High-flame-retardant polyester polyol compatible with cyclopentane and preparation method of high-flame-retardant polyester polyol

A polyester polyol, high flame-retardant technology, applied in the field of polyester polyol, can solve the problems of poor mutual solubility and high polyester viscosity, and achieve the effect of less reaction steps, good flexibility and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

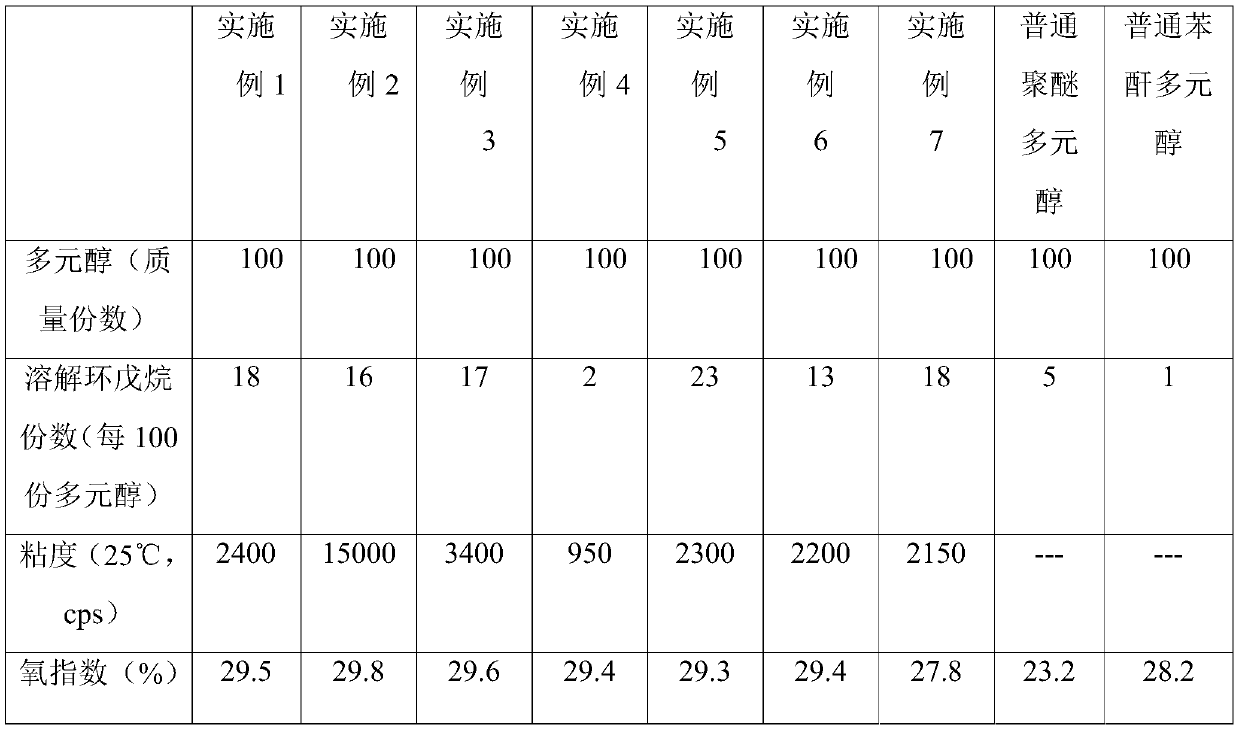

Examples

Embodiment 1

[0030] In a 2000mL reaction flask equipped with nitrogen protection, condensing reflux and stirrer, add 600.00g, 4.05mol phthalic anhydride, 150.00g, 0.90mol terephthalic acid, 100g, 0.68mol adipic acid, 737.38g, 9.69mol of 1,2-propanediol, 216.7g, 1.62mol of trimethylolpropane, start stirring, turn on nitrogen, heat up to 200°C for esterification and dehydration reaction, then heat up to 235°C for ester exchange reaction, reaction time For 2 hours, add 317.92g and 0.49mol of palm oil, and then carry out polycondensation reaction. After the material is clarified, check the acid value and hydroxyl value every 50 minutes. , 0.64mol of DMMP and stir evenly, and pack the material out.

[0031] The polyester polyol synthesized by the present embodiment has a hydroxyl value of 300mgKOH / g and an acid value of 1.55mgKOH / g;

[0032] The polyester polyol number-average molecular weight that the present embodiment synthesizes is 400.0;

[0033] The yield of polyester polyol synthesized...

Embodiment 2

[0035] In a 2000mL reaction flask equipped with nitrogen protection, condensing reflux and stirrer, add 600.00g, 4.05mol phthalic anhydride and 150.00g, 0.90mol terephthalic acid, 100g, 0.68mol adipic acid, 665.31g, 8.74mol of 1,2-propanediol, 195.53g, 1.46mol of trimethylolpropane, start stirring, turn on nitrogen, raise the temperature to 200°C for esterification and dehydration reaction, then raise the temperature to 235°C for ester exchange and polycondensation reaction, Check the acid value and hydroxyl value every 50 minutes. After the acid value and hydroxyl value are qualified, lower the temperature to below 90°C, add 75.38g and 0.61mol of DMMP, stir evenly, and pack it out.

[0036] The polyester polyol synthesized by the present embodiment has a hydroxyl value of 300mgKOH / g and an acid value of 1.27mgKOH / g;

[0037] The polyester polyol number-average molecular weight that the present embodiment synthesizes is 400.0;

[0038] The yield of polyester polyol synthesize...

Embodiment 3

[0040] In a 2000mL reaction flask equipped with nitrogen protection, condensing reflux and stirrer, add 650.00g, 4.05mol of phthalic anhydride, 150.00g, 0.90mol of terephthalic acid, 647.96g, 8.52mol of 1,2-propanediol , 190.43g, 1.42mol of trimethylolpropane, start stirring, turn on nitrogen, raise the temperature to 200°C, carry out the esterification dehydration reaction, then raise the temperature to 235°C, carry out the transesterification reaction, the reaction time is 2h, add 279.96g, 0.43mol palm oil, and then carry out polycondensation reaction. After the material is clarified, check the acid value and hydroxyl value every 50 minutes. After the acid value and hydroxyl value are qualified, cool down to below 90°C, add 69.99g, 0.56mol of DMMP and stir Evenly, out of the packaging.

[0041] The polyester polyol synthesized by the present embodiment has a hydroxyl value of 300mgKOH / g and an acid value of 1.52mgKOH / g;

[0042] The polyester polyol number average molecular...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com