Method of producing high-pure sulfur

A production method and high-purity sulfur technology, applied in the preparation/purification of sulfur, etc., can solve problems such as poor effect, and achieve the effects of high purity, good product quality, and easy industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

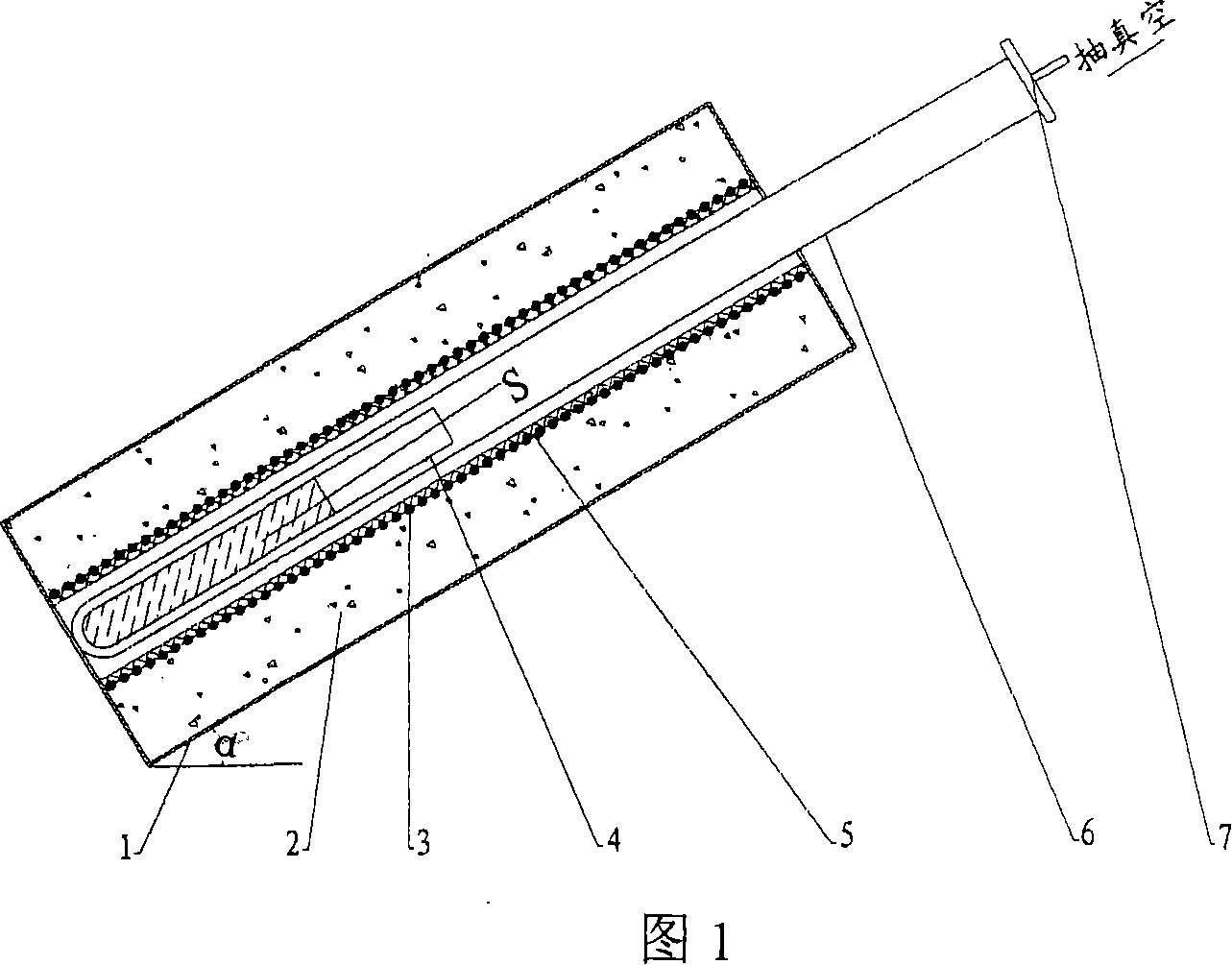

[0015] Put 3.0 kilograms of 99wt% sulfur into the crucible 4, then put the crucible with 99wt% sulfur into the quartz tube 6, put the quartz tube into the heating furnace 1 for vacuum sublimation, and set the insulation layer 2 and the heating wire in the heating furnace 3. Crucible 4, furnace lining 5, quartz tube 6 and vacuum gland 7. The inclination angle α installed in the heating furnace is 30°. One end of the quartz tube is sealed with vacuum gland 7, and the vacuum gland is provided with a vacuum port, which is evacuated to 1×10 -3 Pa, turn on the heating system of the vacuum sublimation heating furnace, wait for the temperature of the heating furnace to rise to 135 ° C, carry out vacuum sublimation and purification for 4.5 hours, then close the vacuum and heating system, cool and discharge, and obtain 2.3 kg of 5N sulfur product, the yield is 78% .

Embodiment 2

[0017] Put 3.5 kilograms of 99wt% sulfur into the crucible 4, then put the crucible with 99wt% sulfur into the quartz tube 6, put the quartz tube into the heating furnace 1 for vacuum sublimation, and set the insulation layer 2 and the heating wire in the heating furnace 3. Crucible 4, furnace lining 5, quartz tube 6 and vacuum gland 7. The inclination angle α installed in the heating furnace is 40°. One end of the quartz tube is sealed with a vacuum gland 7, and a vacuum port is provided on the vacuum gland to evacuate to 5×10 -3 Pa, turn on the heating system of the vacuum sublimation heating furnace, wait for the temperature of the heating furnace to rise to 140 ° C, carry out vacuum sublimation and purification for 4 hours, then turn off the vacuum and heating system, cool and discharge, and obtain 2.4 kg of 5N sulfur product, with a yield of 75%.

Embodiment 3

[0019] Put 4.0 kilograms of 99wt% sulfur into the crucible 4, then put the crucible with 99wt% sulfur into the quartz tube 6, put the quartz tube into the heating furnace 1 for vacuum sublimation, and set the insulation layer 2 and the heating wire in the heating furnace 3. Crucible 4, furnace lining 5, quartz tube 6 and vacuum gland 7. The inclination angle α installed in the heating furnace is 45°. One end of the quartz tube is sealed with a vacuum gland 7, and a vacuum port is provided on the vacuum gland to evacuate to 9×10 -3 Pa, turn on the heating system of the vacuum sublimation heating furnace, wait for the temperature of the heating furnace to rise to 145 ° C, carry out vacuum sublimation purification for 3.5 hours, then turn off the vacuum and heating system, cool and discharge, and obtain 3.0 kg of 5N sulfur product, the yield is 76% .

[0020] Table 15N impurity content of high-purity sulfur (in ppm)

[0021] Impurities

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com