A fresh-keeping process for reeling leftover cocoons when the automatic silk reeling machine stops

A silk reeling machine and technology for reeling leftover cocoons, which is applied in the field of fresh-keeping technology for reeling leftover cocoons after the automatic silk reeling machine stops, can solve the problems of productivity, work efficiency decline, qualitative change and corruption, and defective silk products, etc., to increase production , reduced consumption, and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A process for keeping the freshness of reeling cocoons when the silk reeling machine is stopped, comprising the following steps:

[0019] 1) After the automatic silk reeling machine stops, drain the silk reeling soup in the silk reeling tank;

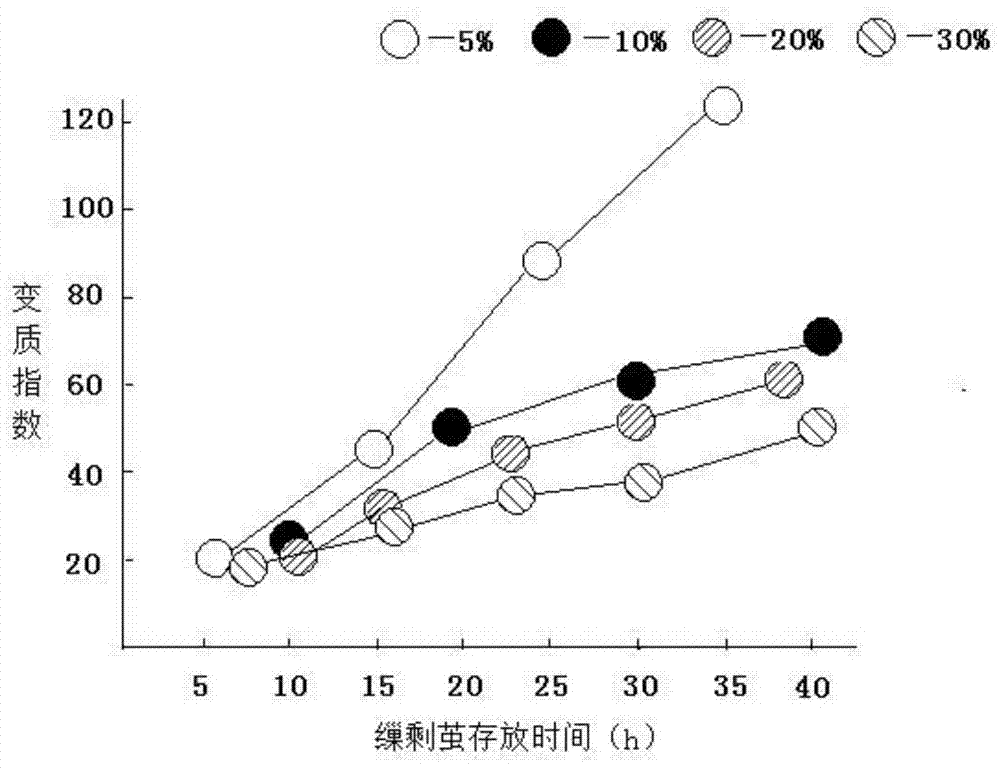

[0020] 2) mixing the glacial acetic acid with water to obtain an aqueous acetic acid solution with a concentration of 10% to 30% (V / V);

[0021] 3) Put the aqueous acetic acid solution obtained in step 2) into a sprayer, spray evenly on the remaining cocoons remaining in the silk reeling tank with the sprayer, and allow it to soak naturally for 15 minutes;

[0022] 4) Slowly add cold water at a temperature of 5°C at a flow rate of 500ml / min into the silk reeling tank until the silk reeling tank is full.

[0023] The deterioration and color change of reeled cocoons are divided into 3 grades: Grade 0: the cocoon body is completely white; Grade 1: slight yellowing; Grade 2: deep yellowing; Grade 3: extremely yellowing of;

[0024...

Embodiment 2

[0027] 1) After the automatic silk reeling machine stops, drain the silk reeling soup in the silk reeling tank;

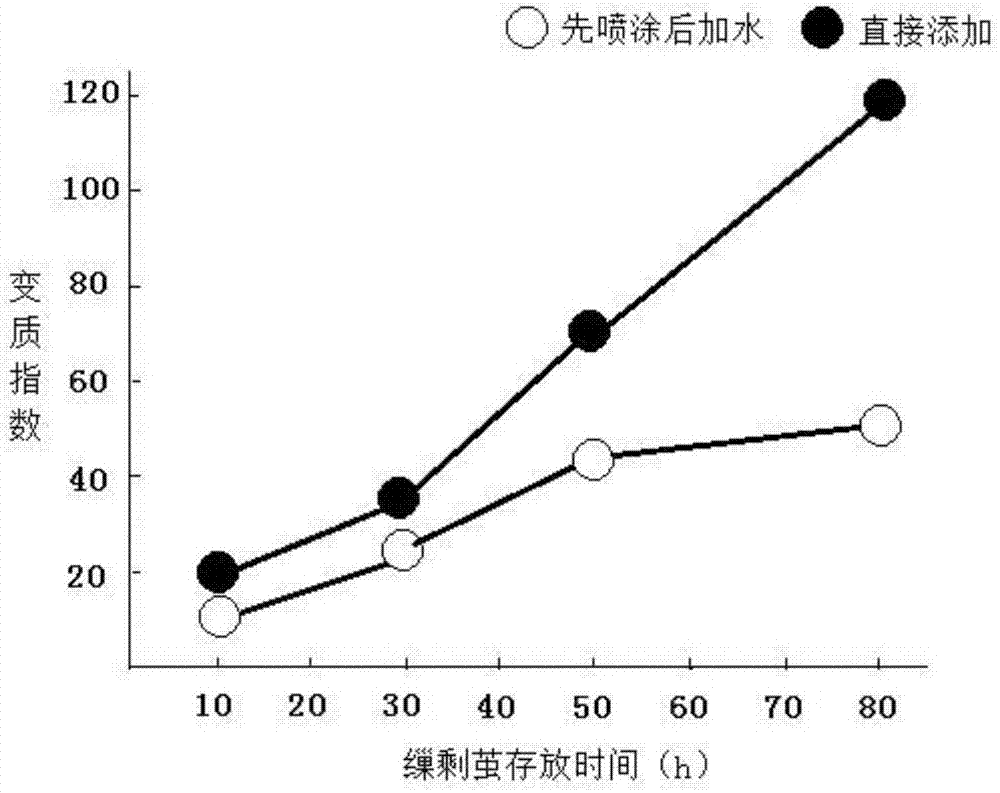

[0028] 2) mixing the glacial acetic acid with water to obtain a 20% (V / V) acetic acid aqueous solution;

[0029] 3) Put the aqueous acetic acid solution obtained in step 2) into a sprayer, and evenly spray it on the remaining reeled cocoons remaining in the silk reeling tank with the sprayer, allowing it to soak naturally for 20 minutes;

[0030] 4) Slowly add cold water at a temperature of 10°C to the silk reeling tank at a flow rate of 1000ml / min until the silk reeling tank is full.

[0031] In this way, do not add water to the silk reeling soup, directly add glacial acetic acid with an equivalent concentration of 20% to the silk reeling soup, and directly add glacial acetic acid to the silk reeling soup to reach a concentration of 20%, as shown in figure 2 Shown, the deterioration index method of embodiment 2 is all lower than all the other two methods, has be...

Embodiment 3

[0033] 1) After the automatic silk reeling machine stops, drain the silk reeling soup in the silk reeling tank;

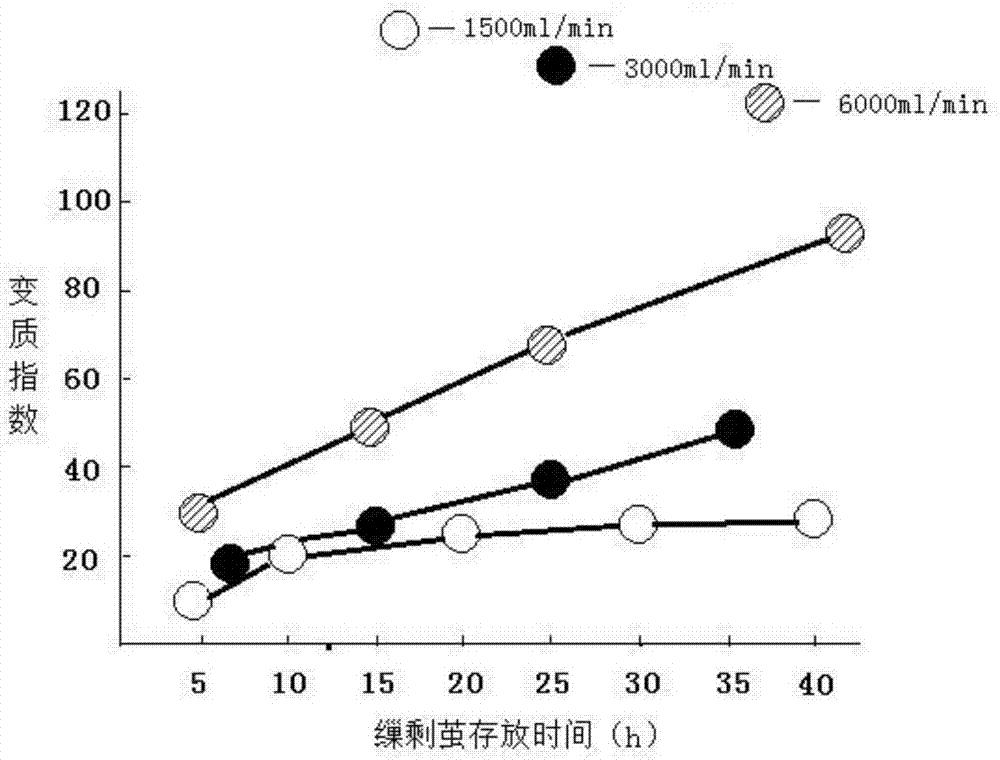

[0034] 2) mixing the glacial acetic acid with water to obtain a 30% (V / V) acetic acid aqueous solution;

[0035] 3) Put the aqueous acetic acid solution obtained in step 2) into a sprayer, spray evenly on the remaining cocoons remaining in the silk reeling tank with the sprayer, and allow it to soak naturally for 15 minutes;

[0036] 4) Slowly add cold water at a temperature of 15°C at a flow rate of 1500ml / min into the silk reeling tank until the silk reeling tank is full.

[0037] This is compared with the 3000ml / min flow rate filling, 20 ℃ silk reeling tank environment, 6000ml / min flow rate filling, 25 ℃ silk reeling tank environment, for example image 3 Shown, the deterioration index method of embodiment 3 is all lower than other two kinds of methods, and flow rate adds water speed too fast and can affect the gradual dilution and the dispersal of the acetic a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com