Regenerative castable prepared from waste main runner materials from blast furnace

A castable and blast furnace technology, which is applied in the field of unshaped refractory materials, can solve problems such as lowering of raw material grades, leakage of slag ditch, and potential safety hazards affecting blast furnace production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

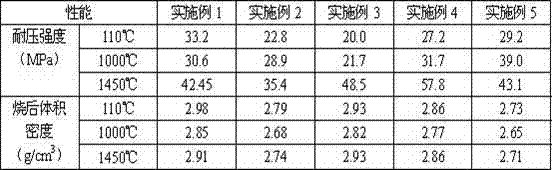

Examples

Embodiment 1

[0020] The proportion of aggregates with bauxite particle size ≤ 8-1mm is 40%; the proportion of aggregates with corundum particle size ≤ 8-1mm is 30%; the proportion of corundum aggregates with particle size ≤ 0-1mm is 3%; the proportion of corundum aggregates with particle size ≤ 0.088mm The proportion of powder is 3.85%; the proportion of waste main channel material fine powder with a particle size of ≤0.088mm is 6%; the silicon carbide with a particle size of ≤1mm is 5%, the metal silicon with a particle size of ≤1mm is 3%, and sodium tripolyphosphate is 0.15%; the particle size is ≤50μm Alumina micropowder 4%; calcium aluminate cement 3%; asphalt 2%, the softening point of asphalt powder is 125°C.

Embodiment 2

[0022] The proportion of aggregates with corundum particle size ≤ 8-1mm is 56.05%; the proportion of alumina aggregates with particle size ≤ 0-1mm is 1%; the proportion of corundum fine powder with particle size ≤ 0.088mm is 10.0%, and the abandoned main ditch with particle size ≤ 0.088mm The proportion of fine powder is 10%, silicon carbide with a particle size of ≤1mm is 15%, silicon metal with a particle size of ≤1mm is 1%, sodium hexametaphosphate is 1%, silica micropowder is 3%, calcium aluminate cement is 4%, and asphalt is 0.95%. The softening point of asphalt powder is 120°C.

Embodiment 3

[0024] The proportion of aggregates with corundum particle size ≤ 8 ~ 1mm is 32.45%, the proportion of aggregates with corundum particle size ≤ 8 ~ 1mm is 25%, the proportion of corundum aggregates with particle size ≤ 0 ~ 1mm is 3%, particle size ≤ 0.088 The proportion of corundum fine powder in mm is 5%, the proportion of waste main channel material fine powder with particle size ≤0.088mm is 10%, silicon carbide with particle size ≤0.074mm is 5%, metal silicon with particle size ≤1mm is 5%, sodium hexametaphosphate 0.05 %, particle size ≤ 50μm alumina micropowder 3%, calcium aluminate cement 2.5%, asphalt 4%, the softening point of asphalt powder is 120°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com