Processing technique for ageing resistance spun-bonded nonwoven fabric

A spun-bonded non-woven fabric and processing technology, which is applied in the textile field, can solve the problems of short service life and easy aging of polypropylene non-woven fabric, and achieve the effects of prolonging service life, good aging resistance and good tensile force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

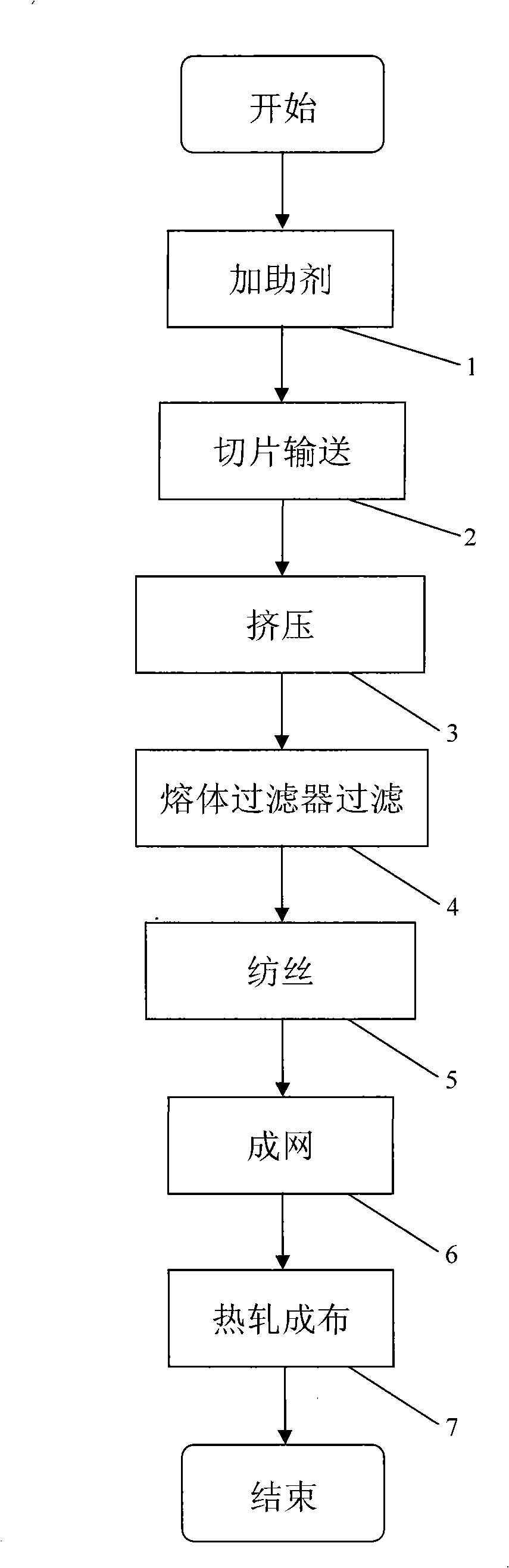

[0019] see figure 1 , the anti-aging spunbond non-woven fabric processing technology, including the following steps in turn:

[0020] Auxiliary agent 1: Add antioxidant and light stabilizer to polypropylene chips. The amount of oxidant added is 0.8-1.0% of the amount of polypropylene chips, and the amount of light stabilizer is 0.2%-0.4% of the amount of polypropylene chips. Polypropylene chips are thoroughly mixed with antioxidants and light stabilizers. The selected light stabilizer is a hindered amine light stabilizer, the chemical name is bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate, and its light stabilization effect is better than the general Ultraviolet absorber, used in combination with antioxidants can improve heat resistance, further improve aging resistance, good compatibility with polymers, excellent thermal stability, can be used for high temperature processing, and can provide maximum protection for polymers, Reduce damage from UV exposure. This product is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com