Usage of streptomyces psammoticus and vanillin production method

一种生产方法、沙链霉菌的技术,应用在沙链霉菌的用途及香兰素的生产领域,能够解决反应条件苛刻、有副产物、不易分离等问题,达到操作简单、污染少的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

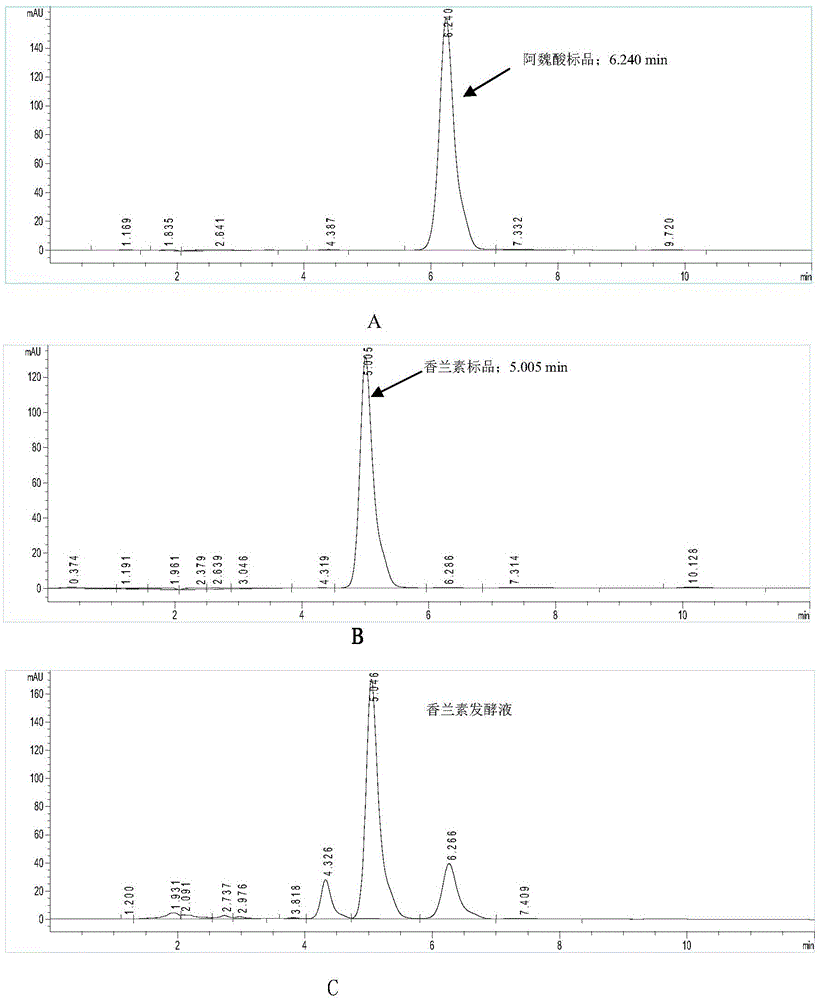

[0046] Embodiment 1: the production of natural vanillin (erlenmeyer flask shaking fermentation)

[0047] Prepare seed culture medium, the composition of which is as follows (g / L): glucose 20, potassium dihydrogen phosphate 3, urea 5, magnesium sulfate 0.3, sodium chloride 1.0, yeast extract powder 5, corn steep liquor powder 5, ammonium sulfate 6 , Calcium carbonate 0.2 The solvent is water, the initial pH is 7.2. Sterilize at 121°C for 20min.

[0048] Preparation of fermentation medium, the composition of the medium is as follows (g / L): glucose 30, potassium dihydrogen phosphate 5, urea 5, magnesium sulfate 0.6, yeast extract powder 8, ammonium sulfate 3, calcium carbonate 1.0 ferulic acid 20, solvent It is water, the initial pH is 7.2. Sterilize at 121°C for 20min.

[0049]Seed preparation: Aseptically transfer the OMK-4 strain in a low-temperature glycerol tube to a fresh, sterile solid plate, activate it at 30°C for 2 days, pick the colony and inoculate it into a 500ml tr...

Embodiment 2

[0051] Embodiment 2: the production of natural vanillin (stirred reactor fermentation)

[0052] The preparation of seed culture medium and fermentation medium is the same as in Example 1.

[0053] Seed preparation: Aseptically transfer the OMK-4 strain in a low-temperature glycerol tube to a fresh, sterile solid plate, activate at 30°C for 2 days, pick colonies and inoculate them in a 3L seed tank with 1.8L seed medium for seed cultivation, ventilate The stirring speed is 300 rpm, and the culture is carried out at 30° C. for 13-18 hours to obtain the seed solution.

[0054] Fermentation of natural vanillin: Put 10.2L of the prepared fermentation medium into a 20L fermenter, sterilize at 121°C for 20min, then put 1.8L of the cultured seed liquid into a 20L fermenter for fermentation, and the fermentation temperature is 37 ℃, stirring speed 400rpm, ventilation ratio 1; 0.2. The fermentation period is 90h. The concentration of natural vanillin in the fermented liquid measured ...

Embodiment 3

[0055] Embodiment 3: the extraction of natural vanillin

[0056] Taking temperature is 80 ℃, and embodiment 2 natural vanillin concentration is 12L of fermented liquid of 15g / L, carries out ceramic membrane filtration, 10L filtrate is carried out ultrafiltration (UF), ultrafiltrate is carried out reverse osmosis (RO), finally obtains 5L of concentrated solution, adjust the pH of the concentrated solution to 5-6, cool to 0-4°C to crystallize for 4 hours, suction filter to obtain crude natural vanillin, and dry to obtain 144g of crude product with a purity of 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com