Method for stamp-laminating a first film onto a film web

A technology used in laminates, used in lamination, lamination devices, lamination auxiliary operations, etc., can solve the problems of high equipment requirements, high equipment costs, high accuracy, etc., to achieve simple process, cost reduction, Design simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

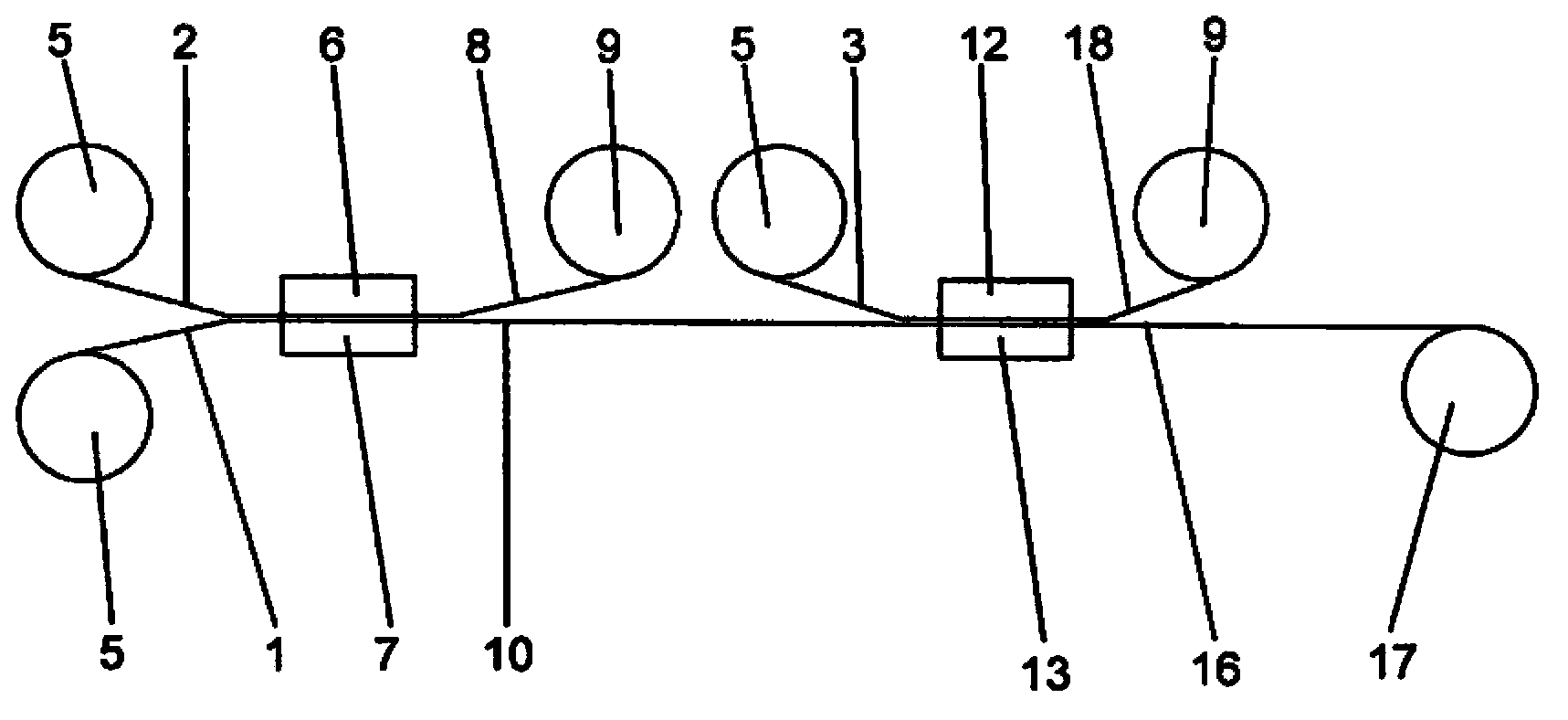

[0067] figure 1 A schematic cross-sectional view of a first device according to the invention for producing laminates is shown. A first film / foil 1, a second film / foil 2, and a third film / foil 3 are fed to the device. The films / foils 1, 2, 3 are rolled onto and unwound from a drum 5 to be fed to the device.

[0068] The first film / foil 1 is prepunched and rolled onto a lower roll 5 . The first film / foil 1 and the second film / foil 2 are unwound and fed to the device. For this, the films / foils 1 , 2 are reoriented in a suitable manner such that they are guided parallel in a first region at a distance of about 5 mm. The first tool 6 of the device is arranged in the first region. The tool 6 comprises a heatable bottom surface 7 over which the first film / foil 1 is rolled over.

[0069] In this region of the tool 6 the second film / foil 2 is applied onto the first film / foil 1 and punched out in the process. The punched-out segment of the second film / foil 2 is then positioned on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com