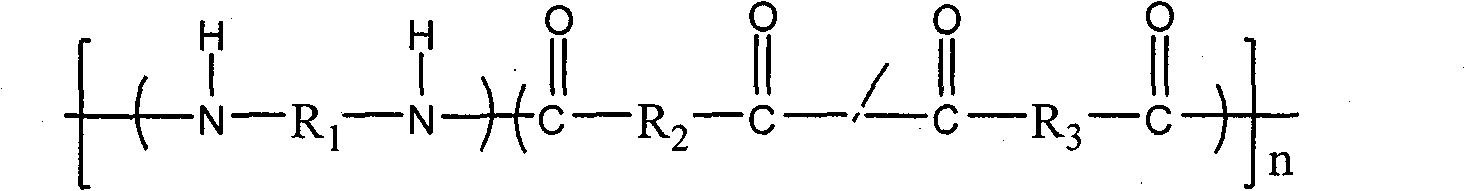

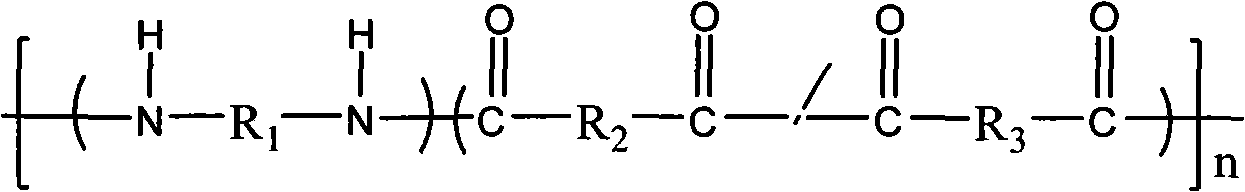

Transparent co-polyamide and preparation thereof

A copolyamide and transparent technology, which is applied in the field of transparent copolyamide and its preparation, can solve the problems of high cost and achieve the effects of low cost, simplified production process, shortened operation cycle and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

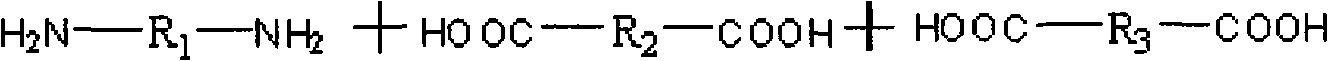

Embodiment 1

[0032] Mix 120g of ethylenediamine and water into a three-necked flask with stirring, heat to 55°C, add 336g of dimer acid C 34 h 62 (COOH) 2 Slowly add the paste made of 232.6g of isophthalic acid and water into a three-necked flask, react at 55°C, adjust the pH of the reaction material to 7.0, keep it warm for 0.5h, and cool to obtain the required salt solution . Mix the prepared salt solution and 0.07g of tin protochloride evenly, add to the polymerization kettle, charge and release CO 2 three times, and finally filled with CO 2 to a pressure of 0.05MPa, then heat up to raise the temperature to 200°C within 1h, and the pressure inside the polymerization tank to 1.8MPa, keep it in this state for 2h, then slowly deflate to normal pressure in 1h, in this state After reacting for 1 hour, the material was discharged to obtain transparent copolymerized polyamide PEDI3, and its various performance indicators are shown in Table 1.

Embodiment 2

[0034] Mix 120g of ethylenediamine and water into a three-necked flask with stirring, heat to 75°C, add 560g of dimer acid C 34 h 62 (COOH) 2 Slowly add the paste made of 166g of isophthalic acid and water into a three-necked flask, react at 75°C, adjust the pH of the reaction material to 7.1, keep it warm for 1 hour, and cool to obtain the desired salt solution. Mix the prepared salt solution and 0.08g of tin protochloride evenly, add to the polymerization kettle, charge and release CO 2 three times, and finally filled with CO 2 until the pressure is 0.1MPa, then heat up to raise the temperature to 280°C within 1.5h, and the pressure in the polymerization tank rises to 2.5MPa, keep it in this state for 3h, then slowly deflate to normal pressure within 1.5h, After reacting in this state for 1.5 hours, the material was discharged to obtain transparent copolyamide PEDI5, and its various performance indicators are shown in Table 1.

Embodiment 3

[0036] Mix 120g of ethylenediamine and water into a stirred three-neck flask, heat to 100°C, and mix 784g of dimer acid C 34 h 62 (COOH) 2 Slowly add the paste made of 100g of isophthalic acid and water into a three-necked flask, react at 100°C, adjust the pH value of the reaction material to 7.2, keep it warm for 2 hours, and cool to obtain the desired salt solution. Mix the prepared salt solution and 0.1g of tin protochloride evenly, add to the polymerization kettle, charge and release CO 2 three times, and finally filled with CO 2until the pressure is 0.2MPa, then heat up to raise the temperature to 320°C within 2h, and the pressure inside the polymerization tank rises to 3.2MPa, keep it in this state for 2.5h, and then slowly deflate to normal pressure within 2h. After reacting for 2 hours under the state, the material is discharged, and the transparent copolyamide PEDI7 is obtained, and its various performance indicators are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com