A kind of preparation method of vegetable enteric-coated capsule

An enteric-coated capsule and plant-based technology, which is applied to enteric-coated starch hollow capsules and the production field thereof, can solve the problems of unstable finished product quality, high production cost and technological difficulty, and no price advantage, and achieves low production cost and source of Rich, easy-to-craft effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

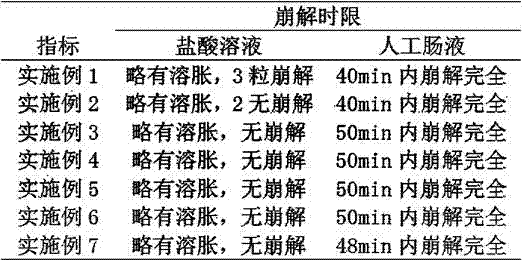

Examples

Embodiment 1

[0020] Put 1kg of carrageenan, 1kg of glycerin and 1kg of dialdehyde starch into 60L of purified water, stir at 50°C for 15min, add 2% NaOH solution to adjust the pH to 8, then continue stirring at 60°C for 20min , lower the temperature to 50°C, add 55 parts of hydroxypropyl starch and continue stirring for 30min at 50°C. The obtained glue solution is dipped in glue, dried, threshed and locked to obtain a finished capsule.

Embodiment 2

[0022] Put 1kg of carrageenan, 8kg of glycerin and 1kg of dialdehyde starch into 60L of purified water, stir at 50°C for 15min, add 2% NaOH solution to adjust the pH value to 8, then continue to stir at 60°C for 20min , lower the temperature to 50°C, add 55 parts of hydroxypropyl starch and continue stirring for 30min at 50°C. The obtained glue solution is dipped in glue, dried, threshed and locked to obtain a finished capsule.

Embodiment 3

[0024] Put 7kg of carrageenan, 8kg of glycerin and 5kg of dialdehyde starch into 60L of purified water, stir at 50°C for 15min, add 2% NaOH solution to adjust the pH value to 8, then continue to stir at 60°C for 20min , lower the temperature to 50°C, add 55 parts of hydroxypropyl starch and continue stirring for 30min at 50°C. The obtained glue solution is dipped in glue, dried, threshed and locked to obtain a finished capsule.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com