Jam containing grain particles, preparation method of jam and application of jam in neutral dairy products

A technology of grain granules and dairy products, applied in the direction of bacteria, applications, lactobacilli, etc. used in food preparation, can solve problems such as unsuitable for development, affecting product sensory, and poor integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The present embodiment provides a kind of oat jam, and its preparation method comprises the following steps:

[0042] (1) Raw material pretreatment: the qualified oat grains are selected and cleaned for later use;

[0043] (2) Microbial fermentation: Put the pretreated oat grains into a fermenter and add sterile water, adjust the pH value to 4.5 at 35°C, add fermentation strains, stir evenly, and heat-preserve and ferment for 12 hours to obtain fermented grain mixtures;

[0044] Based on the total weight of the fermented grain mixture, the added amount of the fermented strains is 0.4‰, the fermented strains include 0.1‰ of Lactobacillus bulgaricus, 0.1‰ of Lactobacillus plantarum, and 0.2‰ of Streptococcus lactis;

[0045] (3) Ingredients: Prepare ingredients according to the following parts by weight: 40% of the fermented grain mixture obtained in step (2), 40% of white sugar, 15% of water, and 5% of stabilizer (modified starch);

[0046] (4) Stir and mix: heat the w...

Embodiment 2

[0059] Present embodiment provides a kind of quinoa white peach jam, and its preparation method comprises the following steps:

[0060] (1) Raw material pretreatment: the qualified quinoa grains are selected and cleaned for later use, and the qualified white peaches are selected and cleaned, then diced and processed into fruit grains with a size of 5mm×5mm×5mm;

[0061] (2) Microbial fermentation: put the pretreated oat grains and white peaches into the fermenter according to the proportion, add sterile water, adjust the pH value to 5.5 at 45°C, add fermentation strains, stir evenly, and keep warm Fermented for 18 hours to obtain the fermented cereal fruit mixture;

[0062] Based on the total weight of the fermented grain and fruit, the amount of fermented strains added is 1.2‰, the fermented strains include 0.4‰ of Lactobacillus bulgaricus, 0.2‰ of Streptococcus thermophilus, 0.2‰ of Lactococcus lactis, and 0.4‰ of Streptococcus lactis. ‰;

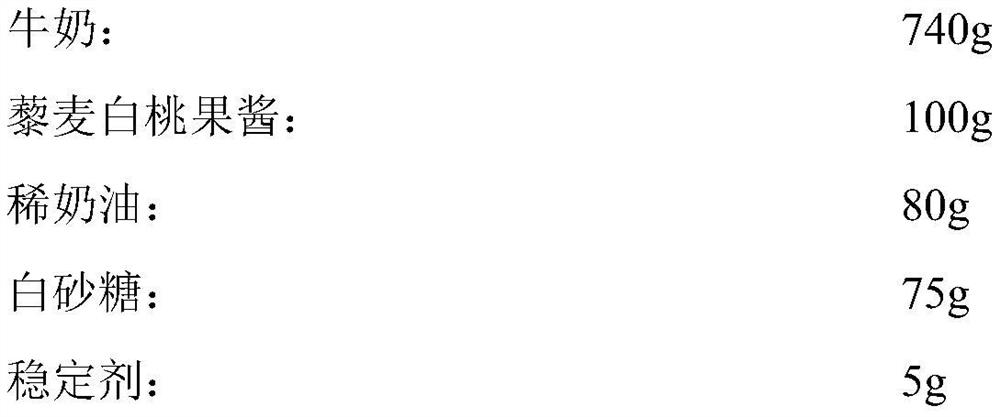

[0063] (3) Ingredients: get the ...

Embodiment 3

[0077] Present embodiment provides a kind of highland barley almond jam, and its preparation method comprises the following steps:

[0078] (1) raw material pretreatment: the qualified highland barley grains are selected and cleaned for later use, and the qualified almonds are selected and cleaned, then diced and processed into particles with a size of 3mm×3mm×3mm;

[0079] (2) Microbial fermentation: Put the pretreated highland barley grains and almond grains into the fermenter according to the proportion and add sterile water, adjust the pH value at 5.0 under the condition of 40°C, add fermentation bacteria, and stir evenly, Insulated and fermented for 15 hours to obtain a fermented grain and nut mixture;

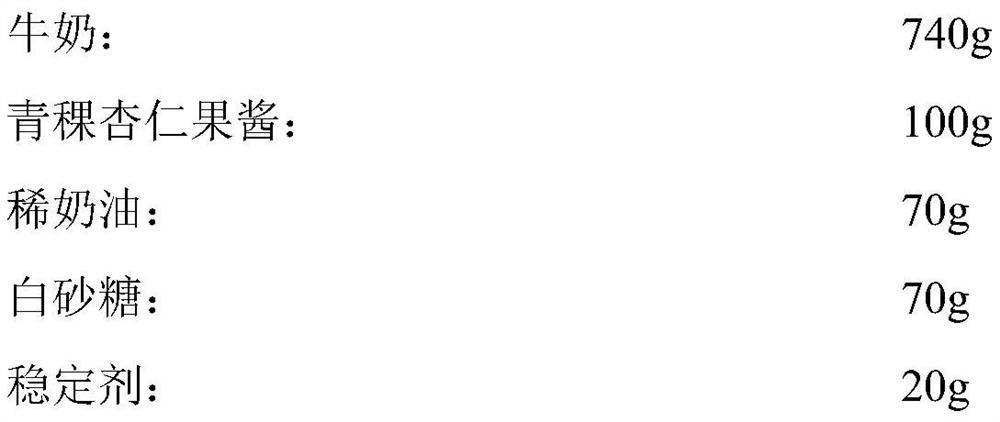

[0080] Based on the total weight of the fermented grain nuts, the amount of fermented strains added is 1.0‰, the fermented strains include 0.3‰ of Lactobacillus bulgaricus, 0.1‰ of Streptococcus thermophilus, 0.2‰ of Lactobacillus plantarum, and 0.4‰ of Streptococcus lact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com