Production process for reducing cross contamination of bagged mortar

A production process and cross-contamination technology, applied to clay preparation devices, cement mixing devices, mixing operation control devices, etc., to achieve the effect of increasing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

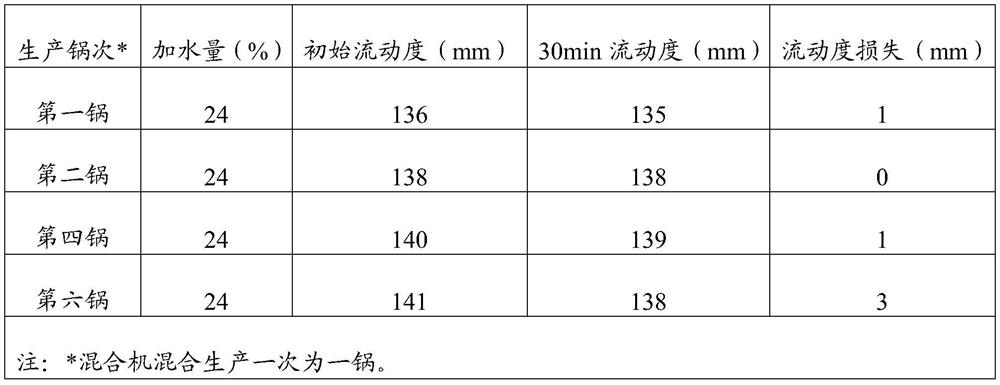

Examples

Embodiment 1

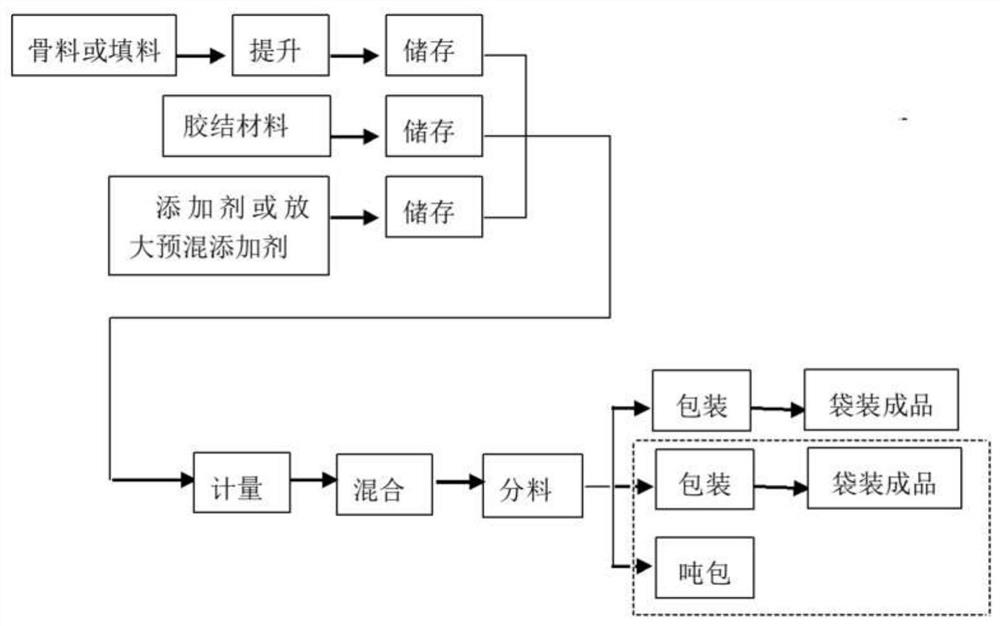

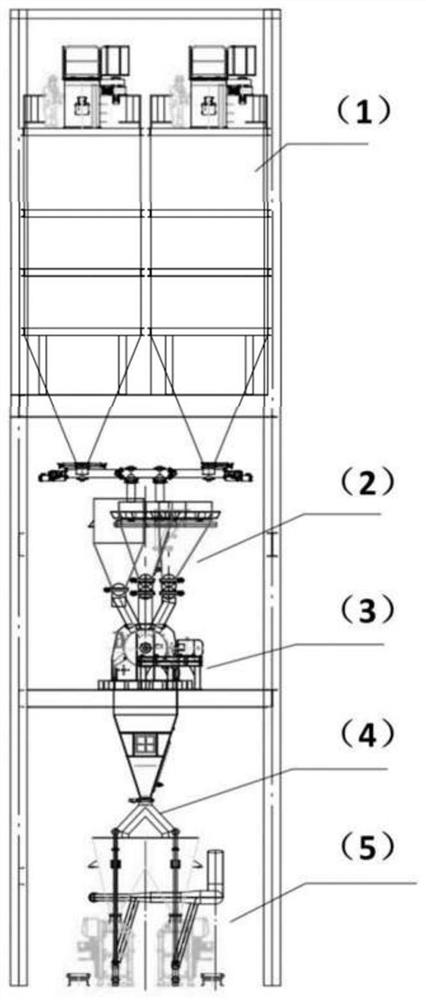

[0033] A production process for reducing cross-contamination of bagged mortar, the process flow and process layout are shown in figure 1 , figure 2 shown, including the following steps:

[0034] Lifting and storage of raw materials: Various materials such as cementitious materials, aggregates, fillers, admixtures, etc. are mechanically lifted or pneumatically lifted into the raw material storage warehouse at the top of the production line, and stored for use.

[0035] Metering and conveying: Various materials in the raw material storage bin enter their own weighing scales successively through the supporting measuring screw, and measure to the formula setting value. The admixture scale should not directly enter the mixer, so as to enter the large scale of the gelling material and filler, It is advisable to enter the mixer together, so as to ensure the metering accuracy of the admixture.

[0036] Mixing and homogenization: various materials in the weighing scale enter the mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com