Nerol and geraniol preparation method

A technology for geraniol and nerol, which is applied in the field of preparation of nerol and geraniol, can solve the problems of high product impurities, reduced profitability, low product price, etc., and achieves low requirements for production equipment and easy separation and purification. , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

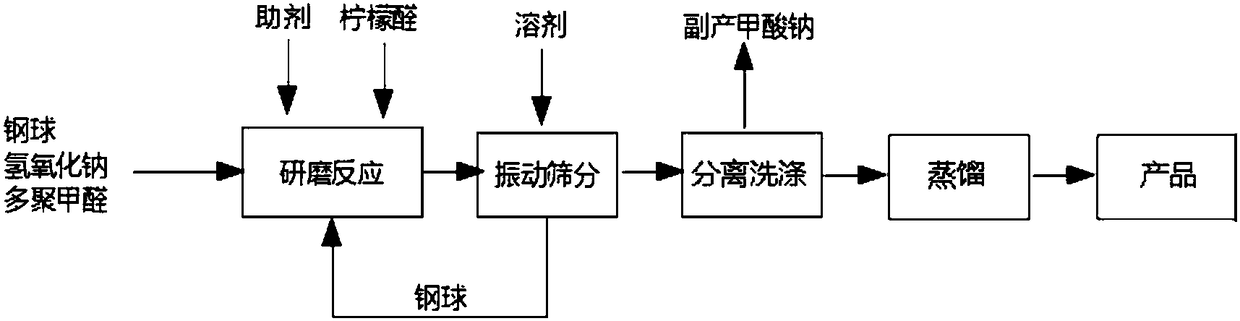

Method used

Image

Examples

Embodiment 1

[0033] Add 3 L of steel balls with a diameter of 5 cm into a 10 L vertical ball mill reactor, then add 1.33 kg of sodium hydroxide, 1.00 kg of paraformaldehyde, and 2.5 g of tetrabutylphosphine bromide. Start the ball mill and turn on the heating to 70°C to preheat the material. After grinding for 10 minutes, remove the hot water from the jacket. Through the feeding port, add 5.07kg of citral into the ball mill reactor in 3 batches. At this time, the reaction is exothermic, and the temperature is lowered by cooling water to maintain the reaction at 65-75°C. After the addition of citral, the grinding reaction was continued for 3 hours to ensure that the conversion of citral was complete. Tracking method: Take out a small amount of reaction materials, add water to dissolve, extract once with ethyl acetate, and analyze the upper layer by gas chromatography.

[0034] Stop grinding, transfer the material to a vibrating screen to separate the slurry and steel balls, and use 15kg o...

Embodiment 2

[0036] Add 3 L of steel balls with a diameter of 3 cm into a 10 L vertical ball mill reactor, then add 1.20 kg of sodium hydroxide, 1.00 kg of paraformaldehyde, and 0.45 g of benzyltriphenylphosphine chloride. Start the ball mill and turn on the heating to 100°C to preheat the material. After grinding for 10 minutes, remove the hot water from the jacket. Through the feeding port, add 4.5kg citral to the ball mill reactor in 3 batches. At this time, the reaction is exothermic, and the temperature is lowered by cooling water to maintain the reaction at 95-100°C. After the addition of citral, the grinding reaction was continued for 1 hour to ensure that the conversion of citral was complete. Tracking method: with embodiment 1.

[0037] Stop grinding, transfer the material to a vibrating sieve to separate the slurry and steel balls, and use 26kg of 1,2-dichloroethane to rinse the steel balls during the sieving process. Transfer the slurry to a centrifuge, turn on the centrifuge...

Embodiment 3

[0039] Add 3 L of steel balls with a diameter of 5 cm into a 10 L vertical ball mill reactor, then add 1.5 kg of sodium hydroxide, 1.00 kg of paraformaldehyde, and 5.5 g of benzyltrimethylphosphine bromide. Start the ball mill and turn on the heating to 30°C to preheat the material. After grinding for 10 minutes, remove the hot water from the jacket. Through the feeding port, add 5.5kg of citral to the ball mill reactor in 3 batches. At this time, the reaction is exothermic, and the temperature is lowered by cooling water to maintain the reaction at 30-40°C. After the addition of citral, the grinding reaction was continued for 5 hours to ensure that the conversion of citral was completed. Tracking method: with embodiment 1.

[0040]Stop grinding, and transfer the material to the vibrating screen to separate the slurry and steel balls. Transfer the slurry to stop grinding, transfer the material to a vibrating sieve to separate the slurry and steel balls, and wash the steel b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com