

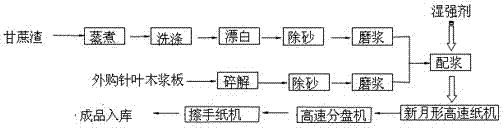

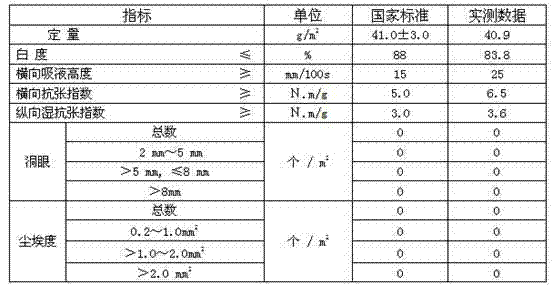

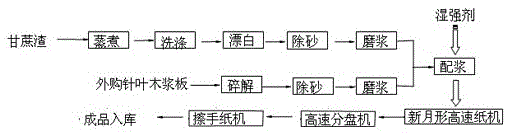

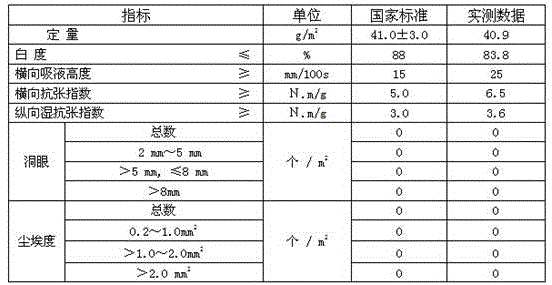

Method and equipment for producing paper hand towel from bagasse pulp

ActiveCN103757973AImprove uniformityGood dry and wet strengthPulp beating/refining methodsPaper-making machinesKraft processPapermaking

The invention relates to a method for papermaking, and particularly relates to a method and equipment for producing a paper hand towel form bagasse pulp as a main raw material. According to the method, firstly, 80%-90% of bagasse pulp and 10%-20% of softwood pulp are taken as raw materials, wherein the bagasse pulp is boiled by a sulfate process, washed and then bleached so as to obtain bleached bagasse pulp, and the softwood pulp adopts market pulp; secondly, an aquapulper, a high concentration grit separator and a double disc refiner are used; thirdly, a proper wet strength agent is adopted; fourthly, a crescent high speed toilet paper machine is adopted; fifthly, a low beating degree is adopted; sixthly, in the whole process from pulp preparation to paper rolling, automatic operation control with a DCS (distributed control system) is adopted, paper sheet quantification and moisture are monitored on line and regulated automatically by a QCS (quality control system); seventhly, a point-to-point embossing manner is adopted; eighthly, a high-speed rewinding and splitting machine is used. The produced paper hand towel has tensile strength and proper air permeability, and reaches high standards in strength, wet strength, water absorption, air permeability, flexibility and the like.

Owner:广西广业贵糖糖业集团有限公司

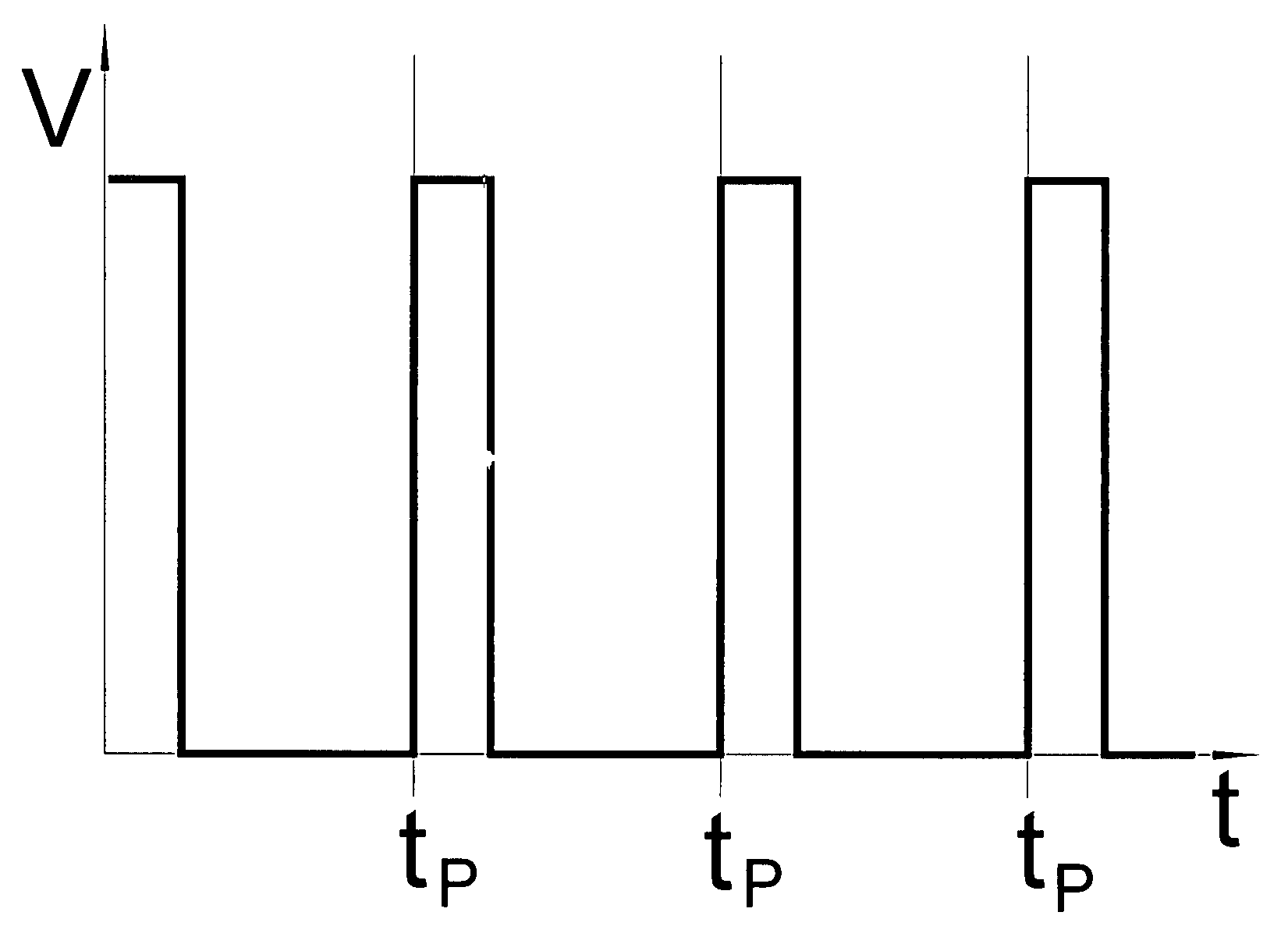

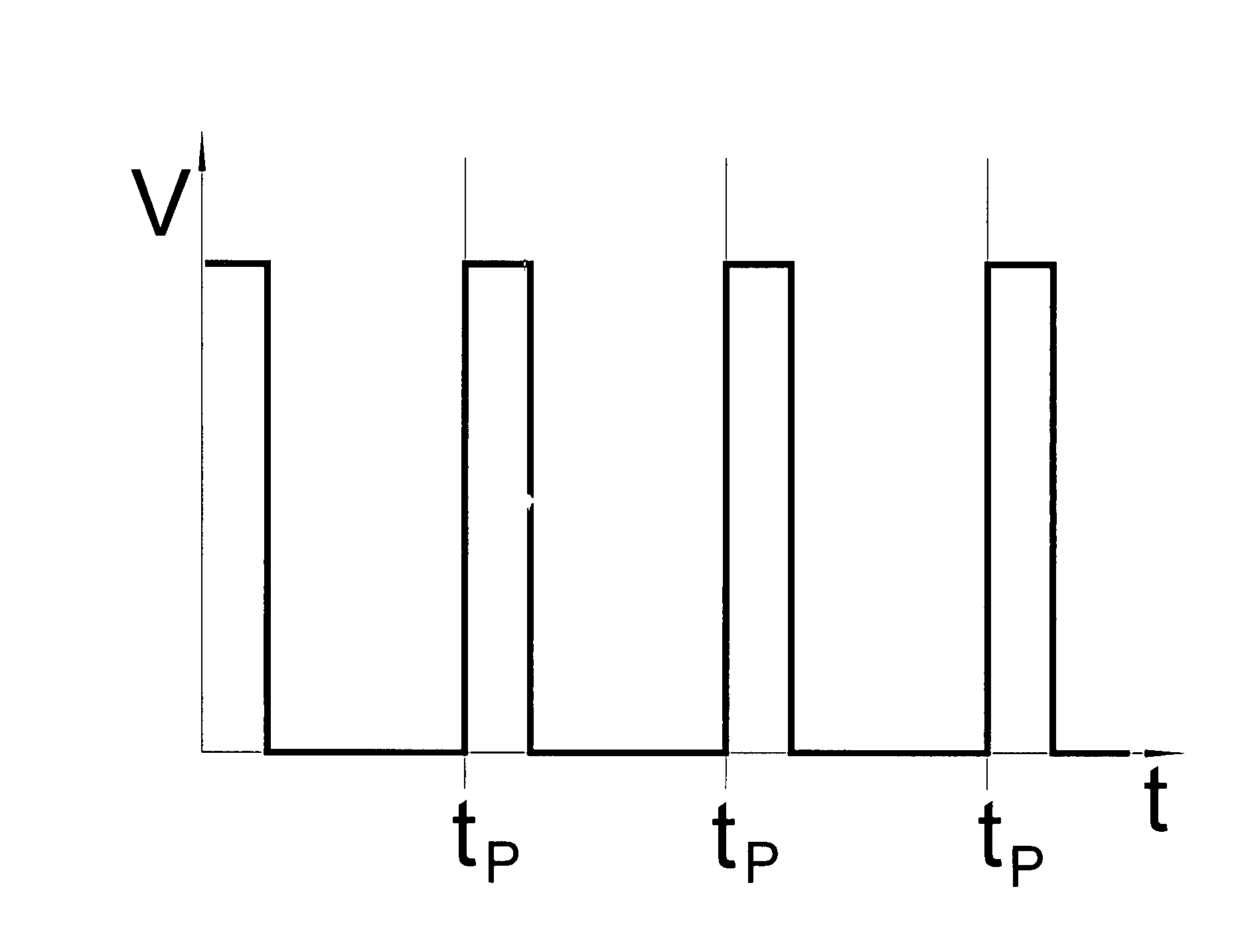

Method for thermal cutting

InactiveUS20080115862A1Quality improvementNeat cutArc welding apparatusPlasma welding apparatusEngineeringNozzle

The invention relates to a method for thermal cutting, wherein a cutting gas is piped into a cutting nozzle and guided on to a work piece to be processed by means of the cutting nozzle. According to the invention the cutting gas is at least reduced in a periodically repetitive manner wherein the time in which the cutting gas is guided onto the work piece in an undiminished manner is shorter than half of a period. In addition the invention relates to a corresponding device with a valve.

Owner:LINDE AG

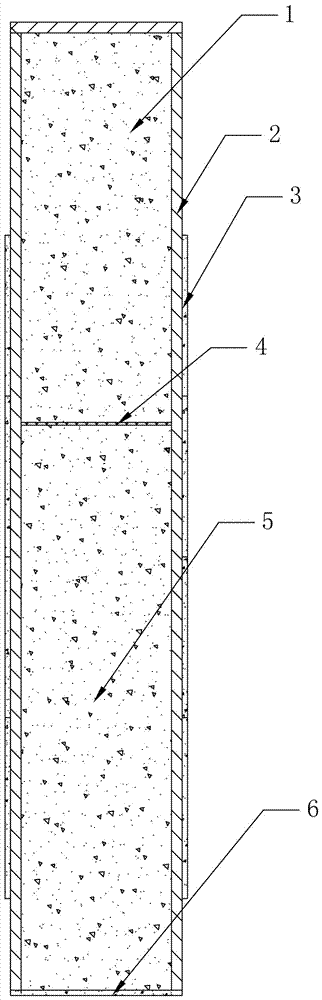

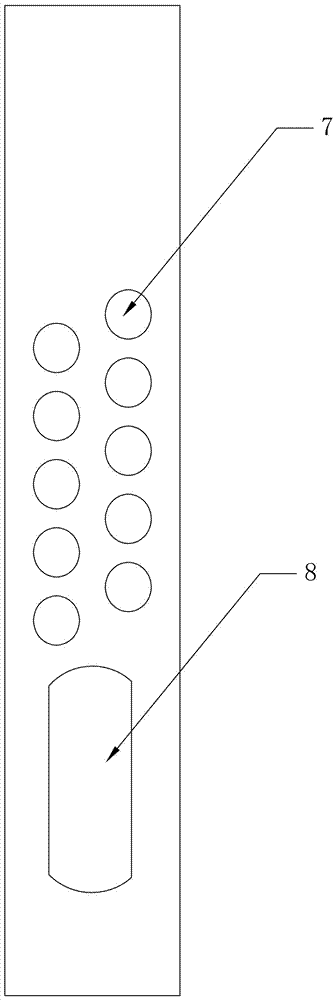

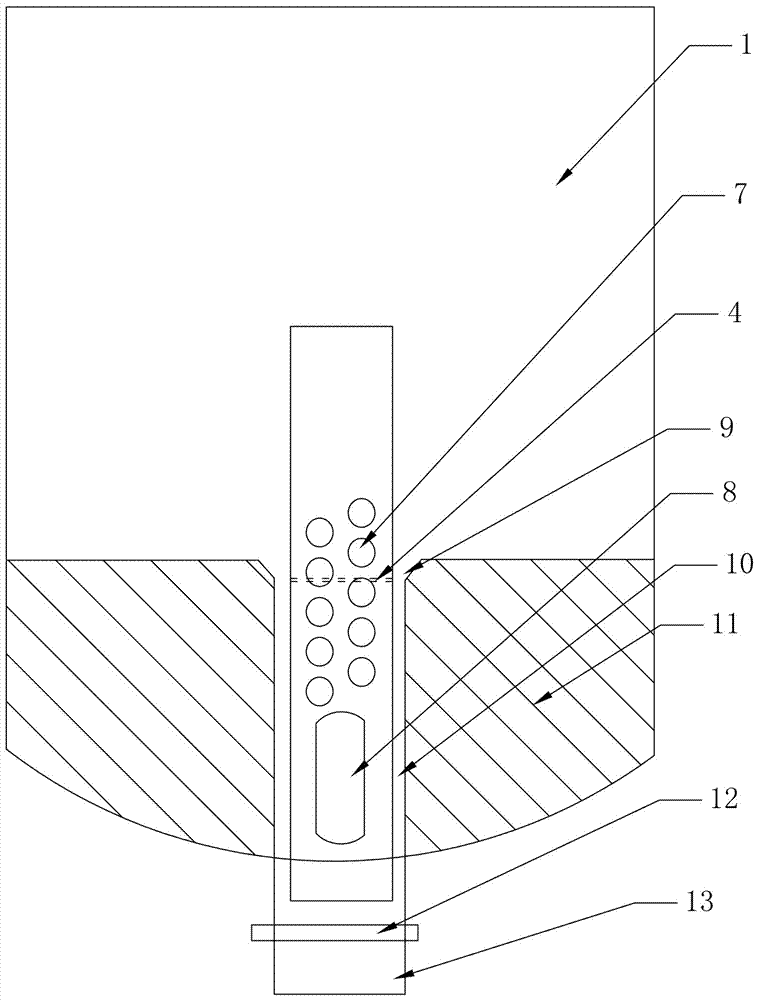

Refining ladle flow diverter and preparation method thereof

ActiveCN106881458ASimple and efficient operationStable qualityMelt-holding vesselsFlow diversionFlow diverter

The invention relates to a refining ladle flow diverter and a preparation method thereof. The flow diverter comprises a flow diverter main body. The flow diverter main body is a hollow cylindrical steel pipe with one end being sealed. Flow guiding holes and a flow guiding window are formed in the flow diverter main body. The refining ladle flow diverter is characterized in that the inner wall of the flow diverter main body is coated with a carbon layer; the flow guiding holes and the flow guiding window are sealed through flow diverter fusible slices; the opening end of the flow diverter main body is sealed through an opening end fusible slice; the positions, located at an water discharging opening and a seating brick part, in the flow diverter main body are filled with lower filling sand; the positions, located above the bottom of a seating brick bowl opening, in the flow diverter main body are filled with upper filling sand; and the upper filling sand and the lower filling sand are separated through an intermediate fusible slice. According to the flow diverter, operation of a using customer is simplified, the pouring rate is increased to 98% or above, and the using quality of a product is stable. Compared with traditional flow diversion sand, the problem of the quality fluctuation of the product is avoided, and market use is met.

Owner:张国令

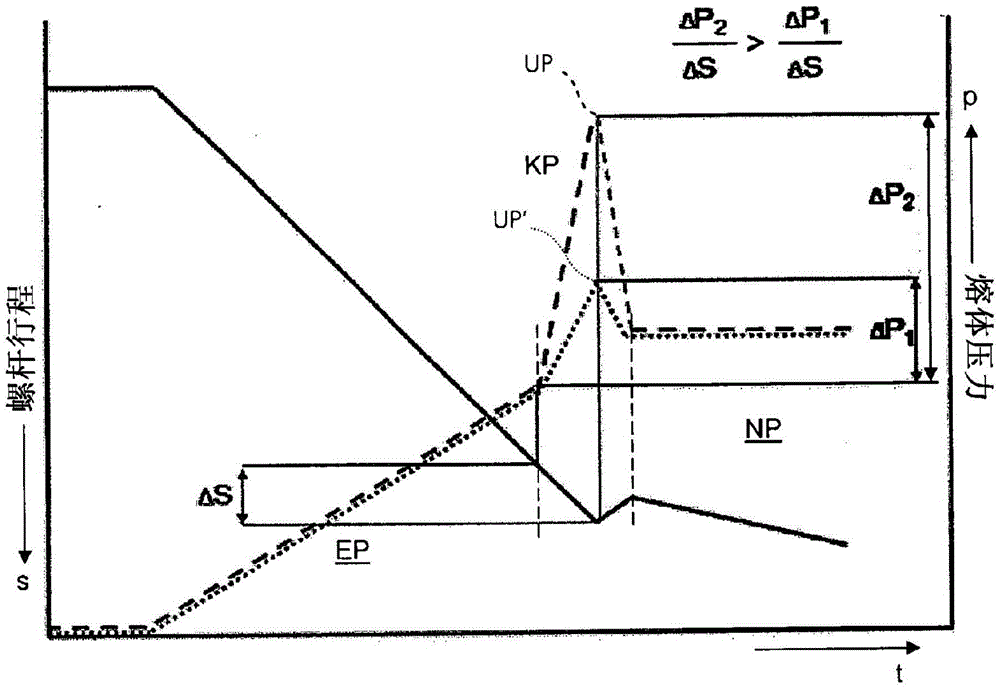

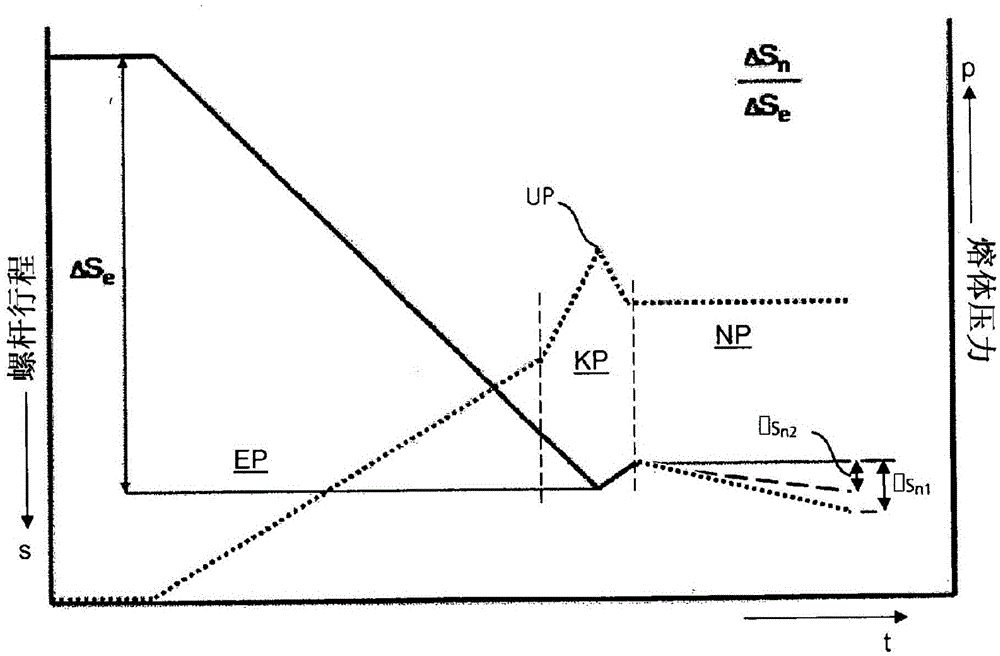

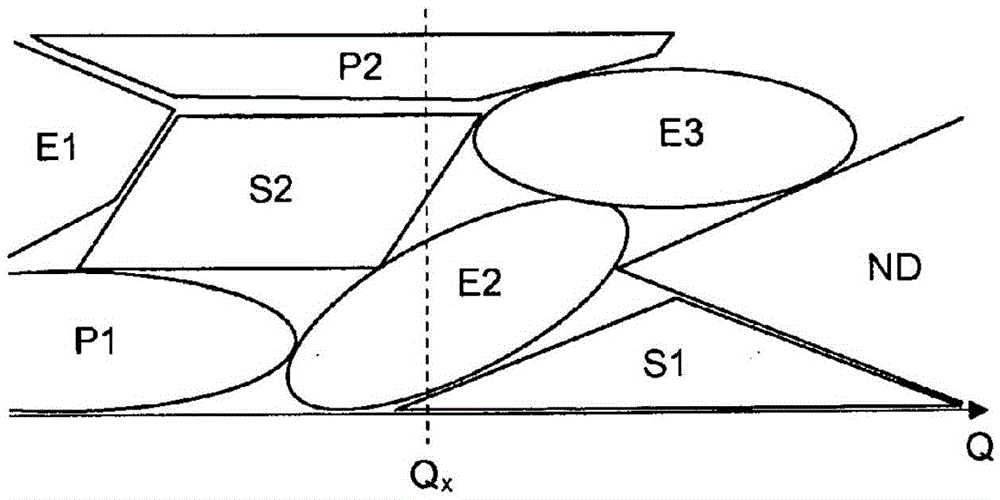

Method for evaluating process characteristics of injection-molding tools

ActiveCN105636757AQuality improvementAvoid quality fluctuationsPressure riseInjection molding machine

Owner:KRAUSSMAFFEI TECH GMBH

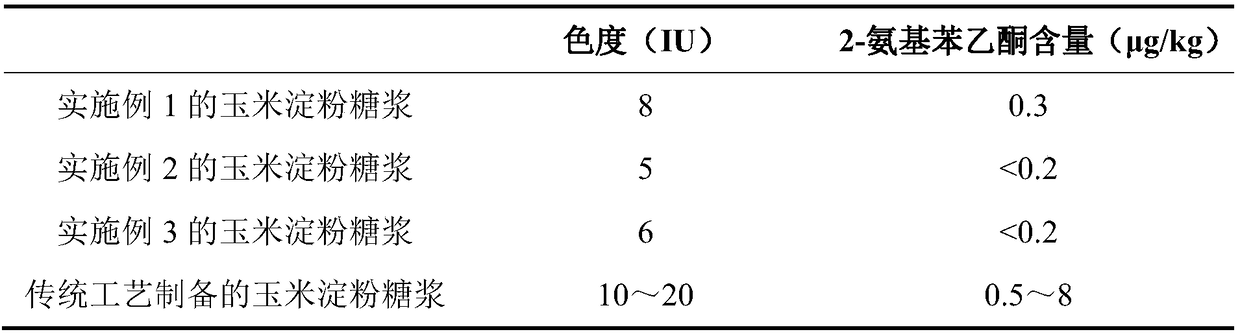

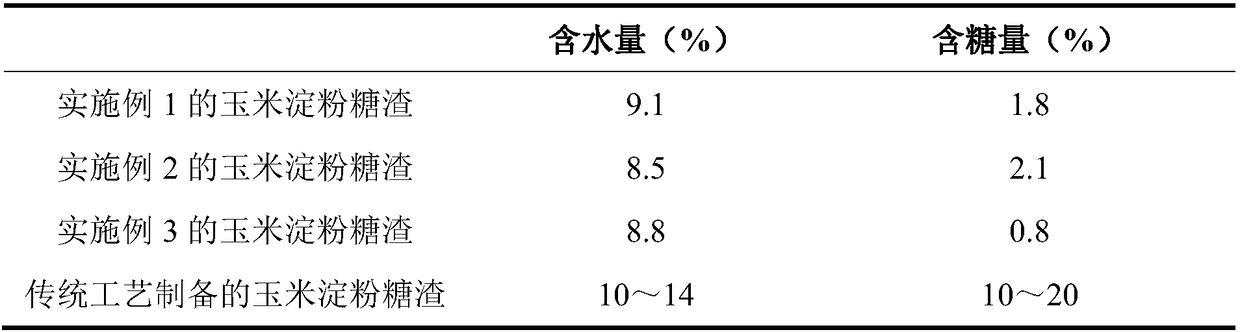

Corn starch sugar production method

ActiveCN108085349AImprove yield and qualityReduce residual sugar contentFermentationWater contentCorn starch

The invention discloses a corn starch sugar production method which includes the steps: 1) liquidation; 2) primary centrifugal separation, sugar residue discharge, saccharification, refining and starch syrup preparation by concentrated clear liquid; 3) sugar residue washing; 4) secondary centrifugation; 5) deep sugar elimination; 6) sugar residue post-treatment. The yield and the quality of a starch sugar product can be improved, high-purity corn starch syrup is obtained, high-quality sugar residues can be obtained, the sugar residues are low in residual sugar content, low in water content andgood in quality stability, and waste of the sugar residues is turned into wealth.

Owner:双桥(厦门)有限公司

Device and production method for continuously producing rubber vulcanization accelerator diphenylguanidine

ActiveCN106810469APrevent volatilizationAchieve instant mixingOrganic chemistryOrganic compound preparationVulcanizationOxygen

The invention belongs to the technical field of production of a rubber vulcanization accelerator diphenylguanidine and particularly relates to a device and a production method for continuously producing rubber vulcanization accelerator diphenylguanidine. The device for continuously producing the rubber vulcanization accelerator diphenylguanidine comprises a diphenylthiourea and ammonium hydroxide mixed solution metering pump, a catalyst peristalsis metering pump, a pipeline type reactor, a preheater, an oxygen compressor, a gas-liquid separator, a gas-liquid washing tower, a continuous filtering device and an ammonium hydroxide receiver. According to the process, sealed continuous equipment is adopted for producing the rubber vulcanization accelerator diphenylguanidine, so that volatilization of materials in the process is avoided, and the environment is protected while the materials are saved; instant mixing of the materials is realized, the problem that by products are easily generated in a traditional still reaction due to excess ratio of local materials is solved, and the production efficiency is greatly improved; what is more important, after continuous production is adopted, due to small size of equipment, materials in a reaction system of a production site in the same time unit are greatly reduced, and safety risk is greatly reduced.

Owner:SHANDONG SUNSINE CHEM

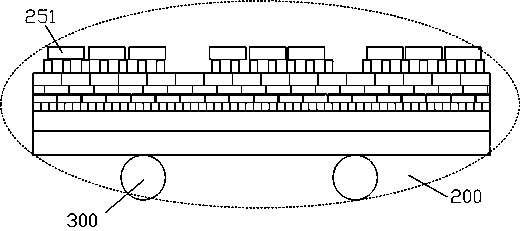

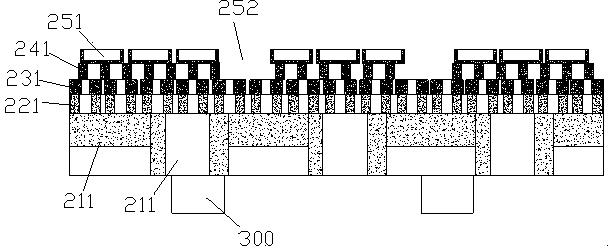

Kiln capable of enhancing sintering quality of coloring material

The invention discloses a kiln which can enhance the sintering quality of a coloring material. The kiln comprises a kiln body and a kiln vehicle, wherein the kiln vehicle sequentially comprises a steel-plate layer, a refractory-brick layer, a perforated-brick layer, a flame-path backing-brick layer and a round sagger layer from bottom to top, wherein a plurality of flues which penetrate through the steel-plate layer are arranged in the steel-plate layer; ventilation holes which penetrate through a whole brick body are formed in a perforated brick; a plurality of round saggers are arranged in the round sagger layer, and a gap is arranged between the adjacent round saggers; a plurality of sagger flame paths are also uniformly arranged in the round sagger layer; the refractory-brick layer and the perforated-brick layer as well as the perforated-brick layer and the flame-path backing-brick layer are arranged in a staggered mode; gaps are arranged among brick bodies in the same brick-body layer. The coloring material is heated and sintered by utilizing the kiln, so that the temperature difference of all parts of the whole kiln is decreased to 5 DEG C from original 50 DEG C, the production quality is guaranteed, and the temperature increase is uniformly quickened; compared with the original sintering time, the whole sintering time of the coloring material is shortened by 10 to 20 percent; the energy-source consumption of the coloring material in the whole sintering process is reduced by 20 to 35 percent.

Owner:GUANGDONG SANSHUI TANDH GLAZE CO LTD

Method for producing heavy-denier mucilage glue flat yarn

ActiveCN103603066ASpeed up the molding processHigh strengthFilament manufactureArtificial filament washing/dryingYarnCandle

The invention relates to a method for producing heavy-denier mucilage glue flat yarn. The method includes the steps that mucilage glue is pumped into a candle type filter through a metering pump to be filtered, the filtered mucilage glue enters a yarn spraying nozzle through a goose neck to be sprayed into yarn, sprayed yarn enters a primary coagulating bath groove to undergo primary solidification forming, then, the yarn is guided to a secondary solidification forming groove through a yarn guiding mechanism to undergo secondary solidification forming, the yarn enters a washing groove to undergo primary washing after the secondary solidification forming is conducted, the yarn is laid on a conveying net of a united refiner in parallel to undergo regeneration, washing, desulfuration, blanching, pH value adjustment, oiling and drying after the primary washing is conducted, finally, the yarn is formed to be in a cylinder shape or a strand shape, and carbon disulfide is recycled in the primary solidification forming process and the secondary solidification forming process of the yarn. The carbon disulfide is recycled, the strength and the elongation of the heavy-denier mucilage glue flat yarn produced through the process completely meet the requirements, and the method is quite beneficial for development of downstream markets.

Owner:YIBIN GRACE +2

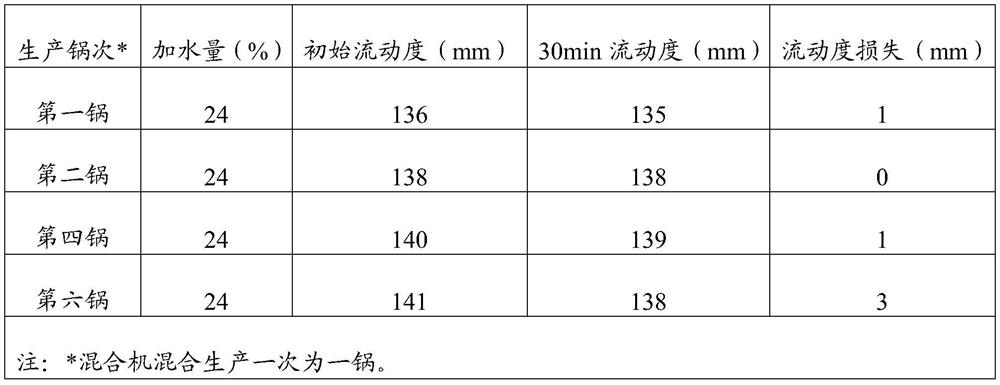

Synergistic binder-reducing concrete admixture and preparation method thereof

PendingCN113173733AImprove strength and work performanceAvoid quality fluctuationsDefoaming AgentsAcid water

The invention relates to the technical field of binder-reducing concrete admixtures, and discloses a synergistic binder-reducing concrete admixture and a preparation method thereof. The synergistic binder-reducing concrete admixture comprises a polycarboxylic acid water reducer, a polycarboxylic acid slump retaining agent, a binder reducing agent, an air entraining agent, a defoaming agent, a water-retaining agent, a retarder, a pH regulator and water. The invention further provides the preparation method of the synergistic binder-reducing concrete admixture. The synergistic binder-reducing concrete has the double effects of reducing a binder and reducing water, and can play a role in dispersing a binding material in concrete to the greatest extent, so the binding material which only plays a filling role originally is fully hydrated, and the strength and the working performance of the concrete are improved; the problem that an admixture storage tank and a binder reducing agent storage tank need to be prepared at the same time in a mixing plant is solved, the problem that the quality of the mixing plant fluctuates due to inaccurate weighing of the binder reducing agent is solved, the mixing plant can well adapt to changes of various materials, and concrete quality fluctuation caused by the changes is avoided.

Owner:武汉中彭化学科技有限公司

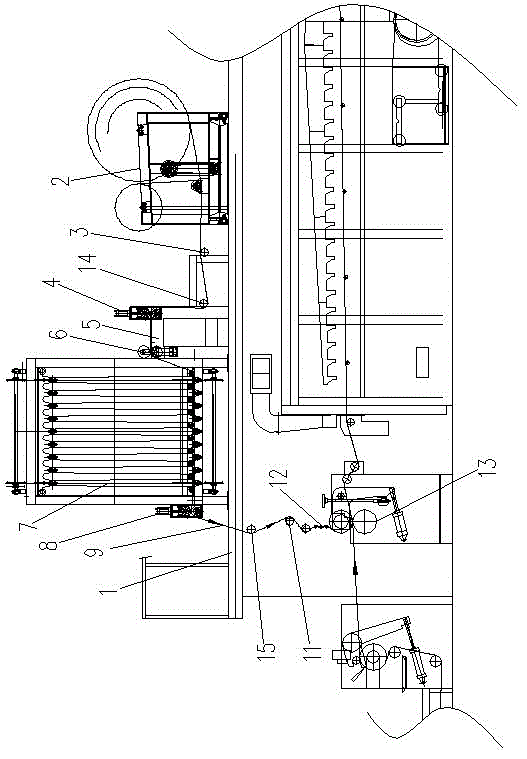

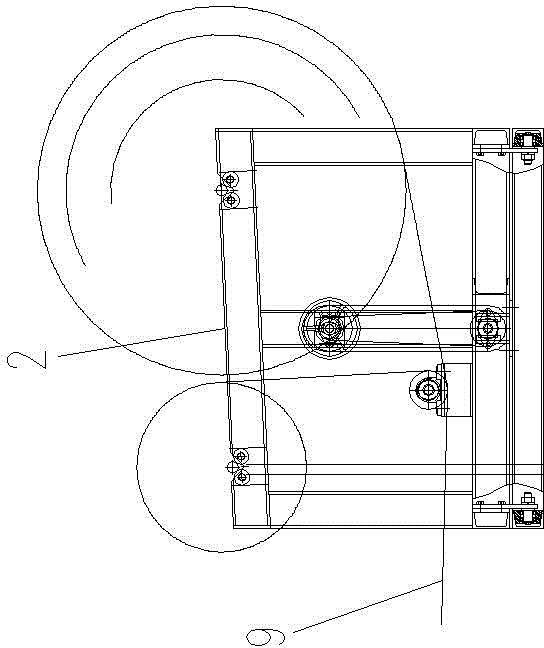

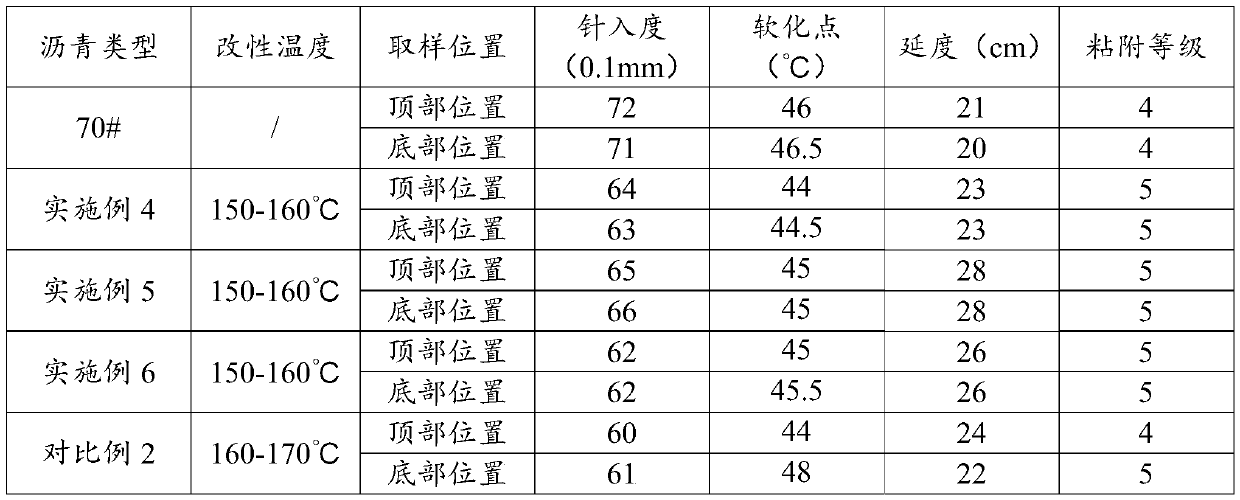

Automatic fabric placing and laminating device of artificial leather and PVC (polyvinyl chloride) floor

ActiveCN102632021BSimple structureAchieve fitLiquid surface applicatorsCoatingsPolyvinyl chlorideEconomic benefits

The invention discloses an automatic fabric placing and laminating device of artificial leather and a PVC (polyvinyl chloride) floor. The automatic fabric placing and laminating device comprises an operation platform, wherein the operation platform is sequentially provided with a dual-station unwinding mechanism, a fabric supporting roller, a first traction device, a fabric receiving platform, a pressing device and a fabric storage device along the movement direction of a base fabric; a second traction device is arranged on the fabric outlet side of the fabric storage device; a driving spiral fabric unfolding device, a triple-finger edge spreader and a laminating mechanism are orderly arranged under the operation platform along the movement direction of the base fabric, and the base fabric is sent out by the second traction device, and enters the laminating mechanism after being unfolded by the driving spiral fabric unfolding device and sent out by the triple-finger edge spreader. By adopting the automatic placing and laminating device disclosed by the invention, automatic fabric placing and laminating can be achieved, the automatic degree of production is improved, the labour cost is saved, and the economic benefit is particularly prominent in the environment of labour tension and rising labour cost at present. According to the automatic fabric placing and laminating device, quality fluctuation caused by manual operation in the past also can be avoided, and the product quality can be stabilized and improved.

Owner:XINXIANG DINGXIN MACHINERY

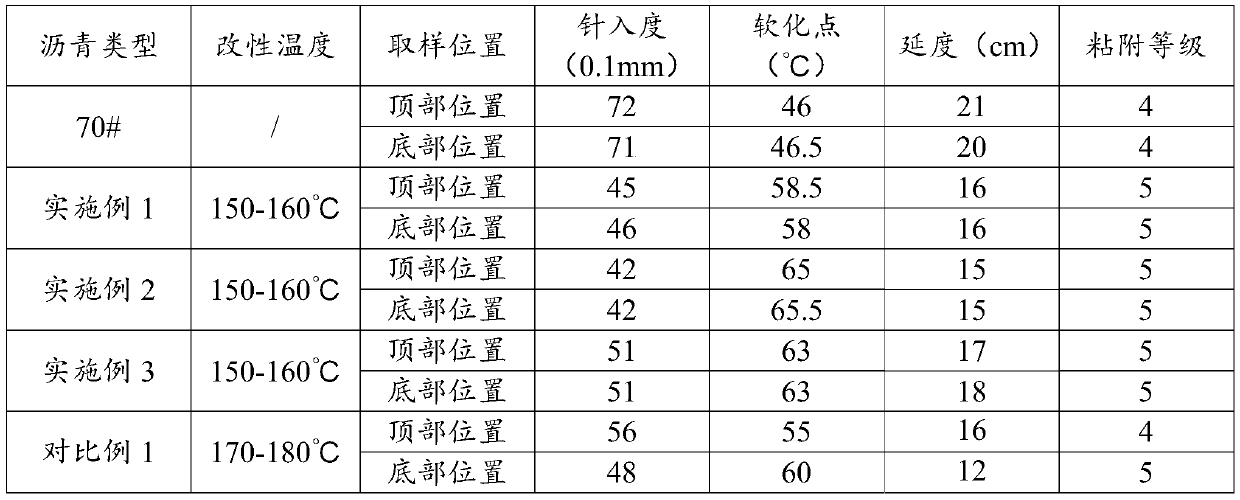

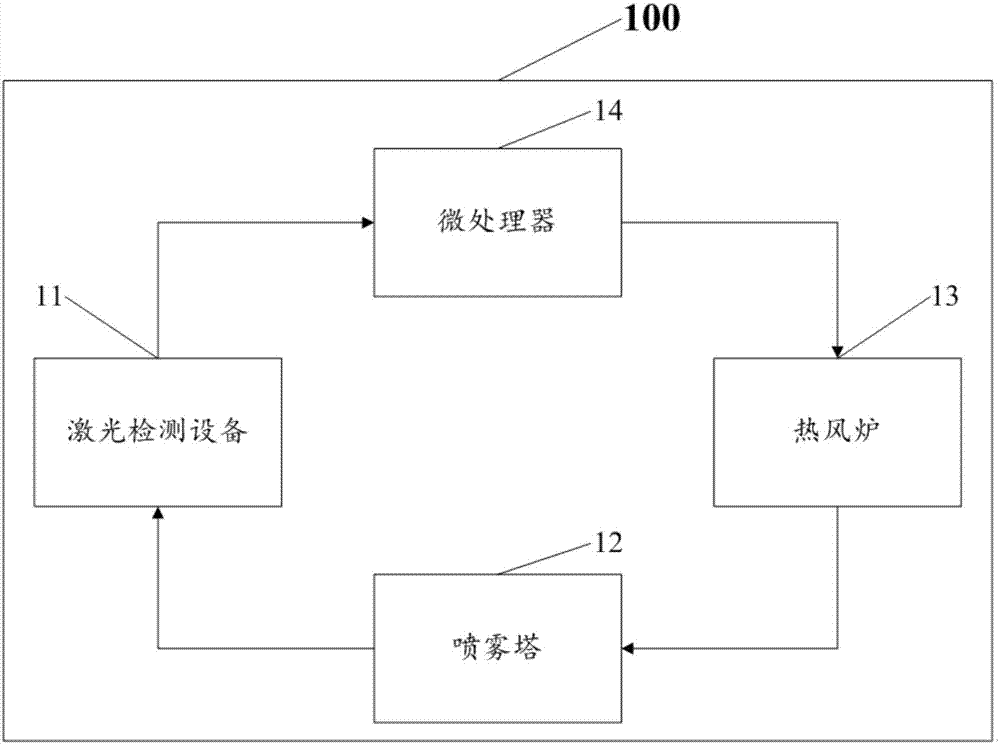

Preparation method for environment-friendly asphalt modifier

ActiveCN110041718AAvoid quality fluctuationsImproves rutting resistanceBuilding insulationsBuilding materialPitch blende

The invention relates to the technical field of building materials for road engineering and especially relates to a preparation method for an environment-friendly asphalt modifier. The preparation method for the environment-friendly asphalt modifier comprises the following steps: filling an asphalt modifier into a hot-melt packaging film and then sealing the package. The environment-friendly asphalt modifier prepared according to the preparation method is capable of solving the problems of environmental pollution, influence on construction efficiency and low environmental adaptability of modified asphalt of the present solid asphalt powder. The environment-friendly asphalt modifier is simply manufactured, is low in cost and has excellent modification effect, high adaptability and obvious environmental protection property.

Owner:山东高速路用新材料技术有限公司

Method for controlling hot rolling aluminum plate quality

InactiveCN103639208AImprove the lubrication effectReduce thicknessRolling equipment maintainenceWork treatment devicesGranularityLayer thickness

The invention relates to a method for controlling hot rolling aluminum plate quality, particularly to a method for controlling black silk and black line on the surface of the hot rolling aluminum plate. The method comprises a lubricating system which is characterized in 1) lubricating liquid: adopting a non-ionic lubricating liquid; 2) consistence: controlling the consistence of the lubricating liquid to be 2.5% to 4.0%; 3) pH value: controlling the pH value of the lubricating liquid to be 5.5 to 7.5; 4) temperature: controlling the temperature of the lubricating liquid to be 40 DEG C to 65 DEG C; 5) granularity: controlling the milk granule of the lubricating liquid to be 0.9 to 0.1 Mum; 6) lubricating grease content: controlling the lubricating grease content of the lubricating liquid to be 25% to 30 %. According to the invention, the lubricating liquid of a rolling mill is replaced from an anionic type into the non-ionic lubricating liquid, and through the control of the consistence, the pH value, the temperature, the granularity and the lubricating grease content of the lubricating liquid in an appropriate range, the lubricating property of the lubricating system can be effectively improved, the aluminum bonding layer thickness of a working roll is greatly reduced, and the quality problems of the black silk and the black line on the surface of the hot rolling product are solved.

Owner:邹平齐星工业铝材有限公司

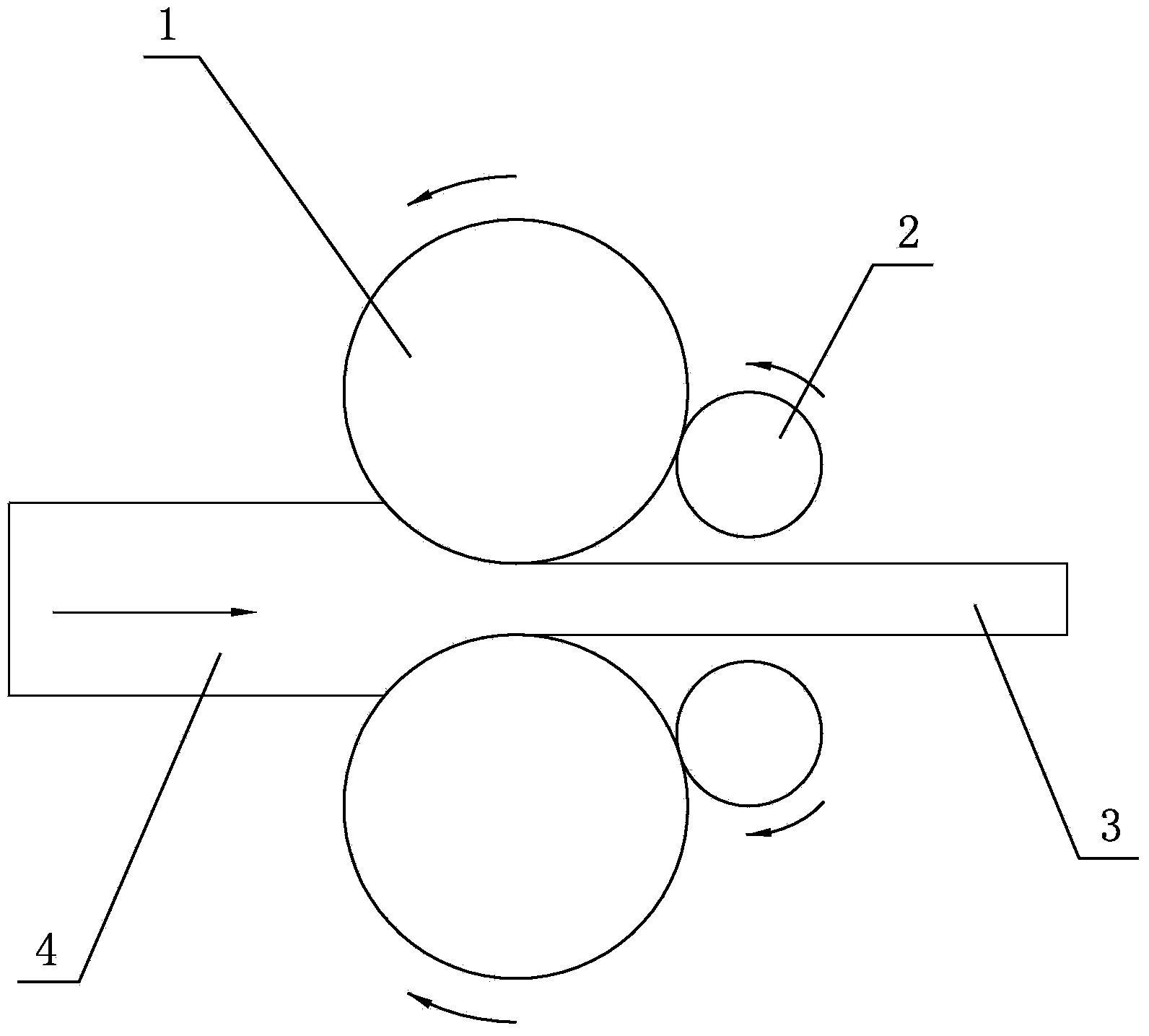

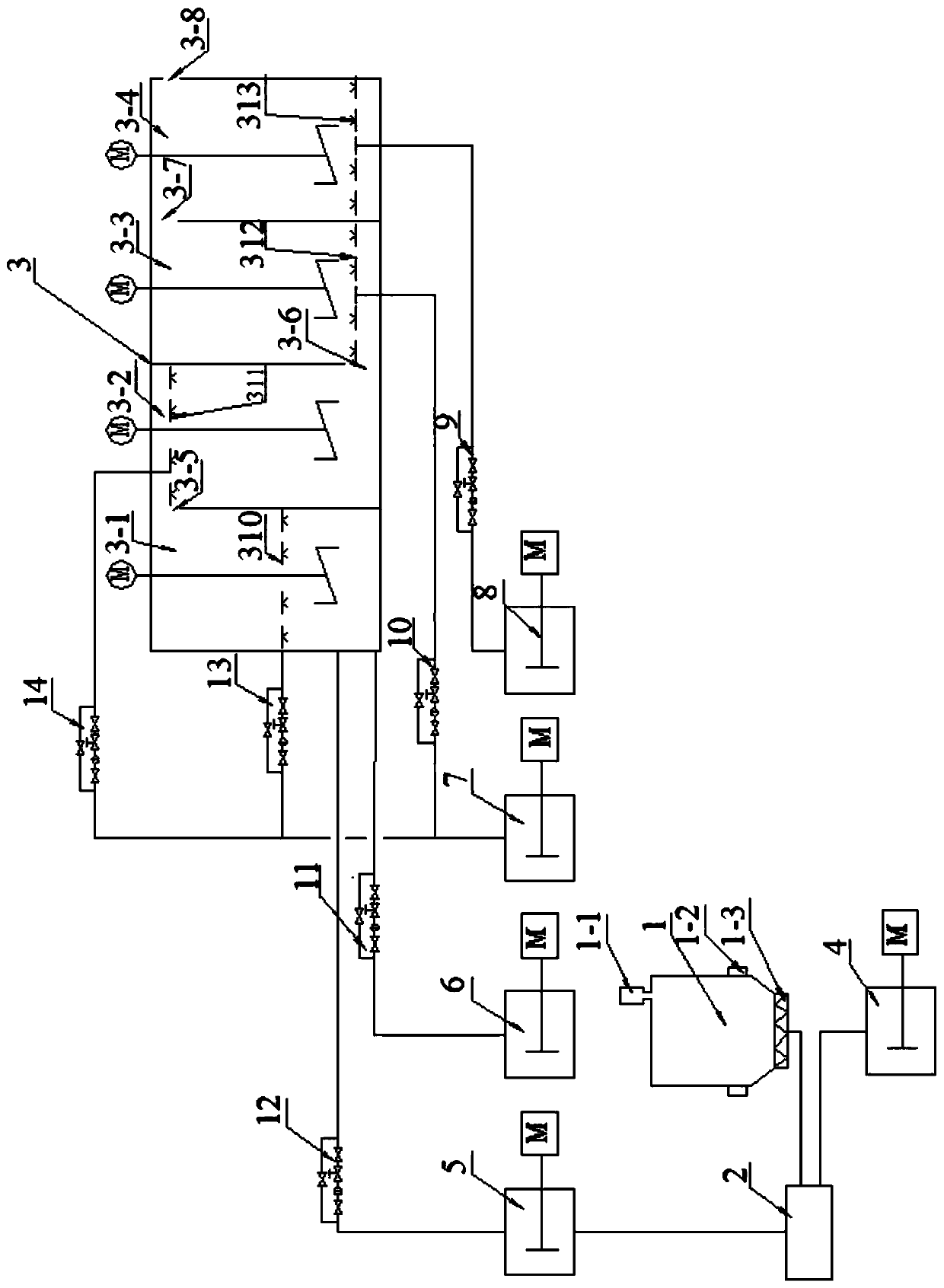

Automation system for powder from spray tower

InactiveCN106964171ASolve quality fluctuationsImprove the honor rateEvaporator regulation/controlEvaporation by sprayingWater contentSpray tower

The invention discloses an automation system for powder from a spray tower. The automation system for powder from the spray tower comprises a laser detection system, the spray tower, an air heating furnace and a micro processor. Laser detection equipment monitors the water content of the powder from the spray tower in real time; the micro processor judges whether the moisture content is within a preset threshold value range according to a detection result; when the moisture content is not within the preset threshold value range, the micro processor outputs a control instruction to adjust a workingenvironment of the air heating furnace or the spray tower, so that the moisture content of the powder can be kept within the preset threshold value range all the time. By the mode, the problem of quality fluctuation of a ceramic enterprise, which is caused by a water disqualification factor of the powder, is solved, so that the qualification rate of a product is increased, automatic control is realized, the employment rate is decreased, and the product production efficiency is also improved.

Owner:佛山市爱摩生科技有限公司

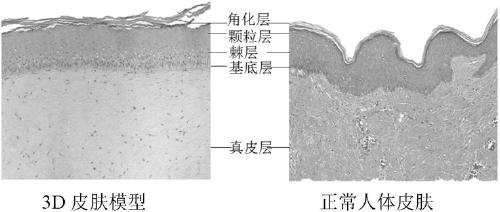

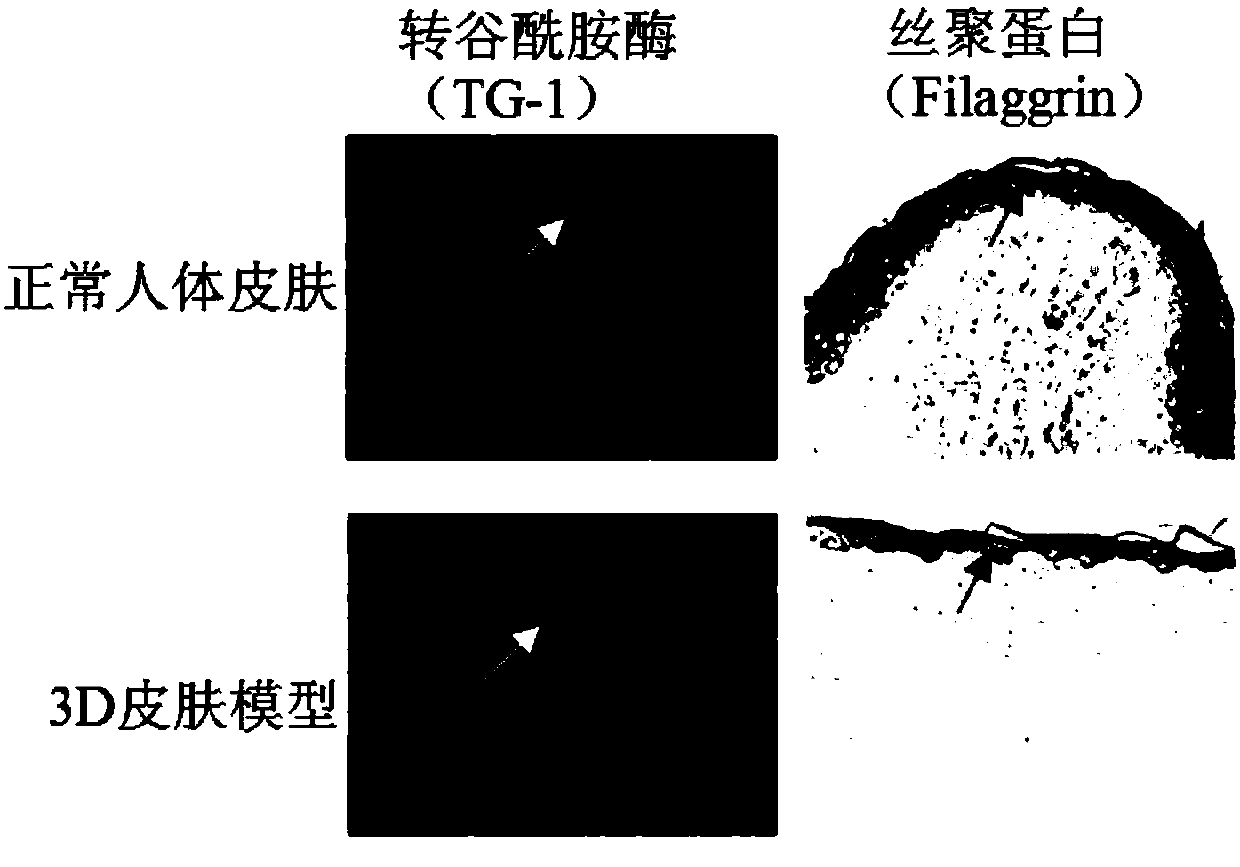

3D full-layer skin model, culture medium for forming 3D full-layer skin model and preparation method of 3D full-layer skin model

PendingCN109722410APromote growth and differentiationRealize large-scale industrial productionMicrobiological testing/measurementVertebrate cellsMedicineLayers skin

The invention discloses a 3D full-layer skin model, a culture medium for forming the 3D full-layer skin model and a preparation method of the 3D full-layer skin model. The culture medium comprises a protein preparation, and the protein preparation comprises the following components in percentage by mass: 0.1-99% of albumin, 0.1-99% of globulin and 0.1-99% of fibronectin. Serum is not needed in thegas-liquid phase process of preparing the 3D full-thickness skin model by combining the culture medium with pig type I collagen; the prepared 3D full-layer skin model is complete, the activity and the stability are remarkably improved, the application field of the type of model is expanded, and large-scale industrial production of the skin model is achieved.

Owner:JALA GROUP CORPORATION

Lignin reinforcing filled butadiene-acrylonitrile rubber hose

The invention discloses a lignin reinforcing filled butadiene-acrylonitrile rubber hose which mainly comprises a lignin reinforcing filled butadiene-acrylonitrile rubber blended elastomer, sulfur, zinc oxide, stearic acid, a accelerant, an anti-aging agent and the like. The lignin reinforcing filled butadiene-acrylonitrile rubber hose has the advantages of high mechanical strength, favorable oil resistance, high adhesion strength with framework materials, such as steel wires and the like; and the finished product has the characteristics of light weight, high pulse resisting capacity and long service life, and can reduce the material cost and the environmental pollution.

Owner:张仲伦

Threaded hole drilling and tapping machine

ActiveCN103934692BAvoid quality fluctuationsImprove processing qualityFeeding apparatusOther manufacturing equipments/toolsDifferential screwGear wheel

The invention discloses a threaded hole drilling and tapping machine which comprises a rack. A linear guide rail is arranged at the top of the rack, a linear bearing is arranged on the linear guide rail, the top of the linear bearing is connected with a connecting steel plate, a single-phase double-speed motor is arranged on the connecting steel plate, a lengthened cutter clamp is arranged on an output shaft of the single-phase double-speed motor, and a drilling and tapping composite cutter is arranged at the front end of the lengthened cutter clamp, the output shaft of the single-phase double-speed motor is connected with a differential screw mechanism through a gear transmission mechanism, and the differential screw mechanism is arranged on the rack and used for driving the connecting steel plate. A drill tool does not need to be held manually to control hole drilling and tapping in the machining process, and therefore quality fluctuation caused by previous manual operations is avoided, and machining quality is improved. One motor can provide power for hole drilling, tapping and feeding at the same time, and therefore one motor is saved. The recoil problem in the hole drilling and tapping process is solved, the work process is more stable, and therefore hole drilling and tapping quality is improved.

Owner:河南华中星科技电子有限公司

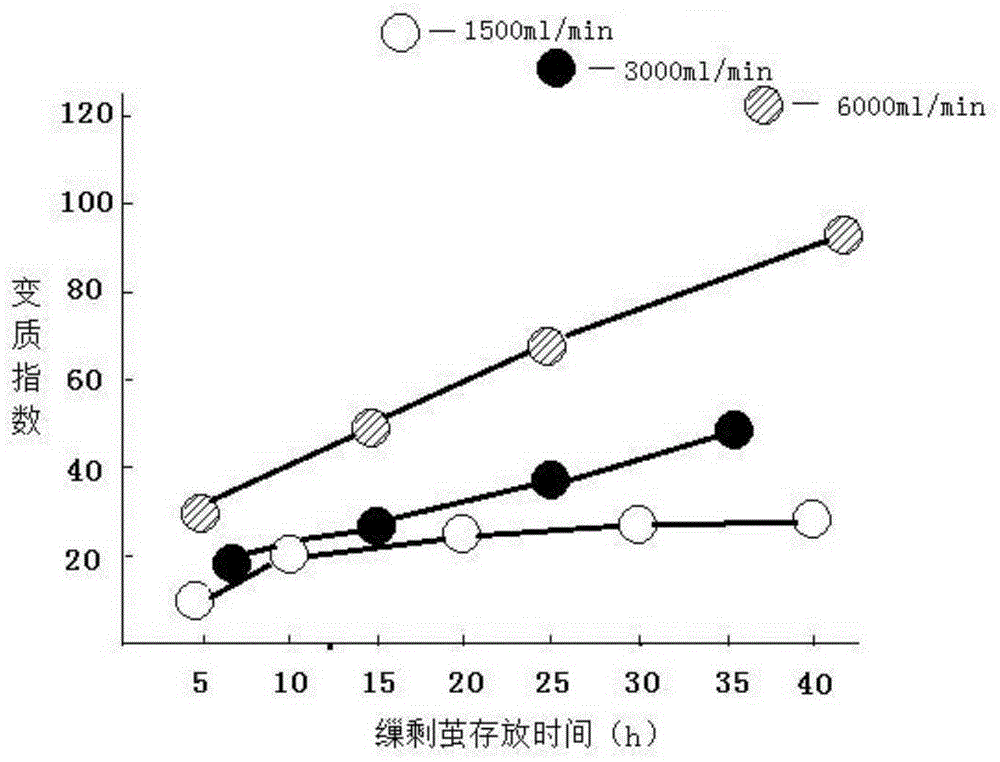

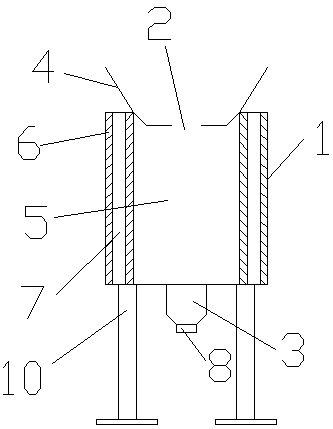

A fresh-keeping process for reeling leftover cocoons when the automatic silk reeling machine stops

Owner:YUNNAN HIRUN COCOON & SILK LTD

Method and equipment for producing paper towels from sugarcane pulp

ActiveCN103757973BImprove uniformityImprove water absorptionPulp beating/refining methodsPaper-making machinesHigh concentrationQuality control system

The invention relates to a method for papermaking, and particularly relates to a method and equipment for producing a paper hand towel form bagasse pulp as a main raw material. According to the method, firstly, 80%-90% of bagasse pulp and 10%-20% of softwood pulp are taken as raw materials, wherein the bagasse pulp is boiled by a sulfate process, washed and then bleached so as to obtain bleached bagasse pulp, and the softwood pulp adopts market pulp; secondly, an aquapulper, a high concentration grit separator and a double disc refiner are used; thirdly, a proper wet strength agent is adopted; fourthly, a crescent high speed toilet paper machine is adopted; fifthly, a low beating degree is adopted; sixthly, in the whole process from pulp preparation to paper rolling, automatic operation control with a DCS (distributed control system) is adopted, paper sheet quantification and moisture are monitored on line and regulated automatically by a QCS (quality control system); seventhly, a point-to-point embossing manner is adopted; eighthly, a high-speed rewinding and splitting machine is used. The produced paper hand towel has tensile strength and proper air permeability, and reaches high standards in strength, wet strength, water absorption, air permeability, flexibility and the like.

Owner:广西广业贵糖糖业集团有限公司

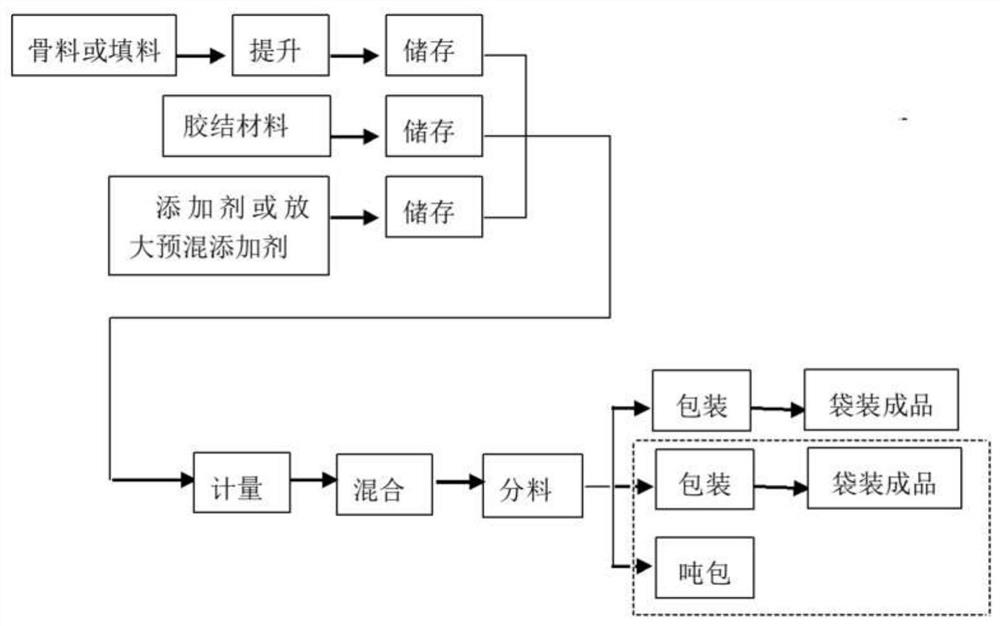

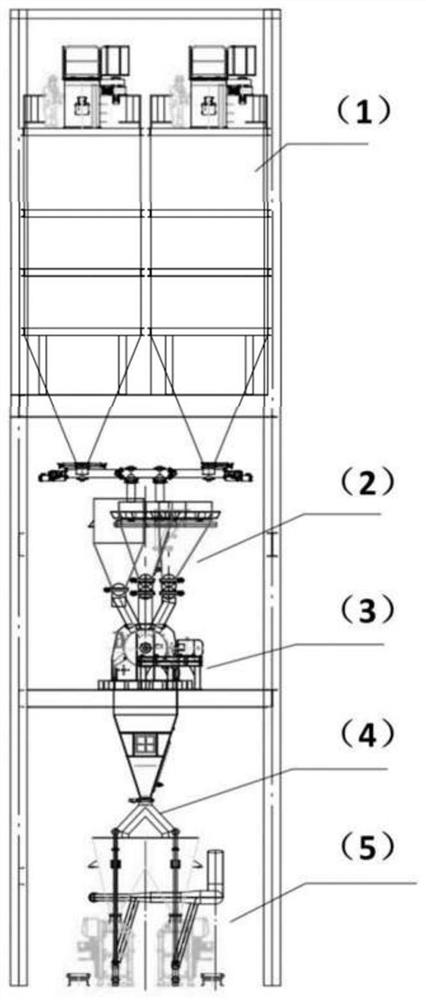

Production process for reducing cross contamination of bagged mortar

PendingCN113858426AAvoid wastingIncreased digestive processing workloadMixing operation control apparatusPretreatment controlDigestion TreatmentControl system

The invention discloses a production process for reducing cross contamination of bagged mortar. The production process comprises the following steps of (1) a lifting and storing procedure; (2) a metering and conveying procedure; (3) a mixing procedure; (4) a material separation procedure; (6) a control system; and (7) a dust removal system. According to the production process, the problem of quality fluctuation caused by cross contamination when different varieties of bagged materials are produced on the same line can be solved; the problems that during collinear production of different varieties of products, material waste is caused by replacement of product flushing equipment, and the workload of waste digestion treatment is increased are solved; and the problems that when the products of different varieties are subjected to collinear production, the production efficiency is reduced due to replacement of the product flushing equipment, and accordingly productivity exertion is affected are solved.

Owner:CHINA NAT BUILDING MATERIALS TECHCAL INNOVATION & RES INST LIMITED

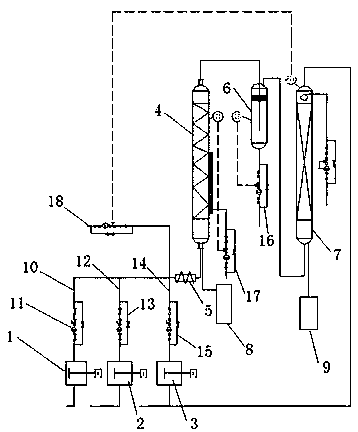

Equipment and method for continuously producing vulcanization accelerator CBS

ActiveCN110523332ARealize continuous productionRealize automatic controlOrganic chemistryTransportation and packagingVulcanizationAutomatic control

The invention discloses equipment and a method for continuously producing a vulcanization accelerator CBS, and belongs to the field of chemical production. The system comprises an accelerator M bin, awater metering pump, a continuous mixing device, an M slurry metering pump, a cyclohexylamine metering pump, a hydrogen peroxide metering pump, a sodium hypochlorite metering pump, continuous reaction equipment and related pipelines; the continuous reaction equipment is provided with four reaction chambers, and each reaction chamber is provided with an independent stirring device; M slurry and cyclohexylamine are introduced into a first reaction chamber usingthe metering pumps, hydrogen peroxide is introduced into a first reaction chamber, a second reaction chamber and a third reaction chamber using the metering pump, and sodium hypochlorite is introduced into a fourth reaction chamber using the metering pump; a discharge overflow port is formed in the fourth reaction chamber; and a M slurry pipeline, a cyclohexylamine pipeline, a hydrogen peroxide pipeline and a sodium hypochlorite pipeline are all provided with flow regulating valve banks. The method is suitable for continuous production of the vulcanization accelerator CBS, automatic control can be achieved, the product quality is more stable, and the frequent operation process of intermittent production is avoided.

Owner:SHANDONG SUNSINE CHEM

A kind of equipment and method for continuously producing vulcanization accelerator cbs

ActiveCN110523332BAvoid quality fluctuationsShort reaction timeOrganic chemistryTransportation and packagingCyclohexylaminesIndustrial engineering

The invention discloses a device and a method for continuously producing vulcanization accelerator CBS, belonging to the field of chemical production. The invention includes accelerator M silo, water metering pump, continuous mixing device, M slurry metering pump, cyclohexylamine metering pump, hydrogen peroxide metering pump, sodium hypochlorite metering pump, continuous reaction equipment and related pipelines. Among them: the continuous reaction equipment has four reaction chambers, and each reaction chamber is equipped with an independent stirring device. M slurry and cyclohexylamine enter the first reaction chamber through the metering pump, hydrogen peroxide enters the first to the third reaction chamber respectively through the metering pump, and sodium hypochlorite enters the fourth reaction chamber through the metering pump; Orifice; M slurry pipeline, cyclohexylamine pipeline, hydrogen peroxide pipeline and sodium hypochlorite pipeline are all equipped with flow regulating valve group. The invention is suitable for the continuous production of the vulcanization accelerator CBS, can realize automatic control, has more stable product quality, and avoids the frequent operation process of intermittent production.

Owner:SHANDONG SUNSINE CHEM

A device for continuous production of rubber vulcanization accelerator diphenylguanidine and production method thereof

ActiveCN106810469BPrevent volatilizationAchieve instant mixingOrganic chemistryOrganic compound preparationVulcanizationOxygen

Owner:SHANDONG SUNSINE CHEM

Method for preparation of methionine by ion exchange acidification of methionine salt and special equipment

InactiveCN107382799AImprove exchange efficiencyHigh yieldOrganic compound preparationSolid sorbent liquid separationIon exchangeReaction temperature

The invention discloses a method for preparation of methionine by weakly acidic cation exchange resin acidification of a methionine salt solution. The acidification reaction temperature is 30-90DEG C, and the reaction pressure is 0.02-0.4MP. The invention discloses equipment for preparation of methionine by acidification of a methionine salt. The equipment consists of a raw material buffer tank, a cleaning agent buffer tank, a regenerant buffer tank, adsorption columns and a circulating pump. The raw material buffer tank, the cleaning agent buffer tank and the regenerant buffer tank are communicated with the adsorption columns respectively through pipelines, the pipelines are equipped with valves for independent control of the communication relation of the raw material buffer tank, the cleaning agent buffer tank, the regenerant buffer tank and the adsorption columns, and the adsorption columns are equipped with reaction product outlets. According to the invention, the cation resin can be reutilized, and high reaction efficiency can be achieved by control of the reaction parameters. In the whole working process of the equipment provided by the invention, adsorption column acidification, cleaning and cation resin regeneration steps can be realized only by controlling the switches.

Owner:NINGXIA UNISPLENDOUR TIANHUA METHIONINE CO LTD

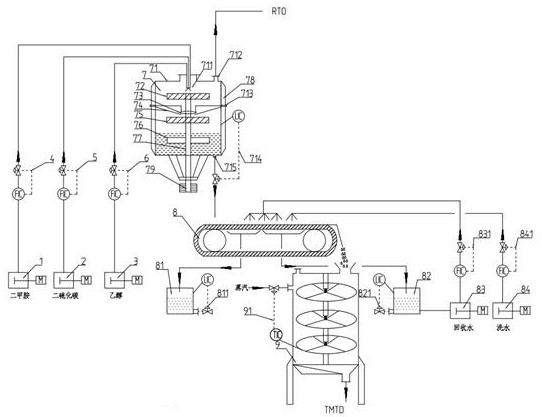

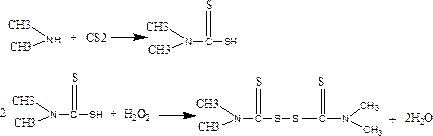

A process and system for continuous production of rubber vulcanization accelerator tetramethylthiuram disulfide

ActiveCN107286066BAvoid quality fluctuationsSolve the problem of difficult pollutionOrganic chemistryTetramethylthiuram disulfideCarbon sulfide

The invention relates to the technical field of production of vulcanizing agents, and discloses a process for continuously producing tetramethyl thiuram disulfide as thiofide. The process comprises the following steps: respectively delivering dimethylamine, carbon disulfide and a solvent into a mixing tank and carrying out ionization reaction to obtain mixed liquor; after feeding the mixed liquor into a tower type reactor, adding an oxidizing agent at the operation temperature of 20-60 DEG C to oxidize the mixed liquor in a segmented manner to obtain reaction liquid; and carrying out solid-liquid separation on the reaction liquid to obtain a solid material. The invention further discloses preparation equipment based on the process. The technical problems that the production efficiency is low and pollution is high in the prior art are solved, and the process and system for continuously producing the tetramethyl thiuram disulfide as the thiofide are provided.

Owner:SHANDONG SUNSINE CHEM

Equipment for continuously producing accelerator TMTD and a method for continuously producing accelerator TMTD

PendingCN113387858AAvoid disadvantagesShort reaction timeOrganic chemistryBelt filterProcess engineering

The invention relates to equipment for continuously producing accelerator TMTD and a method for continuously producing the accelerator TMTD. The equipment comprises a supergravity reactor, a washing device and a drying device, wherein a feeding port and an exhaust port are formed in the top of the supergravity reactor, and the feeding port is connected with a dimethylamine metering pump, a carbon disulfide metering pump and an ethanol metering pump through pipelines; a discharge hole is formed in the bottom of the supergravity reactor, and a hydrogen peroxide inlet is also formed between the top and the bottom of the supergravity reactor; the washing device comprises a vacuum belt filter provided with a feeding port, a discharging port and a mother liquor outlet, the feeding port communicates with the discharging port, and the vacuum belt filter is connected with a washing pipe; and the drying device is provided with a drying inlet and a drying outlet, the drying inlet is connected to the discharging port, and an automatic temperature controller is installed in the drying device. The equipment and the method of the invention overcome the defects that salt-containing wastewater is generated, a reaction period is long, the labor efficiency of intermittent production is low, the quality of products in batches is different and the like in the prior art.

Owner:SHANDONG SUNSINE CHEM

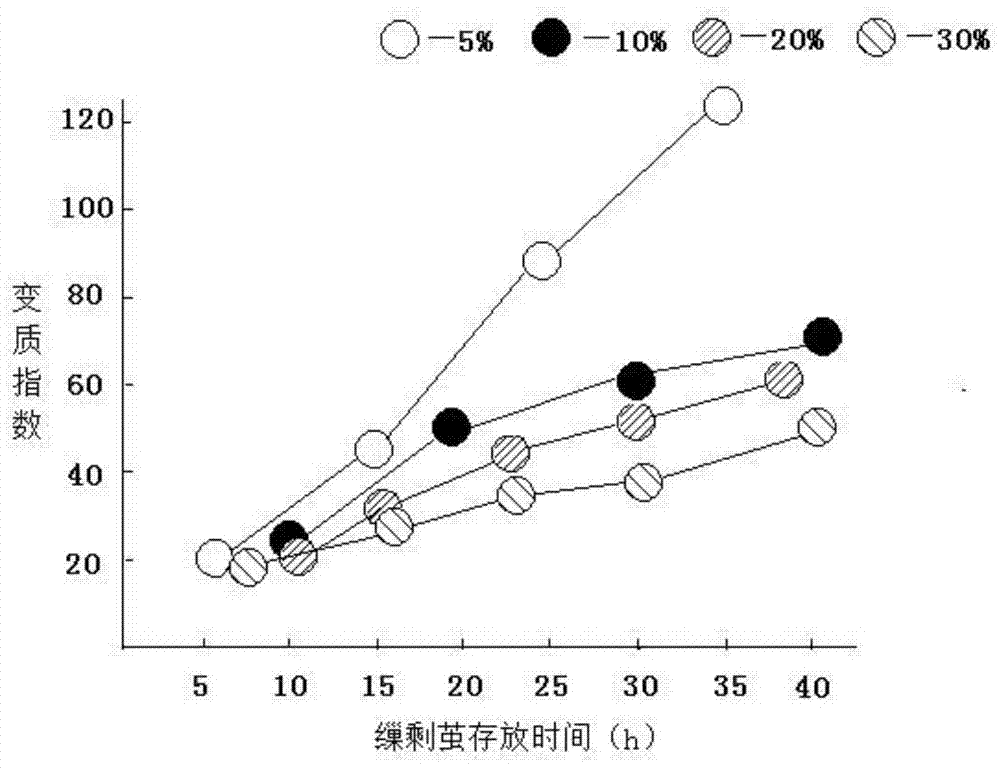

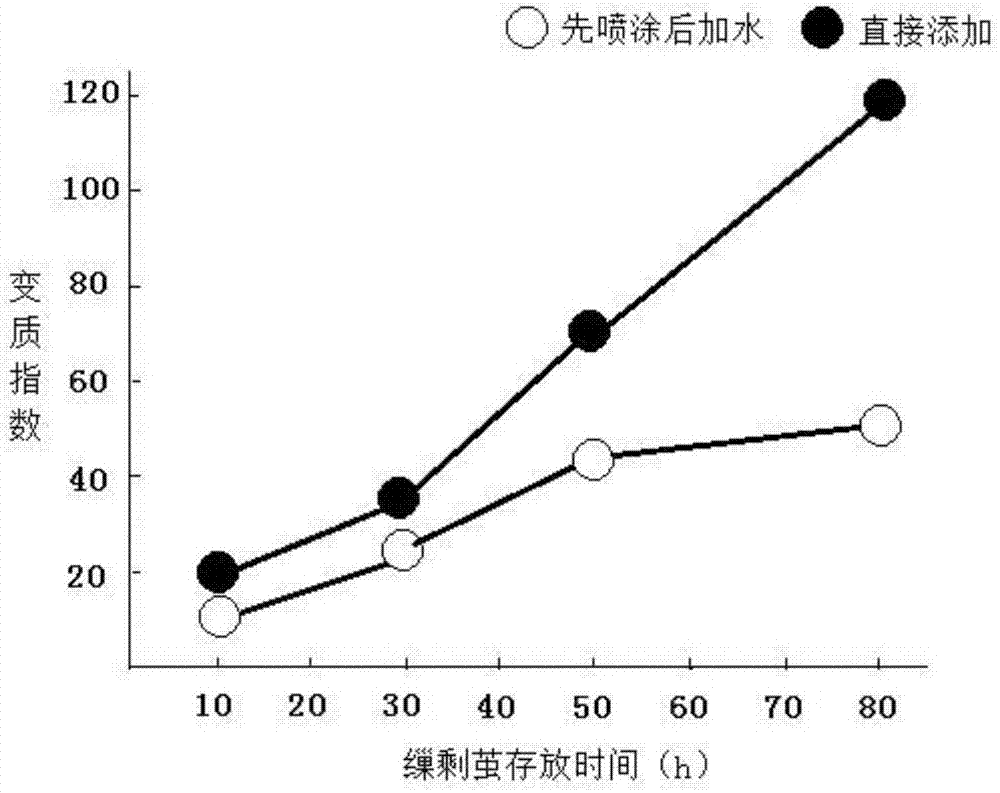

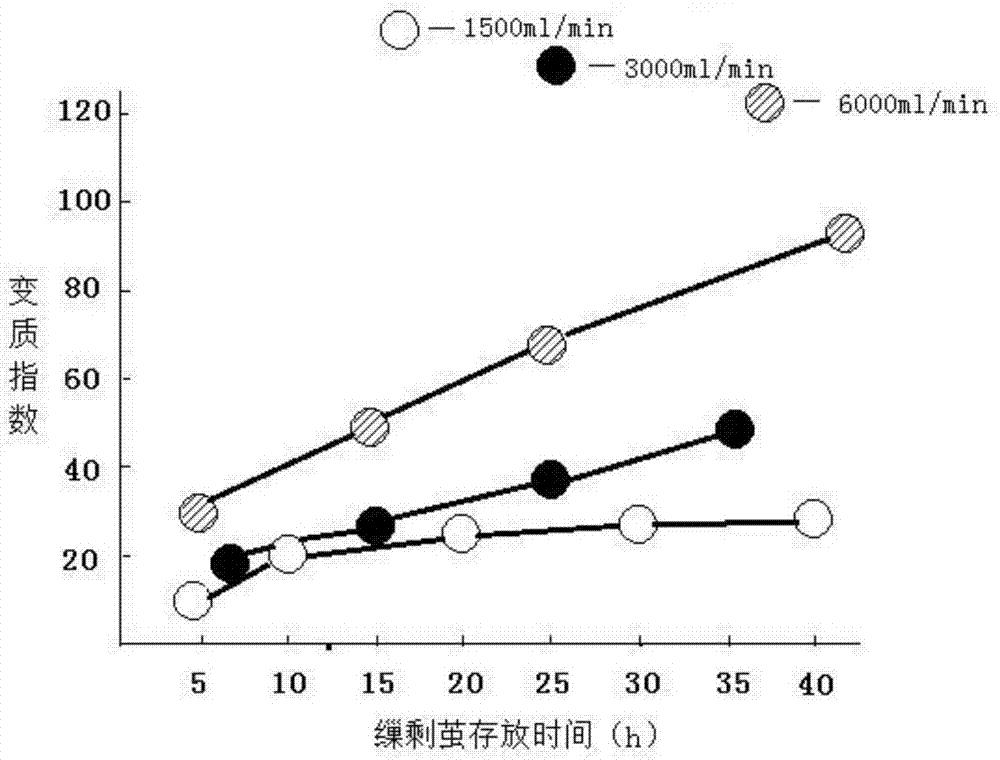

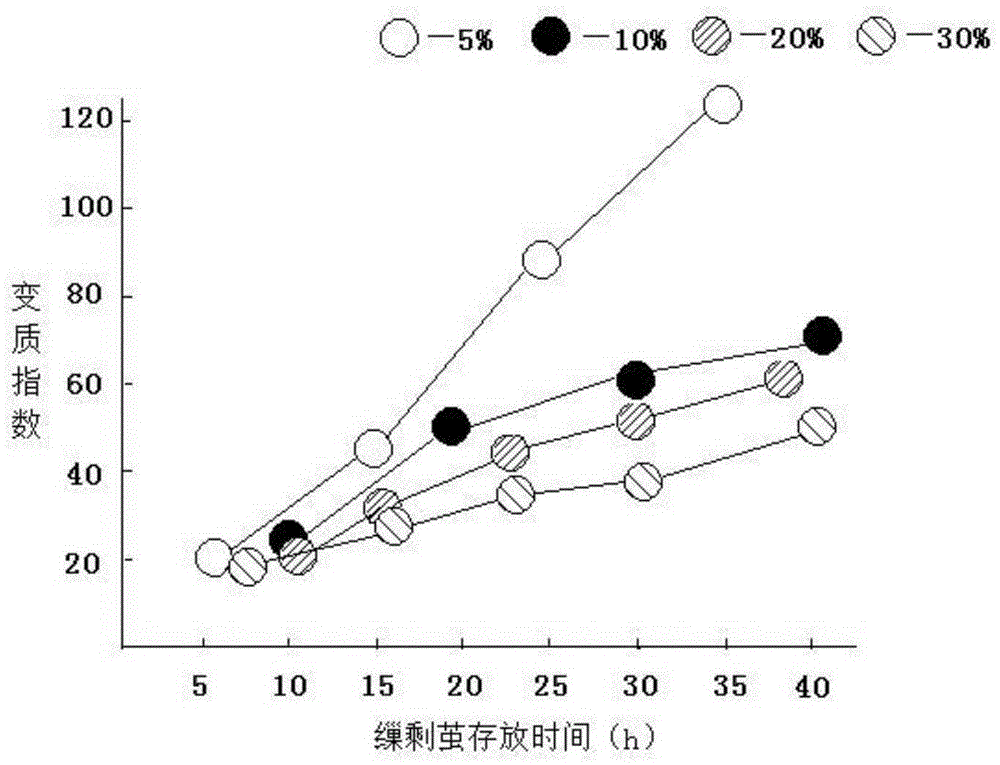

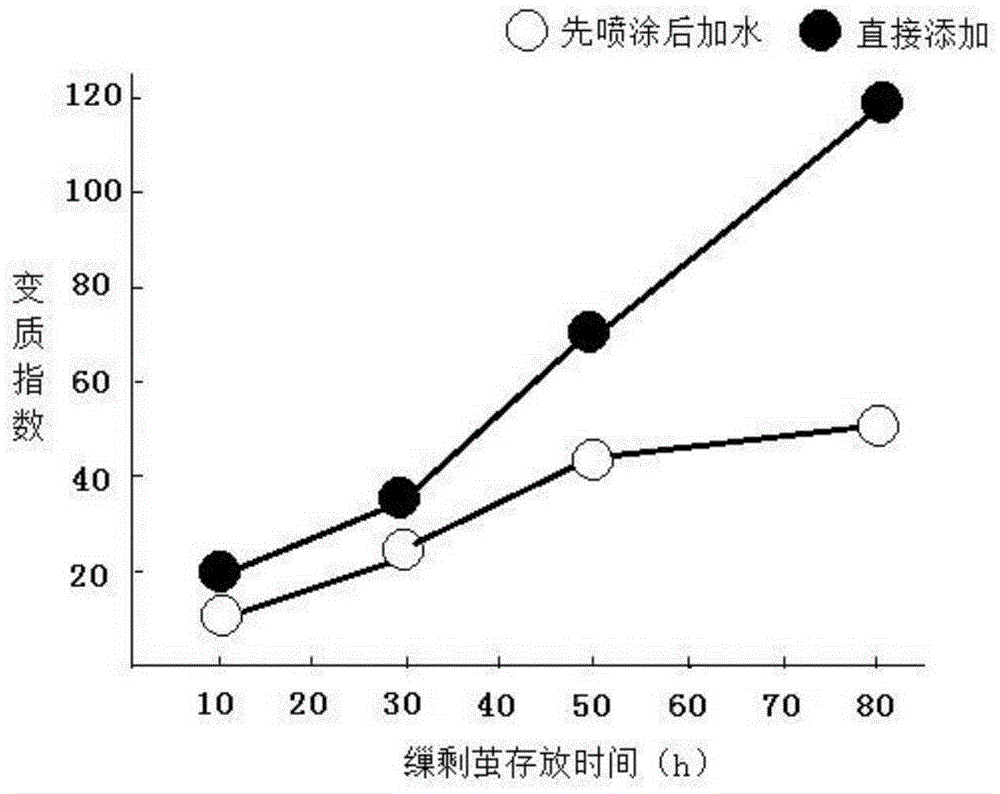

Carry-over cocoon fresh-keeping technology used after automatic reeling machine stoppage

The invention provides a carry-over cocoon fresh-keeping technology used after automatic reeling machine stoppage. According to the technology, after automatic reeling machine stoppage, silk reeling water in a silk reeling groove is dried; glacial acetic acid and water are mixed to obtain an acetic acid aqueous solution; the obtained acetic acid aqueous solution is uniformly sprayed on the residual carry-over cocoon in the silk reeling groove by a sprayer, the residual carry-over cocoon is naturally soaked for 15-20 minutes; and cold water is slowly added in the silk reeling groove until the silk reeling groove is full. The technology does not require reel-up operation after stoppage, so that output is increased, consumption is reduced, quality fluctuation due to reel-up and cocoon feeding can be avoided, quality stabilization is ensured, long fresh-keeping time can be provided for the carry-over cocoon, and the carry-over cocoon cannot generate deterioration and corruption in 60 hours.

Owner:YUNNAN HIRUN COCOON & SILK LTD

Novel storage device

InactiveCN109292282AGuaranteed use effectAvoid quality fluctuationsLarge containersInternal temperatureBiochemical engineering

The invention provides a novel storage device. The novel storage device comprises a tank. The upper portion of the tank is provided with a feed port. The lower portion of the tank is provided with a discharge port. A guide plate is arranged on the feed port. The guide plate is arranged along the side edge of the feed port. A storage cavity is arranged below the feed port. Heat insulation plates are arranged between the tank and the storage cavity. A supporting plate is arranged between the heat insulation plates. The heat insulation plates are attached to the two sides of the supporting plate.Opposite opening plates are arranged below the discharge port. The feed port is arranged on the upper portion of the tank so that materials can be fed into the tank conveniently. The guide plate is arranged at the feed port, so that the materials are fed into the tank more uniformly and reasonably, and the using effect of the storage device is ensured. The heat insulation plates are arranged in the tank and can keep the internal temperature of the tank constant to a certain extent, and a certain quality fluctuation of the materials in the tank due to temperature variation is avoided.

Owner:扬州万坤机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com