Blueberry anthocyanin edible composite film and preparation method thereof

A blueberry anthocyanin and composite film technology, applied in the direction of climate sustainability, sustainable manufacturing/processing, flexible coverings, etc., can solve mechanical properties, poor gas barrier properties, low protein film tensile strength, polysaccharide film Low hydrophobicity and other problems, to achieve the effect of improving mechanical properties, excellent oxidation resistance and antibacterial properties, and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

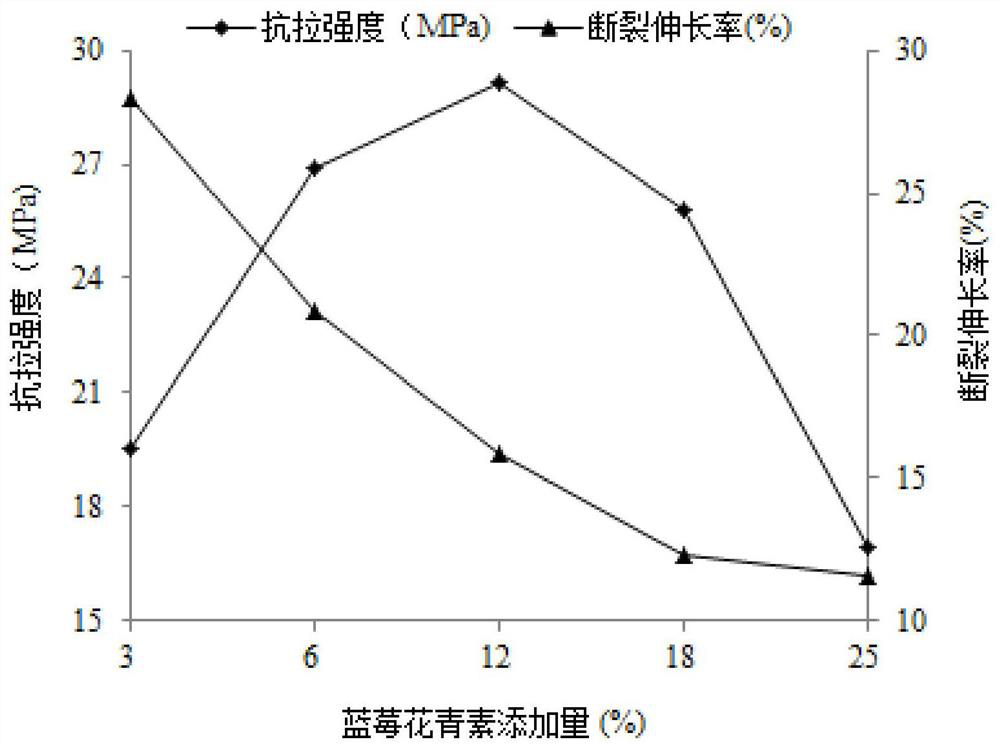

[0034] Blueberry anthocyano-edible composite film consists of the following weight percent raw materials:

[0035] Sample 1: Blueberry anthocyanin 3%, corn starch 2%, carboxymethylcellulose 2%, 1% glycerol, deionized water 92%.

[0036] Sample 2: Blueberry anthocyanin 6%, corn starch 2%, carboxymethylcellulose 2%, glycerol 1%, deionized water 89%.

[0037] Sample 3: Blueberry anthocyanin 12%, corn starch 2%, carboxymethylcellulose 2%, glycerol 1%, deionized water 83%.

[0038] Sample 4: Blueberry anthocyanin 18%, corn starch 2%, carboxymethylcellulose 2%, glycerol 1%, deionized water 77%.

[0039] Sample 5: 25% blueberry anthocyanin, 2% of corn starch, 2% carboxymethylcellulose, 1% glycerin, deionized water 70%.

[0040] The preparation method of the blueberry anthocyanin edible composite film of the above sample 1-5 is: taking the above proportion of corn starch, add deionized water, stirring the rotational speed of 350 to 450 r / min, 75 ° C water bath, stirred for 20 min, Capil...

Embodiment 2

[0044] Blueberry anthocyano-edible composite film is composed of a weight percentage of raw materials: Blueberry anthocyanin 12%, potato starch 1%, carboxymethylcellulose 2%, glycerol 1.5%, deionized water 83.5%.

[0045] The preparation method of the blueberry anthocyano-edible composite film of the present embodiment is: Take the proportion of potato starch, add deionized water, 75 ° C water bath 15min, temperature cooling to 50 ° C, carboxymethylcellulose, water bath 25min, then add glycerol to stir for 15 min, cooled to 25 ° C, and finally add blueberry anthocyano powder, stir for 15 min, defoam, defoamen, flow in the organic glass plate, drying, drying the revelation of the dried film at 30 ° C It is a blueberry anthocyanin edible composite film.

[0046] The properties of the blueberry anthocyanin edible composite film prepared in this example are: tensile strength 19.33MPa, 4.05% water vapor transmittance 3.05 × 10 -4 [(g · mm) / (m 2 · H · PA)], a water content of 20.51%, ...

Embodiment 3

[0048] Blueberry anthocyano-like composite film consists of the following weight percent raw materials :: Blueberry anthocyanin 18%, corn starch 3%, carboxymethylcellulose 2%, glycerol 1%, deionized water 76%.

[0049] The preparation method of the blueberry anthocyano-like composite film of the present embodiment is: taking the above proportion of corn starch, add deionized water, 75 ° C water bath, temperature cooling to 55 ° C, carboxymethylcellulose, water bath is stirred 30min, then add glycerin to stir for 15 min, cooled to 25 ° C, and finally add blueberry anthocyano powder, stir for 20 min, defoamed, flow in the organic glass sheet, dry, cool, cool It is a blueberry anthocyanin edible composite film.

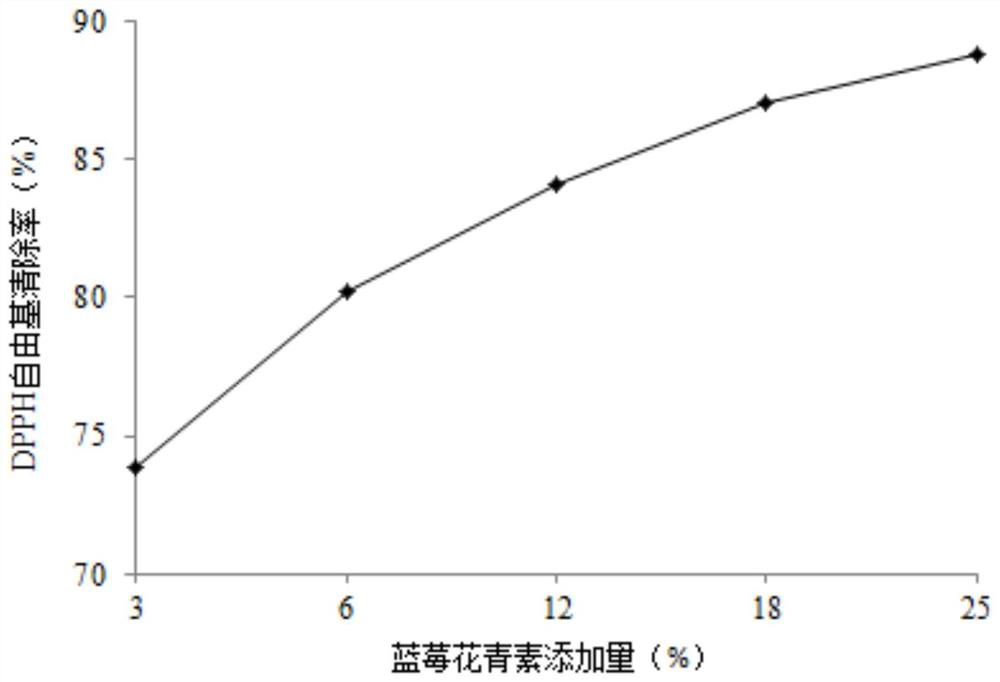

[0050] The properties of the blueberry anthocyanin edible composite film prepared in this example are: tensile strength 23.94 MPa, elongation at break, 14.85%, water vapor transmittance 3.27 × 10 -4 [(g · mm) / (m 2 · H · PA)], with a water content of 18.93%, DPPH free radic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com