Method for producing alkyl phosphorus dichloride

A technology for producing alkyl phosphorus dichloride and phosphorus trichloride, which is applied in the chemical industry, can solve problems such as low yield, high technical difficulty, complex composition, etc., achieve stable and smooth process operation, overcome large safety risks, The effect of reducing the amount of generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

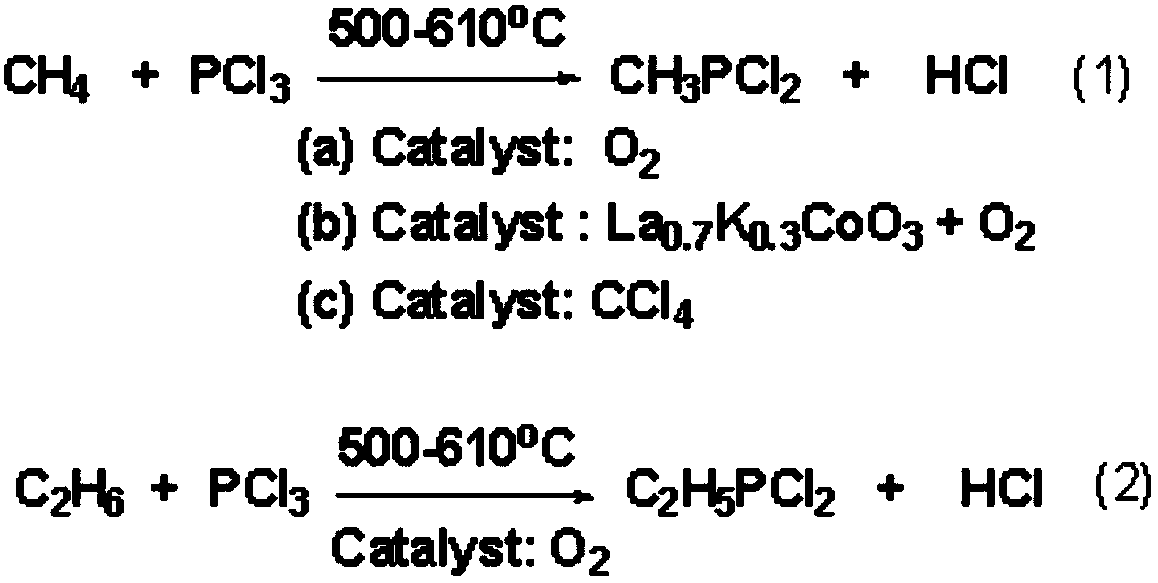

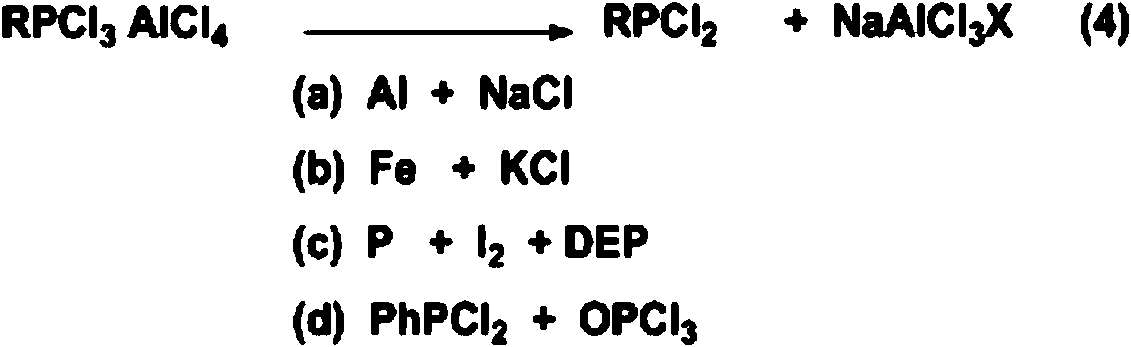

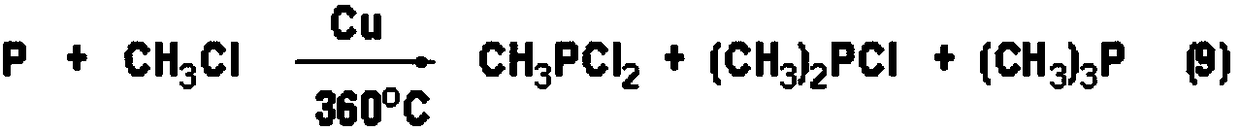

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The synthesis of embodiment 1 methyl phosphorus dichloride

[0054] After mixing phosphorus trichloride and chloroform evenly, pour it into the tubular reactor continuously, and feed methane gas at the same time, wherein the molar ratio of phosphorus trichloride, methane and chloroform is 1:5:0.04, and the reaction residence time is 8s. The reaction temperature is 490°C, the reaction pressure is 1.5MPa, the reaction liquid is extracted after condensation, and the uncondensed hydrogen chloride is neutralized and absorbed with sodium hydroxide solution. The conversion rate of phosphorus trichloride is 22%, and the selectivity of generating methyl phosphorus dichloride is 95%.

Embodiment 2

[0055] The synthesis of embodiment 2 methyl phosphorus dichloride

[0056] Mix phosphorus trichloride and dichloromethane evenly and pour them into the tubular reactor continuously, while feeding methane gas, wherein the molar ratio of phosphorus trichloride, methane and dichloromethane is 1:3:0.03, and the reaction stays The time is 15s, the reaction temperature is 650°C, and the reaction pressure is 6.0MPa. The reaction liquid is extracted after being condensed, and the uncondensed hydrogen chloride is neutralized and absorbed with sodium hydroxide solution. The conversion rate of phosphorus trichloride is 30%, and the selectivity of generating methyl phosphorus dichloride is 92%.

Embodiment 3

[0057] The synthesis of embodiment 3 ethyl phosphorus dichloride

[0058] Phosphorus trichloride and chloroform are mixed evenly and continuously poured into the tubular reactor, and ethane gas is introduced at the same time, wherein the molar ratio of phosphorus trichloride, ethane and chloroform is 1:12:0.12, and the reaction residence time is 1s, the reaction temperature is 490°C, the reaction pressure is 0.2MPa, the reaction liquid is extracted after condensation, and the uncondensed hydrogen chloride is neutralized and absorbed with sodium hydroxide solution. The conversion rate of phosphorus trichloride is 24%, and the selectivity of forming methyl phosphorus dichloride is 96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com