Method for evaluating process characteristics of injection-molding tools

A technology for injection molds and molds, which is used in the field of evaluating the technical characteristics of injection molds, and can solve problems such as high cost and high maintenance consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

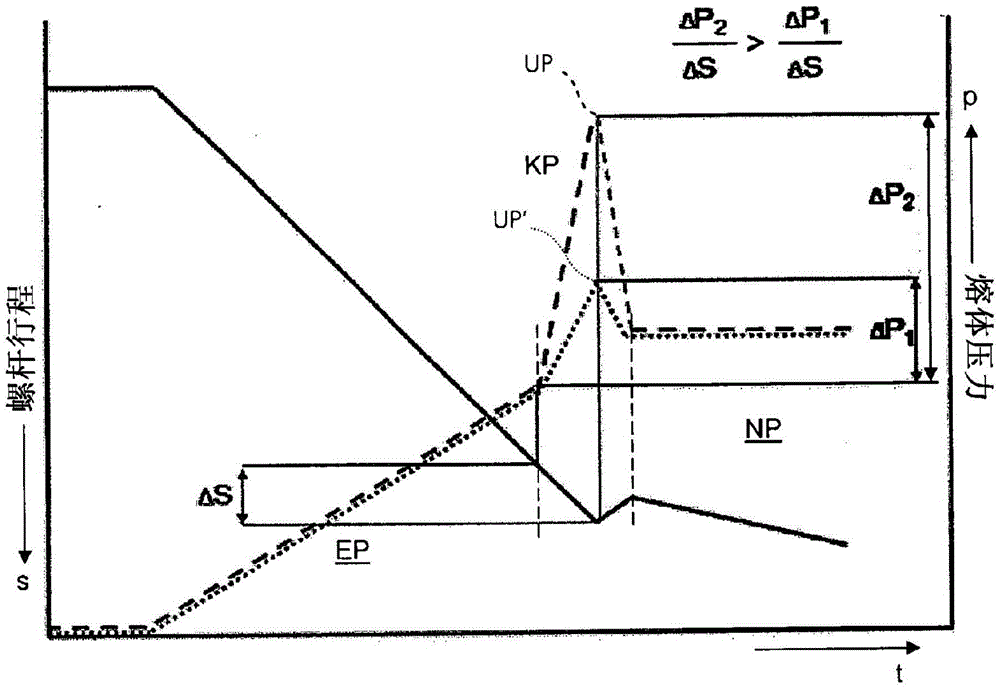

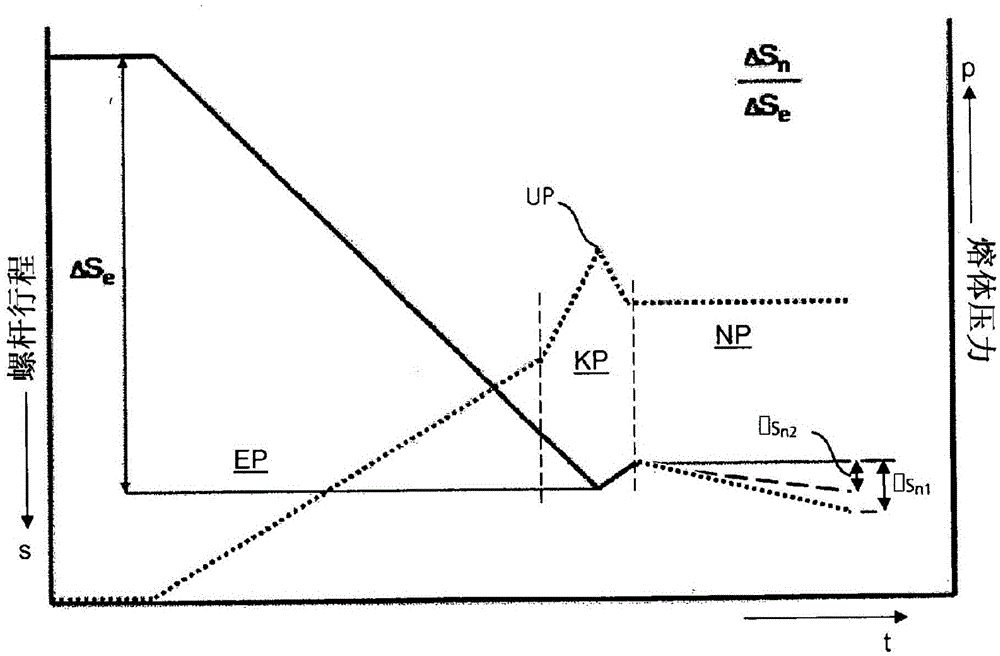

[0042] figure 1 The schematic graph of , shows the time profile of the screw stroke s and the melt pressure p over an injection cycle of the injection mold. The individual stages are briefly described below so that mold-specific properties can then be elucidated:

[0043] at time t 0 In the initial injection phase EP, the injection unit of the injection molding machine is moved onto the closing unit of the mold and is pressed against the mold by means of the outlet of the injection unit in the form of a nozzle. The screw of the injection molding machine is now moved by a specific screw stroke s in the direction of the nozzle, so that the prepared melt is pressed under high pressure p through the opened nozzle and the gate of the injection mold into the molding cavity. During this injection phase EP, the screw moves at an approximately constant speed, which likewise causes an approximately constant rise in the pressure p, as in figure 1 as shown in.

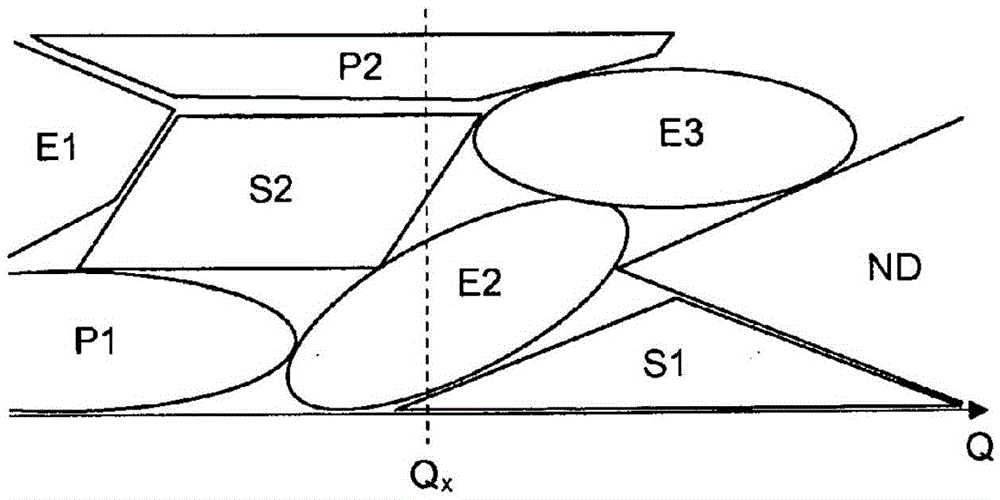

[0044] A clear increas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com