Polypropylene foaming material and production method thereof

A foamed material and polypropylene technology, which is applied in the production field of polypropylene foamed materials, can solve the problems of high manufacturing cost and difficult recycling, and achieve the effects of no environmental pollution, low production cost and safe production method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

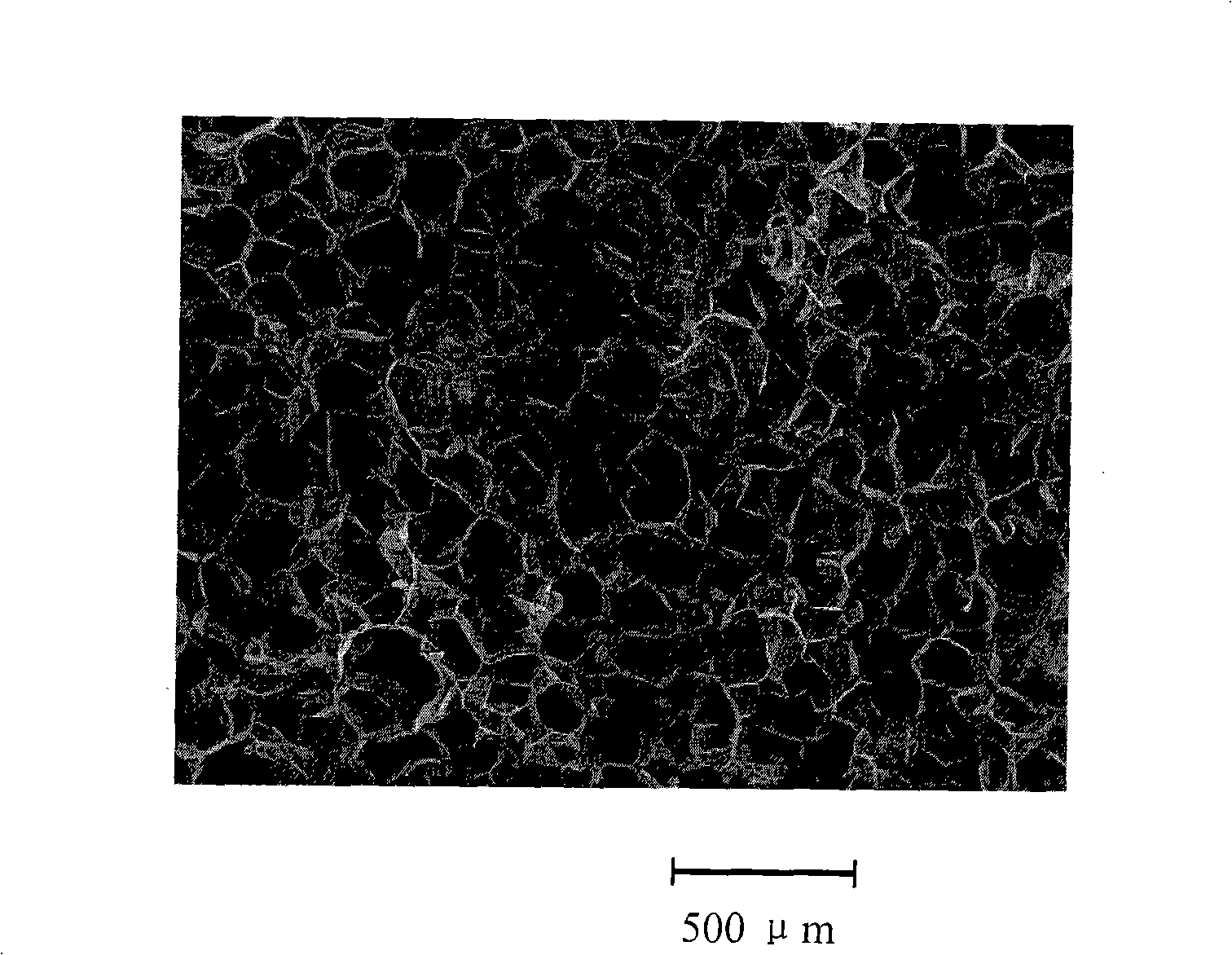

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0046] The production method of polypropylene foam material comprises the following steps successively:

[0047]① Evenly mix polypropylene resin, nucleating agent, antioxidant, coloring agent and appropriate amount of lubricant, filler and other additives according to a certain weight ratio;

[0048] ②Extrude and granulate the above mixture through a twin-screw extruder into raw materials that can be used for foaming;

[0049] ③Take the above raw materials and place them in a special foaming extruder, and at the same time inject a supercritical fluid with a weight ratio of 0.1 to 20 parts as a foaming agent. And take shape.

[0050] Among them, the foaming extruder is a single-screw extruder, two serial single-screw extruders, or a co-rotating twin-screw extruder in series with a single-screw extruder, and the die can be a circular die, an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com