Potato starch-based edible composite food packaging film and preparation method thereof

A potato starch and composite food technology, applied in the field of food packaging, can solve the problems of affecting the flavor of the packaged food, not easy to be degraded, toxic and side effects, etc., and achieve the effect of low price, low production cost and safe production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

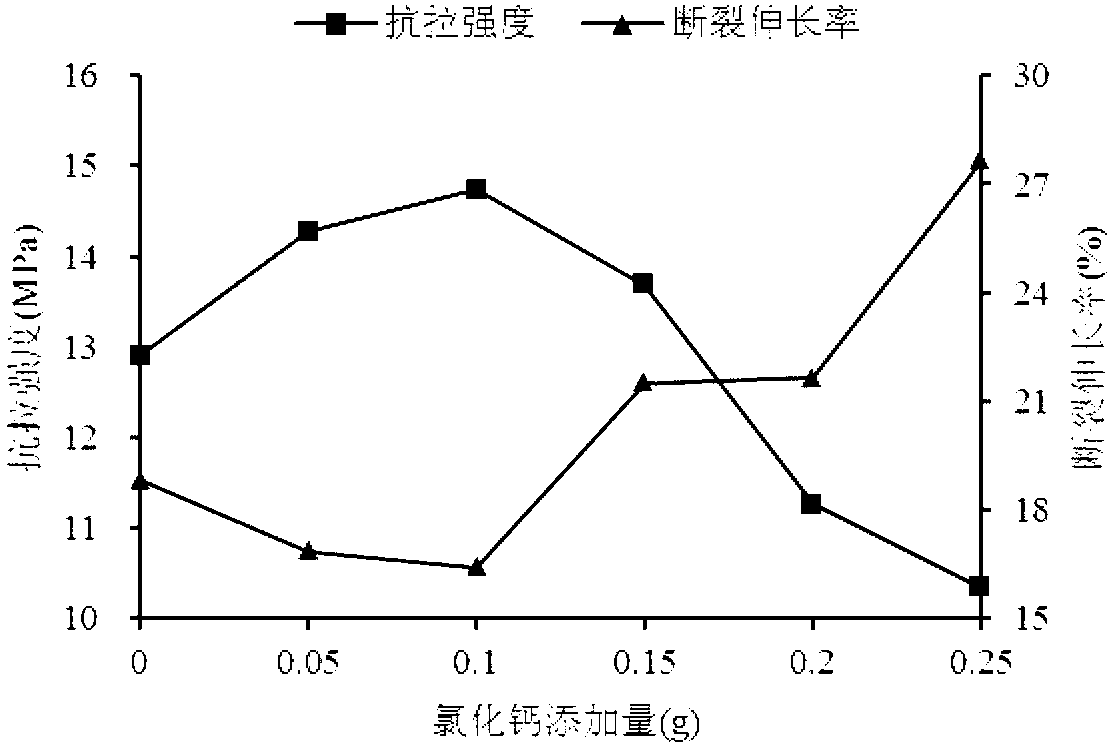

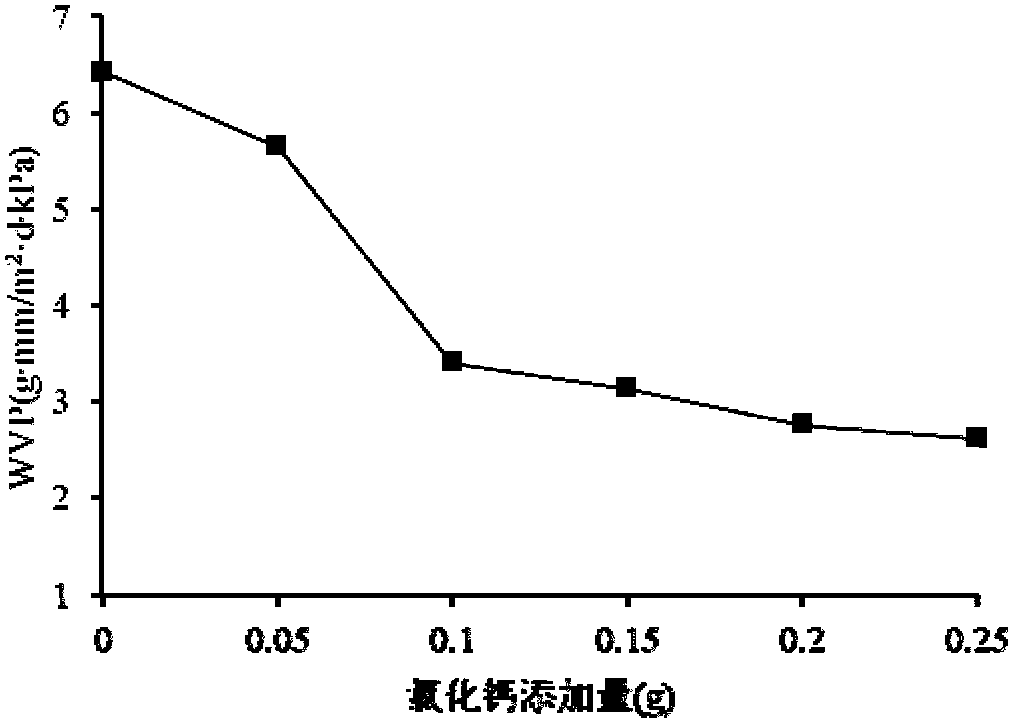

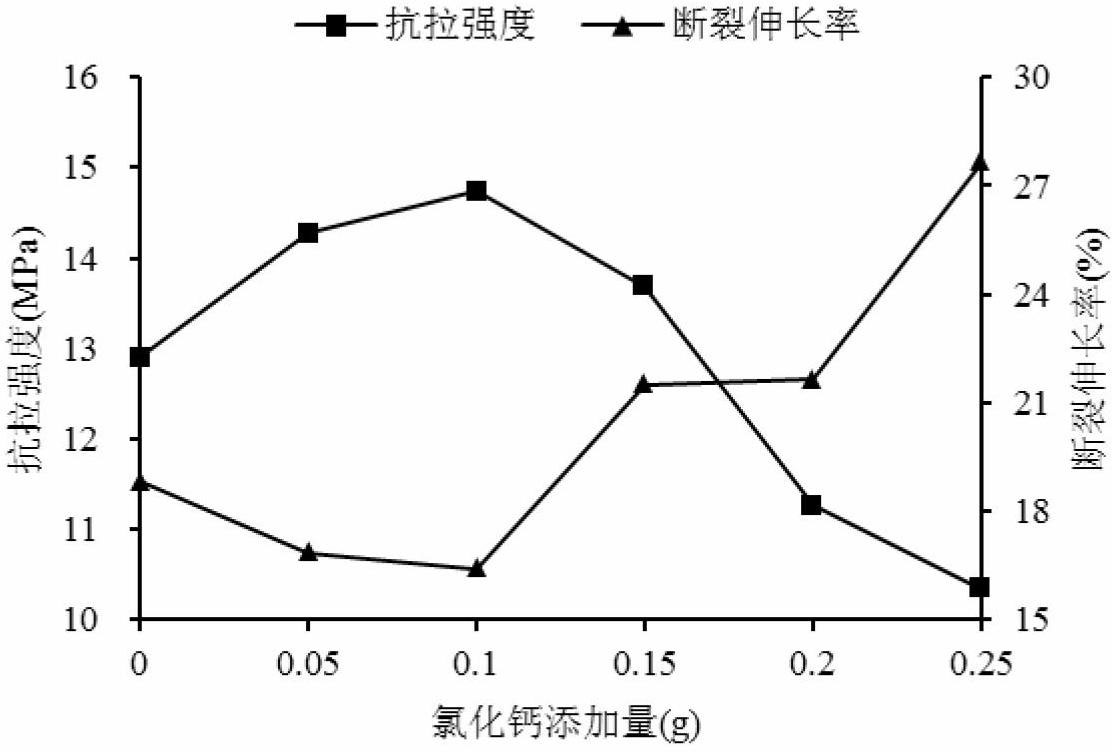

[0029] Potato starch-based edible composite food packaging film, its components and weight in grams are: 3.5 g of potato starch, 1 g of pullulan, 0.5 g of gelatin, 0.75 g of glycerin, and the addition of calcium chloride is 1-0.05 g of the product respectively , Product 2-0.1g, Product 3-0.15g, Product 4-0.2g and Product 5-0.25g.

[0030] Add 3.5g of potato starch and 100mL of deionized water, gelatinize in a water bath at 80°C for 20min, add 1g of pullulan, 0.5g of gelatin and 60mL of deionized water, stir in a water bath for 20min, add 0.75g of glycerin and calcium chloride, and use deionized Dilute water to 200ml, stir in water bath for 15min, pour 48mL of film-forming solution on an area of 220cm 2 The surface is dry and clean on a plexiglass plate, cast into a film, dried at 50° C., cooled and peeled off the film to obtain potato starch-based edible composite food packaging film products 1-5.

[0031] The tensile strength and elongation at break of the obtained product...

Embodiment 2

[0033] The potato starch-based edible composite food packaging film has the following components and grams by weight: 3.5 g of potato starch, 1 g of pullulan, 0.5 g of gelatin, 0.75 g of sorbitol, and 0.1 g of calcium chloride.

[0034] Add 3.5g of potato starch to 100mL of deionized water, gelatinize in a water bath at 80°C for 20min, add 1g of pullulan, 0.5g of gelatin and 60mL of deionized water, stir in a water bath for 20min, add 0.75g of sorbitol and 0.1g of calcium chloride, and use Dilute the volume to 200ml with deionized water, stir in a water bath for 15min, pour 50mL of film-forming solution on an area of 230 cm 2 The surface is dry and clean on a plexiglass plate, cast into a film, dried at 50°C, cooled and peeled off the film to obtain a potato starch-based edible composite food packaging film.

[0035] The properties of the potato starch-based edible composite food packaging film prepared with this component and weight in grams are: tensile strength 15.25MPa, ...

Embodiment 3

[0037] The potato starch-based edible composite food packaging film has the following components and grams by weight: 3.5 g of potato starch, 0.75 g of pullulan, 0.75 g of gelatin, 1.25 g of glycerin, and 0.1 g of calcium chloride.

[0038]Add 3.5g of potato starch and 100mL of deionized water, gelatinize in a water bath at 80°C for 20min, add 0.75g of pullulan, 0.75g of gelatin and 60mL of deionized water, stir in a water bath for 20min, add 1.25g of glycerin and 0.1g of calcium chloride, Dilute to 200mL with deionized water, stir in a water bath for 15min, pour 45mL of film-forming solution on an area of 210cm 2 The surface is dry and clean on a plexiglass plate, cast into a film, dried at 50°C, cooled and peeled off the film to obtain a potato starch-based edible composite food packaging film.

[0039] The properties of the potato starch-based edible composite food packaging film prepared with this component and weight in grams are: tensile strength 9.13MPa, elongation at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com