Patents

Literature

100results about How to "Production methods are environmentally friendly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing organic selenium-enriched rice

ActiveCN102511346AImprove conversion rateImprove securityRice cultivationFertilizer mixturesNutrientBiology

The invention discloses a method for producing organic selenium-enriched rice, wherein the organic selenium-enriched rice is planted according to a normal rice cultivation method. The method is characterized in that the method comprises the steps of: carrying out root dipping treatment to rice seedlings by using selenium-enriched nutrient before transplanting the rice seedlings, transplanting therice seedlings into a big field, planting according to a conventional rice planting method, harvesting organic selenium-enriched paddy, and processing the organic selenium-enriched paddy to obtain the organic selenium-enriched rice. The selenium-enriched nutrient comprises substances with effective application dose, wherein the substances contain selenium and potassium sulfate,. The selenium content of the rice, obtained by the method, is 50-300mug / kg and is improved by 2-10 times in comparison with that of common rice, organic selenium ratio is greater than or equal to 80% and the standard of the organic selenium-enriched rice is achieved.

Owner:宁夏硒产业发展有限责任公司

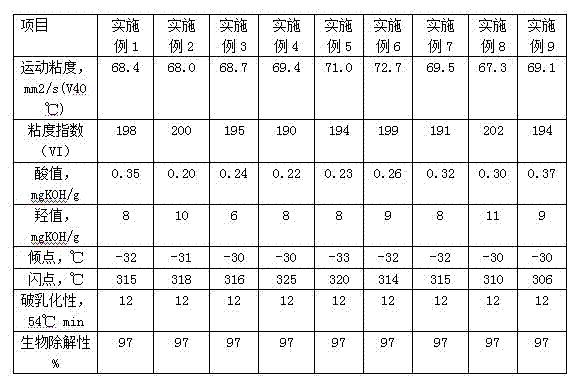

Method for producing pentaerythritol oleate under catalysis of granular solid superacid

InactiveCN102875374ANo pollutionHigh yieldOrganic compound preparationCarboxylic acid esters separation/purificationPentaerythritolAcid catalyzed

The invention discloses a method for producing pentaerythritol oleate under catalysis of granular solid superacid, and relates to a method for synthesizing ester base oil in biodegradable lubricating oil. The method comprises the following steps of: mixing pentaerythritol and oleic acid in a mass ratio of 1:(7.2-9.5), adding the granular solid superacid, and reacting at the temperature of between 140 and 240DEG C for 4 to 10 hours in the vacuum degree of 100-1,000Pa; filtering by using a 200-12,500 mesh filter screen or filter plate; and heating crude grease to the temperature of between 160 and 280DEG C, removing unreacted acid or alcohol, keeping the vacuum degree of the system ranging from 1 to 500Pa, and distilling under reduced pressure for 40 to 120 minutes to obtain the pentaerythritol oleate. The pentaerythritol oleate produced by the method has excellent low temperature fluidity, lubricity, viscosity-temperature characteristics, oxidation safety, cleanness and good biodegradability, and the method is an environment-friendly and high-efficiency production method having advantages of simple treatment, short production period, high esterification rate and high product yield.

Owner:SICHUAN SIPO CHEMICAL CO LTD

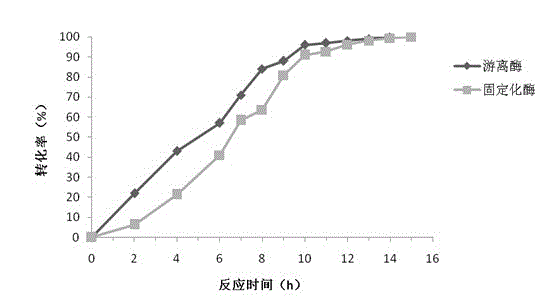

Co-immobilization glucose oxidase/catalase microspheres and application thereof in production of gluconic acid or gluconic salt

InactiveCN102943069AFacilitates covalent attachmentExtended service lifeChemical industryOn/in organic carrierMicrosphereCatalytic oxidation

The invention discloses co-immobilization glucose oxidase / catalase microspheres and application thereof in preparation of gluconic acid (salt) for catalytic oxidation of glucose. The co-immobilization glucose oxidase / the catalase microspheres can effectively promote covalent linkage of carriers and enzyme molecules, immobilization efficiency is improved greatly, service life of immobilization glucose oxidase (GOD) / catalase (CAT) is prolonged remarkably, the co-immobilization glucose oxidase / the catalase microspheres can be used repeatedly, are low in production cost, and facilitate sustainable development. Gluconic acid (salt) prepared by the co-immobilization glucose oxidase / the catalase microspheres is high in yield, reaction condition is temperate, a device is simple and easy to obtain, and the production method is environment-friendly.

Owner:BEIJING UNIV OF CHEM TECH

Cultivation method of scindapsus aureus hanging basket

ActiveCN101766112AImprove qualityEasy to viewAgriculture gas emission reductionCultivating equipmentsDirect visionPeat

The invention discloses a cultivation method of scindapsus aureus hanging basket. The method comprises that fine perlite, coir dust and peat are mixed completely to obtain seedling matrix, and the seedling matrix is packed separately. Scindapsus aureus long vine is cut to be cuttings and soaked into water with the temperature of 40 to 45 DEG C, after the cuttings are soaked for 10 to 15 minutes, then the cuttings are taken out and water accumulated on leaf surface of the cuttings is dried. The cuttings are soaked into water after being cut, then are transferred to a nursery bed. In the first to the tenth day after being cut, the temperature is maintained to be 20 to 32 DEG C, the illumination is less than 5000 Lux, the illumination is increased gradually after 10 days, the illumination can reach 20000 Lux after new roots are grown, until the plant shape is plumpy and matrix can not be seen by direct vision, the illumination is decreased to less than 10000 Lux, then the cuttings are cultured for 7 to 10 days and sold. In the invention, the quality of the scindapsus aureus hanging basket which is cultured by the cultivation method is good, the leaf surface is clean and lustrous and the ornamental is pretty good. The weight is light by using the soilless culture, the pesticide residual volume is low, the production mode is environmental friendly, and has high and stable yield.

Owner:GUANGZHOU GREEN SAIL AGRI

Phenol-formaldehyde resin of lignin and biomass oil in use for moulding plastic material, and preparation method

This invention discloses a method for preparing lignin bio-oil phenolic resin used as molding material. The method comprises: mixing phenol, lignin bio-oil, aldehyde and acid catalyst to obtain a reaction system, adjusting the pH value of the reaction system to 1.0-3.0 by changing the addition amount of the acid catalyst, heating to 75-85 deg.C at 0.5-2 deg.C / min, ending heating, reacting (exothermic reaction), boiling when the temperature is increased to 95-106 deg.C, refluxing, keeping the temperature for 0.5-4.5 h, and vacuum-dehydrating to obtain lignin bio-oil phenolic resin. The method utilizes bio-oil obtained by rapid pyrolysis of lignin to replace phenol in preparing phenolic resin, and molding material with the same performance as that of pure phenolic resin. The method has such advantages as abundant and inexpensive raw material, and is environmentally friendly.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

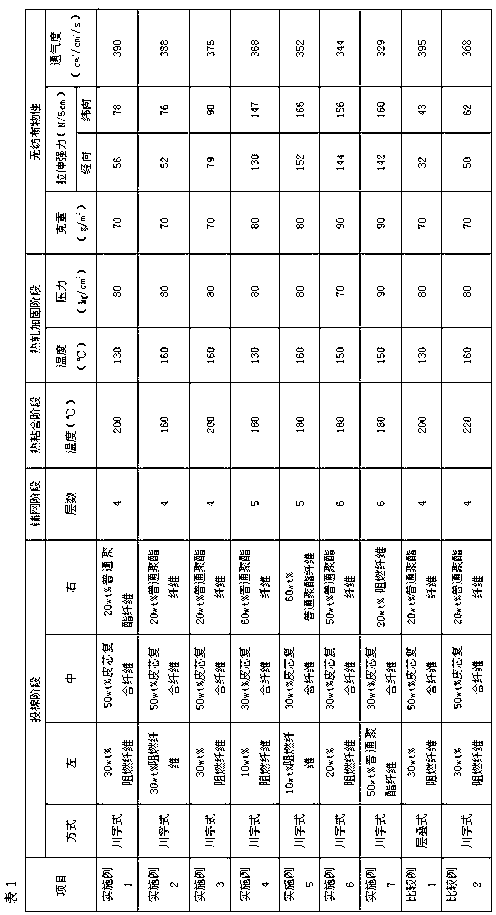

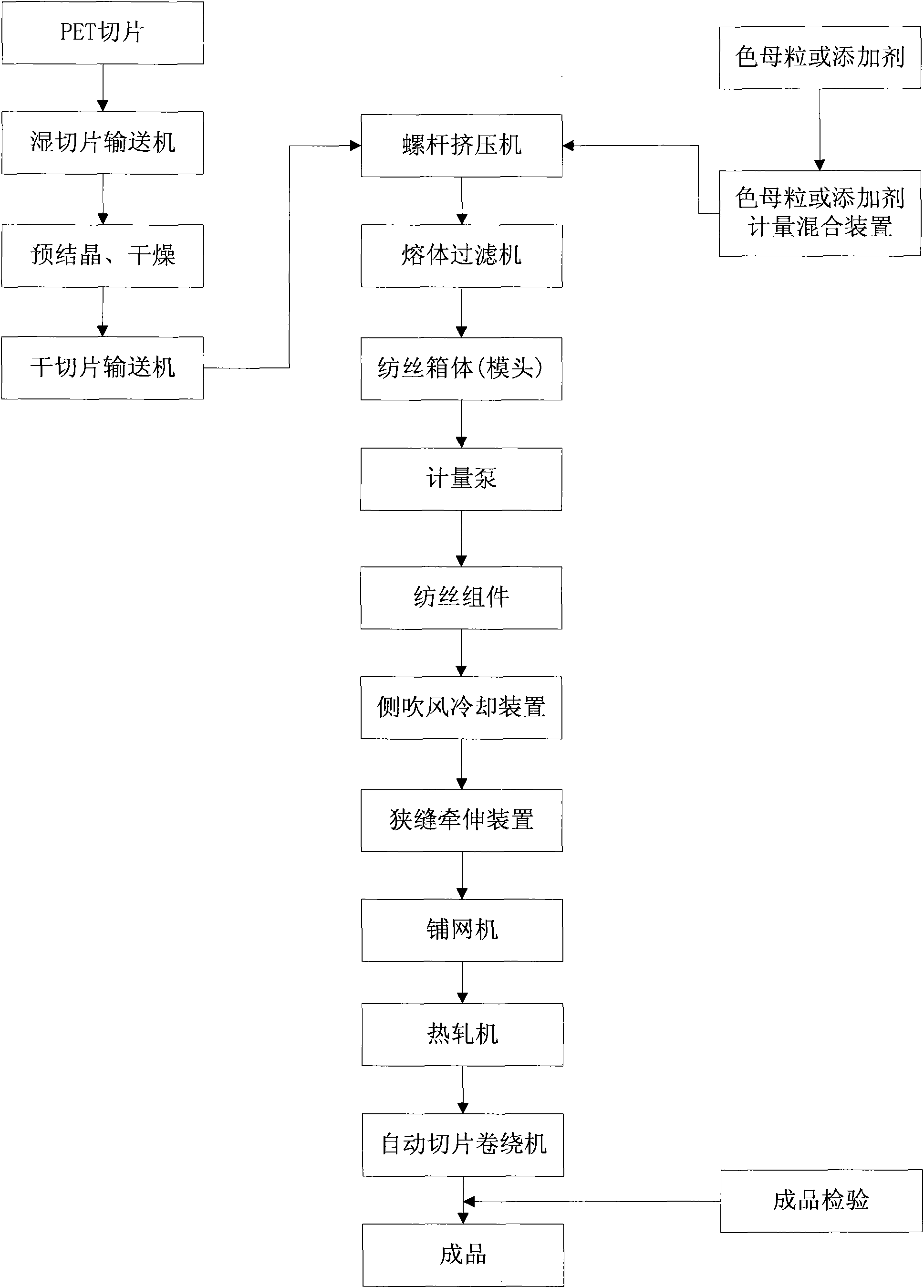

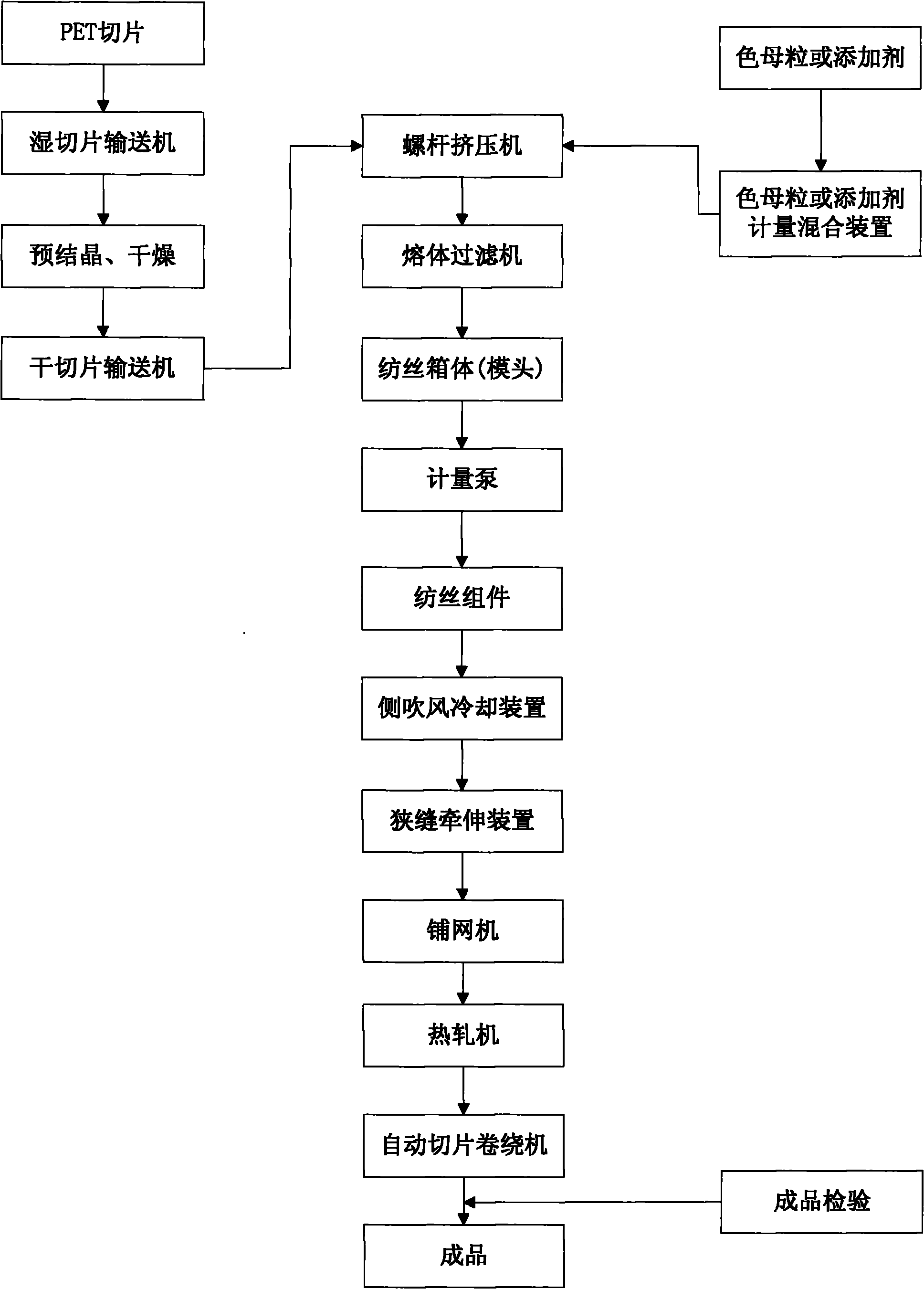

Production method of high strength heat bonding non-woven fabric

InactiveCN103173936AImprove flame retardant performanceImprove breathabilityNon-woven fabricsPolyesterCarding

The invention discloses a production method of high strength heat bonding non-woven fabric. The high strength heat bonding non-woven fabric comprises, by weight, 30-50% of skin-core complex fiber, 10-30% of fire resistant fiber and 20-60% of ordinary polyester fiber. Cotton dropping, opening, carding and net cross laying are conducted in a mode shaped like a Chinese character 'chuan'. Heat bonding and hot rolling strengthening are conducted on a formed fiber net through a hot air box and then the non-woven fabric is obtained. The manufactured non-woven fabric is high in strength and air permeability, long in service life and capable of being widely used in the field of air filtration.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

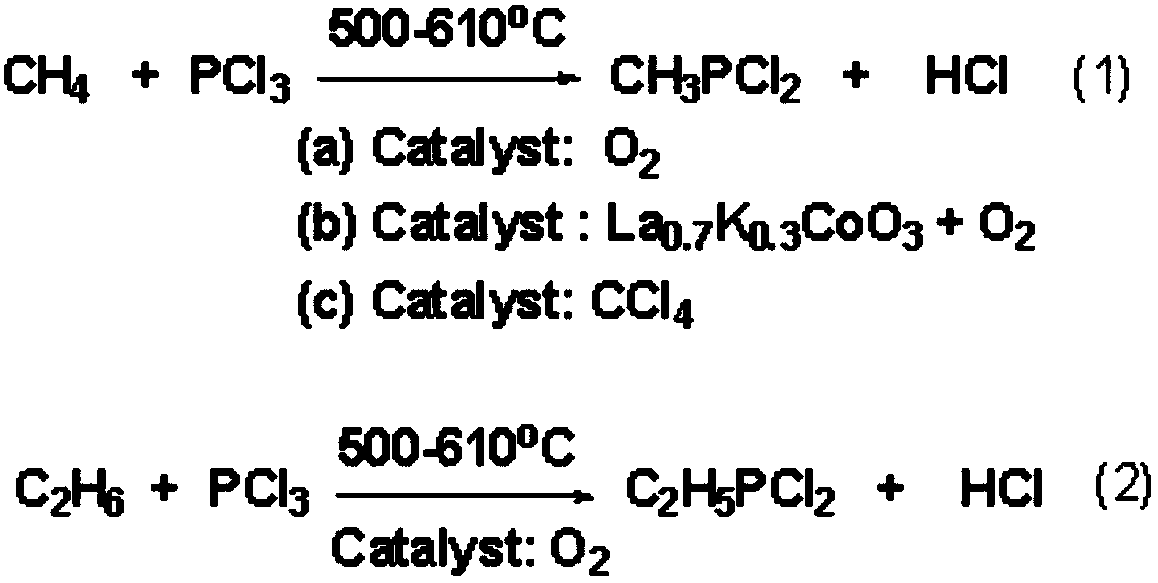

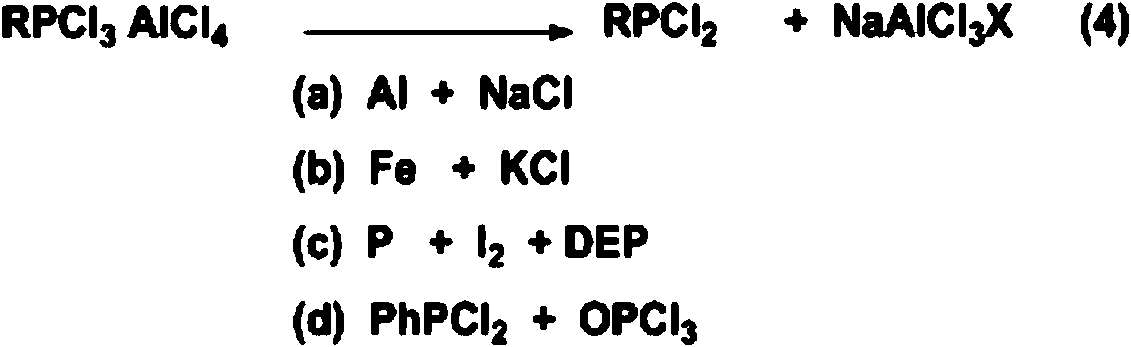

Method for producing alkyl phosphorus dichloride

ActiveCN108864190AOvercoming the large amount of three wastesOvercome costsGroup 5/15 element organic compoundsAlkaneChemical industry

The invention relates to the field of chemical industry and further relates to a production method of an organic phosphorus intermediate, and in particular relates to a method for producing alkyl phosphorus dichloride. The method comprises the following specific step: in the presence of a catalyst, enabling phosphorus trichloride and alkane to react in a tubular reactor under high temperature andhigh pressure, so as to generate the alkyl phosphorus dichloride, wherein the alkane is selected from one or two of methane and ethane and the catalyst is selected from one or two of chloroform and dichloromethane. The method provided by the invention has the advantages of low production cost, great industrial feasibility, measurable and controllable technological conditions, high reaction conversion rate and selectivity, good product quality and the like.

Owner:HEBEI VEYONG BIO CHEM

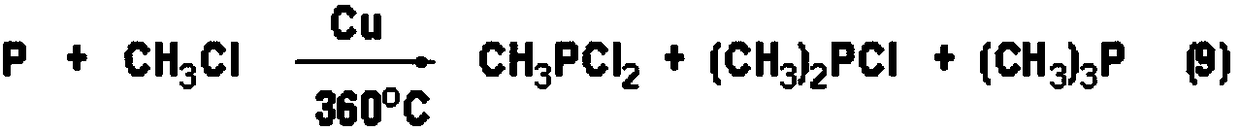

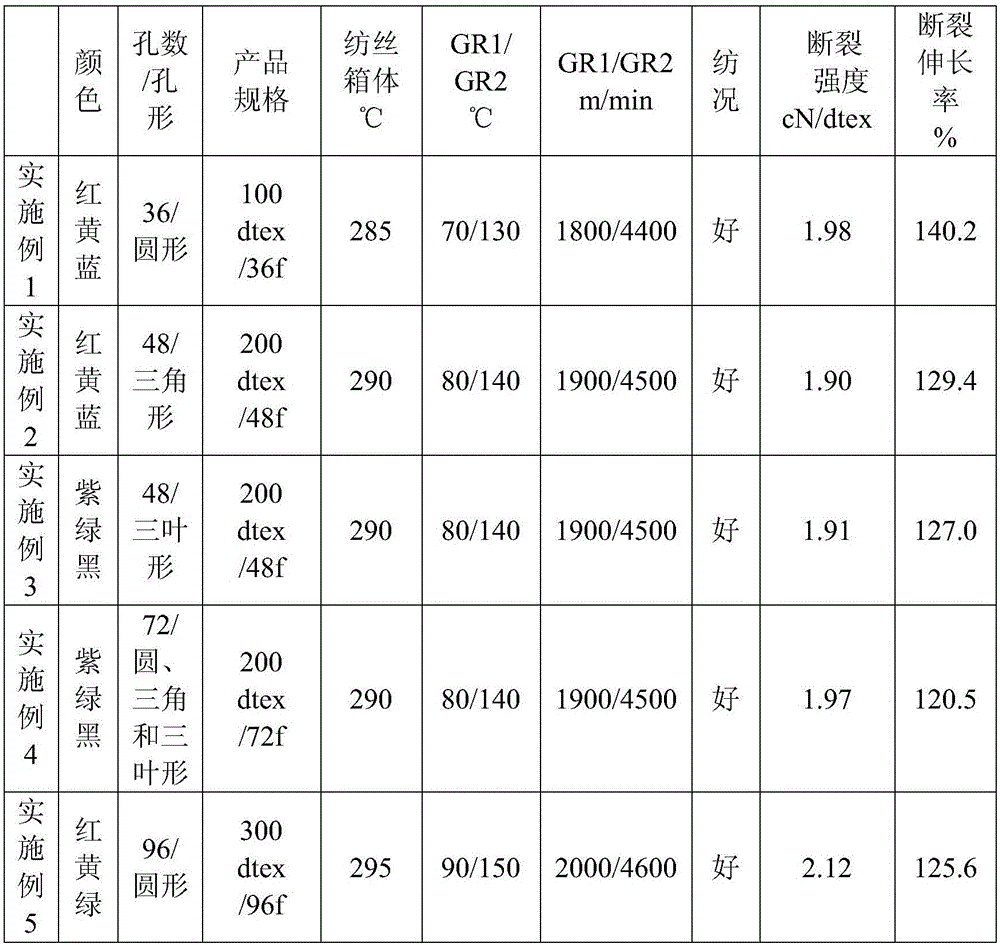

Processing technology of veneer multi-difference polyester fiber

InactiveCN105862148AShort production processImprove product qualitySpinnerette packsArtificial filament heat treatmentMelt extrusionHeat setting

The invention relates to a processing technology of a veneer multi-difference polyester fiber. The processing technology of the veneer multi-difference polyester fiber belongs to the technical field of filament yarn generation. The processing technology comprises the following steps of adopting a normal polyester as a raw material; after melting and extruding through different screw extruders respectively, entering a three-component spinning component; spraying out from a same spinneret plate; carrying out a one-step spinning method including cooling, oiling, drafting, heat setting and winding to obtain the multi-difference polyester fiber. The processing technology of the veneer multi-difference polyester fiber provided by the invention can be applied to the processing of fiber forming and fabric processing, and has the advantages of short technological process, high product quality, low cost, and no need of post-dyeing.

Owner:ZHEJIANG GUXIANDAO INC CO

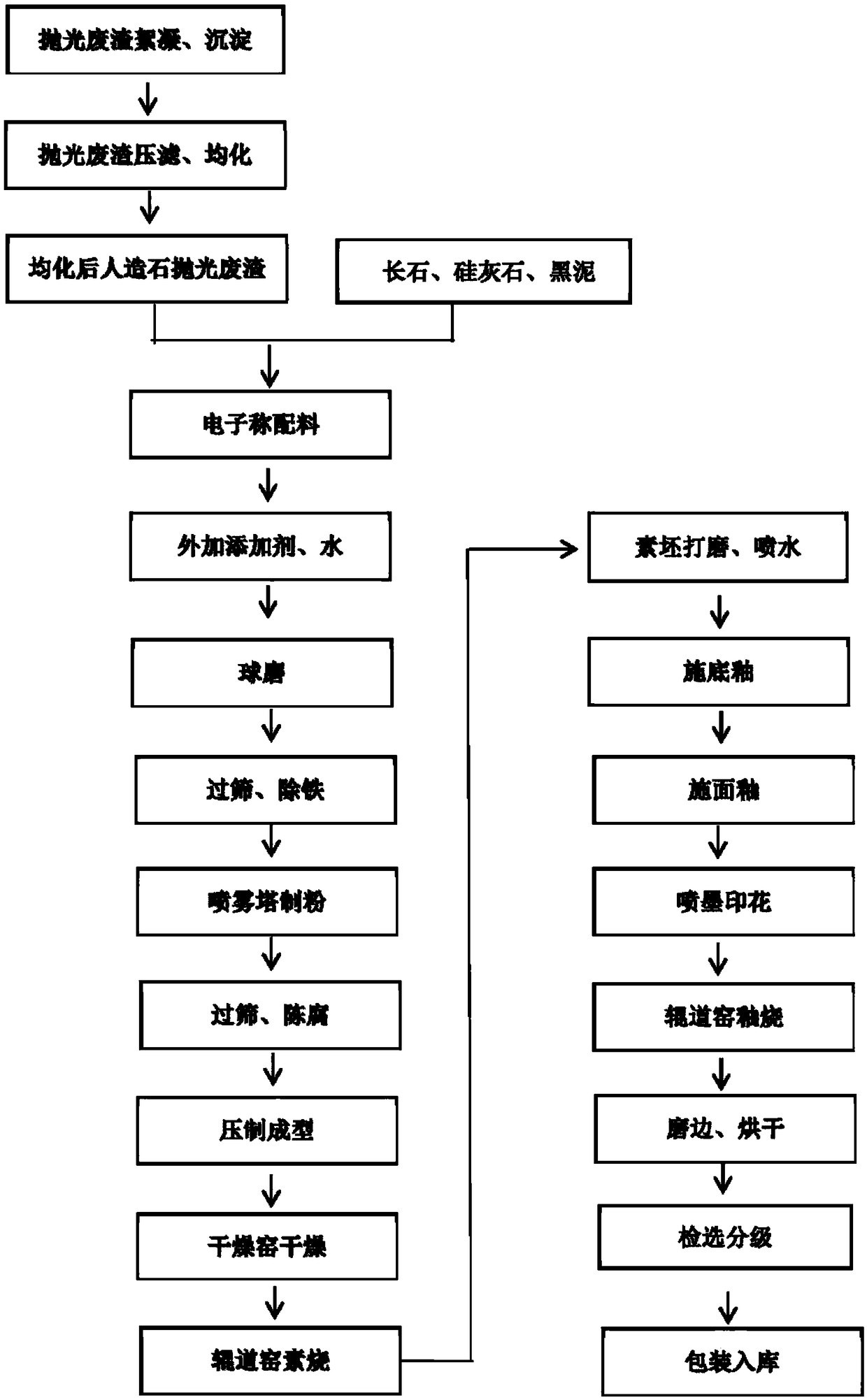

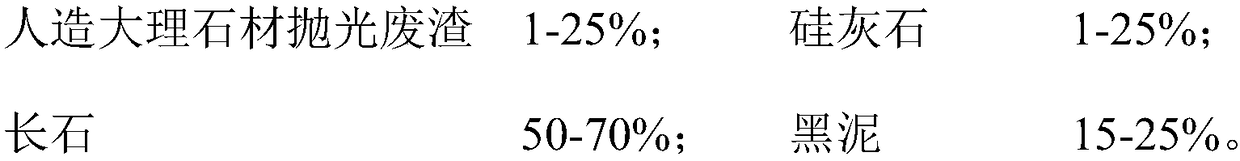

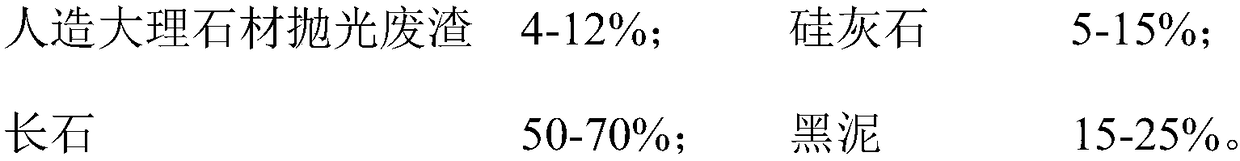

Artificial marble polishing waste residue-based ceramic glazed tiles and preparation method thereof

The invention discloses artificial marble polishing waste residue-based ceramic glazed tiles which are prepared from the following main components in percentage by weight: 1 to 25 percent of artificial marble polishing waste residues, 1 to 25 percent of wollastonite, 50 to 70 percent of feldspar and 15 to 25 percent of black mud. The ceramic glazed tiles are prepared from the artificial marble polishing waste residues serving as the raw materials; long-term pollution to the environment due to the artificial marble polishing waste residues treated in a landfill treatment manner can be completely avoided; meanwhile, by the use of the characteristic that the CaCO3 content in the artificial marble polishing waste residues is high, the artificial marble polishing waste residues can completely replace conventional limestone in the formula of ceramic glazed tile green bodies, so that the cost of the formula can be reduced, and wastes can be turned into treasures. The invention further discloses a preparation method of the artificial marble polishing waste residue-based ceramic glazed tiles. The preparation method is simple in flow and convenient to operate, can realize commercial production, and has an extremely application prospect.

Owner:YANGXI BODE PRECISION IND BUILDING MATERIAL CO LTD

Lignin modified phenol furfural resin for moulding material and preparation method thereof

The invention discloses a making method of modified furfural phenol resin of lignin of mould plastic with molecular weight at 1000-11000 and softening point temperature at 106-135. 5 deg. c, which comprises the following steps: blending phenol and alkaline catalyst; heating to 140-200 deg. c; dripping furfural into the reacting system to obtain the furfural phenol resin; adding lignin to react under 150-200 deg. c for 4-8h until water is not released; decompressing; distilling; extracting into vacuum; obtaining the product. The invention uses rich lignin to replace phenol to prepare phenol resin, which reduces cost obviously.

Owner:JIANGSU QIANGLIN BIO ENERGY

Preparation method of dibutoxy methane

ActiveCN102241571AModerate dosageEasy to separateOrganic chemistryOrganic compound preparationPtru catalystSolid acid

The invention relates to a preparation method of dibutoxy methane. The preparation method is characterized by comprising the following step of: undergoing a normal-pressure gap type aldol condensation reaction on formaldehyde and n-butyl alcohol under the action of a solid acid catalyst by taking n-butyl alcohol as an azeotropic dehydrating agent in a reactor with a stirrer, a condenser and a water knockout vessel to obtain the dibutoxy methane, wherein the molar ratio of the formaldehyde to the n-butyl alcohol is 1:2-1:4, the concentration of a formaldehyde solution is more than or equal to 25 percent by mass, the reaction temperature is 60-140 DEG C, the reaction time is 0.5-8 hours, the solid catalyst is an HZSM-5 molecular sieve or an active carbon immobilized sulfuric acid catalyst, the active ingredient of the active carbon immobilized sulfuric acid catalyst is sulfuric acid, the immobilized quantity of acid is 15-25 percent by mass, and the using amount of the solid acid catalyst is 0.1-8 percent of the total mass of reactants. The method has the advantages of easiness in separation of the solid acid catalyst from a product, small corrosion to equipment and catalyst recyclability, and is a novel, efficient and environmentally-friendly production method.

Owner:NANJING FORESTRY UNIV +1

Method of producing high-pure sulfur

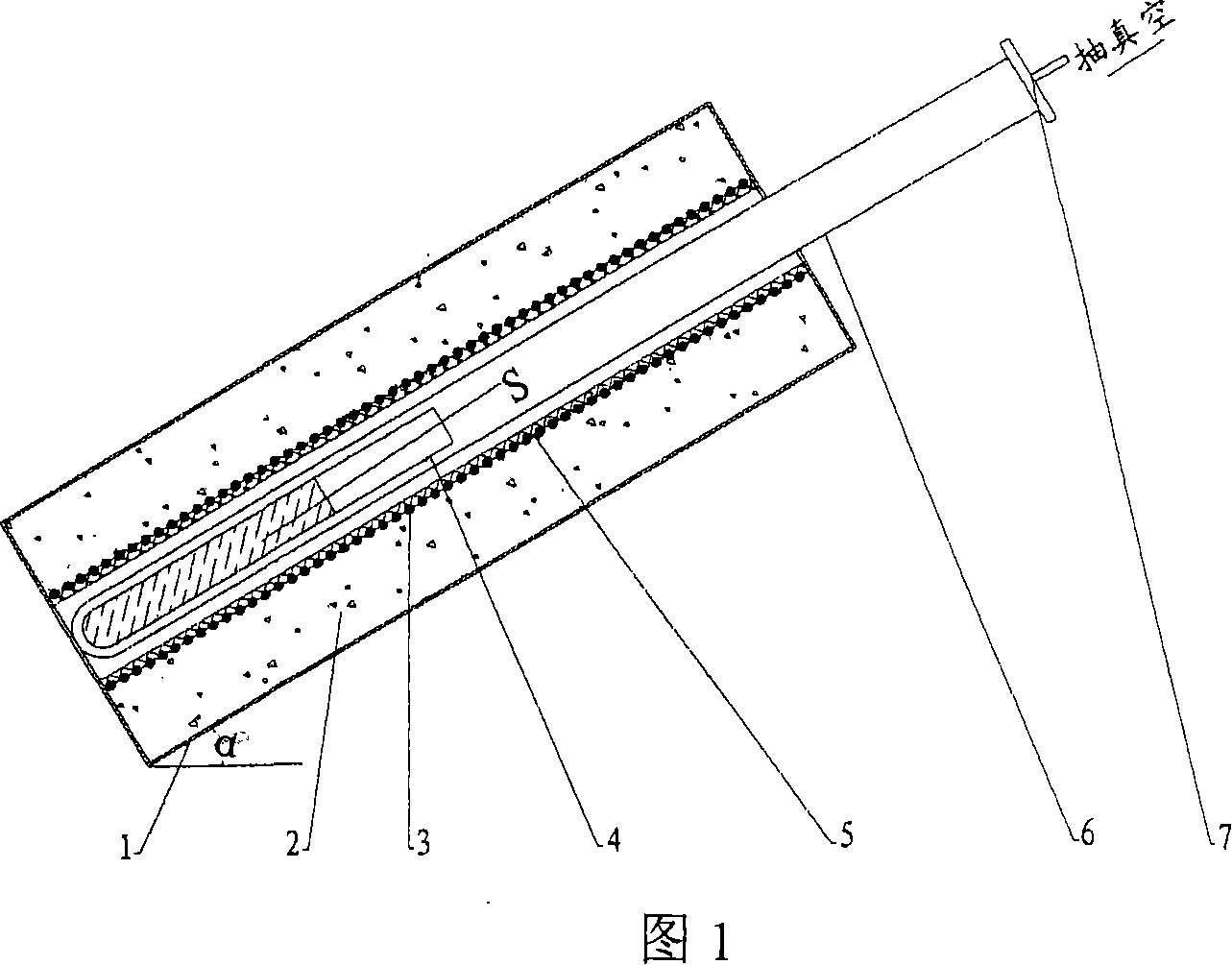

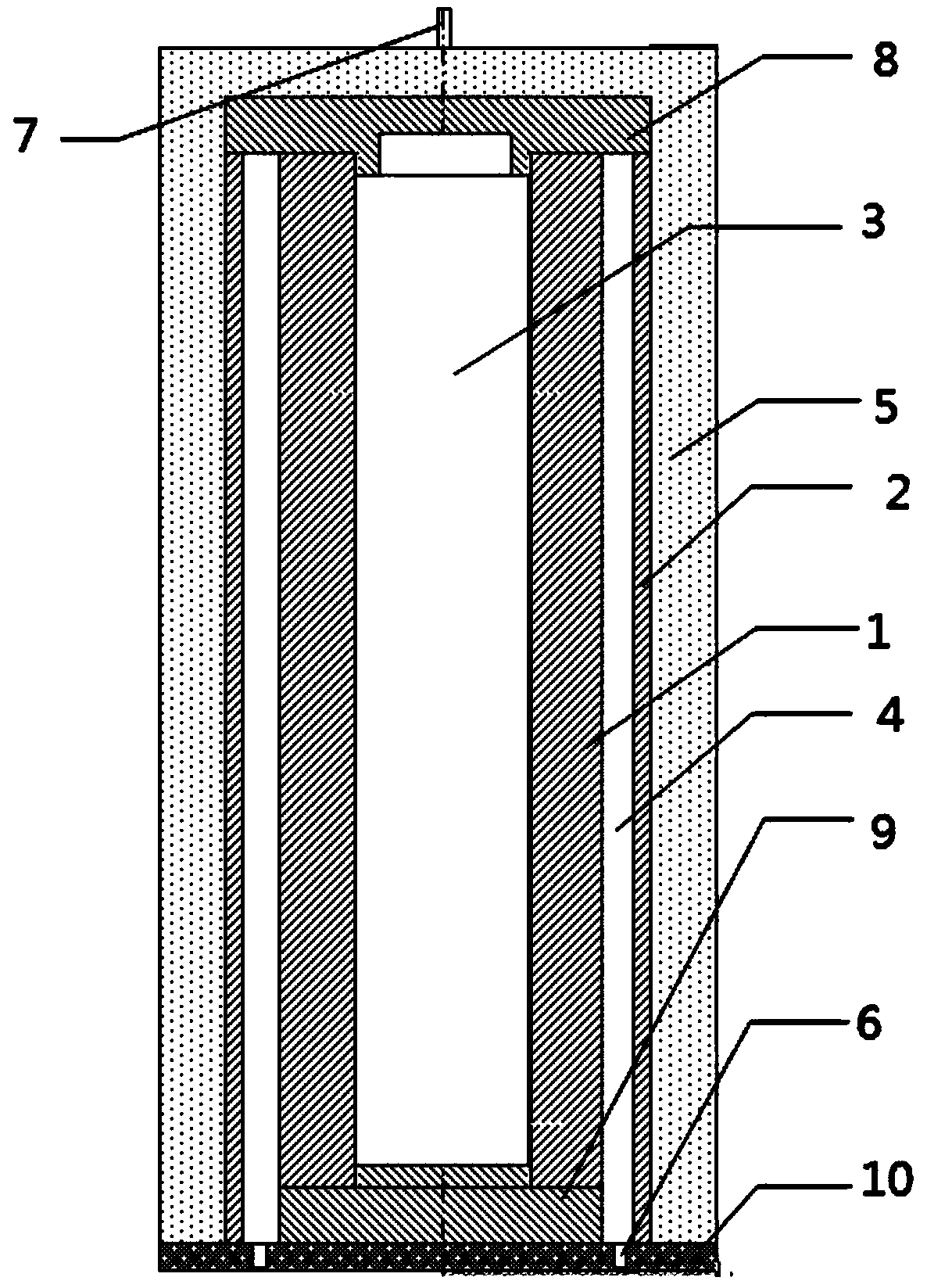

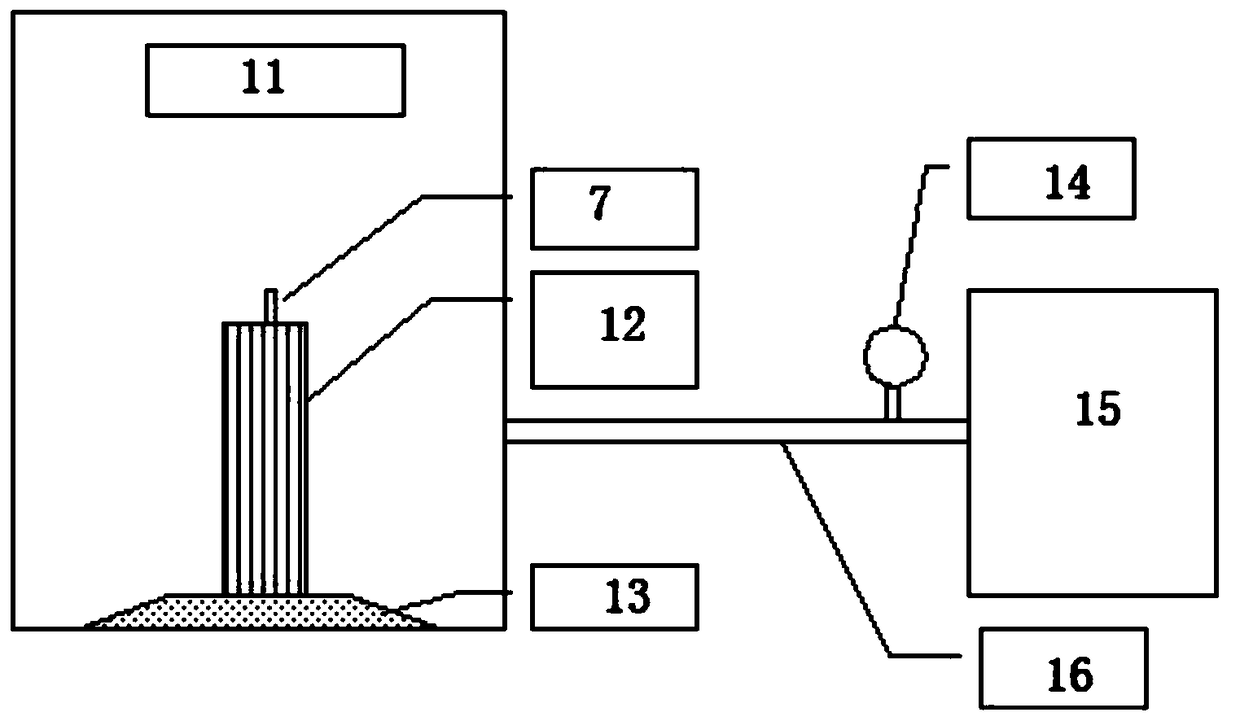

InactiveCN101125640AProduction method safetyProduction methods are environmentally friendlySulfur preparation/purificationInsulation layerVacuum pressure

The invention provides a producing method of high pure sulfur, which is characterized in filling 3 to 4 weight parts of 99 wt percent sulfur into a pot(4), then putting the pot with 99 wt percent sulfur into a quartz tube(6) which is put into a vacuum sublimation heating furnace(1). Wherein, the heating furnace is internally provided with an insulation layer(2), a heating wire(3), a pot(4), a furnace lining(5), a quartz tube(6) and a vacuum pressure cover(7), whose mounting obliquity Alpha is 30 to 45 degrees; moreover, one end of the quartz tube is sealed with the vacuum pressure cover(7) which is provided with an extraction vacuum hole; once the vacuum is extracted to 1 multiplies by 10-3 to 9 multiplies by 10-3Pa, the heating system of the vacuum sublimation heating furnace is opened, after that, waiting till the temperature of the heating furnace is up to 135 to 145 DEG C, the vacuum sublimation purifying is performed for 3.5 to 4.5 hours; after that, the vacuum and heating system is closed for cooling and discharging, thus, obtaining 2.3 to 3.0 weight parts of 5N sulfur product and having a yield of 75 to 78 percent.

Owner:四川鑫龙碲业科技开发有限责任公司

Economical, environment-friendly and efficient desulfurization refining slag system and preparation method

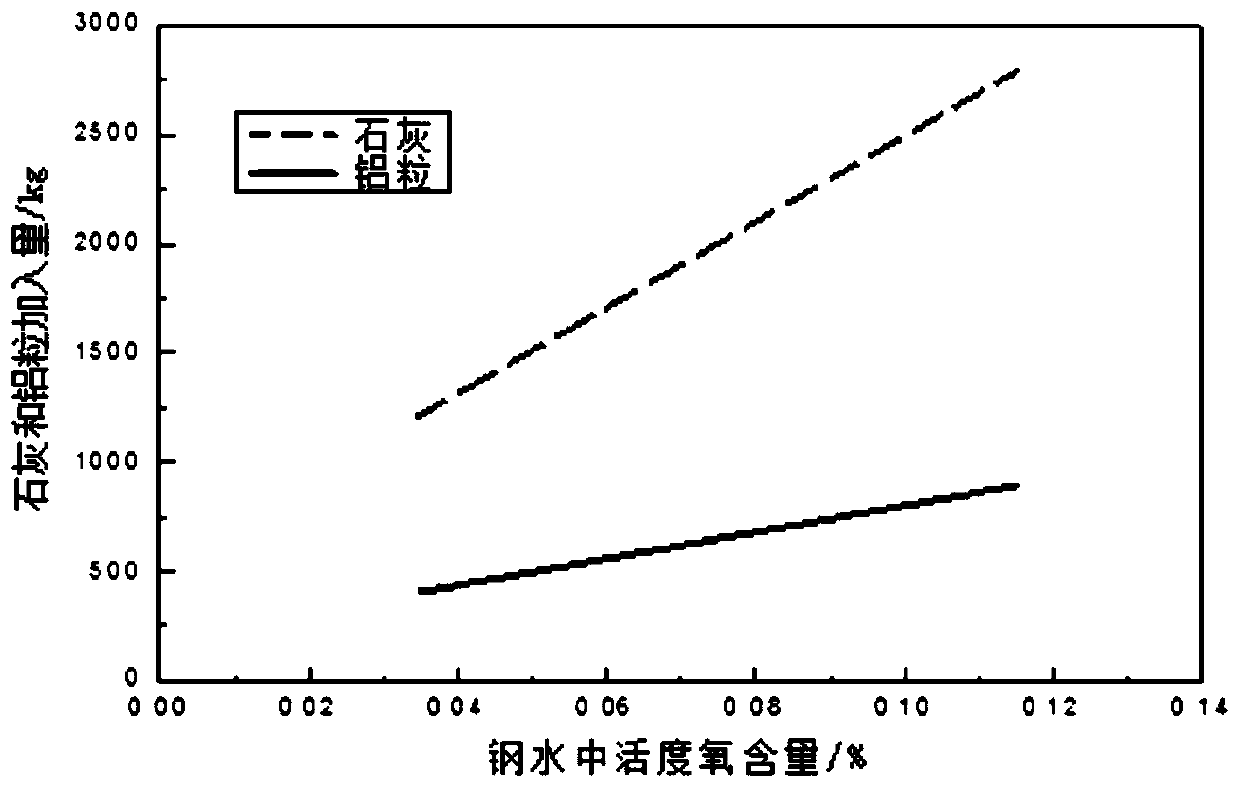

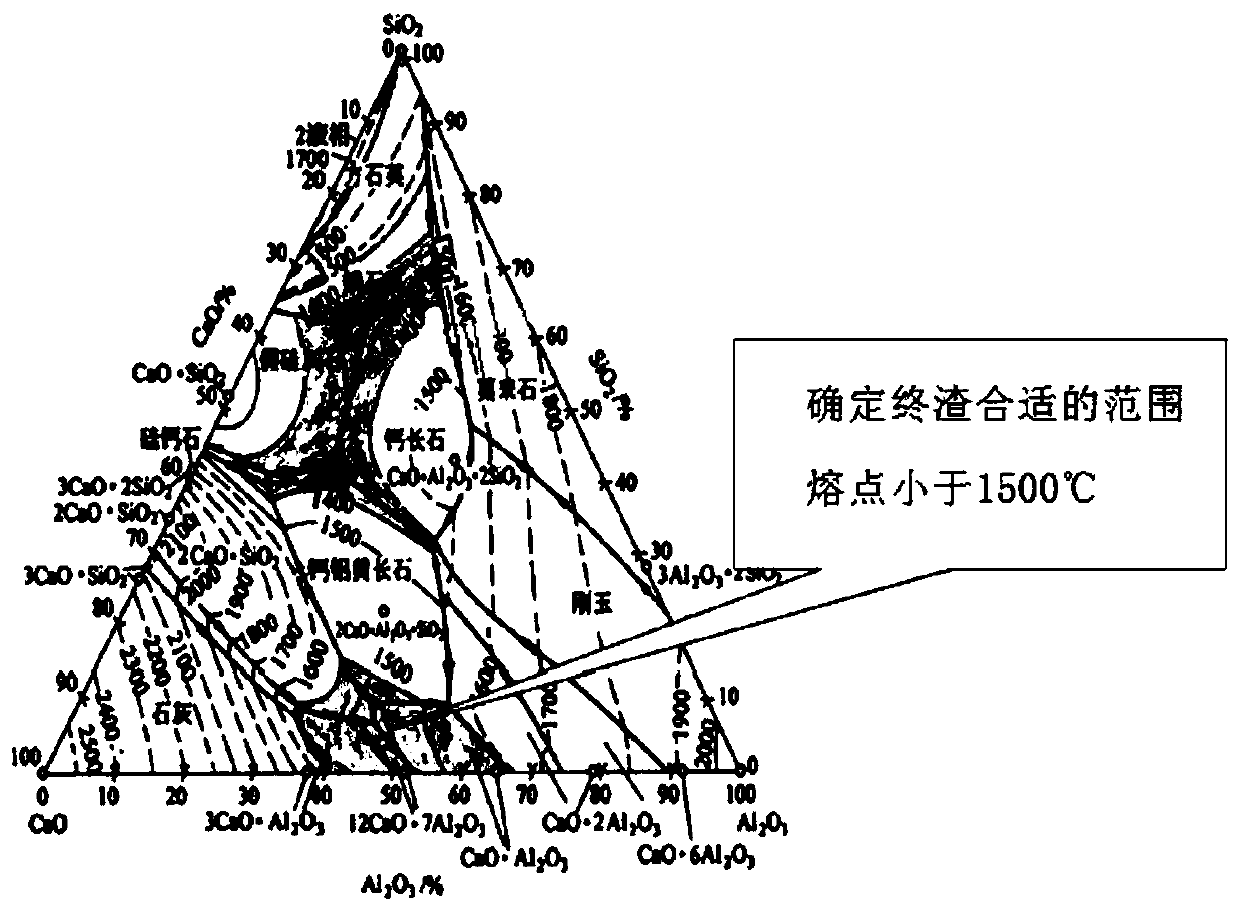

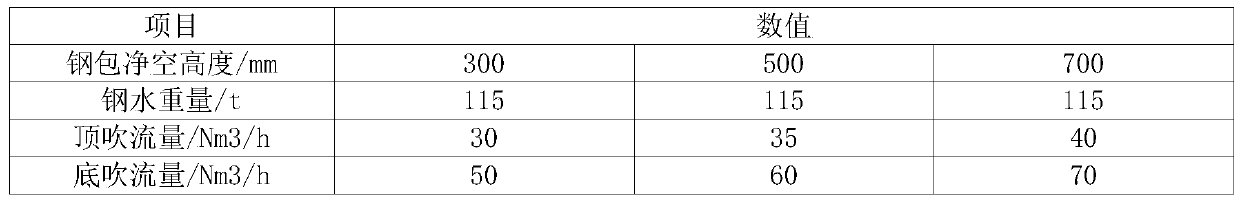

InactiveCN111057817AReduce oxygen contentReduce sulfur contentProcess efficiency improvementRefining (metallurgy)Slag

The invention belongs to the technical field of steel and iron metallurgy, and in particular, relates to an economical, environment-friendly and efficient desulfurization refining slag system and a preparation method. The slag system comprises raw materials of lime, aluminum particles for deoxidation, light-burned dolomite and bauxite; and the ratios of the raw materials are designed according tothe following refining slag composition: 55-60 wt% of CaO, 7-12 wt% of SiO2, 28-33% of Al2O3, 4-8 wt% of MgO, and 1.8 of CaO to Al2O3. The preparation method of the slag system comprises four steps ofconverter tapping and lime and aluminum particle adding, slag feeding, argon blowing in an alloy fine adjustment station and LF refining furnace slagging. In the converter tapping process, the designed slag system raw materials are fed to form the refining desulfurization slag; and through the gas supply system of top / bottom compound argon blowing of the alloy fine adjustment station, the oxygencontent and the sulfur content of molten steel before LF furnace refining and the content of FeO+MnO in top slag are reduced.

Owner:TIANJIN TIANGANG UNITED SPECIAL STEEL CO LTD

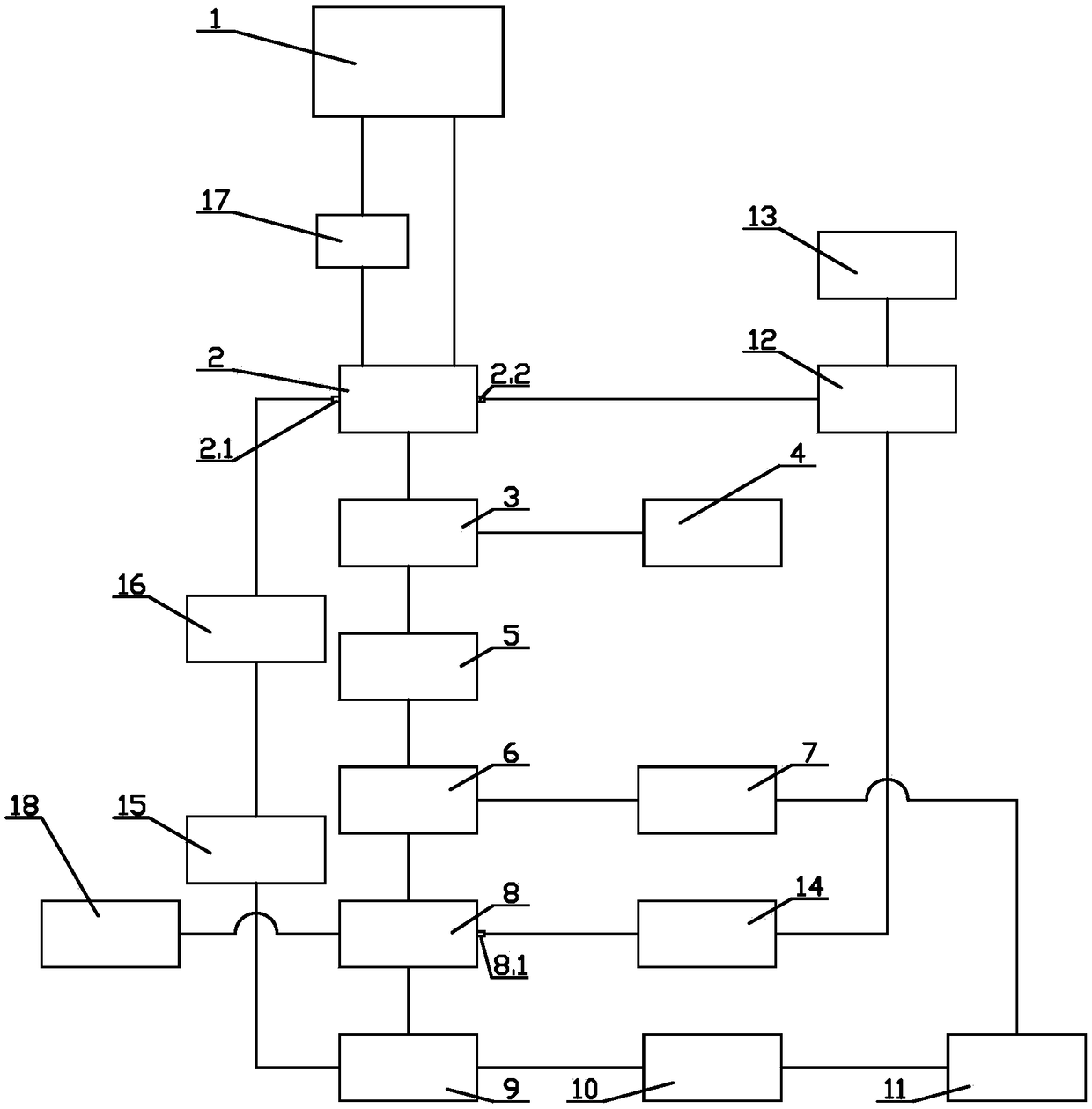

Treatment system and treatment method for wastewater containing low-concentration sulfuric acid

ActiveCN108569812ASimple structureEasy to implementTreatment involving filtrationAmmonium sulfatesEnvironmental resistanceDecomposition

The invention discloses a treatment system for wastewater containing low-concentration sulfuric acid. The treatment system comprises a collection tank, a neutralization barrel, a first filter press, asewage treatment system, a first conveyor belt, a pulping tank, a liquid storage tank, a double decomposition reaction barrel, a second filter press, a cooling crystallizer and a centrifugal machine.The treatment system has the beneficial effects that the structure is simple and easy to implement; evaporation and concentration of an evaporator are avoided, the production cost of ammonium sulfateis reduced, and the system is suitable for treatment of wastewater containing sulfuric acid of any concentration; at the same time, the energy consumption is low, the method is simple, and the treatment efficiency is high; the production method is environmentally friendly; sulfuric acid in wastewater is recovered and separated from the wastewater, so as to create favorable conditions for the biochemical treatment of the wastewater.

Owner:乌海青石化学有限公司

Industrial process of producing xylanase with Aspergillus usamii

InactiveCN101067129AImplement solid-state fermentation industrial productionProduction methods are environmentally friendlyFungiMicroorganism based processesInorganic saltsExoxylanase activity

The industrial process of producing xylanase with Aspergillus usamii belongs to the field of enzyme engineering technology. In the industrial process of producing xylanase, bagasse, corn cob, bran and other crop leftovers are used as the fermenting base material, and proper amount of inorganic salt, surfactant, water, etc are added for solid fermentation in a 30M3 solid fermenting tank with Aspergillus usamii E001 strain. The mature fermented material is stoved with hot blast at 45-50 deg.c to obtain xylanase product possessing xylanase activity of 7783-9616 IU / g. The present invention provides also the recipe of fermenting culture medium and the fermenting conditions.

Owner:JIANGNAN UNIV

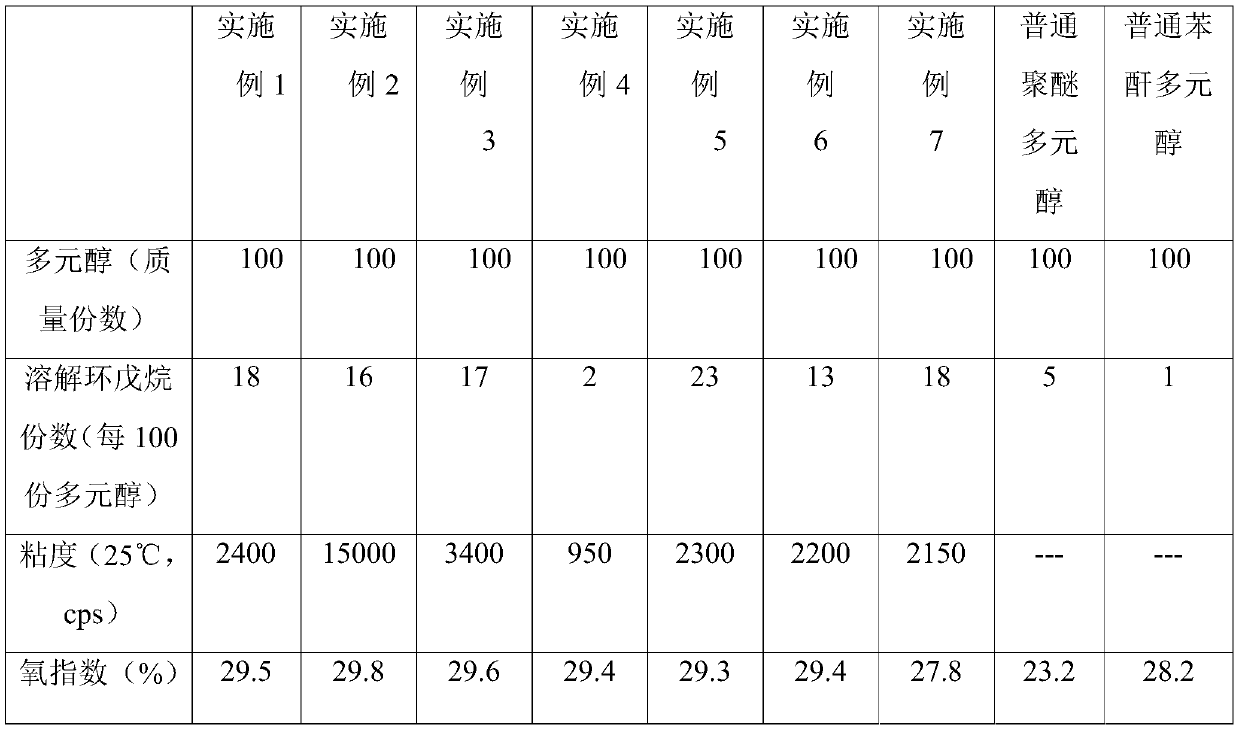

High-flame-retardant polyester polyol compatible with cyclopentane and preparation method of high-flame-retardant polyester polyol

The invention relates to high-flame-retardant polyester polyol compatible with cyclopentane and a preparation method of the high-flame-retardant polyester polyol, and belongs to the technical field ofpolyester polyol. The preparation method comprises the following steps: carrying out esterification reaction and transesterification reaction on a mixture of adipic acid, an aromatic dibasic acid andan aromatic dibasic acid anhydride and a mixture of a dihydric alcohol and a trihydric alcohol which are used as raw materials, adding vegetable oil to carry out polycondensation reaction, and addinga flame retardant to obtain the high-flame-retardancy polyester polyol compatible with cyclopentane. The high-flame-retardant polyester polyol compatible with cyclopentane, disclosed by the invention, not only can be mutually dissolved with cyclopentane, but also has relatively low viscosity, good flexibility and high operability; the invention also provides the preparation method which is simpleand feasible and is beneficial to industrial production.

Owner:SHANDONG INOV POLYURETHANE

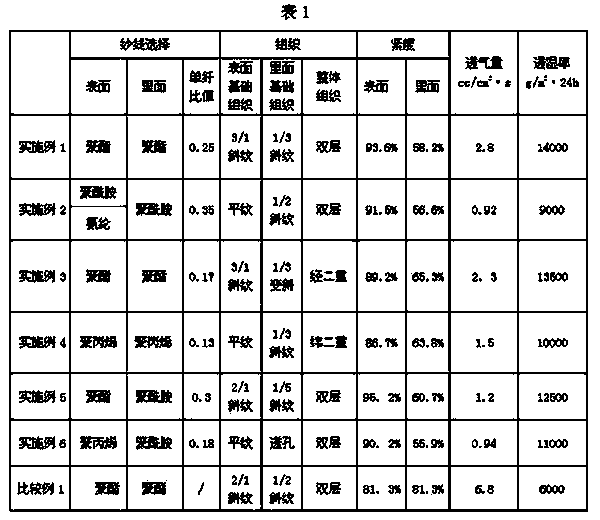

Windproof breathable fabric

The invention discloses windproof breathable fabric. The surface of the fabric is made of fine fibers, the inner layer of the fabric is made of coarse fibers, the structure of the fabric can be a warp-backed weave or a weft-backed weave or a double-layer weave, the surface tightness ranges from 85 percent to 100 percent, the inner layer tightness ranges from 55 percent to 70 percent, and the single fiber fineness ratio of the fine fibers to the coarse fibers ranges from 0.1 to 0.8. The air permeability is measured to be less than or equal to 3cc / cm<2> / s according to the standards of JISL1096, and the moisture permeability is measured to be 8000-15000g / m<2> / 24h according to the standards of GB / T12704.2. The fabric is low in production cost, good in moisture permeability, good in windproof performance, soft in hand feel, stiff and smooth, good in resilience and particularly suitable for manufacturing of high-end casual coat products.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Preparation method of 2-amino-5- chlorobenzophenone

InactiveCN107698453AHigh yieldEmission reductionOrganic chemistryOrganic compound preparationPalladium on carbonAmmonium formate

The invention discloses a preparation method of 2-amino-5- chlorobenzophenone. The preparation method comprises the following steps: (1) mixing ethanol with the mass concentration of 95%, sodium hydroxide, parachloronitrobenzene and benzyl cyanide, mixing the mixture and performing ultrasonic oscillation on the mixture at the temperature of 25-35 DEG C for 1h; (2) performing microwave heating on aproduct obtained in step (1) for 10min, adding water in a system, filtering, washing filter residues with methanol three times and drying the filter residues, so as to obtain 5-chlorine-3-phenyl-2, 1-benzisoxazole; (3) mixing methanol, the 5-chlorine-3-phenyl-2, 1-benzisoxazole, a palladium carbon catalyst and ammonium formate, heating and refluxing for 2h, cooling to room temperature, filteringand performing vacuum drying on the filter residues. The method provided by the invention is high in product yield, short in reaction time and less in waste discharge and is environmentally friendly.

Owner:SHAANXI JUJIEHAN CHEM CO LTD

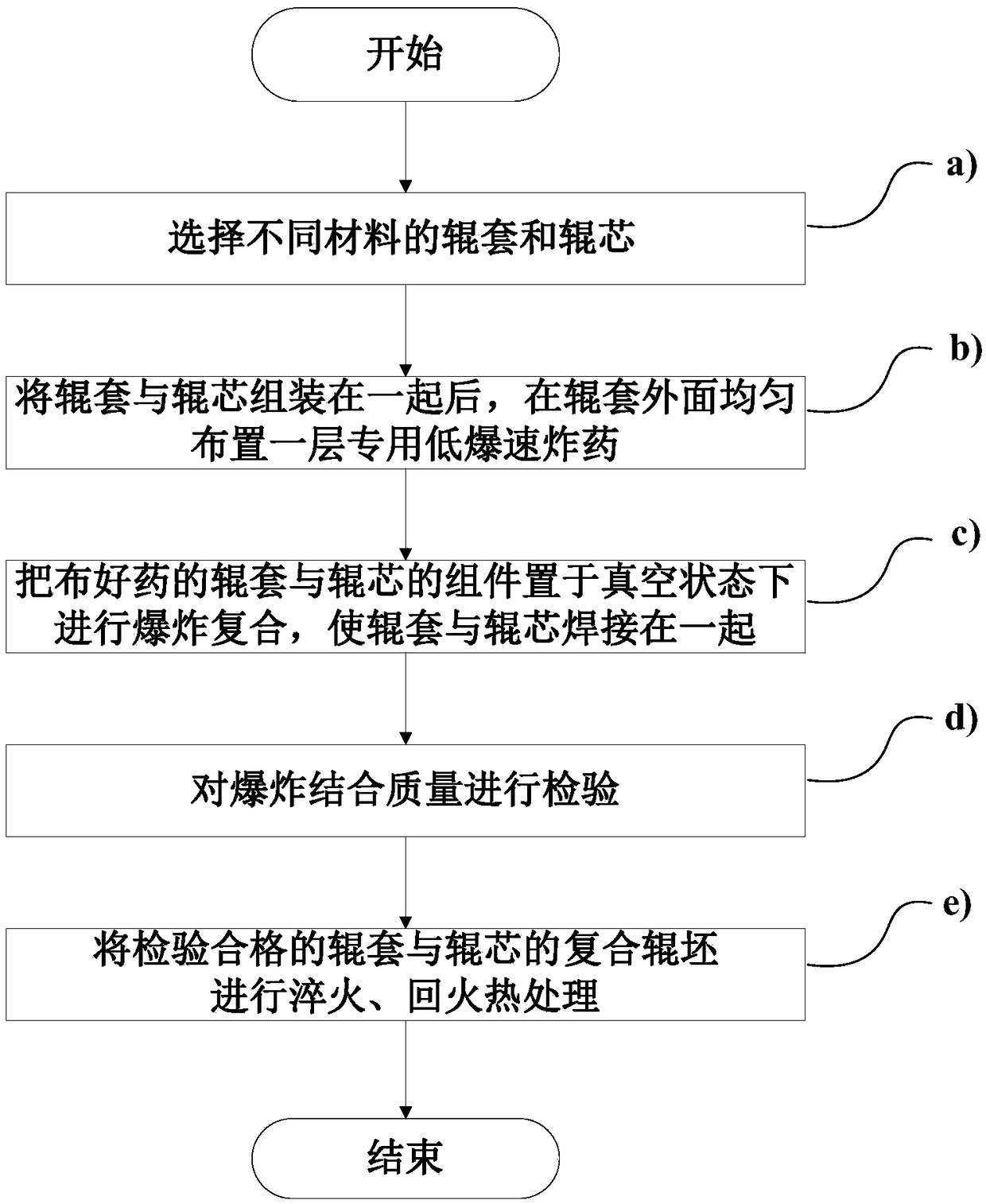

Method of manufacturing composite roller by use of vacuum-state explosive welding technology

InactiveCN108608106AUniform performanceGood hardness consistencyNon-electric welding apparatusHardnessPulp and paper industry

The invention discloses a method of manufacturing a composite roller by use of a vacuum-state explosive welding technology. The method comprises the steps that (a) a roller sleeve and a roller core are selected, wherein the roller sleeve and the roller core are made of different materials; (b) after the roller sleeve and the roller core are assembled together, special low-detonation-velocity explosives are uniformly arranged on the exterior of the roller sleeve; (c) an assembly which is formed by the roller sleeve and the roller core and processed by explosive arrangement is put in a vacuum state to be subjected to explosion composition, and the roller sleeve and the roller core can be welded together, so that a composite roller blank is formed; (d) the explosion composition quality is inspected; and (e) quenching and tempering thermal treatment are conducted on the composite roller blank which passes inspection and is formed by the roller sleeve and the roller core. Compared with a roller build up welding processing method, the composite roller manufactured by use of the vacuum-state explosive welding technology has the advantages that the processing efficiency can be improved, the cost can be reduced, the performance and the surface hardness uniformity of the roller can be improved, and the service life of the roller can be prolonged. The method of manufacturing the compositeroller by use of the vacuum-state explosive welding technology can be used for manufacturing various rollers such as continuous casting rollers, laminar flow cooling rollers and clamping rollers.

Owner:TAIYUAN IRON & STEEL GROUP

Flame-retardant and efficient air filter paper

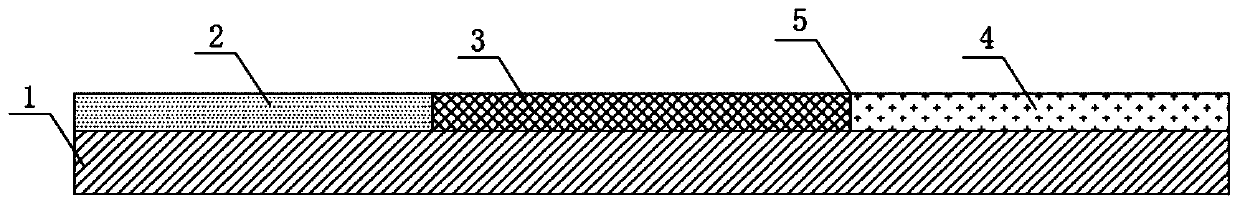

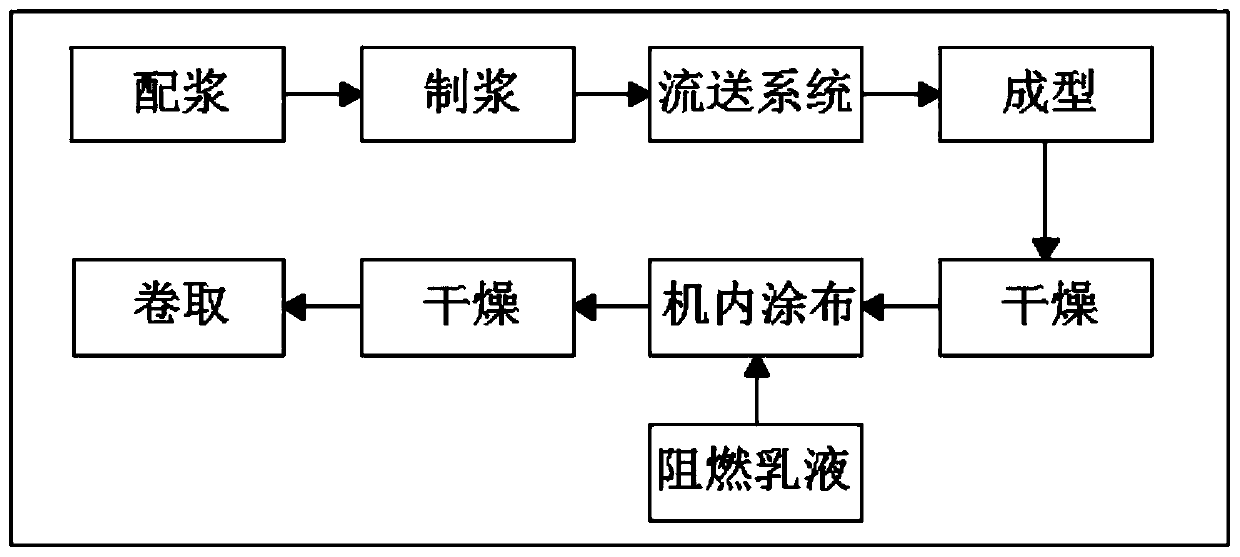

InactiveCN111254747AImprove flame retardant performanceImprove filtering effectNatural cellulose pulp/paperWater-repelling agents additionAir filtrationPolymer science

The invention discloses flame-retardant and efficient air filter paper, which comprises a raw paper sheet, a flame retardant emulsion; wherein the flame-retardant emulsion comprises phenolic resin glue, a hydrosol film and a flame retardant; wherein the flame-retardant emulsion is coated on the surface of a raw paper sheet; the invention can provide a production mode of the flame-retardant filterpaper, has the advantages of favorable flame retardancy, excellent filter performance and environment friendliness, can continuously and effectively keep flame retardancy, is not easy to absorb moisture, and retains higher dust holding performance.

Owner:SHANDONG RENFENG SPECIAL MATERIALS

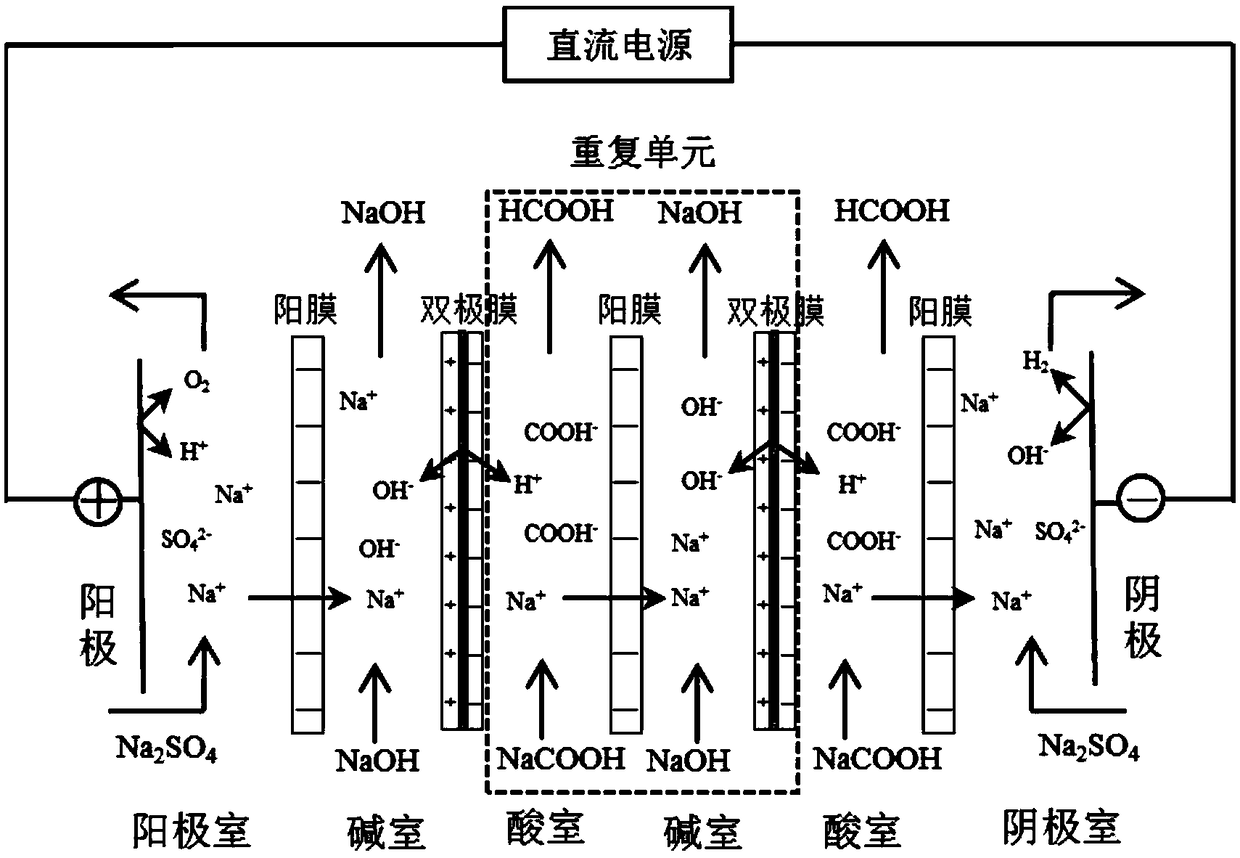

Method for preparing formic acid by bipolar membrane electrodialysis

InactiveCN108689827AIncrease added valueInhibit productionPreparation from carboxylic acid saltsSodium sulfateReagent

The invention discloses a method for preparing formic acid by bipolar membrane electrodialysis. The method is characterized in that sodium formic acid is converted into the formic acid by bipolar membrane electrodialysis, and the byproduct of sodium hydroxide with high added value is obtained and is recycled for the previous procedures; the content of sodium ions in the sodium formic acid is reduced to be lower than 0.05mol / L in the process, and the conversion rate reaches 98% or above. The preparation method has the advantages that the operation is simple, the consumption of any chemical reagent is avoided, and the consumption of sulfuric acid and the production of byproduct of sodium sulfate in the traditional technology are avoided; when the formic acid is prepared by bipolar membrane electrodialysis, the economic, green and environment-friendly effects are realized, and the important industrialized application value is realized.

Owner:HEFEI CHEMJOY POLYMER MATERIALS CO LTD

Method for preparing OBSC (4,4'-oxo-bis-benzenesulfonyl chloride) from basic chemical raw materials

InactiveCN104072393ALow costAvoid raw material consumption and waste water dischargeSulfonic acid preparationDiphenyl etherSulfur dioxide

The invention discloses a method for preparing OBSC (4,4'-oxo-bis-benzenesulfonyl chloride) from basic chemical raw materials, which comprises the following steps: (1) irradiating chlorine gas in light under the catalytic action of iron trichloride to crack into chlorine free radicals; (2) combusting sulfur in air to prepare sulfur dioxide gas; (3) adding diphenyl ether into a reaction kettle, introducing the chlorine gas treated by the step (1) and the sulfur dioxide gas prepared in the step (2) into the reaction kettle, reacting with the diphenyl ether at 55-90 DEG C for 3-5 hours, and reacting at 30-60 DEG C for 2-4 hours; and (4) introducing chlorine gas into the reaction kettle, reacting at 35-50 DEG C, stopping introducing the chlorine gas when the oxidation-reduction potential suddenly increases, and continuing the reaction at 35-50 DEG C for 1-3 hours, thereby obtaining the OBSC. The product prepared by the method has the advantages of lower production cost, high yield, high purity and no generation of waste liquids, and has higher yield and purity than that of the traditional preparation method.

Owner:SHANDONG TIANYI CHEM

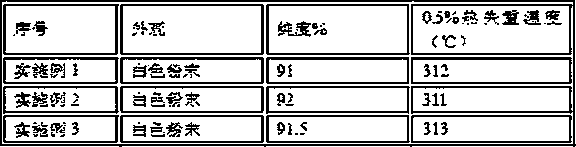

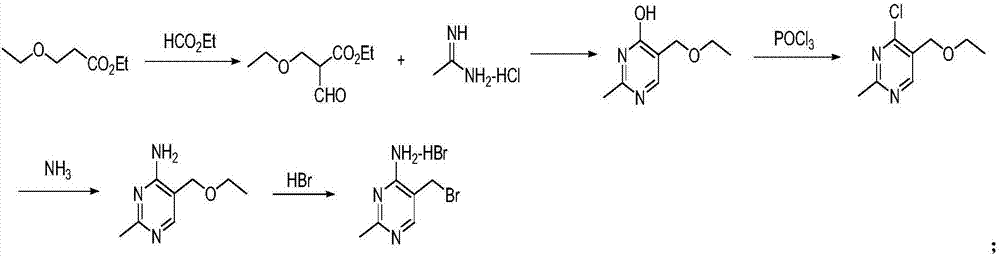

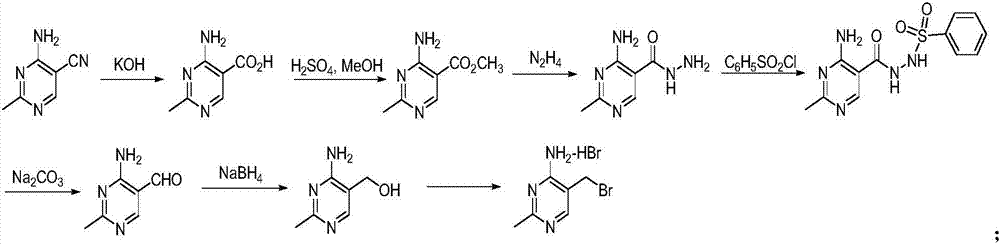

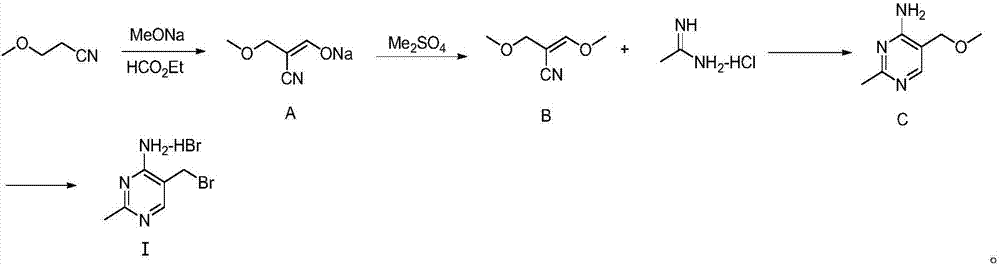

Synthesizing method for 4-amino-2-methyl-5-(brooethyl) pyrimidine hydrobromide

InactiveCN107382877ACheap to prepareRaw materials are easy to getOrganic chemistryHydrobromideSodium methoxide

The invention discloses a synthesizing method for 4-amino-2-methyl-5-(brooethyl) pyrimidine hydrobromide. The method comprises the following steps: acquiring formylated midbody sodium salt A by reacting 3-methoxypropionitrile with ethyl formate under the effect of sodium methylate; reacting the midbody sodium salt A with dimethyl sulfate, thereby acquiring a midbody B; condensing the midbody B with acetamidine hydrochloride, thereby acquiring a midbody C; and reacting the midbody C with hydrobromic acid, thereby acquiring a target product 4-amino-2-methyl-5-(brooethyl) pyrimidine hydrobromide I. According to the invention, the raw material source is wide and the cost is low; the synthesizing method is simple in production operation and has low requirement for processing equipment; the rigorous production conditions, such as, anhydrous condition, anaerobic condition and high-pressure hydrogenation, are not required; the reaction condition is mild; the method is easy for large-scale industrial production; the process is simple; the production period is short; the production efficiency is high; the production method is green and environmentally friendly and is suitable for large-scale industrial production.

Owner:CHENGDU BAISHIXING SCI & TECH IND

A kind of preparation method of brewer's yeast soy sauce

InactiveCN102283371ASimple production methodEasy to produceFood preparationLiquid wasteNutrients substances

The invention relates to a method for preparing a beer yeast soy sauce, which is a method for preparing a high-nutrient soy sauce by using beer yeasts directly. The method comprises the following steps: pretreatment of yeast paste, fermentation of mother liquor, modulation of soy sauce, sterilization, packaging and storage. The soy sauce produced by the method contains nutrient substances required by a human body, such as a great quantity of amino acids, various trace elements, vitamin B1, vitamin B2 and the like. In the method, the technology is simple, the debitterization and washing treatment processes are not required, waste liquors are not discharged in the production process, the fermentation period is short, filtered solids are used as raw materials of a biological fertilizer, and the beer yeasts are utilized maximally.

Owner:JILIN NORMAL UNIV

Method for producing simulation plants by utilizing non-woven cloth

InactiveCN101836775ALow costProduction methods are environmentally friendlyArtificial flowers and garlandsMelt spinning methodsMelt spinningEngineering

The invention discloses a method for producing simulation plants by utilizing non-woven cloth, which is characterized by comprising the following steps: (1) preparing spinning melt with a melt method; (2) preparing color master batch according to color requirements of the simulation plants; (3) mixing the color master batch into the spinning melt and preparing colored non-woven cloth in a melt spinning method; and (4) stamping and setting the colored non-woven cloth in a precast simulation plant stamping die at 160-190DEG C.

Owner:SUZHOU RONGXIAYUAN TEXTILE DYEING & FINISHING

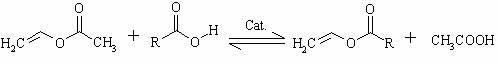

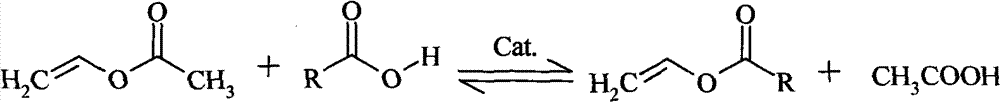

Preparation method of vinyl carboxylate

ActiveCN102627558AReduce dosageHigh catalytic activityPhysical/chemical process catalystsOrganic compound preparationEnvironmental resistanceCarboxylic salt

The invention relates to a preparation method of a vinyl carboxylate. According to the method, a carboxylic acid and vinyl acetate are subjected to a vinyl group exchange reaction under refluxing in the presence of a supported HgSO4 / C solid catalyst to obtain a reaction solution containing a corresponding vinyl carboxylate. The method which allows the catalyst to be simply prepared, have a high catalytic activity and be easily separated from products is a high-efficiency environmental-protection production method.

Owner:JIANGSU YIDA CHEM +1

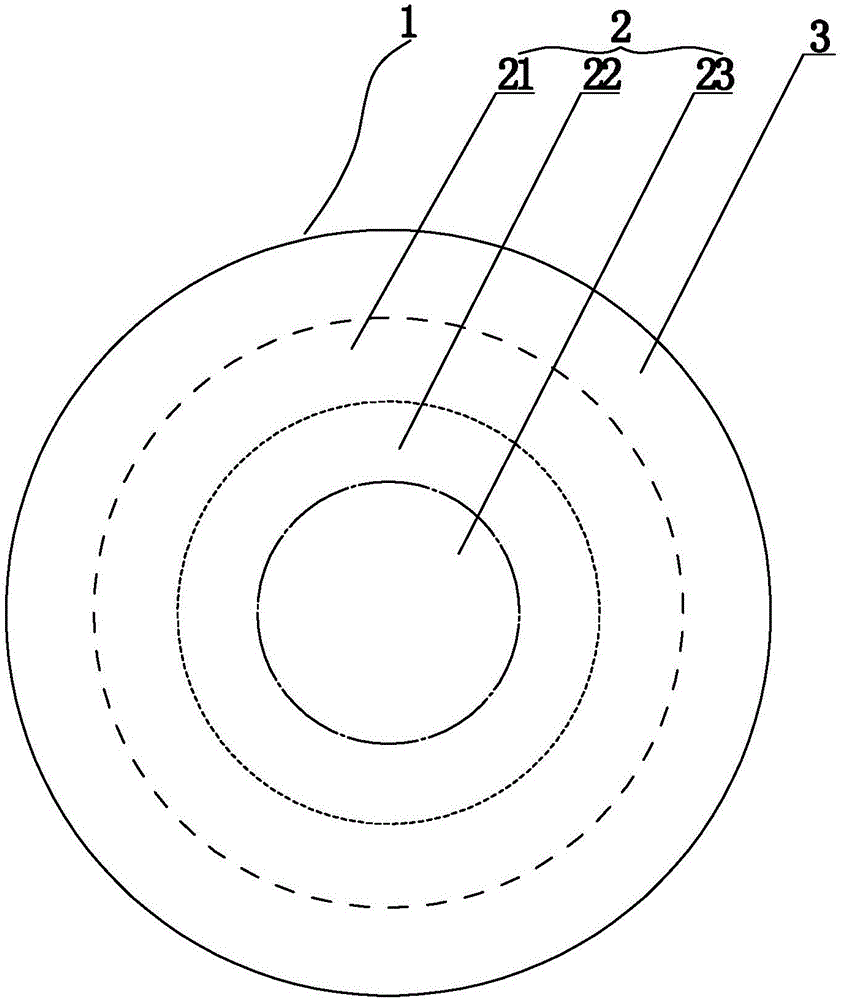

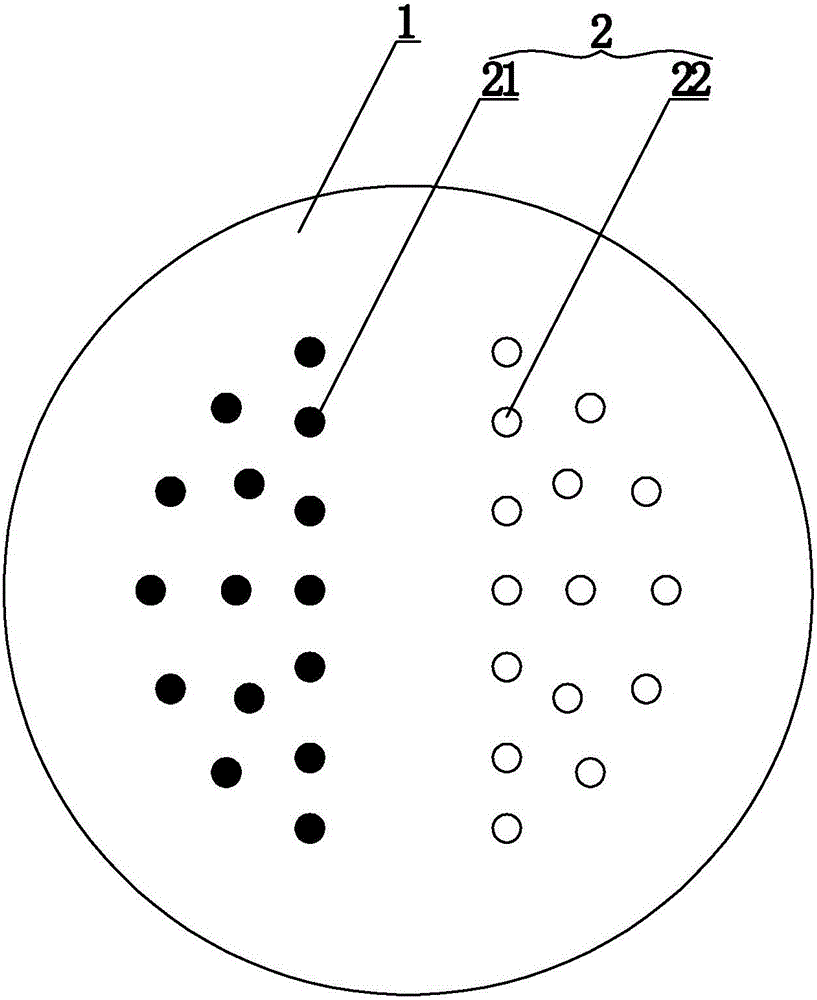

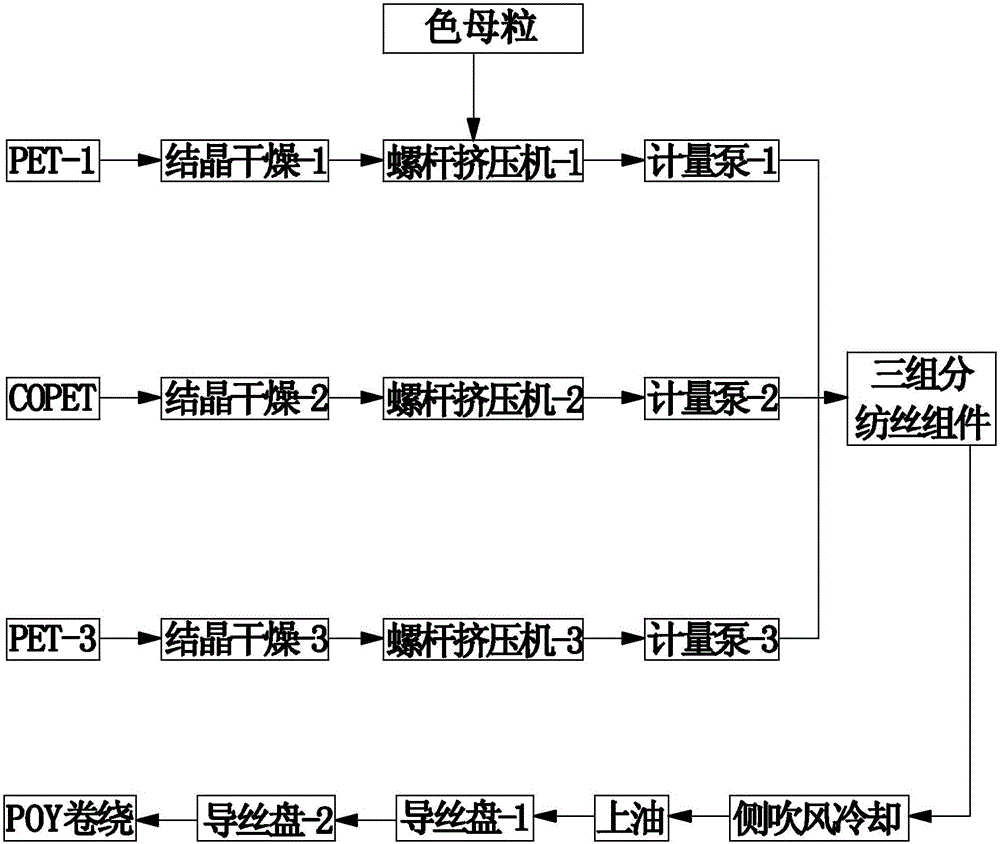

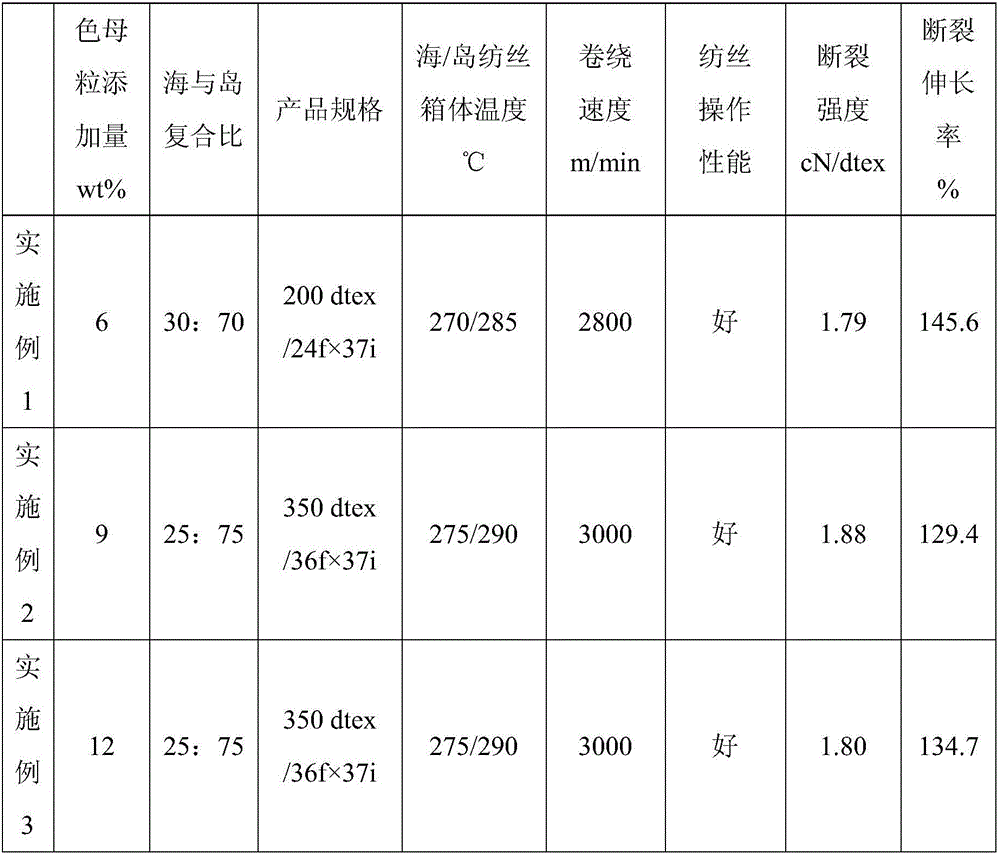

Process for producing same-plate two-tone superfine composite draw textured yarns

ActiveCN105908286AShort production processImprove product qualityArtificial filament heat treatmentMelt spinning methodsCopolyesterCompanion animal

The invention relates to a process for producing same-plate two-tone superfine composite draw-textured yarns, and belongs to the technical field of filament yarns production. An alkali-soluble copolyester is used as a sea component, while PET-1 and PET-3 are used as island components; both the sea and island components are fed into a three-component composite spinning manifold and a specially designed spinneret pack after being subjected to screw extruding and melting, conveying and metering, respectively; a two-tone seal-island composite melt is jetted from the left and right sides of a same spinneret plate, respectively, and then cooled, oiled and wound to obtain two-tone sea-island polyester pre-oriented yarns; afterwards, the two-tone sea-island polyester pre-oriented yarns are subjected to a draw texturing procedure to obtain two-tone sea-island polyester draw textured yarns (DTY). The process for producing same-plate two-tone superfine composite draw-textured yarns is applied to production of sea-island yarns, and has the advantages of short production procedure, good product quality, energy conservation, environmental protection and the like.

Owner:ZHEJIANG GUXIANDAO INC CO

Preparation method of vinyl ester carboxylic acid

InactiveCN102775298AIncrease dispersionReduce dosagePhysical/chemical process catalystsOrganic compound preparationActivated carbonVinyl acetate

The invention provides a preparation method of vinyl ester carboxylic acid. The method comprises in the presence of activated carbon load PdCl2 or an activated carbon load PdCl2-alkali halide solid catalyst, enabling carboxylic acid and vinyl acetate to undergo a vinyl exchange reaction in a backflow state, and obtaining reaction liquid containing corresponding vinyl acetate. According to the method, the catalyst is prepared simply and conveniently, the catalytic activity is high, and the catalyst is separated from a product easily. The preparation method is an efficient, green and environment-friendly production method.

Owner:NANJING FORESTRY UNIV

Method for producing tie-dyeing texture colored glass products

This invention discloses a production method of tie-dyed texture colored glassware. The production method is characterized in that a clean glass board is put on a workbench, then a tie-dyed texture coating is applied to the surface of the glass board; after the needed color and effect are made, another glass board is covered on the first glass board, the two pieces of glass boards are pressed tightly until the bubbles are forced out; next, the upper glass board is taken away, the two boards with the tie-dyed texture coating are placed into a tunnel stove and baked for 20 minutes at 200 DEG C. The main film forming materials of the tie-dyed texture coating comprise alkyd resin, amino resin, thermosetting acrylic resin and epoxy resins. After the coating film is formed, the coating film is characterized by gorgeous color, bright luster, high grade of transparency, high adhesion and good water and fire resistance performance. By applying the coatings to the surface of the glass board, single or various colors and different textures or pictures can be obtained. The production method is environment-friendly and energy-saving and can be easily operated.

Owner:山东嘉业日用制品有限公司

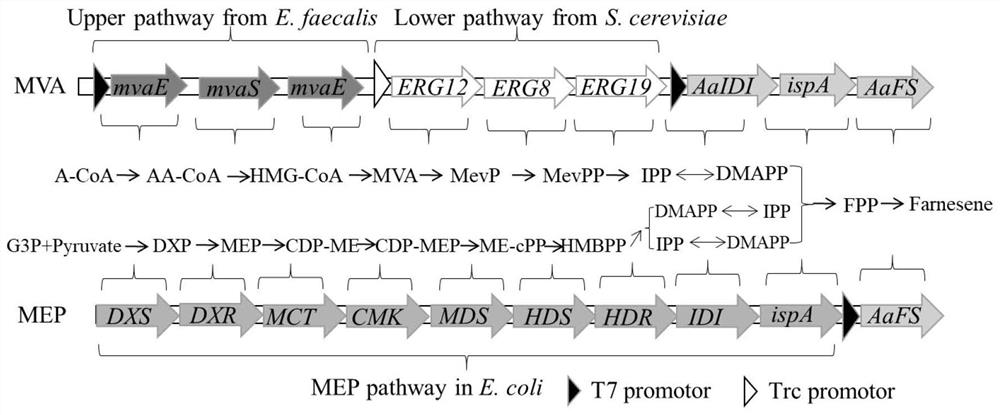

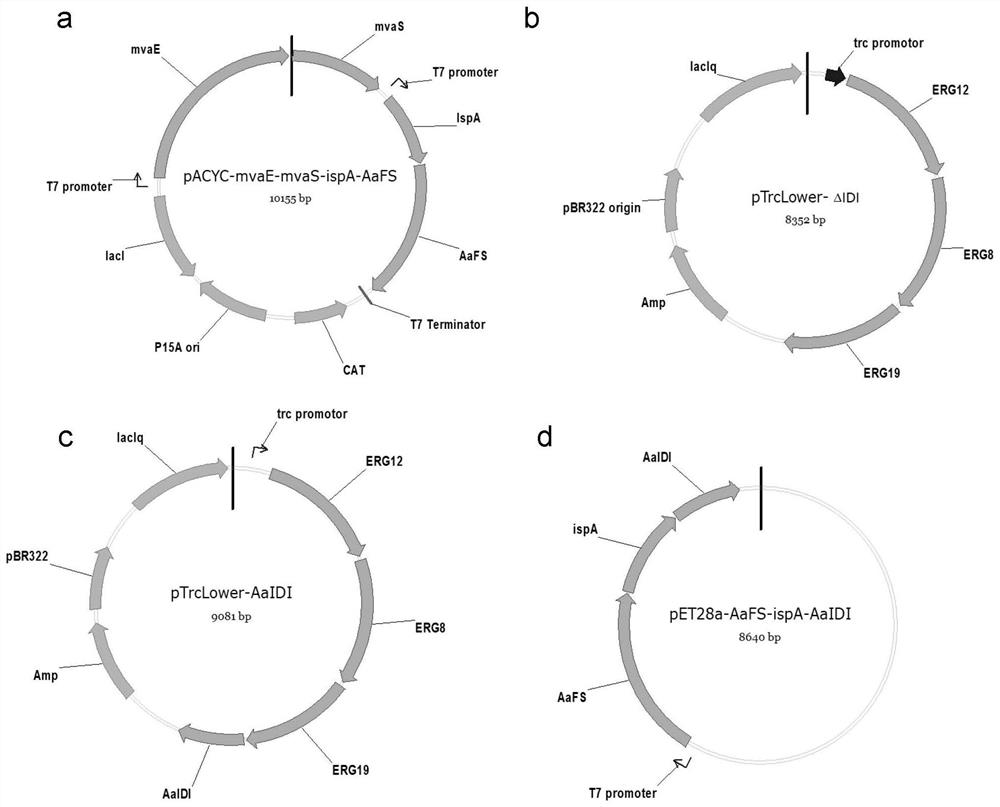

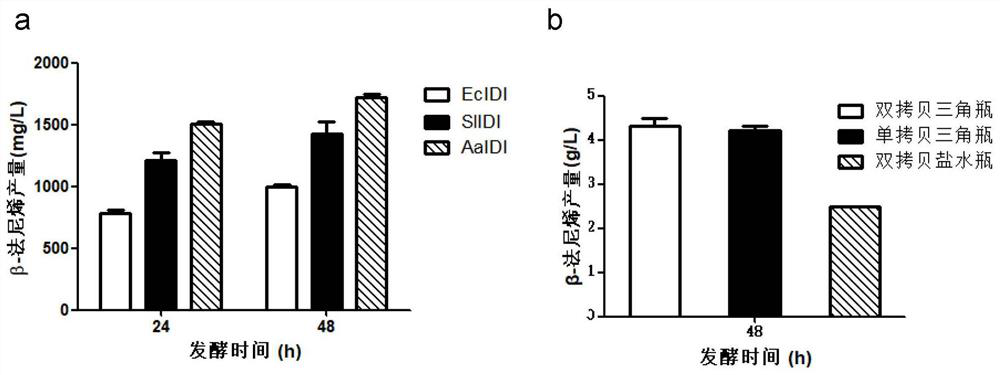

Genetically engineered bacterium for high yield of farnesene and construction method and application thereof

The invention discloses a genetically engineered bacterium for high yield of farnesene and a construction method and application thereof, and belongs to the technical field of microorganisms. In orderto solve the problem that in the process of synthesizing farnesene from escherichia coli, the catalysis efficiency of a heterologous MVA downstream path is low, and the farnesene yield is low, plasmids pACYC-mvaE-mvaS-ispA-AaFS, pTrcLow-delta IDI, pTrcLower-AaIDI and pET28a-AaFS-ispA-SlIDI / AaIDI (IDI genes are respectively from tomatoes and artemisia apiacea) are constructed; after the plasmids are combined, escherichia coli is transformed, culture conditions are improved, the prepared genetically engineered bacterium can remarkably improve the farnesene synthesis yield, and the industrialization process of synthesizing farnesene by a biological method is promoted.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com