Ready-to-prepare beverage production line and process

A production line and beverage technology, which is applied in the field of ready-made beverage production lines and processes to achieve the effect of efficient production methods and fully automated production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

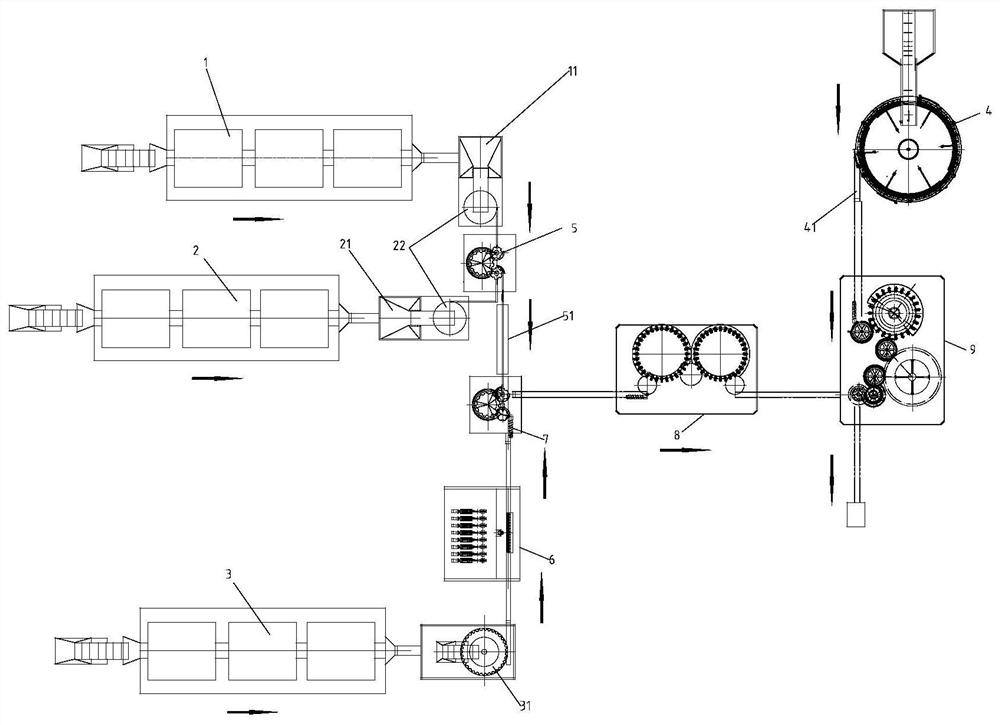

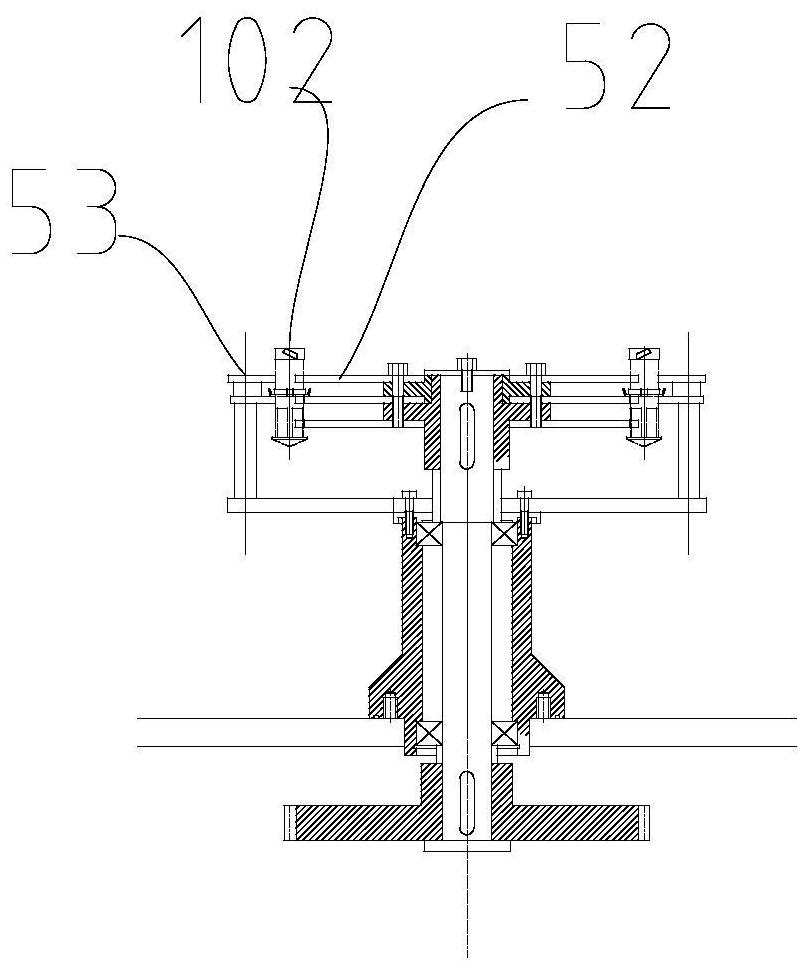

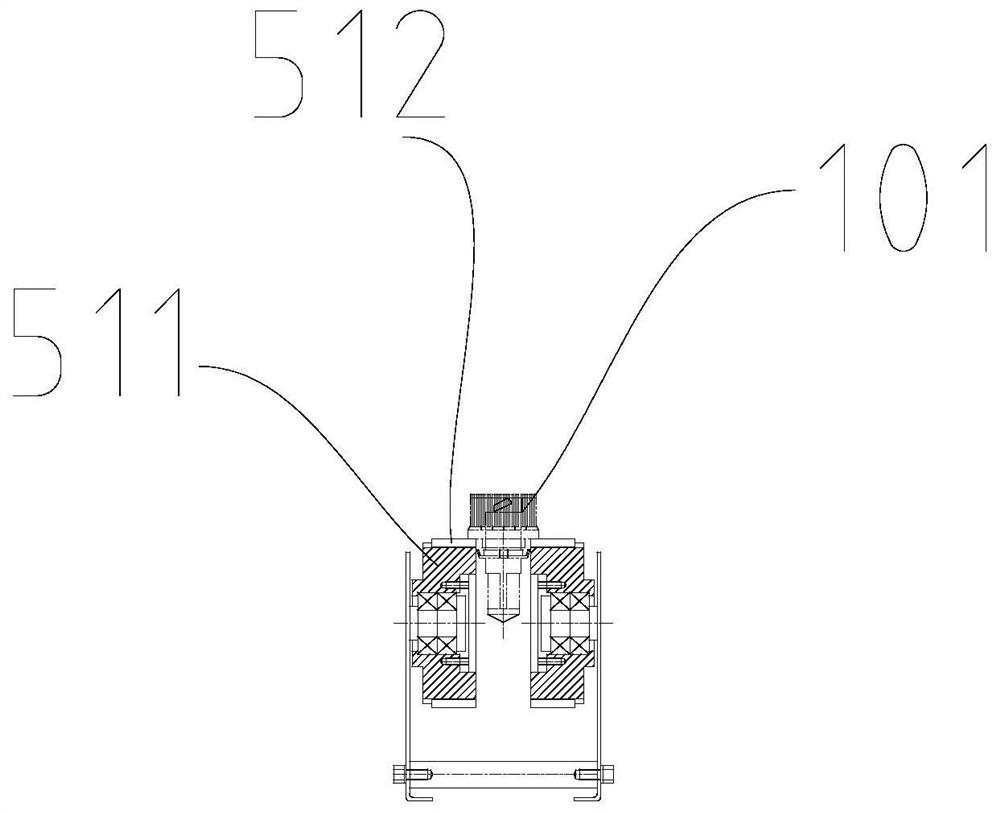

[0025] like Figures 1 to 4 As shown, the present invention includes a ready-made beverage production line, including a push rod cleaning machine 1 (using an XM700 fully automatic tunnel cleaning machine), a bottle cap cleaning machine 2 (using an XM700 fully automatic tunnel cleaning machine), a dense cup cleaning machine Machine 3 (using XM700 automatic tunnel cleaning machine), bottle cap ejector capping machine 5 (using XG12 capping machine), dense cup storage and sorting machine 31 (using XLP900 bottle unscrambler), filling machine 6 (using SGB14 Servo filling machine 6), dense cup screwing machine 7 (using XG12 capping machine), combined dense cup washing and drying machine 8 (using CX32 bottle rinsing machine), water bottle finishing machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com