Patents

Literature

64results about How to "Production method safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

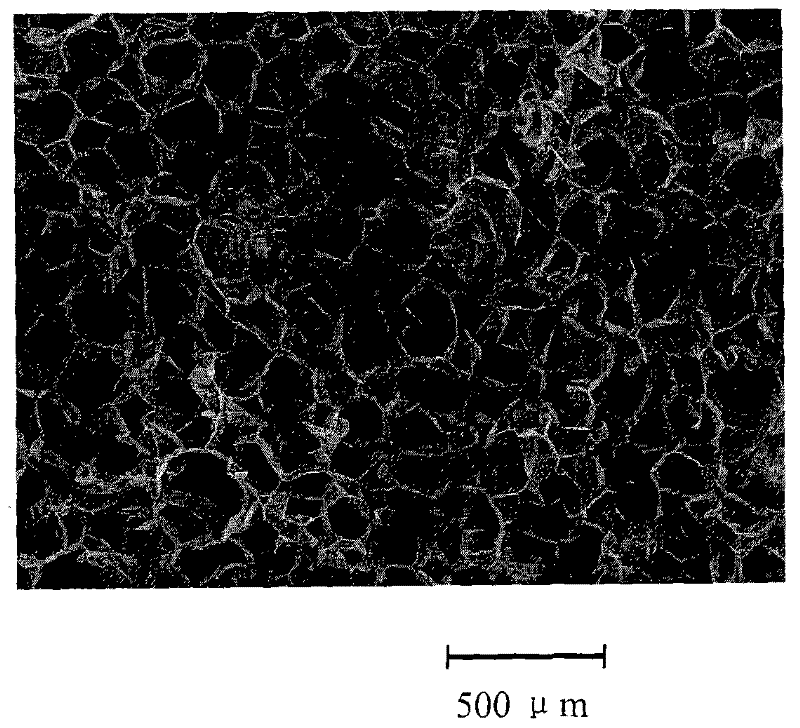

Polypropylene foaming material and production method thereof

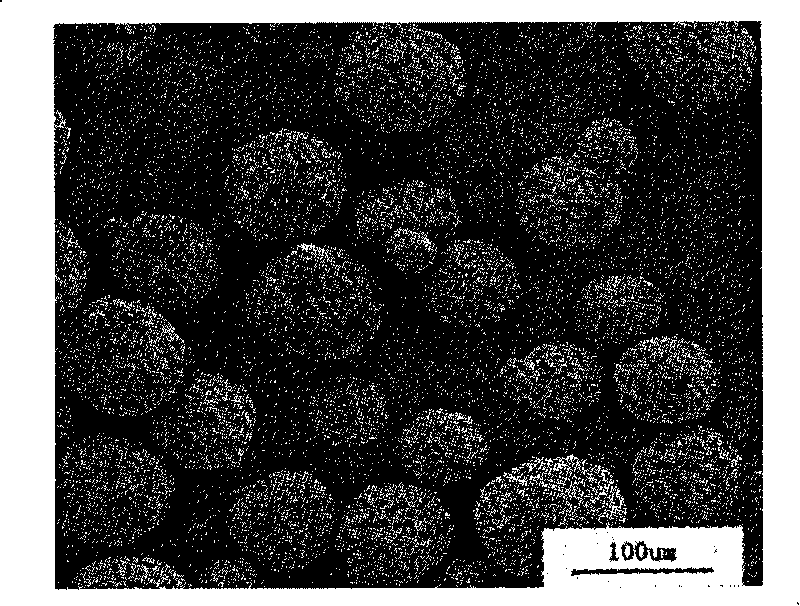

The invention discloses a polypropylene foaming material. The polypropylene foaming material comprises the following components according to proportioning by weight: 60-99 parts of polypropylene resin; 0.1-10 parts of nucleating agent; 0.1-5 parts of antioxidant; 0-5 parts of colorant; 0-5 parts of lubricant; and 0-20 parts of filling material; and the melt index of the polypropylene resin is 0.1-20 g / 10 min, and the foaming process adopts supercritical fluid as the foaming agent, i.e. 0.1-20 parts of supercritical fluid (proportioning by weight). The invention also discloses a production method of the foaming material. Compared with the prior art, the invention has the advantages that the universal polypropylene can be adopted as a base material, no polymer is provided, the cross-linking reaction does not occur, the foaming process is free from environmental pollution, and the production method is safe; the quality of the obtained foaming material is stable, the foaming percentage and the cell density are high, the distribution is uniform, and the invention is suitable for the industrial production at a large scale; and meanwhile, the overall production method is simple, the operation is easy, and the production cost is relatively lower.

Owner:合肥朗润中科材料有限公司

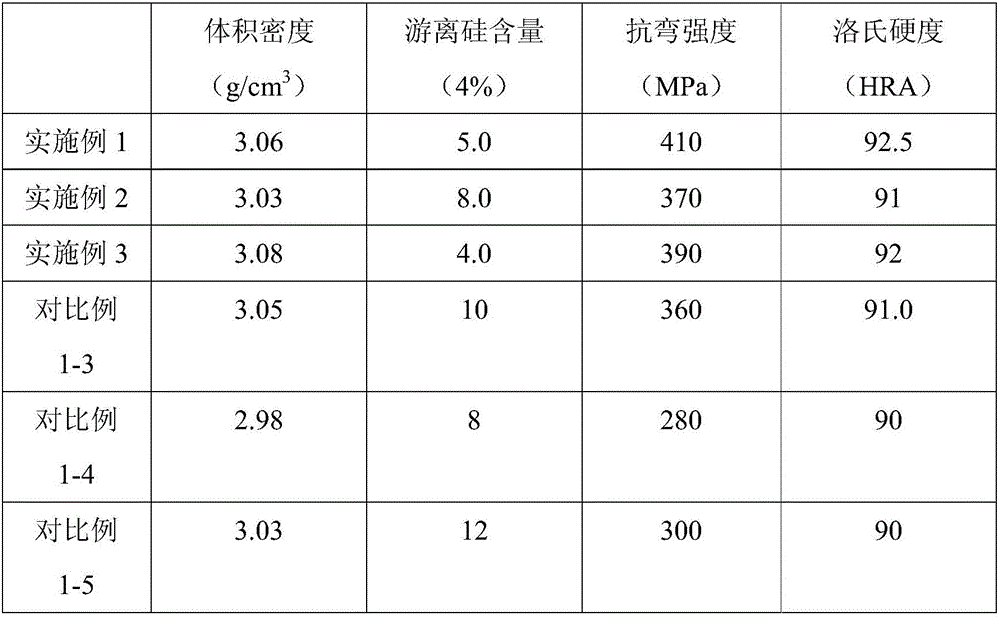

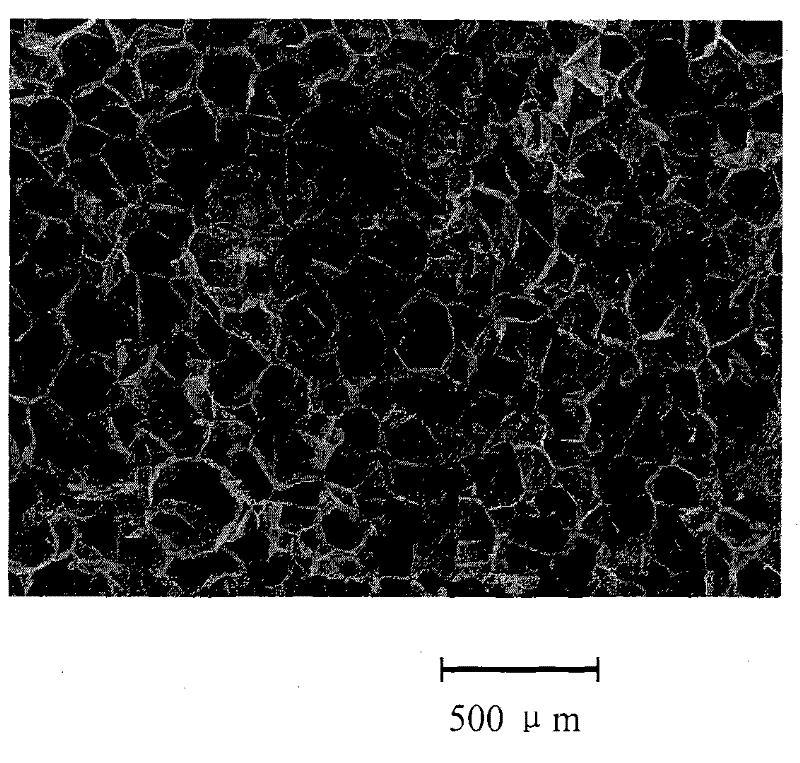

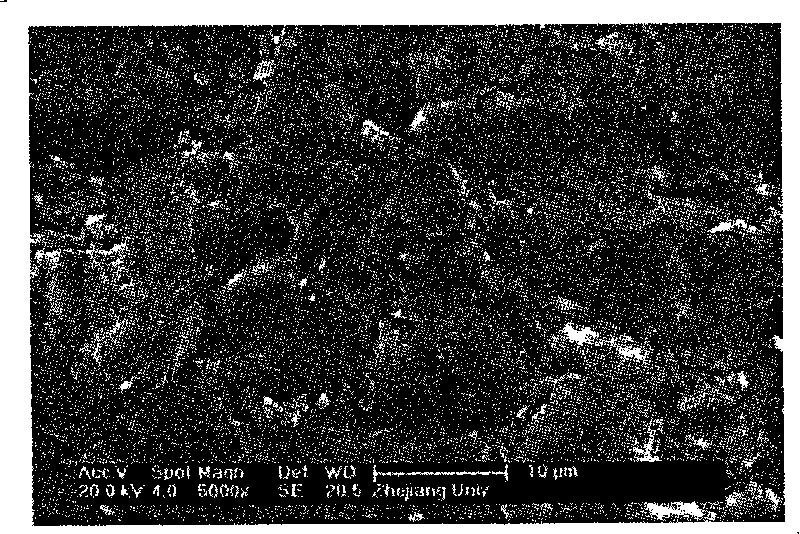

Method for preparing fine-grain silicon carbide ceramic through reaction sintering

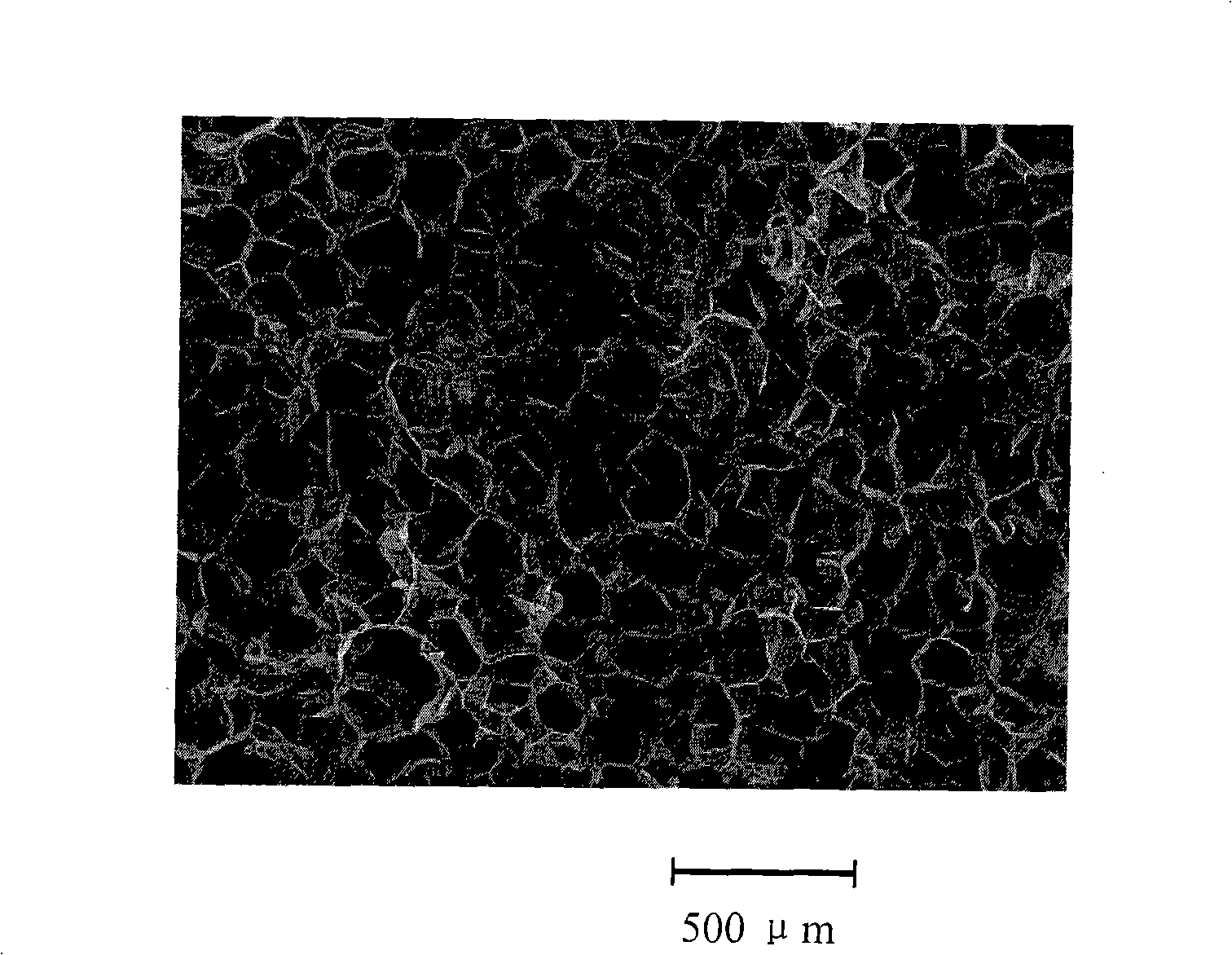

The invention discloses a method for preparing fine-grain silicon carbide ceramic through reaction sintering. The method sequentially comprises the following steps: preparing a main material comprising 75-90wt% of silicon carbide micro-powder and 10-15wt% of active carbon powder; adding a dispersant and deionized water to the main material, sequentially adding an aqueous solution of organic matters containing high temperature carbon residue and a water-soluble polymer binder solution, and stirring and mixing above materials in a ball mill to prepare a uniformly-dispersed water-based silicon carbide slip; and sequentially carrying out spray granulation, dry press molding, dewaxing, vehicle working, high temperature siliconising sintering and alkali treatment desilication to obtain the silicon carbide ceramic.

Owner:浙江东新新材料科技有限公司

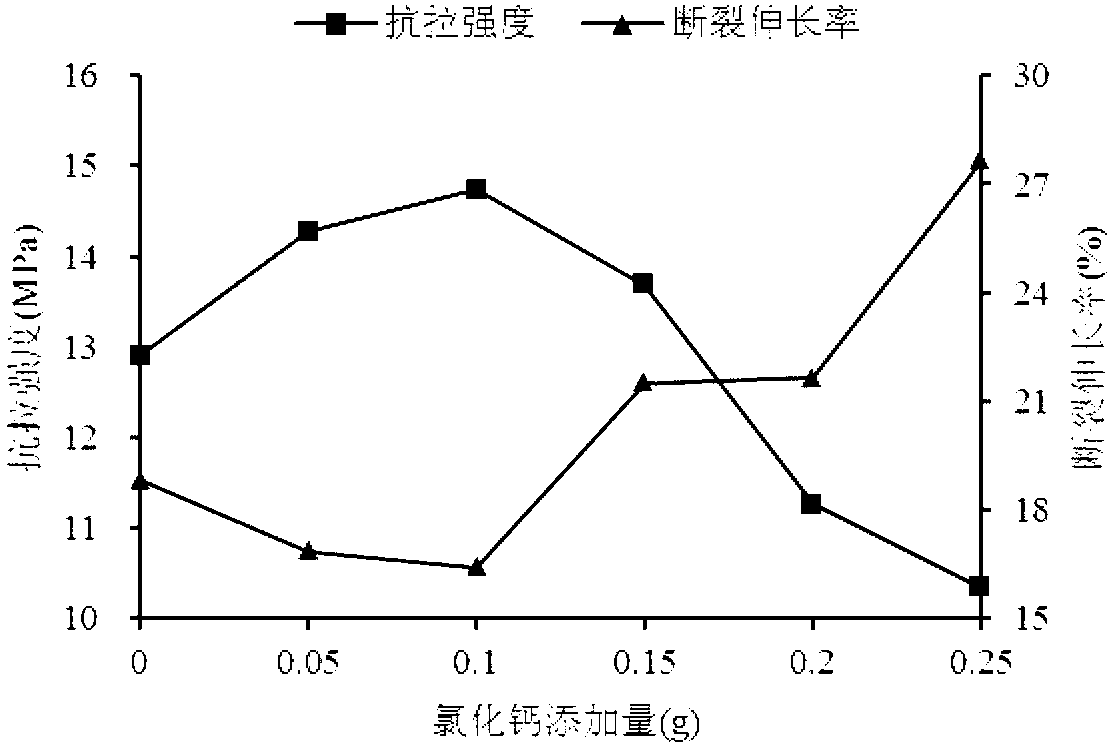

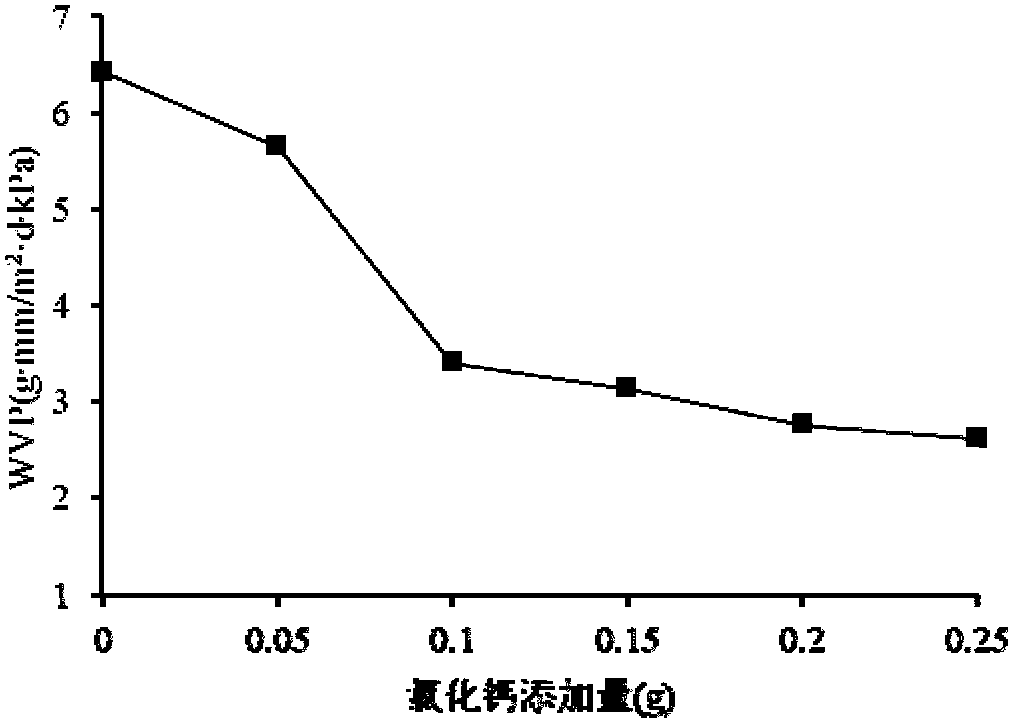

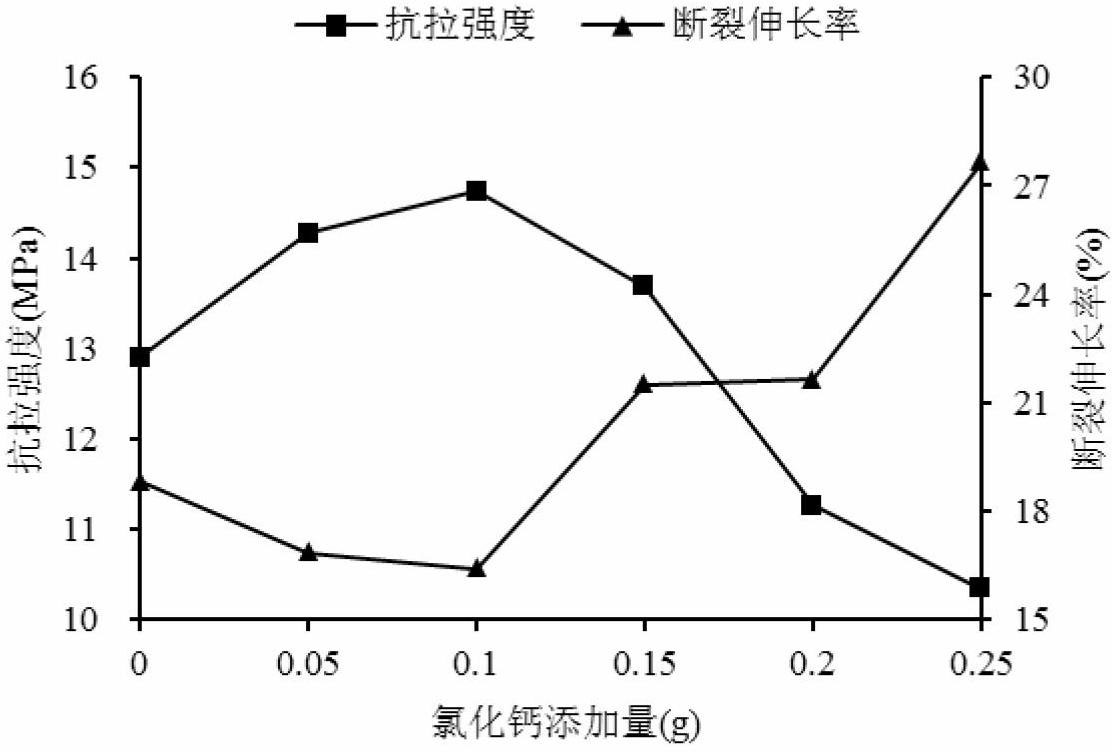

Potato starch-based edible composite food packaging film and preparation method thereof

The invention relates to a potato starch-based edible composite food packaging film and a preparation method thereof, and belongs to the technical field of food packaging. According to the potato starch-based edible composite food packaging film, potato starch, pullulan polysaccharide and gelatin are used as main film-forming materials, and a plasticizer and a cross-linking agent are used as auxiliary materials. The preparation method comprises the following steps of: adding water into the potato starch, performing water bath, stirring and gelatinizing, adding the pullulan polysaccharide and the gelatin, adding the plasticizer and the cross-linking agent finally, and casting the prepared solution to form the film. The potato starch-based edible composite food packaging film has the advantages that the raw materials for preparing the film are edible, harmless to human bodies and environment-friendly, and the raw materials are can be degraded biologically after being discarded; defoaming is not required in the film preparation process, and the process is simple and low in production cost; and the prepared film is transparent and glossy, high in mechanical performance and obstruction performance and attractive in appearance. The prepared film can be used for the inner packaging of food, so that harm of nondegradable food packages to the human bodies and environment is avoided.

Owner:JIANGNAN UNIV

Method for producing organic selenium-enriched rice

ActiveCN102511346AImprove conversion rateImprove securityRice cultivationFertilizer mixturesNutrientBiology

The invention discloses a method for producing organic selenium-enriched rice, wherein the organic selenium-enriched rice is planted according to a normal rice cultivation method. The method is characterized in that the method comprises the steps of: carrying out root dipping treatment to rice seedlings by using selenium-enriched nutrient before transplanting the rice seedlings, transplanting therice seedlings into a big field, planting according to a conventional rice planting method, harvesting organic selenium-enriched paddy, and processing the organic selenium-enriched paddy to obtain the organic selenium-enriched rice. The selenium-enriched nutrient comprises substances with effective application dose, wherein the substances contain selenium and potassium sulfate,. The selenium content of the rice, obtained by the method, is 50-300mug / kg and is improved by 2-10 times in comparison with that of common rice, organic selenium ratio is greater than or equal to 80% and the standard of the organic selenium-enriched rice is achieved.

Owner:宁夏硒产业发展有限责任公司

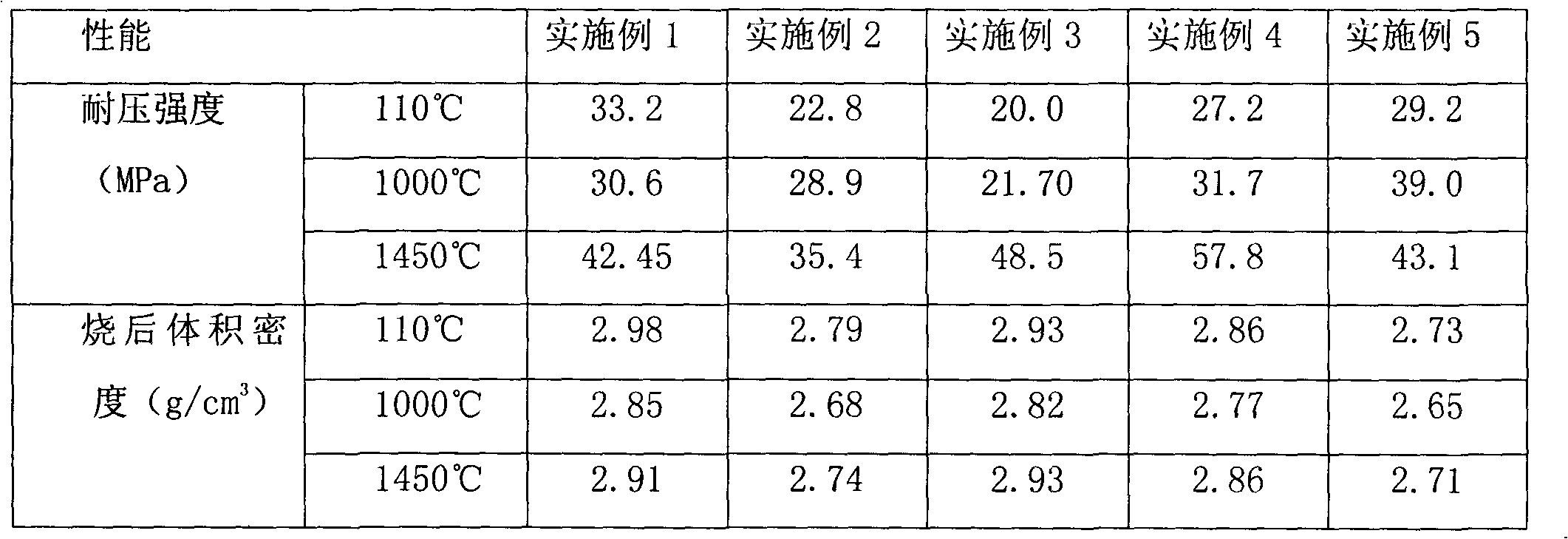

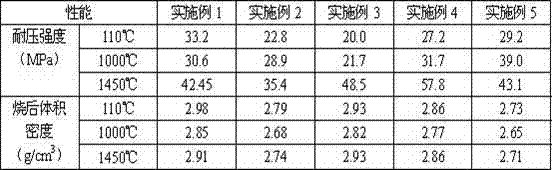

Regenerated castable manufactured by waste main blast furnace trough castables

The invention discloses a regenerated castable manufactured by waste main blast furnace trough castables. The technical proposal is as follows: the regenerated castable comprises the components with mass percents as follows: 55-70 of aggregates with granularity of 1-8mm, 1-10 of aggregates with granularity of 0-1mm, 3-10 of corundum powder with granularity less than or equal to 0.088mm, 3-20 of waste main trough castable powder with granularity less than or equal to 0.088mm, 5-15 of silicon carbide with granularity less than or equal to 1mm, 1-5 of metallic silicon with granularity less than or equal to 1mm, 1-5 of auxiliary bonding agents, 3-7 of alumina or silicon oxide powder with granularity less than or equal to 50mu m and 2.5-7 of calcium aluminate cement. The invention provides a regenerated castable which can be used safely. The waste main trough castables have low fine powder proportion and are safe and reliable. The prepared regenerated castable features good oxidation resistance and strong erosion resistance and can be safely used for production in blast furnace slag troughs and iron runners.

Owner:WUHAN IRON & STEEL (GROUP) CORP

Method for preparing graphene/carbon nanotube composite material by intensive microwave process

The invention relates to a method for preparing a graphene / carbon nanotube composite material by an intensive microwave process. The method is based on a microwave irradiation process, and comprises the following steps: putting graphite oxide into a microwave oven, and carrying out microwave irradiation for 2-5 minutes to obtain the reduced and stripped graphite oxide; and mixing the reduced and stripped graphite oxide with ferrocene, and carrying out secondary microwave treatment under identical conditions, thereby finally obtaining the graphene / carbon nanotube composite material. The method has the advantages of simple technique and low cost. The produced Gr / CNTs (carbon nanotubes) composite material has favorable electric conductivity and magnetism.

Owner:临沂星火知识产权服务有限公司

Cyanoethyl cellulose based high-dielectric flexible nano-composite film and preparation method thereof

The invention discloses a cyanoethyl cellulose based high-dielectric flexible nano-composite film and a preparation method thereof, and aims to provide a cyanoethyl cellulose based high-dielectric flexible nano-composite film which has high dielectric constant, low dielectric loss, good mechanical properties and good thermal stability as well as a preparation method of the nano-composite film. The cyanoethyl cellulose based high-dielectric flexible nano-composite film is prepared through the steps as follows: a solution is prepared from cyanoethyl cellulose serving as a matrix as well as ceramic filler and conductive filler which serve as auxiliaries, the film is subjected to film casting and forming, and the film is prepared. The cyanoethyl cellulose based high-dielectric flexible nano-composite film and the preparation method thereof have the following benefits: raw materials have wide sources and are renewable; a product has high dielectric constant and lower dielectric loss, can be applied to the industries of electronics, motors and cables, and has certain application prospect in the fields of artificial muscles, wave-absorbing materials, drug release and the like; the product has glossy surface, certain flexibility, good mechanical properties and good thermal stability; the production method is safe, the technological process is simple, the production cost is low, and the market prospect is broad.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +2

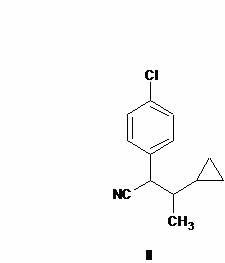

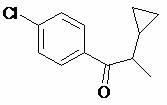

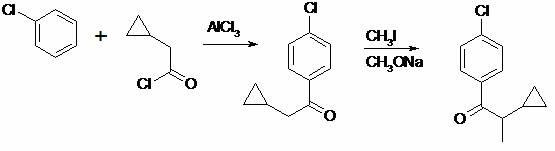

Preparation method of cyproconazole key intermediate 1-(4-chlorphenyl)-2-cyclopropyl-1-acetone

InactiveCN102675074AMeet needsLow costOrganic compound preparationCarbonyl compound preparationPtru catalystChlorobenzene

The invention relates to a preparation method of cyproconazole key intermediate 1-(4-chlorphenyl)-2-cyclopropyl-1-acetone, comprising the following steps of: obtaining a compound (II) by 2-(4-chlorphenyl)-3-cyclopropyl-2-crotononitrile through selectively reducing double bonds; using the oxygen to oxidize cyan group in the compound (II) to carboxyl in the present of the catalyst, obtaining 80% of crude1-(4-chlorphenyl)-2-cyclopropyl-1-acetone; and finally, obtaining more than 95% of cyproconazole key intermediate 1-(4-chlorphenyl)-2-cyclopropyl-1-acetone by high vacuum rectification. The method has the characteristics of high yield, good quality, low cost and safety in production, and can achieve industrial production completely.

Owner:JIANGXI HUASHI PHARMA

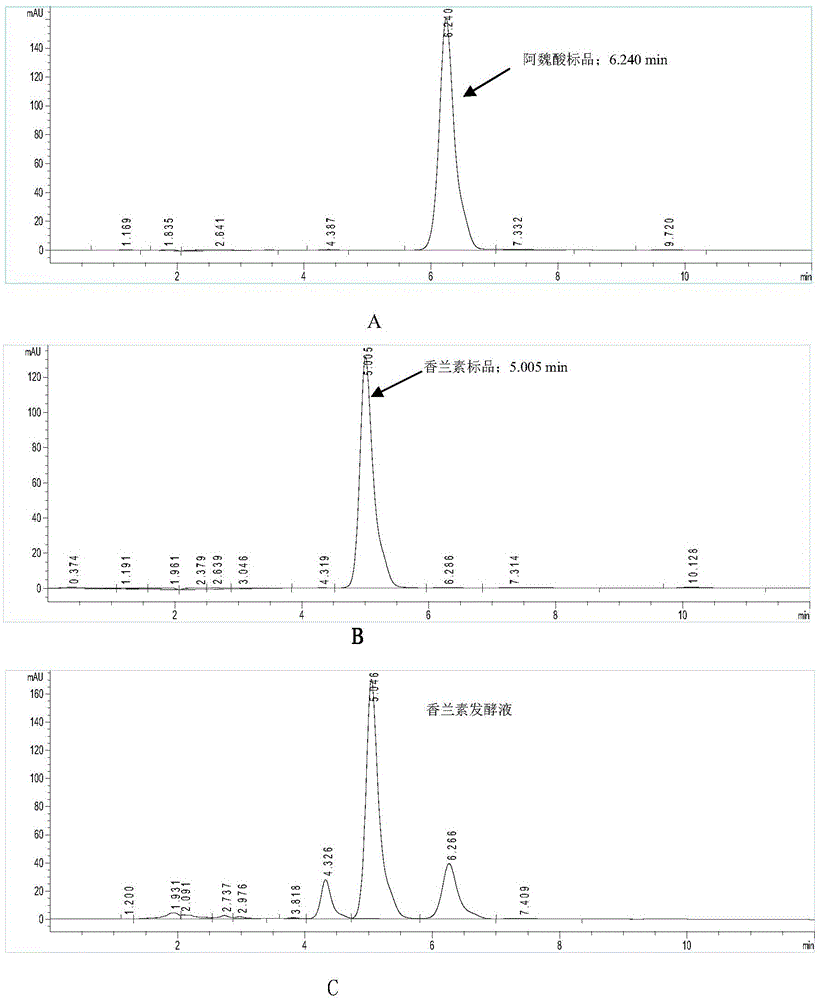

Usage of streptomyces psammoticus and vanillin production method

ActiveCN105132472AProduction method safetyEasy to operateBacteriaMicroorganism based processesMicroorganismMildew

The invention discloses a usage of streptomyces psammoticus and a vanillin production method. The streptomyces psammoticus is Streptomyces psammoticus OMK-4 and used for vanillin production. The streptomyces psammoticus is adopted for production of vanillin according to a fermentation method which includes steps of strain activation, seed culture, fermentation, extraction and the like. By means of the microbiological fermentation method for vanillin production, raw materials including ferulic acid and the like are adopted for generation of a target product through microbial metabolism. The vanillin production method is implemented under the conditions of low temperature and low pressure, thereby having the advantages of high safety, operational simplicity, less pollution and environment friendliness.

Owner:XIAMEN OMIC BIOTECH CO LTD

Method for producing ultra-low-acid ginkgo leaf extract

InactiveCN102772452ASimple processReduce manufacturing costGinkgophyta medical ingredientsCardiovascular disorderSolventAqueous solution

The invention discloses a method for producing an ultra-low-acid ginkgo leaf extract. According to the method, ginkgo leaves or extracts of the common ginkgo leaves are used as raw materials; the ginkgolic acid content in the produced ginkgo leaf extract is less than 1 ppm. The ginkgo leaves are used as the raw materials, and the method comprises the following steps of: extracting by an organic solvent aqueous solution; concentrating an extracted solution, and recycling a solvent; adding water to dilute the solution, standing and sedimentating; centrifugating or filtering to eliminate sedimentations; adsorbing the supernate by large-hole resin; washing by water to remove impurities; desorbing the organic solvent aqueous solution, directly deacidifying gel type hydrogen-bonding adsorbent resin, and washing; and concentrating and drying the flow-out solution and the washed solution to obtain the ultra-low-acid ginkgo leaf extract. The extracts of the common ginkgo leaves are used as the raw materials, and the method comprises the following steps of: dissolving the organic solvent aqueous solution, directly removing ginkgolic acid through the gel type hydrogen-bonding adsorbent resin, washing, and concentrating and drying the flow-out solution and the washed solution to obtain the ultra-low-acid ginkgo leaf extract. According to the method, the process is simple and reliable; the production cost is low; in the production process, toxic organic solvents are not used; and the production process is safe and environment-friendly.

Owner:TIANJIN TAIYANG PHARMA

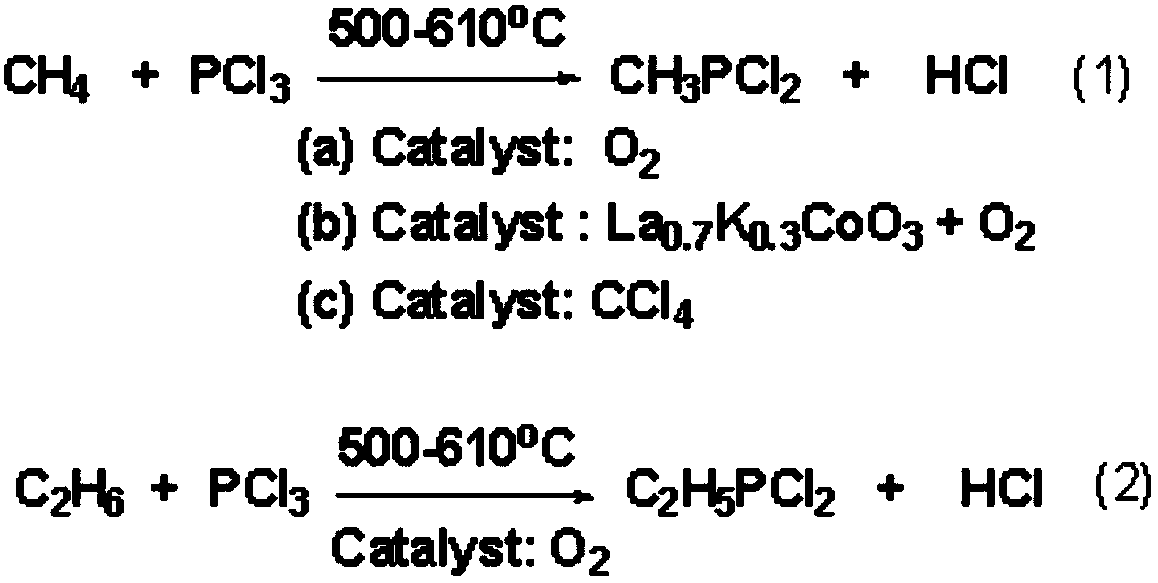

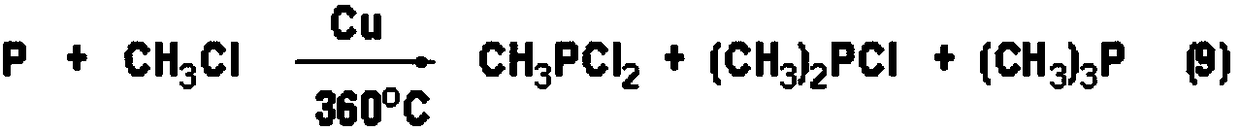

Method for producing alkyl phosphorus dichloride

ActiveCN108864190AOvercoming the large amount of three wastesOvercome costsGroup 5/15 element organic compoundsAlkaneChemical industry

The invention relates to the field of chemical industry and further relates to a production method of an organic phosphorus intermediate, and in particular relates to a method for producing alkyl phosphorus dichloride. The method comprises the following specific step: in the presence of a catalyst, enabling phosphorus trichloride and alkane to react in a tubular reactor under high temperature andhigh pressure, so as to generate the alkyl phosphorus dichloride, wherein the alkane is selected from one or two of methane and ethane and the catalyst is selected from one or two of chloroform and dichloromethane. The method provided by the invention has the advantages of low production cost, great industrial feasibility, measurable and controllable technological conditions, high reaction conversion rate and selectivity, good product quality and the like.

Owner:HEBEI VEYONG BIO CHEM

Method for fermentation production of fish sauce through Halobacteriaceae sp. mixed strain

The invention discloses a method for fermentation production of fish sauce through a Halobacteriaceae sp. mixed strain and belongs to the technical field of aquatic product processing. Low-value Bombay duck is fermented through Halobacteriaceae sp. CGMCC 1.10122, Halomicrobium mukohataei CGMCC 1.6192 and Halogranum rubrum CGMCC 1.7738 as mixed starters so that a fish sauce product with high quality and high safety is obtained. The fish sauce has a bright brown-red color, has a delicious fragrance specially belonging to fish sauce, has no putridflavor, has a delicious taste, has no other peculiar smell, is transparent and clear, does not contain foreign matter, has soluble total nitrogen and amino acid nitrogen content reaching or close to the national first order fish sauce product standard, has histamine and nitrite content far below the fish sauce product national standard and greatly improves safety.

Owner:JIANGSU UNIV

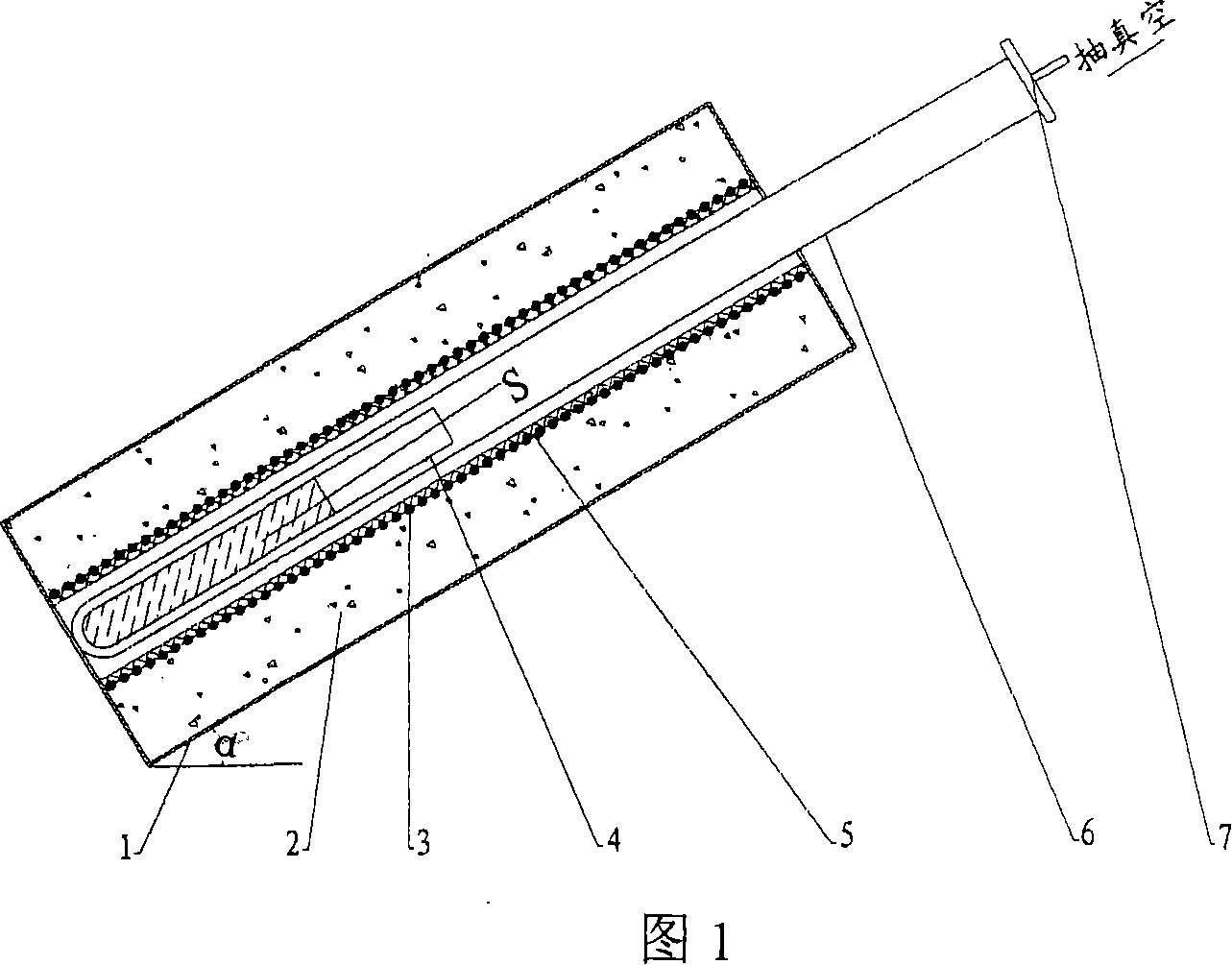

Method of producing high-pure sulfur

InactiveCN101125640AProduction method safetyProduction methods are environmentally friendlySulfur preparation/purificationInsulation layerVacuum pressure

The invention provides a producing method of high pure sulfur, which is characterized in filling 3 to 4 weight parts of 99 wt percent sulfur into a pot(4), then putting the pot with 99 wt percent sulfur into a quartz tube(6) which is put into a vacuum sublimation heating furnace(1). Wherein, the heating furnace is internally provided with an insulation layer(2), a heating wire(3), a pot(4), a furnace lining(5), a quartz tube(6) and a vacuum pressure cover(7), whose mounting obliquity Alpha is 30 to 45 degrees; moreover, one end of the quartz tube is sealed with the vacuum pressure cover(7) which is provided with an extraction vacuum hole; once the vacuum is extracted to 1 multiplies by 10-3 to 9 multiplies by 10-3Pa, the heating system of the vacuum sublimation heating furnace is opened, after that, waiting till the temperature of the heating furnace is up to 135 to 145 DEG C, the vacuum sublimation purifying is performed for 3.5 to 4.5 hours; after that, the vacuum and heating system is closed for cooling and discharging, thus, obtaining 2.3 to 3.0 weight parts of 5N sulfur product and having a yield of 75 to 78 percent.

Owner:四川鑫龙碲业科技开发有限责任公司

Method for producing carboxypeptidase by aspergillus niger

InactiveCN102154251AProduction method safetyIn line with the laws of natureHydrolasesMicroorganism based processesNitrogen sourceBio engineering

The invention provides a method for producing carboxypeptidase by aspergillus niger, belonging to the technical field of biological engineering. The method comprises the following steps: taking agricultural and sideline products such as the bran, the bean cake flour, the corn flour and the like as the fermentation base material, optimizing enzyme liquid extraction time by properly changing the proportion of a carbon source and a nitrogen source in a culture medium, and performing the solid fermentation by the aspergillus niger LW-1 strain. The method provides the solid fermentation medium prescription and the culture condition for the small-scale production in the laboratory; and the carboxypeptidase activity of the mature leaven material achieves 3194.4U / g-5584.2U / g. The method has the characteristics of being simple in equipment, small in investment, fast in effect, low in production cost, environment-friendly, higher in carboxypeptidase activity and the like, is good for the development and the application of the carboxypeptidase, and is higher in economic value and practical value.

Owner:JIANGNAN UNIV

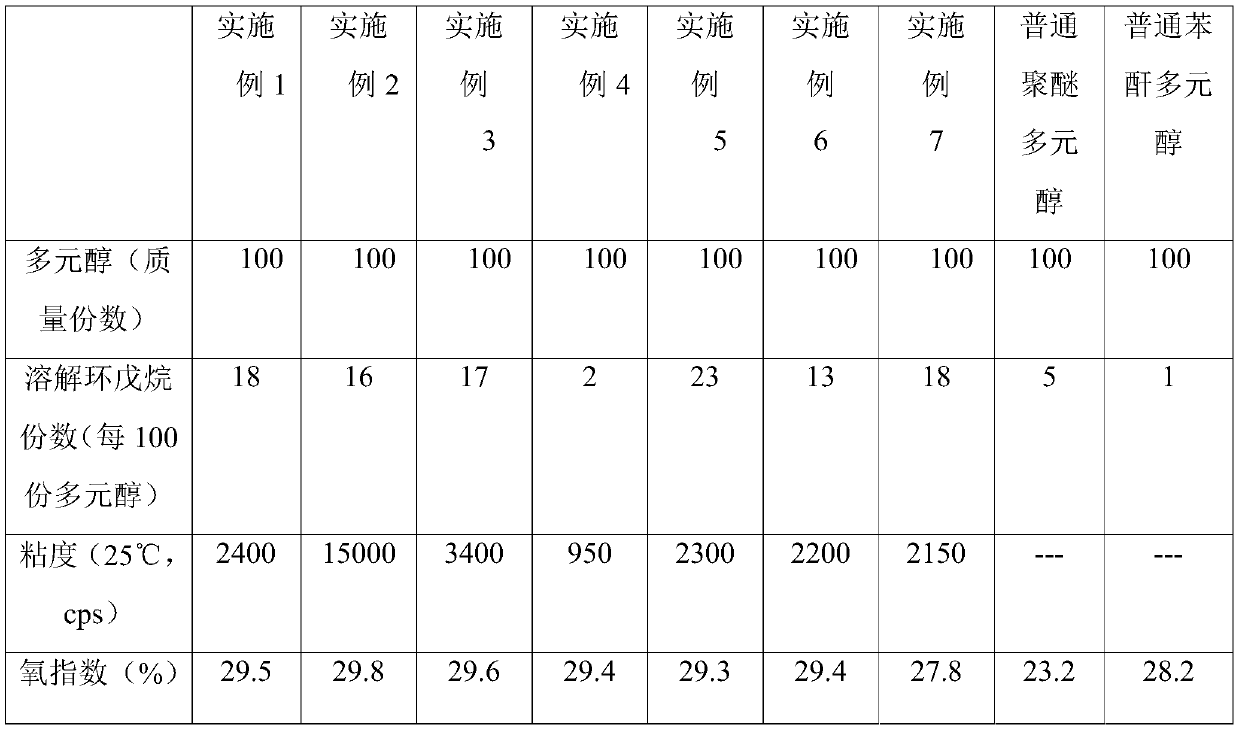

High-flame-retardant polyester polyol compatible with cyclopentane and preparation method of high-flame-retardant polyester polyol

The invention relates to high-flame-retardant polyester polyol compatible with cyclopentane and a preparation method of the high-flame-retardant polyester polyol, and belongs to the technical field ofpolyester polyol. The preparation method comprises the following steps: carrying out esterification reaction and transesterification reaction on a mixture of adipic acid, an aromatic dibasic acid andan aromatic dibasic acid anhydride and a mixture of a dihydric alcohol and a trihydric alcohol which are used as raw materials, adding vegetable oil to carry out polycondensation reaction, and addinga flame retardant to obtain the high-flame-retardancy polyester polyol compatible with cyclopentane. The high-flame-retardant polyester polyol compatible with cyclopentane, disclosed by the invention, not only can be mutually dissolved with cyclopentane, but also has relatively low viscosity, good flexibility and high operability; the invention also provides the preparation method which is simpleand feasible and is beneficial to industrial production.

Owner:SHANDONG INOV POLYURETHANE

Ripe tomato one-time harvesting type cultivation method

ActiveCN110301308AHigh yieldEasy to mechanizeHorticulture methodsFruit crop cultivationDiseaseHigh density

The invention discloses a ripe tomato one-time harvesting type cultivation method. By main vein pinching for cultivating tomato multiple branches, synchronous formation of first inflorescences, flowering, fruiting and maturing of all branches are realized. Corresponding plant physiological and agricultural operation regulation measures are adopted aiming at the target, and moisture and nutrient management and light and temperature regulation are carried out in different stages to realize group high-density branching in unit area and short-period high yield on the premise of a conventional planting quantity of tomato seedlings. By adoption of the method, one-year multi-crop cultivation of tomatoes in unit area can be realized, one-time harvesting in each crop is realized, and accordingly tomato quality controllability is realized while diseases and pest damages are reduced, consumption of pesticides is avoided, and convenience in implementation of mechanical harvesting is achieved.

Owner:汪晓云

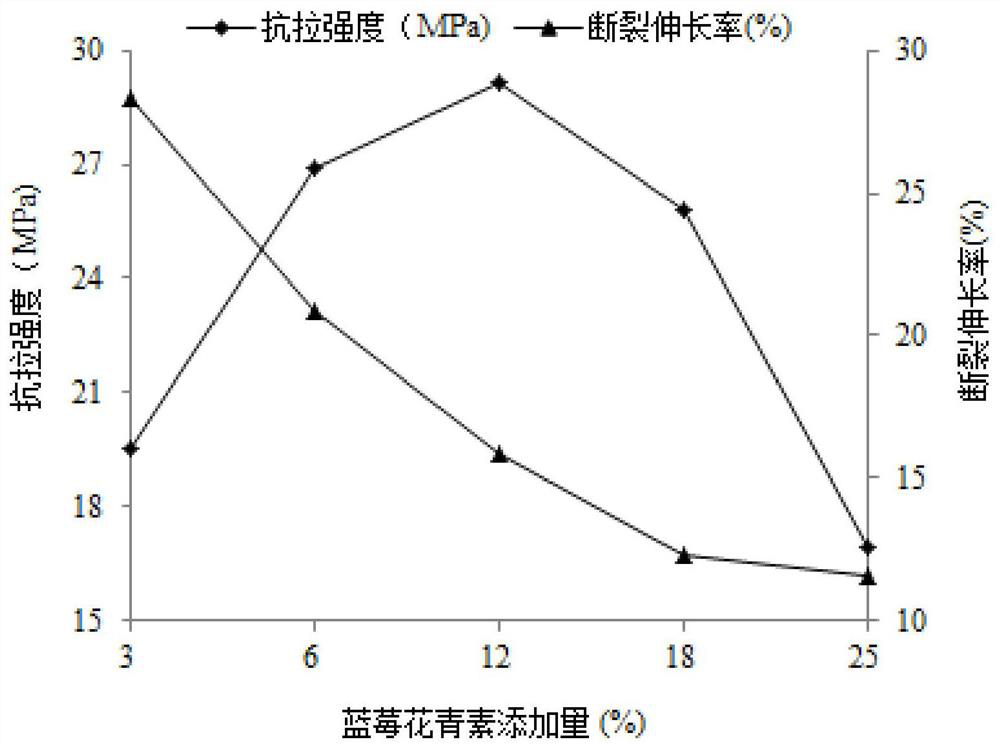

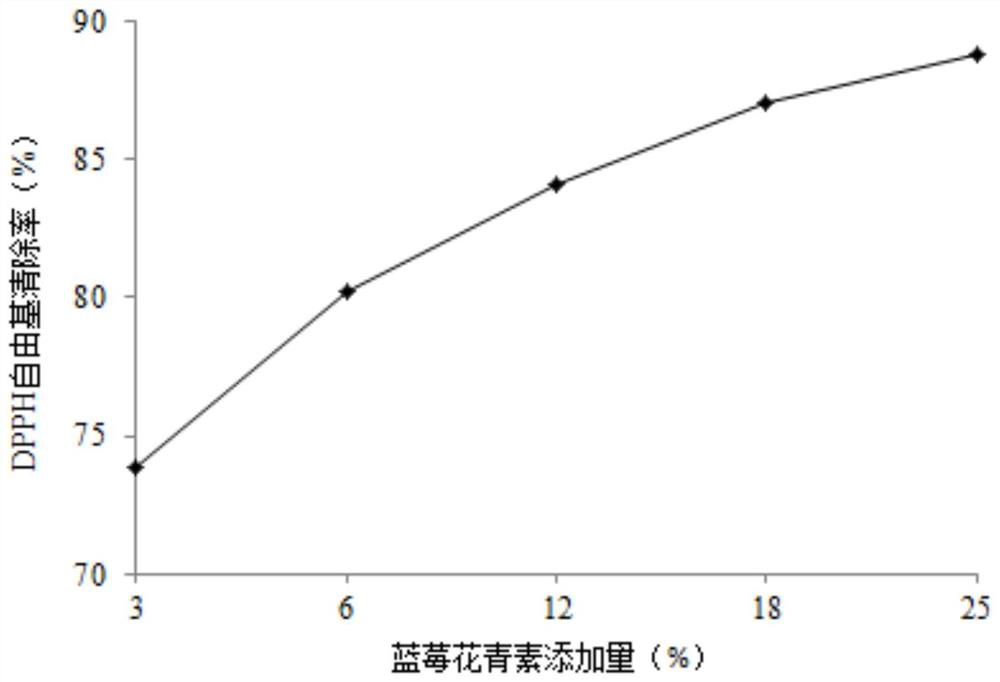

Blueberry anthocyanin edible composite film and preparation method thereof

InactiveCN113045802AImprove mechanical propertiesImprove toughnessFlexible coversWrappersComposite filmPlasticizer

The invention discloses a blueberry anthocyanin edible composite film and a preparation method thereof, belonging to the technical field of food packaging. The blueberry anthocyanidin edible composite film is prepared by preparing a solution from blueberry anthocyanidin and starch serving as main film-forming materials and a binding agent and a plasticizer serving as auxiliary materials and then carrying out film casting. The preparation method comprises the following steps: firstly, adding deionized water into the starch, conducting stirring and gelatinizing in a water bath kettle, then adding the binding agent, then adding a plasticizer, adding blueberry anthocyanin powder, conducting stirring to obtain a mixed solution, and carrying out film casting on the prepared mixed solution. The raw materials of the blueberry anthocyanin edible composite film provided by the invention are edible, widely available, renewable, non-toxic and pollution-free; and the blueberry anthocyanin edible composite film is good in degradability, simple in process flow and excellent in antibacterial activity and oxidation resistance, can be used for inner packaging of food, protects the environment, and has fresh-keeping and anti-corrosion effects on the inner packaged food.

Owner:JIANGNAN UNIV

Polymer-modified nano-lecithin composite material and preparation method thereof

The invention relates to a polymer-modified nano-lecithin composite material and a preparation method thereof, and belongs to the technical field of functional package materials. The polymer-modified nano-lecithin composite material is prepared by taking modified nano-lecithin serving as a plasticizer, adding a cross-linking agent, taking polyethylene or polypropylene as a base material, and performing blow moulding and film forming. A polyethylene composite film with high stability, high barrier property (that is, the oxygen and water vapour barrier properties are improved) and high mechanical properties (that is, the tensile strength and the breaking elongation are remarkably improved) is obtained; moreover, the used plasticizer is the green and natural soybean lecithin, and is harmless to human body health; the prepared thin film can be widely applied to the fields of food package and medicinal package.

Owner:JIANGNAN UNIV

Compounding process for low-melting-point suspending agents

InactiveCN108782549ASimple stepsSimple production methodBiocideAnimal repellantsAnti freezingPreservative

The invention discloses a compounding process for low-melting-point suspending agents, the compounding process includes the following steps of weighing certain amounts of low-melting-point crude drugs, wetting agents, dispersing agents, anti-freezing agents, preservatives, defoaming agents and water, performing uniform mixing and shearing to obtain mixed liquid, sanding the mixed liquid, obtainedin the step S2, at the temperature of less than 30 DEG C until the particle size reaches 1-5 micrometers, adding thickening agents for uniform shearing to obtain materials A for standby use, sanding another crude drugs according to the above steps into materials B, mixing the materials A with the materials B proportionally, and performing uniform stirring and mixing to obtain the low-melting-pointcomposite compound suspending agents, the compounding process based on a new concept of step-by-step addition has the advantages that the production safety is guaranteed, the production cost is reduced, the processing method is safe, the production efficiency is high, the production method is simple, and the formula is easy to screen.

Owner:郭秦

Polypropylene foaming material and production method thereof

The invention discloses a polypropylene foaming material. The polypropylene foaming material comprises the following components according to proportioning by weight: 60-99 parts of polypropylene resin; 0.1-10 parts of nucleating agent; 0.1-5 parts of antioxidant; 0-5 parts of colorant; 0-5 parts of lubricant; and 0-20 parts of filling material; and the melt index of the polypropylene resin is 0.1-20 g / 10 min, and the foaming process adopts supercritical fluid as the foaming agent, i.e. 0.1-20 parts of supercritical fluid (proportioning by weight). The invention also discloses a production method of the foaming material. Compared with the prior art, the invention has the advantages that the universal polypropylene can be adopted as a base material, no polymer is provided, the cross-linkingreaction does not occur, the foaming process is free from environmental pollution, and the production method is safe; the quality of the obtained foaming material is stable, the foaming percentage and the cell density are high, the distribution is uniform, and the invention is suitable for the industrial production at a large scale; and meanwhile, the overall production method is simple, the operation is easy, and the production cost is relatively lower.

Owner:合肥朗润中科材料有限公司

Regenerative castable prepared from waste main runner materials from blast furnace

The invention discloses a regenerated pouring material manufactured by using waste blast furnace main channel material. Its technical solution: a recycled castable made by using the waste blast furnace main channel material, its components and mass percentage content are: 55-70% of the aggregate with a particle size of 1-8mm, and 55-70% of the aggregate with a particle size of 0-1mm 1-10%; 3-10% for corundum powder with particle size ≤0.088mm, 3-20% for waste main channel powder with particle size ≤0.088mm, 5-15% for silicon carbide with particle size ≤1mm, and 5-15% for silicon carbide with particle size ≤1.0mm 1-5% of metal silicon, 1-5% of auxiliary binder, 3-7% of alumina or silica powder with particle size ≤50μm; 2.5-7% of calcium aluminate cement. The invention provides a recycled castable that can be safely used. The proportion of fine powder of the discarded main ditch castable is not high, which is safe and reliable. The prepared recycled castable has good oxidation resistance and strong corrosion resistance, and can be safely used in blast furnace slag. Ditch and iron ditch production.

Owner:SUZHOU NORETA NEW MATERIAL TECH

Reaction sintering silicon carbide ceramic and production method thereof

ActiveCN101289319BQuality improvementMeet the technical requirements of drying processWater basedWater soluble

The invention relates to reactive sintering carborundum ceramics, which is characterized in that the weight percentages of the components are as following: carborundum is 80 to 95 percent, powdered carbon is 5 to 20 percent, and sintering accessory ingredient is 1 to 2 percent. The preparation method is as following: the raw materials are put into de-ionized water and caking agent, water-soluble macromolecule mixture collosol and dispersant are added; mixing by ball milling is carried out for 5 to 20 hours to form water-based carborundum sizing agent; spray dry technique is adopted to carry out spraying and drying the sizing agent, thereby obtaining carborundum compound powder amyloplastid; the amyloplastid is carried out dry pressing to obtain carborundum ceramics biscuits; the biscuits are put into a vacuum response sintering furnace for siliconizing and sintering; preparing the reactive sintering silicon carbide ceramics at the temperature of 1500 to 1800 DEG C after heat preservation for 1 to 5 hours. The reactive sintering silicon carbide ceramics of the invention has the advantages of scientific and rational raw materials and mixture ratio, safe production method and low cost. The prepared carborundum ceramics can meet requirements of mechanical seal under special working conditions.

Owner:浙江东新新材料科技有限公司

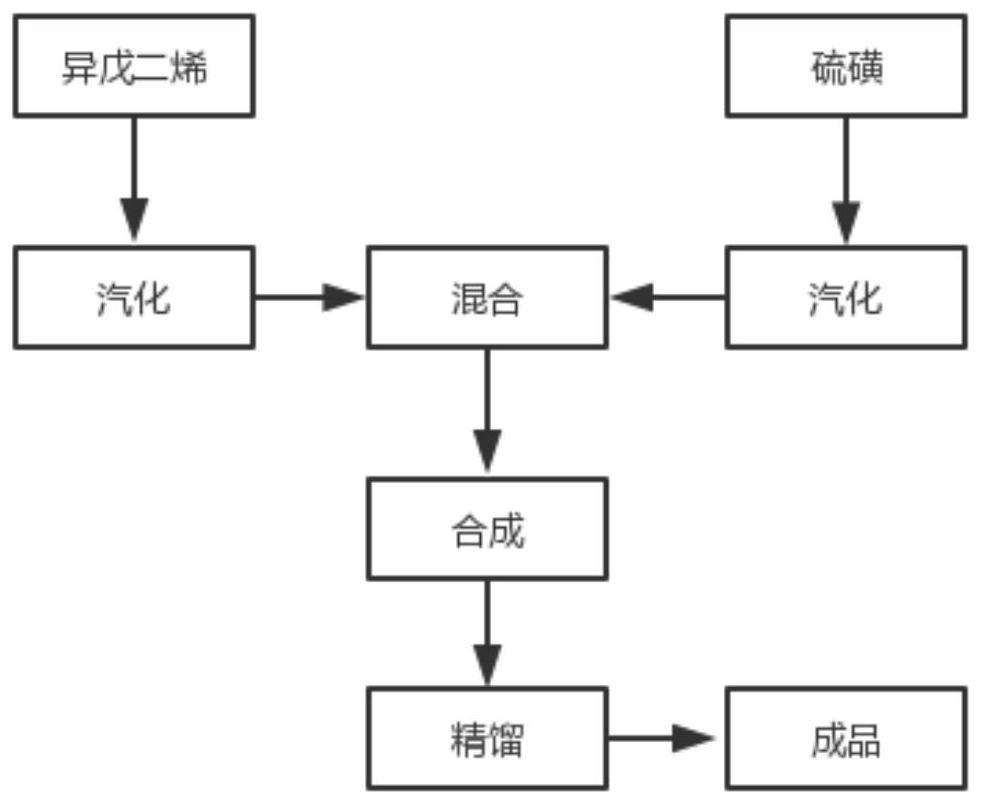

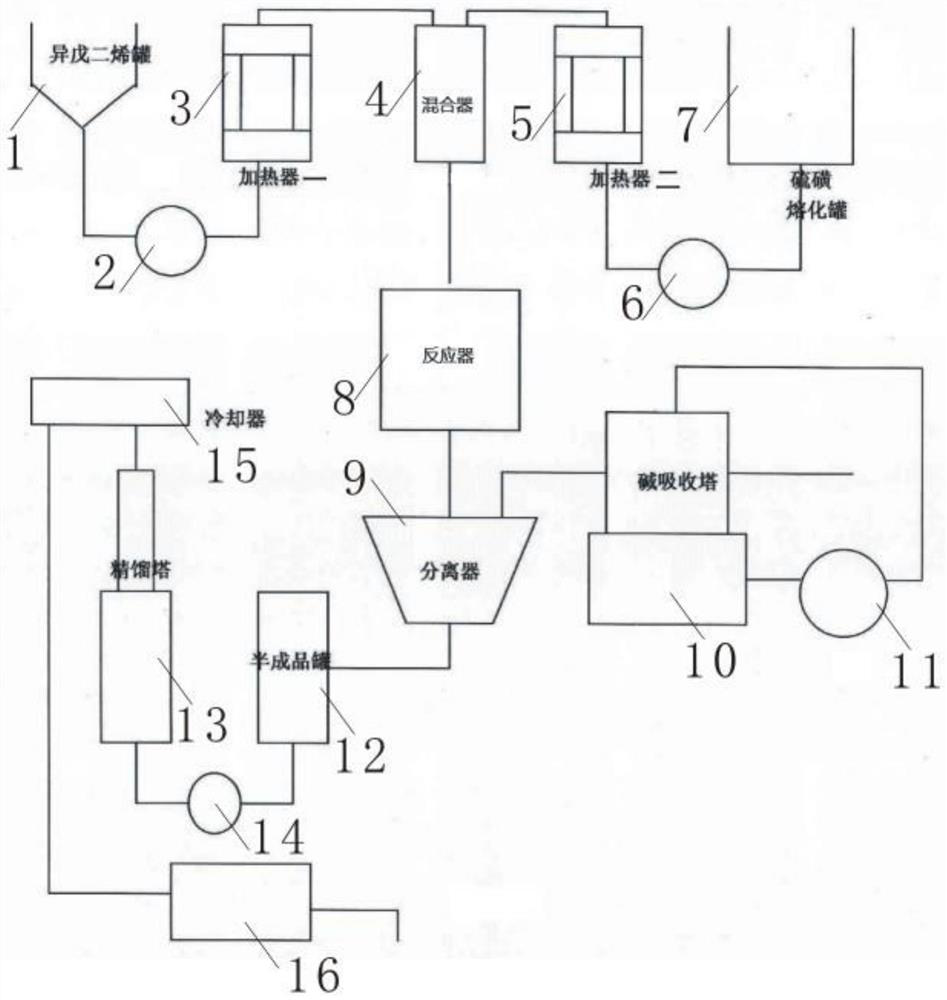

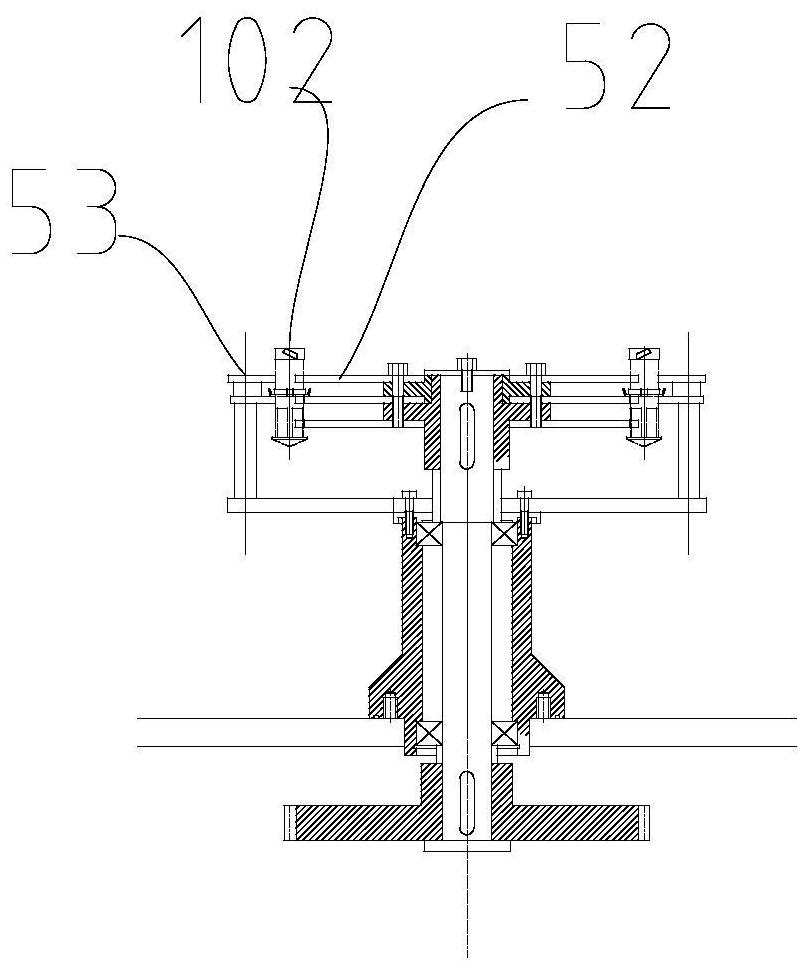

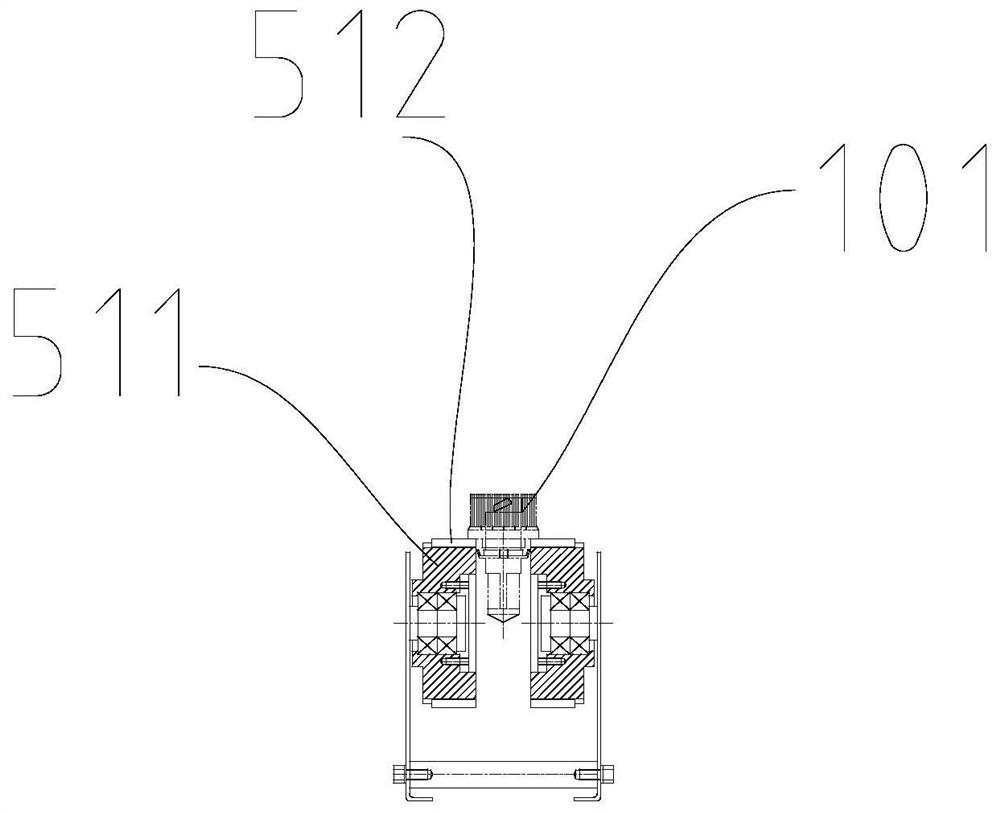

Production method of 3-methylthiophene and equipment

PendingCN113801093AImprove reaction efficiencyLow reaction temperatureOrganic chemistryPtru catalystPhysical chemistry

The invention relates to a production method of 3-methylthiophene and equipment thereof, and the production method comprises the following steps: sulfur is fed into a liquefier and liquefied, fed into a vaporizer II, vaporized, and fed the vaporized sulfur and vaporized isoprene into a mixer according to a ratio, a mixture is fully vaporized and mixed, the mixed gas is fed into a normal pressure tubular reactor filled with a catalyst, and synthesized to generate a 3-methylthiophene crude product; after the 3-methylthiophene crude product is discharged from the reactor, the trimethylthiophene crude product is cooled to below 80 DEG C through a cooler I, hydrogen sulfide gas is separated through a separator, and the hydrogen sulfide gas enters an alkali absorption tower to be absorbed; the trimethylthiophene from which the hydrogen sulfide gas is separated enters a rectifying tower to be refined, and after a certain reflux ratio is controlled, the tower top produced liquid is analyzed to be qualified, and is produced to enter a qualified product tank. The production method has the remarkable characteristics of simple process, safety and environmental protection.

Owner:HUBEI UNIV OF ARTS & SCI +1

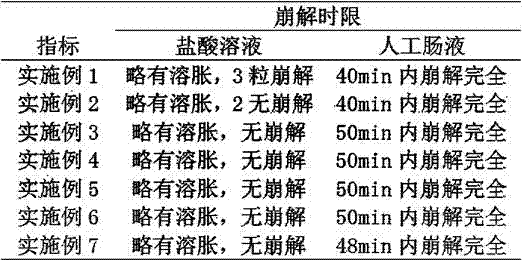

A kind of preparation method of vegetable enteric-coated capsule

ActiveCN104922087BGood compatibilityRich sourcesPharmaceutical non-active ingredientsCapsule deliveryPlasticizerDialdehyde starch

A preparation method of vegetable enteric-coated capsule is characterized in that: the ingredients of enteric starch capsule include hydroxypropyl starch, vegetable gum, dialdehyde starch, and plasticizer; A certain amount of dialdehyde starch was added to a certain amount of purified water, stirred at 50 ° C for 15 minutes, added 2% sodium hydroxide to adjust the pH value to 8, and continued to stir at 60 ° C for 20 minutes, and then added a certain amount of hydroxypropyl The base starch was continuously stirred at 50° C. for 30 minutes; the obtained mixture was dipped in glue, dried, and threshed to obtain capsule bodies and capsule caps.

Owner:HUNAN ER KANG PHARMA

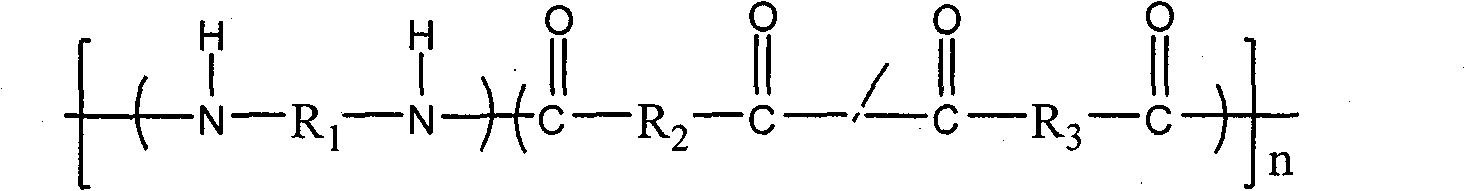

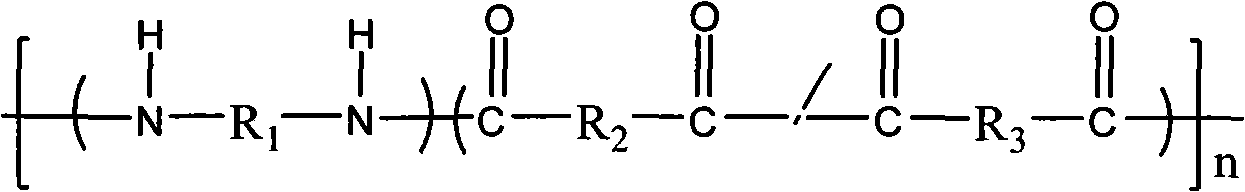

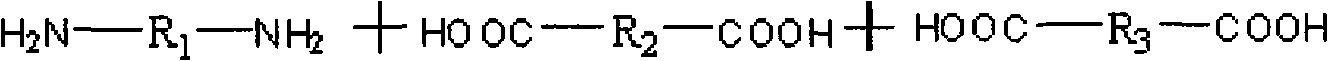

Transparent co-polyamide and preparation thereof

The invention discloses a transparent copolyamide and a preparation method thereof. The cheap domestic dimer acid, aromatic dibasic acid and aliphatic linear chain diamine are taken as raw materials to undergo melt polycondensation and obtain the copolyamide. The light transmittance of the copolymer is up to more than 90%, and the copolymer has high heat resistance and good forming and processingperformance. By taking the dimer acid, the aromatic dibasic acid and the aliphatic linear chain diamine as the raw materials, compared with the existing salt forming method, the method for forming salt in aqueous solution greatly reduces the production cost, simplifies the production process and shortens the operation period. The transparent copolyamide is a polymer which has high molecular weight and is prepared by taking the dibasic acid and the aliphatic linear chain diamine as the raw materials, forming salt and polymerizing in the aqueous solution, and the intrinsic viscosity of the transparent copolyamide is up to 2.1dL.g<-1>.

Owner:SOUTH CHINA UNIV OF TECH

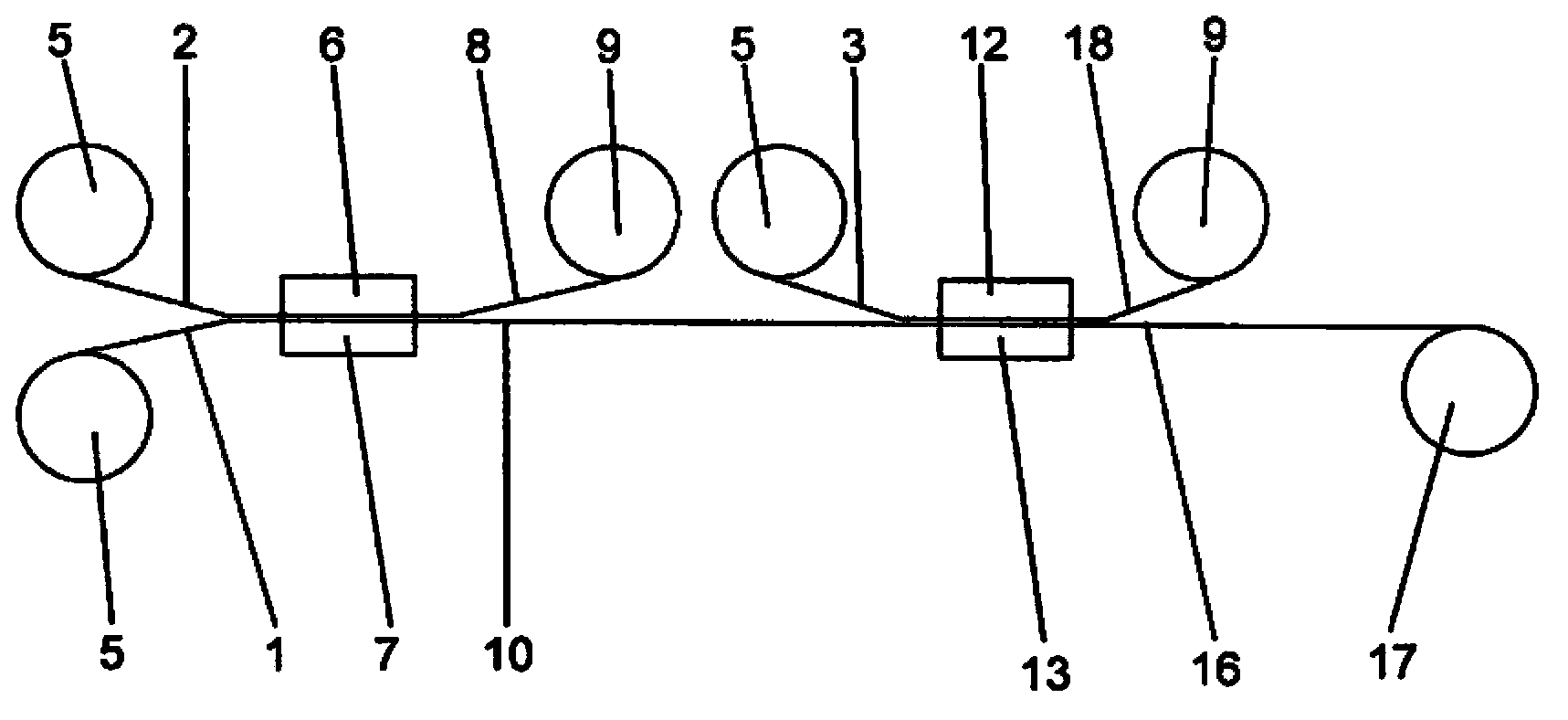

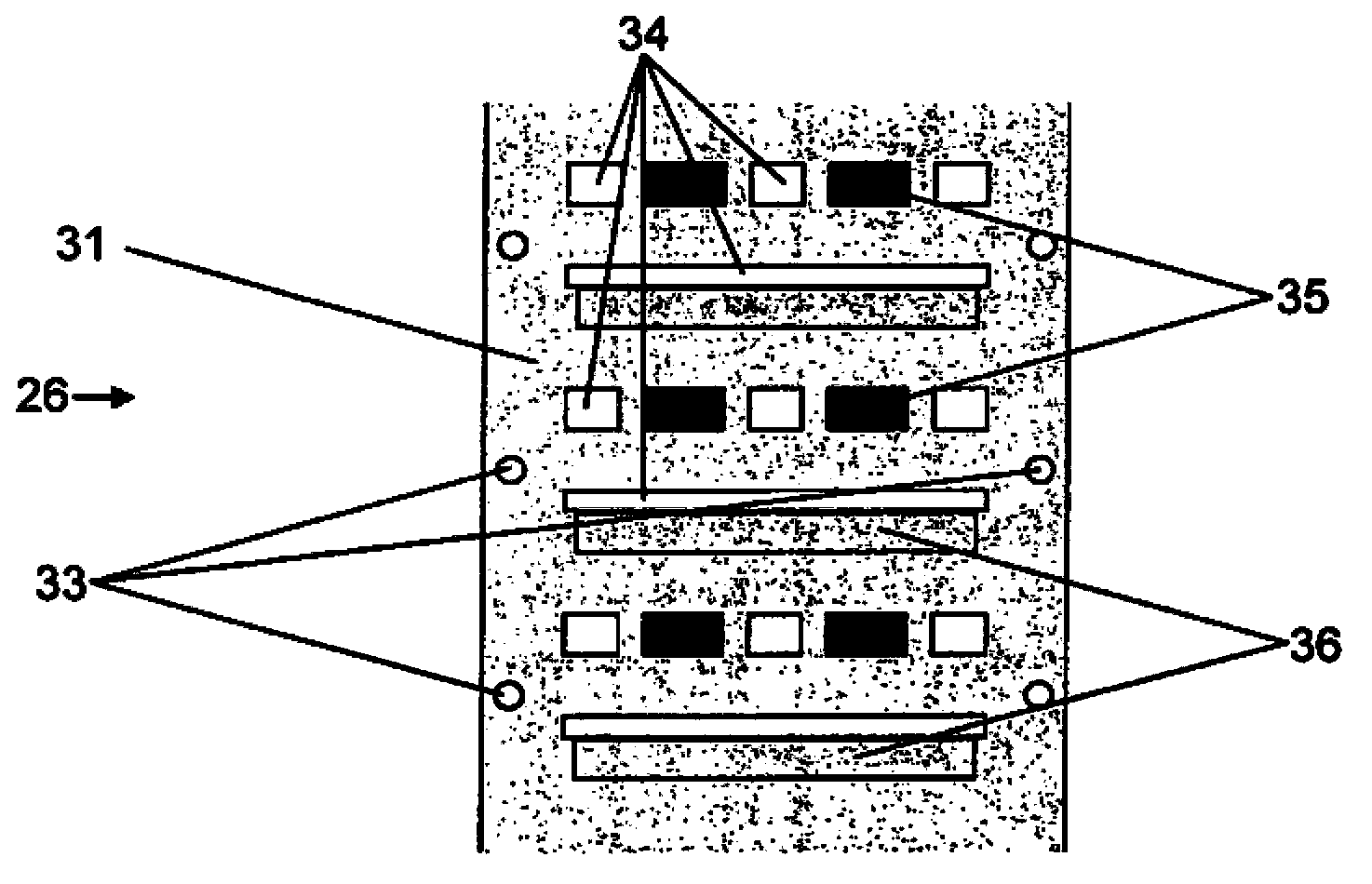

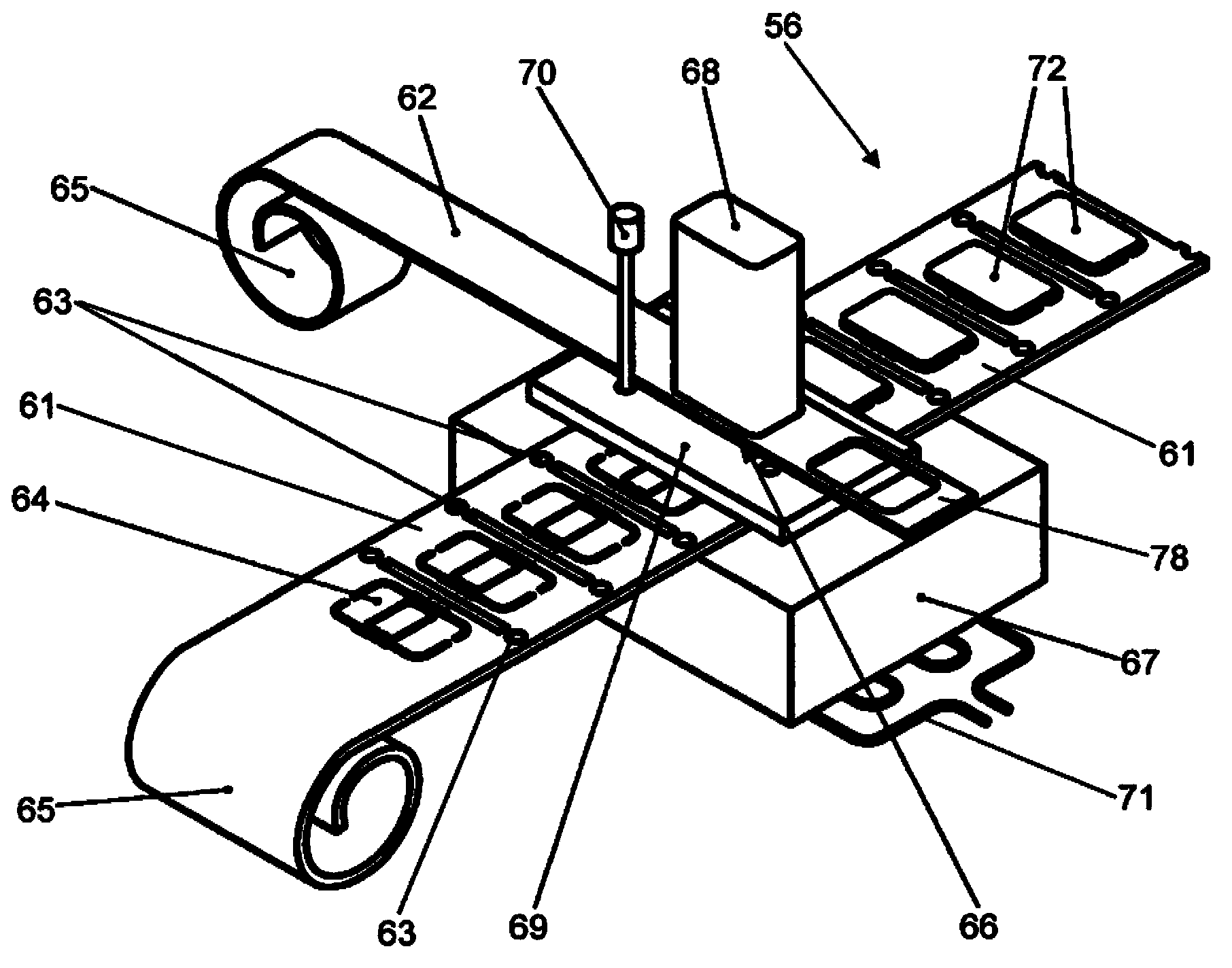

Method for stamp-laminating a first film onto a film web

ActiveCN103502008AReduce in quantityProduction method safetyLamination ancillary operationsLaminationPolymer sciencePolymer chemistry

Owner:HERAEUS MATERIALS TECHNOLOGY GMBH & CO KG

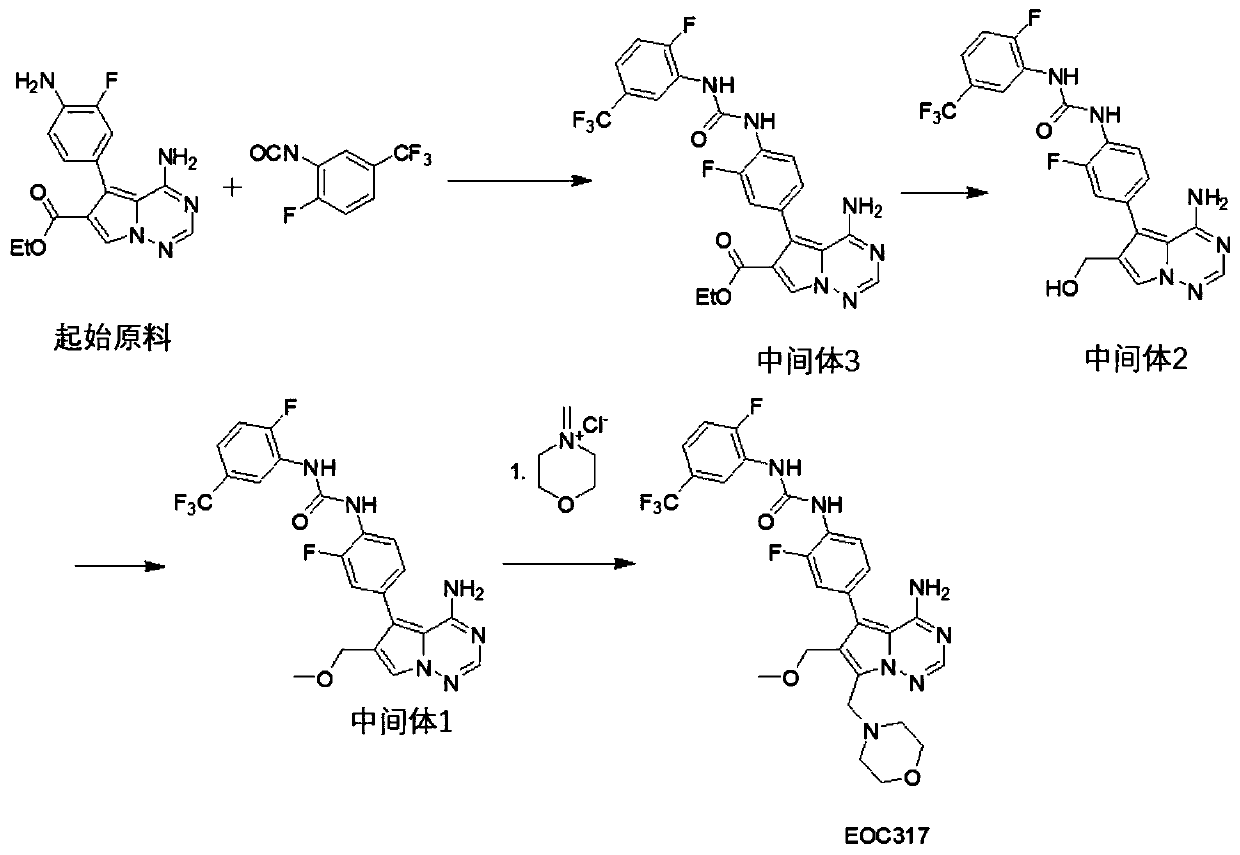

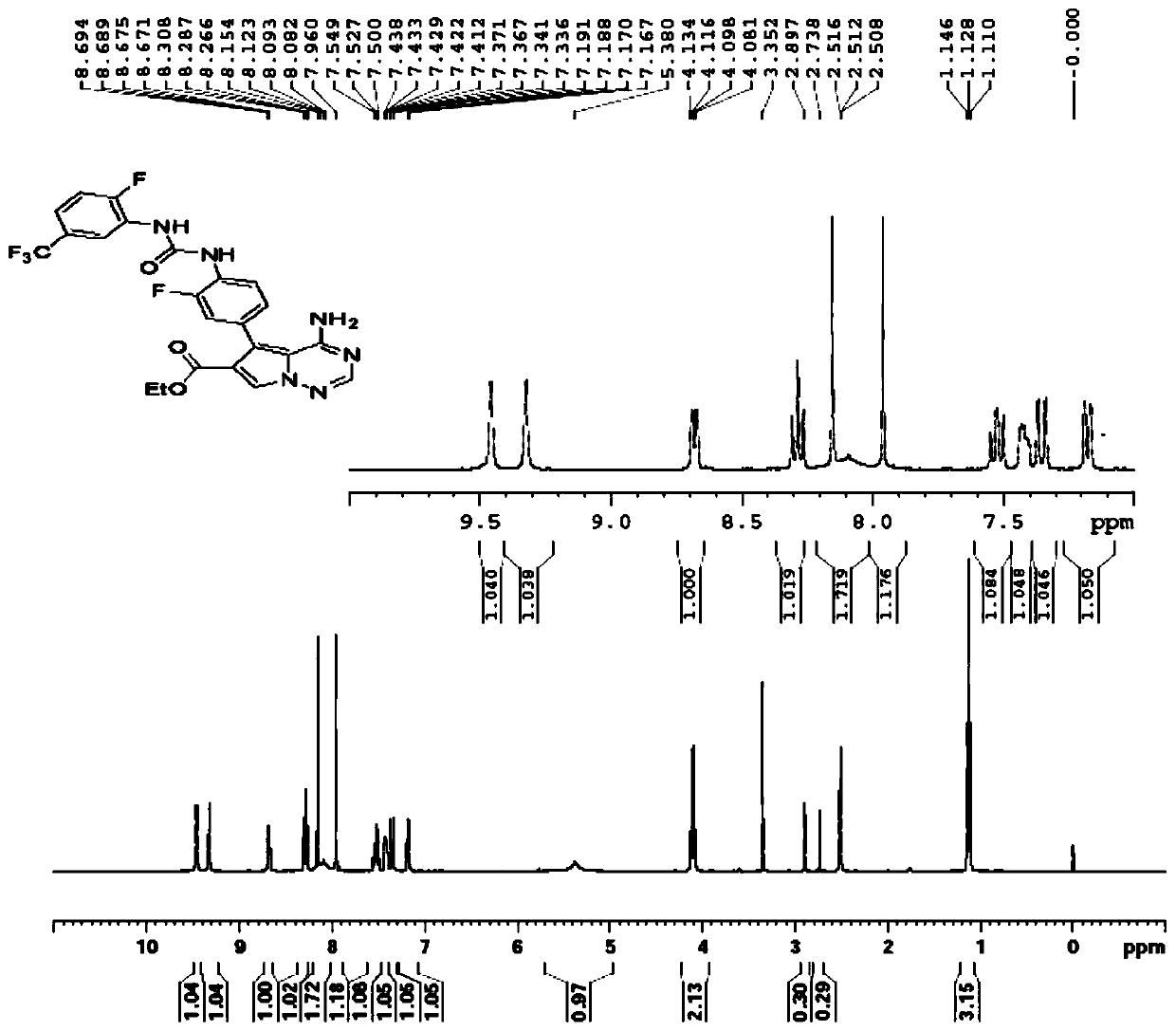

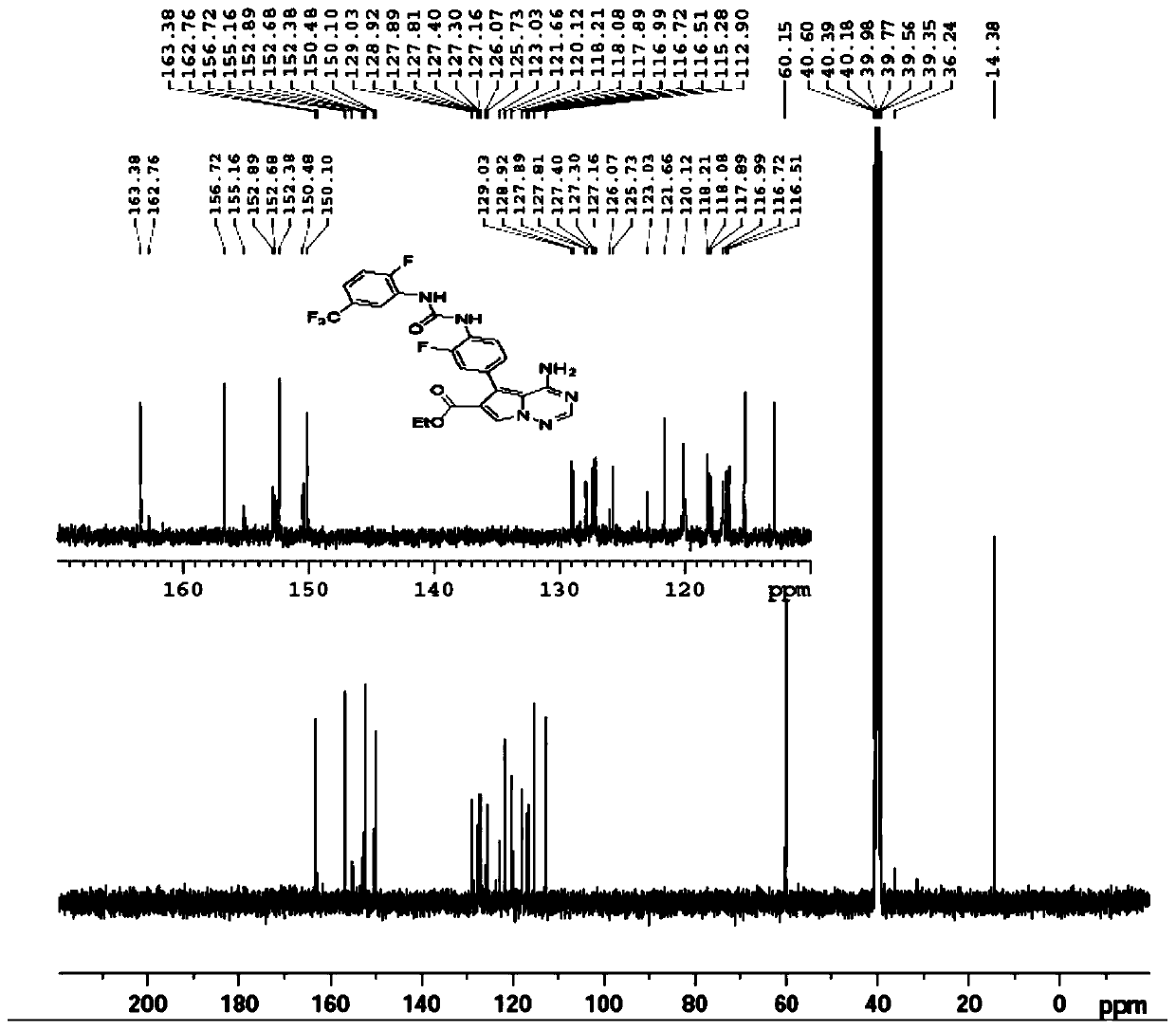

Method for industrially producing EOC 317

InactiveCN109928976AProduction method safetyReduce manufacturing costOrganic chemistryPyrroleTrifluoromethyl

The application relates to a method for preparing N-{4-[4-amino-6-(methoxymethyl)-7-(morpholin-4-yl-methyl) pyrrolo [2,1-f] [1,2,4] triazine-5-yl]-2-fluorophenyl}-N'-[2-fluoro-5-(trifluoromethyl) phenyl] urea, and the method comprises the following steps: a) obtaining an intermediate 1, wherein the intermediate 1 is 1-(4-(4-amino-6-(methoxymethyl) pyrrole [1,2-f] [1,2,4] triazine-yl)-2-fluorophenyl)-3-(2-fluoro-5-(trifluoromethyl) phenyl) urea; and b) reacting the intermediate 1 with N-methylenemorpholin-N-chloride to obtain N-{4-[4-amino-6-(methoxymethyl)-7-(morpholin-4-yl-methyl) pyrrolo [2,1-f] [1,2,4] triazine-5-yl]-2-fluorophenyl}-N'-[2-fluoro-5-(trifluoromethyl) phenyl] urea.

Owner:TAIZHOU EOC PHARMA CO LTD

A kind of reinforced polyethylene film and preparation method thereof

The invention relates to a reinforced polyethylene (PE) film and a preparation method thereof, belonging to the technical field of functional packaging materials. The preparation method comprises the following steps: by using modified nano kaolin as a toughener, modified organic montmorillonite as a reinforcer and organic montmorillonite and maleic anhydride grafted PE as compatibilizers, adding a certain lubricant; and by using the PE as the substrate, carrying out blow molding to form the film. The reinforced PE composite film has the advantages of high stability, high barrier property, certain flame retardancy, high stretchability, high elongation at break and favorable aging resistance, can be widely used in the fields of daily supplies, household appliances and the like, and widens the application range of the PE material.

Owner:JIANGNAN UNIV

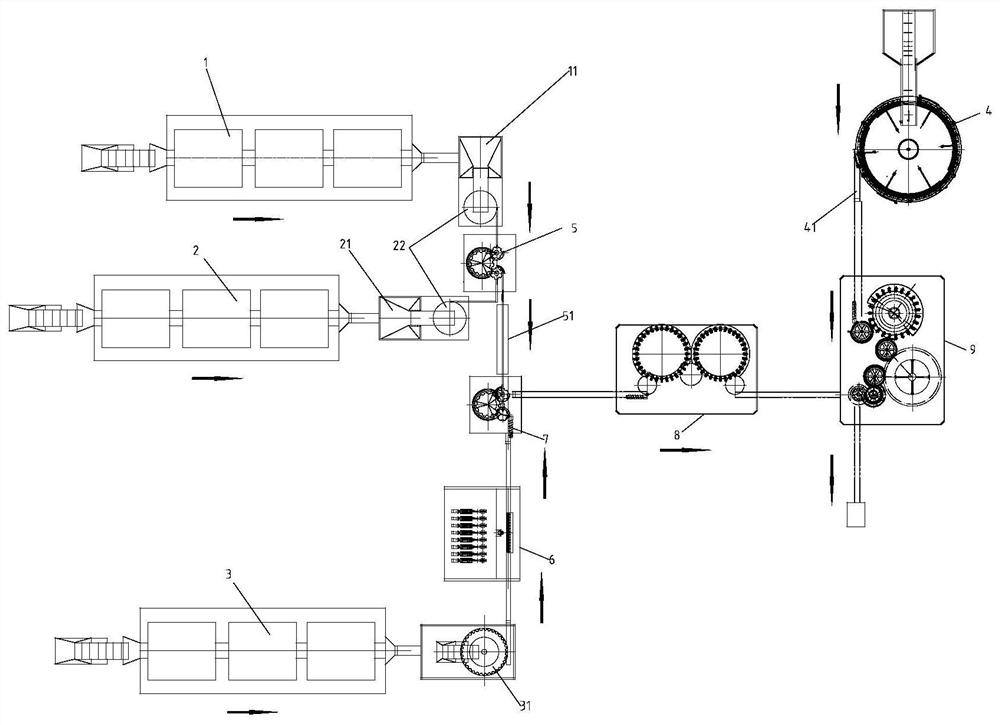

Ready-to-prepare beverage production line and process

ActiveCN112062081ARealize automated productionComplete production methodBottle-handling machinesProcess engineeringBottle cap

The invention relates to a ready-to-prepare beverage production line and process. The ready-to-prepare beverage production line comprises an ejector rod cleaning machine, a bottle cap cleaning machine, a sealed cup cleaning machine, a filling machine, a bottle cap ejector rod cap screwing machine, a sealed cup storage finishing machine, a sealed cup screwing machine, a combined sealed cup washingand drying machine, a water bottle finishing machine and a water bottle washing, filling and sealing machine. A discharging port of the ejector rod cleaning machine is connected with a material storage hopper of an ejector rod storage finishing machine. A discharging port of the bottle cap cleaning machine is connected with a material storage hopper of a bottle cap storage finishing machine, and an outlet of the material storage hopper of the ejector rod storage finishing machine and an outlet of the material storage hopper of the bottle cap storage finishing machine are connected with two feeding ports of the bottle cap ejector rod cap screwing machine through a spiral oscillation finishing machine separately. A discharging port of the bottle cap ejector rod cap screwing machine is connected with a feeding port of the sealed cup screwing machine through a belt conveyor. According to the ready-to-prepare beverage production line and process, all the components are combined through thebottle cap ejector rod cap screwing machine, the sealed cup screwing machine and the water bottle washing, filling and sealing machine, a finished product of instant beverage is finally formed, full-automatic production of ready-to-prepare beverage can be achieved through the ready-to-prepare beverage production device, and defects in the prior art are overcome.

Owner:CHANGSHA PINGXIN PHARMACY PACKING MACHINERY

Method for producing fermented feed through straw and pomace

InactiveCN104413259ARich sourcesSimple production methodAnimal feeding stuffBiotechnologyAgricultural science

The present invention provides a method for producing a fermented feed through straw and pomace. The feed comprises the following raw materials: straw, pomace, corn, soy bean meal, bran, calcium hydrogen phosphate, rice bran, rapeseed meal, trace elements, vitamins, salt, and beneficial microbial flora according to a reasonable proportion. The raw materials are formed by steps including impurity removing, granulating, drying, crushing and stirring. The raw materials are packaged and fermented in a special plastic bag, and then the fermented feed is packaged, warehoused, and sold or standby. The breeding cost of herbivores can be reduced, the raw materials are easy to buy, and the waste materials such as the straw and the pomace can be turned into things of value and recycled. The fermented feed is green, environmentally friendly and ecological, and is the most ideal professional feed for herbivores.

Owner:李雷

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com